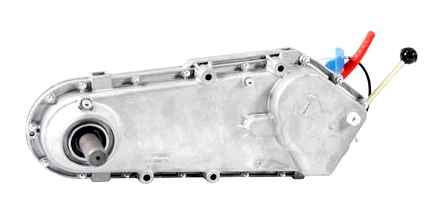

How to assemble a gearbox from a Neva walk-behind tractor

Reducer for motoblock Neva

Land cultivation for modern gardeners is no longer as big of a problem as it was in the recent past. Such versatile equipment as walk-behind tractors has appeared on sale, which greatly facilitate the life of agronomists and gardeners.

Motoblocks Neva are one of the best units in their line. They are reliable, durable and versatile. You will be able to cultivate the land, and care for plants, and collect and transport crops, garbage.

Here we will tell you about the gearbox for the Neva walk-behind tractor, about its design, repair. This is one of the most significant elements in any car, so if you want it to serve for a long time and without breakdowns, you should know all the subtleties of its device, as well as the causes of malfunctions and methods of their elimination.

Adjustment and tuning of the carburetor Neva MB-2

The functionality and durability of the walk-behind tractor engine depend on the stable operation of the carburetor. This is why adjusting and tuning it is so important. In addition, if the carburetor is incorrectly adjusted, the gasoline walk-behind tractor may experience increased fuel consumption.

The carburetor of the Neva MB-2 walk-behind tractor is adjusted as follows:

- The screw for full throttle and idle throttle is unscrewed to the limit.

- Both screws are unscrewed 1-1.5 turns.

- Next is starting and warming up the motor.

- The throttle control lever is set to the position at which the engine will operate at minimum speed.

- Set the minimum idle speed until stable operation of the unit.

- Idling speed is set to maximum.

- The minimum idle speed is being corrected.

- Steps 6 and 7 are performed until the engine runs smoothly (smoother by ear) at idle speed.

CARRARO TRANSMISSION TLB1-4WD UP TRANSMISSION ASSEMBLY LESSON / ОБУЧАЮЩИЙ УРОК СБОРКИ КПП КАРРАРО

For long-term and uninterrupted operation of the walk-behind tractor, it is necessary to regularly diagnose the engine operation, monitor the frequency of oil changes, and also observe the operating conditions and time intervals for scheduled maintenance.

Gearbox device on the Neva walk-behind tractor

The Neva walk-behind tractor gearbox is responsible for the transmission of rotation coming from the motor to the wheels and attachments. It controls rotational number, speed, and direction. forward or backward. In principle, the gearbox for the MB 2 and MB 1 models is not much different, so here we will consider the second option. The device of the gearbox is made in such a way that the components necessary for changing gears are located on its outer part.

The gearshift lever has 5 positions. When you push down on it, the fork disengages the clutch. When you drop the lever, the fork resumes its original position. a single axle tractor will stop when the drive is connected to the right axle shaft. Torque comes from the sprocket. When the handle is recessed by engaging the left sprocket, the gear is down. If you need top gear, the handle must be fully extended.

DIY repair of the Neva MB 2 walk-behind tractor

Auto mechanic specializing in agricultural machinery

over, the price of agricultural machinery is quite affordable. Reliable and multifunctional assistants have appeared. motoblocks, which quickly and efficiently process a plot of land: plowing, hilling, planting, mowing, as well as removing garbage and snow in the local area. All these and other operations are performed by means of attachments driven by the gearbox of the MB 2 walk-behind tractor.

The gearbox can be repaired by hand

If the device fails, the process of repairing breakdowns is identical to other designs of walk-behind tractors. The most common violations in the operation of mini tractors, which are worth paying attention to:

- when the rotation of the crankshaft stops, it is necessary to unscrew the gearbox and carefully inspect the internal elements for destruction;

- if white smoke poured out of the muffler. the reason is in the carburetor;

- the engine slows down and stalls. you must wait for the engine to cool, then check the oil level and clean the cylinder head and block surface from dirt.

Basic rules for using the mechanism will help to avoid expensive unit repairs.

Checking and adjusting the clutch of the Neva MB-2 walk-behind tractor

The main function of the clutch is to connect the gearbox to the engine, disconnect it, as well as connect other working devices to the engine. If an overload occurs during operation, the clutch begins to slip. this is how other parts of the walk-behind tractor are protected from breakage.

