How to Assemble a Makita Screwdriver Video

Innovative technologies in construction are developing every day, it is no longer a secret that a screwdriver is an indispensable assistant for both an experienced specialist and a novice master. Thanks to him, you can easily tighten all kinds of screws and self-tapping screws when assembling furniture designs, as well as when repairing equipment and residential premises.

The fact that any equipment fails over time is no longer news to us, so it becomes possible to disassemble a screwdriver and try to repair it with your own hands. But only without fanaticism, be careful when disassembling, especially such models as: interskol yes 12er 01, interskol yes 18er.

How is a screwdriver arranged? (Video)

What problems can I fix in my home environment? How to recognize this or that breakdown? To give specific answers to the questions asked, let’s first look at the internal mechanism of the tool. The main protruding element is the power button. It is used to start the device and to change the speed, the direction of rotation of the working part. the cartridge.

Speed adjustment is carried out thanks to an electronic device based on a transistor. The speed of revolutions is directly proportional to the force of pressing the button. The reverse is triggered by replacing the polarity of the electric current at the terminals. Traditionally, a screwdriver is equipped with single-phase collector type motors that operate on continuous current. The engine includes a housing, magnets, an anchor and brushes.

Rotation from the motor goes to the gearbox. Further, it converts high engine speeds into reduced cycles on the shaft, a cartridge with active bits is fixed in it. The gearbox can be used classic, as on a conventional drill, including a planetary one. Recently, the classic gearbox is almost not used, so we will not stop and go further. The planetary gear includes:

- Ring gear

- Sun gear mounted directly on the motor shaft

- Satellites

- two or three drove

Then follows a force stabilizer with sixteen positions. These positions give a specific tension on the self-tapping screw, so as not to spoil the material with which they are attached. The last component is the cartridge.

How to disassemble a screwdriver in general form (Video)

Let’s do a disassembly analysis, an example is a Makita screwdriver:

- We remove the block housing where the battery is located.

- We remove the screws that combine the two halves of the case with a Phillips screwdriver.

- We take out everything that is contained inside the tool body.

- Disconnect the reverse button.

- Dismantle the speed switch.

- We disconnect the engine and gearbox.

How the cartridge is disassembled (Video)

If the cartridge fixing is conical, then it is removed simply. by careful blows with a hammer on the block case. If the fasteners are threaded, you will need the following steps:

- In the clockwise direction, unscrew the screw with the left thread.

- We squeeze the hexagon in a vise, put a key on it and make blows with a hammer. Similarly, the cartridge should move from its original position. You can choose another option:

- Put the screwdriver on a flat surface, on the table, for example.

- Turn it on.

- Observe if the cartridge has moved off the table. when striking a hexagon.

It also happens that all of the above methods do not work, and then one thing remains. to disassemble the screwdriver, after which:

- Remove gearbox and spindle;

- Position the assembly in the vise clamps;

- Take the pipe wrench and then disconnect the chuck.

And if garbage is found in the gearbox, then you need to do so.

How to disassemble the battery (Video)

- Disconnect the screws at the bottom of the box.

- Open the box.

- Check and discard components.

- Replace and assemble again.

The mounting screws on the underside can vary in number, from four to six. Often unscrew with a Phillips screwdriver. Screws come in various lengths. This must be taken into account so as not to confuse them with each other during assembly. On some modifications, you can find a non-separable case. Then examine the entire surface and find a special strip along which the factory gluing passes. Next, you need to take a strong knife and insert it into the groove, slightly swaying to the sides. If the case breaks into the upper and lower parts, the autopsy was successful. Not a problem if this happens past the groove. All discrepancies can be glued with good superglue. The upper part of the housing contains several parts for the battery. At each of these components, a voltage is measured, which must certainly be in the range of the optimal level. If the difference is over 10%, such a battery needs to be replaced.

Each manufacturer seeks to create a tool that will be as convenient as possible in the work process, creating an extensive assortment of models. from basic level screwdrivers to professional samples.

Hitachi screwdrivers prioritize the excellent build quality as well as the practicality of their tools. Bosch’s model cordless screwdriver collection is practically no different from its counterparts, which have a cord for connecting to 220 V. Equipped with mode switches, as well as an off button and an accelerator option, Bosch screwdrivers are an excellent solution for home and professional use. In addition, such brands as Interskol, Makita, Cmi, Bison have proven themselves well.

Repair of the cartridge and other parts of the Makita screwdriver

Next, a screwdriver from the famous Makita brand will be considered, we will describe its technical properties and the general device, we will talk about the main dilemmas and defects that arise during the use of the tool, and of course, how to diagnose a breakdown at home and repair the one that is also called another element screwdriver.

Makita screwdriver

Description, general information

The Makita company makes various power tools among which screwdrivers are considered. The company began its history from the 20th century, and to this day, it continues to amuse consumers with its products of quality work. It is necessary to consider the general features and properties of the models of this office.

Makita screwdrivers are very powerful. The average indicator of the stroke frequency for different models is about 2300 rpm, which is a good indicator, compared with other brands. The weight of most models of instruments lies during 1.5 kg. Its small mass says that in fact, that such an inventory will work comfortably. The manufacturer also took care of the convenience of working in poorly lit rooms, making LED lighting on most models. Separately, it is worth highlighting the type of handle for holding these tools on weight. You, they become rubberized, so they are comfortable to hold in your hands, respectively, the process is much easier.

The disadvantage of these screwdrivers is the powerful vibration of the handle during operation, as well as their short-lived batteries. Today, the cost of the products of this office is quite high, which is important for the Russian consumer.

Scheme, device screwdriver "Makita"

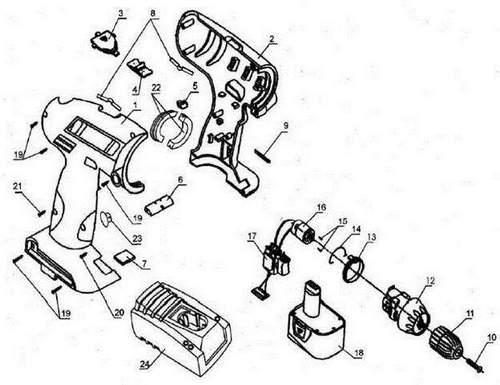

Let’s look at the device of a screwdriver on a specific model 6271D. The scheme of this model is presented in the figure below.

Scheme 1

The diagram shows:

- Shift lever

- Body assembly

- Nameplate

- Screw

- Spring

- Lever arm reverse shift

- Start button

- Contact terminal

- Screw

- Keyless Chuck

- Gear assembly

- Electric motor

- Screw

- Body assembly

- Charging unit

- Battery

Read the same

A modern screwdriver is an ultra-technological device. Principal structural elements:

- Removable battery

- Rubberized handle grip

- The most powerful electric motor

- Iron planetary gear

- Soft start button

- Reverse button

- Torque regulator

These are the main components of the construction of a screwdriver, which are included in the basic configuration of any model of a screwdriver.

Dismantling a screwdriver "Makita"

To disassemble a screwdriver, you will need a Phillips screwdriver and a little personal time. In order to completely disassemble a screwdriver, it is required:

- unscrew fastening screws housing;

- remove the composite mechanism of the start button;

- remove the electric motor coupled with the gearbox;

- disconnect the gearbox from the motor by unscrewing the bolts securing them.

To disassemble the battery of the screwdriver, you need to unscrew the bolts connecting the case, otherwise divide the case connections on the glue base with a soldering iron. Inside the battery there are several nickel-cadmium batteries that have a certain capacity and carry a charge. If the battery repair passage requires a change to new ones.

How to repair a reducer in 6271 Makita Restoring a reducer 6271

IN Makite 6271 gearbox failed in this matter video I will show how to return it. For this purpose, you will come in handy.

Change ”screwdriver gear. (Replacement gear screwdriver on Makita 8280d)

When replacing the gear unit, the cartridge was removed and the case cleaned from the inside. Hope it video It was fascinating for you.

The cartridge is changed with a screwdriver and an allen key. First, with a screwdriver, you unwind the fastening screw in the cartridge by rotating it clockwise. Then the hexagon is inserted, the reverse button is cut in, clamped, and later the cartridge simply lends itself.

Failures of the Makita screwdriver

frequent breakdowns of the Makita office screwdriver are as follows:

- Do not cut the screwdriver. Here, well, what remains to make our client clear. First you need to look at the battery, in addition, the contacts and connections in the case, the wiring. A multimeter will help you to check.

- The reverse button does not work. This means that you cannot either twist or unscrew the screws and bolts. Here you need to check the resistance of the button with a multimeter by placing the probes on the input and output wires of the button.

- The speed controller does not work. In this case, the revolutions will be either constantly reduced or constantly overestimated. Here the regulating transistor or brushes will be to blame. Need a visual inspection of the details.

Repair of the Makita screwdriver

Repair of the Makita screwdriver button

Read the same

The on / off button of the instrument is a complex electrical mechanism. It consists of several constituent parts:

- launch buttons

- reverse buttons;

- speed change buttons;

- soft start buttons.

When repairing a button, you first need to disassemble it by loosening the screws body mounts and disconnecting the battery. As a result, it is necessary to check the connections and contacts for contamination, clean them. If the passage, if the stripping of the contacts did not help remove the problem, the button should be replaced as an assembly.

Repair of the charger of the Makita screwdriver

When repairing the charger, you need to unscrew the screws that fasten the housing covers. Inside is an integrated circuit with contacts. First you need to check the transformer with a tester. For this purpose, you need to measure the output voltage. Later, you should ring the cable to prevent it from breaking. Then the primary and secondary windings of the transformer and the fuse are checked. It must be assembled in the reverse order.

Repair of a battery of the Makita screwdriver

When performing battery repair with a Phillips screwdriver, unwind fastening screws corps. Inside the case there are several cans. With the help of visual inspection, you need to look at them and identify geometry violations, such as bloating, for example. We test banks with a multimeter for the presence of a residual charge. In its absence, the bank is replaced with the latest.