Checking the clutch operation can be carried out according to the scheme below.

If the clutch lever is in the OFF position, the clutch cable is loose. Consequently, the idler pulley goes down and comes into contact with the drive belt. Then the drive belt and the small roller move to the lowered position. this is how the power supply from the engine to the transmission stops.

When the clutch lever is in the on position, the clutch cable tightens the tension roller, so the bottom of the belt is tightly pressed, the small pulley drives the large pulley and power is transferred.

Adjustment or adjustment of the clutch of the Neva MB-2 walk-behind tractor is performed as follows:

- if the clutch lever is engaged, it will raise the idler pulley, driving the single axle tractor. Correct position. parallel V-belts on either side of the engine pulley.

- if the clutch lever is loose, the idler roller will lower and disengage the clutch. To avoid disengaging the clutch, and therefore slipping the walk-behind tractor, you need to monitor the position of the V-belts, bringing them to a parallel position.

Oil seal replacement

If oil leaks appear, this means that it is time to change the oil seal. The work should be done as soon as possible, otherwise you can be left without a walk-behind tractor, because the movement of metal elements inside the device will lead to its destruction.

- Dismantle the attachment mounted on the output shaft.

- Clean the shaft and gearbox from dirt and debris.

- Having unscrewed the fastening bolts, remove the cover.

- The old one is being replaced with a new oil seal.

- The cover is put in place and fixed with bolts.

AGRICULTURAL TRANSMISSION CARRARO 506 4WD FINAL DRIVE ASSEMBLY & DISASSEMBLY; КОРОБКА ПЕРЕДАЧ РЕМОНТ

The first start-up and running-in of the Neva MB-2 walk-behind tractor

The first start-up must be done according to the following scheme:

- make sure that the single-axle tractor is complete (the height of the steering rod and handles must correspond to the height of the user);

- the engine can only be started if the uniaxial tractor is located on a level surface;

- check the oil and fuel level in the tank;

- also check the places of threaded connections;

- then you can start the engine by smoothly turning the ignition knob;

- idling time (without load and movement) should be about 10 minutes, then you can move from a place and operate a single-axle tractor.

Making two wheel behind tractor part 3

The running-in period is the first 20 hours of the walk-behind tractor, after which you need to change the oil. During this period, the most important:

- do not run at full throttle;

- work only on previously prepared soils (not virgin soil);

- for cultivation, use only the number of cutters that is included in the kit;

- the single-axle tractor “Neva” MB-2 during the running-in period can be loaded only at ¾ of the power;

- shifting gears in the gearbox can only be done when the rotation of the drive pulley is completely stopped;

after the first 20 hours of operation after the first start, change the oil in the engine.

Breakdown of the gearbox of the Neva MB-2 walk-behind tractor

Correction of breakdowns of the “Neva MB2″ gearbox is practically no different from other models, but still there are some points that need to be mentioned. Our tips will help you not only identify the problem, but also decide whether you can repair it yourself or whether you will need to call a technician.

- The crankshaft stopped rotating. Repair is definitely needed here, since the reason may lie either in the destroyed ratchet housing or in the ratchet clutch. You must examine and unwind the device and replace all damaged elements;

- White smoke began to come out of the muffler when you turn on the equipment. At the same time, the electrodes of the candle may remain dry, but they are covered with a white coating. The reason is a poor mixture. To fix it, you need to adjust the carburetor;

- The motor suddenly starts to slow down and stops altogether. Your engine might just be overheated. You need to stop work and leave the equipment off until it has completely cooled down. You also need to check the oil level and clean the surface of the block and the cylinder head from dirt.

Simple operating rules allow you to avoid any breakdowns. If they do arise, you should definitely study the instruction manual, where you will find answers to any questions. Also, there will be detailed descriptions of all types of breakdowns and ways to eliminate them. This must be done without fail, since for different models of walk-behind tractors, the methods of finding and fixing the problem may differ to some extent.

uniaxial tractor Neva gearbox repair

Possible breakdowns of the gearbox of the Neva walk-behind tractor

Oil must be poured into the gearbox of the walk-behind tractor. You need to make sure that the oil level is sufficient. Many people wonder about what kind of oil to fill in the gearbox. It is important that it is of very high quality and from a well-known manufacturer, so that the entire system works properly and lasts a very long time.

To repair the gearbox, you must disassemble it. But first you need to clear all the dirt, drain the oil. After that, neat disassembly is carried out and the origin of the breakdown is found. You can visually inspect each component and find breakdowns, or mechanically test the parts. If you find a breakdown and you need to replace one or another component, be sure to buy and install only new parts and only genuine ones, if, of course, you value your unit. Changing the oil in the gearbox of the Neva walk-behind tractor is a mandatory and last step in the repair process. If you don’t, the device will simply fail.

- Oil flows along the shift shaft. It may not even require a gearbox repair here. First of all, you need to check the presence and quantity of oil. Then you can replace the oil with a new one and drain off the excess. Another reason is the worn out cuff. To do this, you need to carefully examine the device and replace the damaged part;

- Oil flows through the output shaft. Cuff replacement is also required here. The origin of the breakage is the wear of the semiaxis cuff edge;

- There is no kinematic connection inside the gearbox. This comes from the breaking of the sprocket in the block. To repair the gearbox in this case, you need to completely inspect it and replace all faulty sprockets;

- The gearbox is seized. You need to study it and change the broken chain;

- Gears are not included or switched. There may be several reasons for a malfunction at once. The first. the switch cracker is spoiled. The second. the thread of the gear shift knob is cut off. You can fix the breakage yourself by simply replacing the parts.

It should be noted that you will not need to repair the gearbox for a long time, if you use high-quality oil, monitor its level and change and fill in new oil in time, and also operate the equipment carefully, without overloading.

Device by assembly type

Depending on the ability to disassemble and repair the device, converters are divided into two types:

- A budget option that installs inexpensive disposable parts. If the spare part fails, it is better to replace the gearbox with a new one.

- A collapsible design that allows you to easily replace a failed spare part. Can serve reliably for several years without breakdowns.

According to the type of gearbox design, there are the following:

This type of mechanism is equipped with a reverse motion of the walk-behind tractor.

The influence of oil on the operation of the gearbox of the walk-behind tractor Cascade

Particular attention should be paid to the lubricating fluid, oil. It is worth noting that the oil must be changed every 50 hours of operation of the walk-behind tractor. Also, do not heavily load a uniaxial tractor, because this can lead to quick wear of the equipment. Do not forget that it is undesirable to install additional cutters with your own hands. The gearbox chains are severely affected by additional loads (bushings burst), after which the chains begin to jump. With strong side loads, the support washer wears out quickly, as a result of which the alignment of the two gears is lost, and the bushings fly off the chain. The conclusion can be made as follows: you do not need to work on the walk-behind tractor at an angle, in spite of cleaner work, you harm your unit and you should turn the single-axle tractor more carefully when working.

The oil change is done as follows:

- Initially, we put the uniaxial tractor on a flat surface and find a rod, about 70 centimeters long.

- We bend the rod into an arc and push it into the filler hole of the gearbox through the entire body of the gearbox until it stops and protrude the rod.

- Next, we look at the oil level in the gearbox. Ideally, the oil should be filled in at least 25 cm.After that, either add oil (1.5 liters), or pour oil into a dry gearbox (2 liters). It is necessary to fill in the oil provided for by GOST, in addition, it is permissible to mix various types of oils in any ratio.

What does the cascade walk-behind tractor gearbox consist of??

In order to disassemble the gearbox of the Cascade walk-behind tractor, you must first of all remove it from the walk-behind tractor. Then you need to remove the covers, then remove the screws and tap to remove the cover. Remove the input shaft sleeve, remove the lever and shift fork. Remove the input shaft with the gear on it. Remove the shaft from the bushing and remove the chain from the shaft. After that it is necessary to remove the block shaft itself. Get the sprocket block. Take out the intermediate shaft with gears. Take out the right axle shaft, clutch and left axle shaft.

The gearbox device consists of the following main parts:

- covers;

- pulley;

- bearings;

- bushings (input shaft);

- shift lever;

- intermediate shaft gear;

- shift axis, shift fork;

- input shaft with gear;

- shaft block;

- double-row chain;

- connector, small chain;

- sprocket block;

- intermediate shaft with gear;

- input shaft;

- washers;

- oil seals;

- right semiaxis;

- double asterisk;

- clutch;

- left semiaxis;

- clutch fork;

- bracket;

- spring.