Repair of a reducer of the Makita screw gun (scheme)

To remove the gearbox, you need to disassemble the housing by unscrewing the screws with a Phillips screwdriver. We take out the start button, reverse switch button, disconnect the bolts of the motor to the gearbox. Then you need to pull out the contents of the gearbox (different gears), the speed switch washer. When examining an empty gearbox, special attention should be paid to the teeth placed around the circumference of the gear case. For which the design of their attrition is intended, the gearbox will not be able to do its function: the speed switch does not work correctly. To restore the teeth, you need to use small bolts, inserting them into the unique plastic area. Assemble the gearbox in reverse order. The gearbox diagram is shown in the figure below. He presented a general diagram of the gearbox.

Scheme 2

Brushes on screwdriver "Makita"

The brushes used for a screwdriver have a graphite base. Their price currently varies between 2-5 y. e. They are located in the motor housing and are two graphite cubes mounted on iron plates. With intense work, they wear out and wear out.

Carrying out repairs at home they have the option of turning rattles from brushes from another tool, for example, a car starter. After undercutting, they should be inserted into the brush holder and put into the area, collecting the engine.

Keyless chuck "Makita"

This cartridge is used to clamp bits with a cylindrical shank. This cartridge features ease of installation. It is installed with just one movement of the hand. It is used for drills with a diameter from 1 to 10 mm. This is a movable structural element in the tool, because it often breaks. To disassemble it, you need to read the tips, first described articles, on disassembling the cartridge using a hex wrench and a Phillips screwdriver. The cost of this product is about 20 y. e.

Video: How to Assemble a Makita Screwdriver Video

The material in this article came out great. Here we outlined to our client the probable tasks that arise during the operation of Makita office screwdrivers remain, told how to remove them with our own hands, separately talked about the various structural elements that make up the base of any screwdriver. The materials of the article show the scheme of the gearbox and the general device of the screwdriver. We hope that the information will be useful to you.

Read the same

Related posts

Dismantling the Makita 2450 Hammer Barrel

Diagram of a Makita 2450 rotary hammer Repair of a Makita 2450 rotary hammer by a do-it-yourself manual Perforators are percussion drilling devices designed for drilling and chiselling holes in especially strong materials. Two ideas are implemented in the puncher: the working tool rotates and immediately moves longitudinally, creating a shock impulse. Hammers always work in extreme conditions. The duration of the drill depends not only on [.]

Alteration of the Makita Screwdriver Battery For Lithium

Converting a cordless screwdriver to lithium cells Some screwdriver owners want to recycle batteries from their characteristics into lithium battery cells. Many articles have been written on this topic, and in real material I would like to summarize information on this topic. Immediately we will examine the reasons for the purpose of obtaining the alteration of a screwdriver on and against lithium batteries. And of course, let’s look at the individual [.]

Repair of Makita Screwdriver (Motor)

Repairing a Makita screwdriver (motor) Read the same Charge the Battery with the Charger From the Screwdriver. Do you need to charge the battery of the screwdriver without a charger? Charge the screwdriver’s battery with auto charging How to properly charge the screwdriver’s battery The screwdriver is the most necessary tool used by professionals and amateurs. The introduction of network screwdrivers is not necessarily comfortable, especially if you are away from 220. How much to charge the battery [.]

The screwdriver can be repaired independently, having studied its structure and principles of operation of individual units.

Device and screwdriver malfunctions

All screwdrivers are arranged approximately the same. They consist of the following functional units:

- start button;

- pulse width regulator;

- electric motor;

- transistor;

- planetary reductor.

All components of the device are in a strong and aesthetic case, which has a rubberized handle, control and adjustment buttons, as well as a slot for installing the battery (if the screwdriver is designed only for 220 V operation, it does not have a battery).

When you press the start button, the screwdriver may not be squeaking. This is a normal occurrence of DC motors at startup and at low speeds.

Why and how to adjust the ratchet

A ratchet screwdriver is a clutch designed to limit the force during rotation of the chuck. Its presence in the power tool can be determined by a rotating ring with numbers. Some users do not understand the meaning of the coupling and do not touch it. Using a ratchet, you can adjust the screwing depth of the screw. In too soft material, the fastener cap is easily recessed and can pass through. When using small fasteners, very high torque can destroy it. A ratchet prevents the cutting of a slot from self-tapping screws and the wear of a screwdriver bit. To determine the desired value on the control ring, make several passes, starting with the minimum.

If the screwdriver has a drilling mode, then the last icon on the coupling will be the icon with the image of the drill. In this position, maximum torque is used.

Frequent screwdriver malfunctions

Since all modern screwdrivers have a standard device layout, their malfunctions, as a rule, are also typical. The main defects of this tool include:

- battery malfunction;

- brush wear;

- button breakage;

- runout of a cartridge;

- lack of response to attempts to turn on or off;

- interruption work.

You can fix all these failures yourself if you have experience working with measuring and soldering devices. In some cases, you will have to change the components completely, since not all parts are sold separately. If repairing the gearbox or motor is too complicated for you, these elements can be completely replaced or taken to the workshop.

DIY screwdriver repair

To eliminate most of the malfunctions of a screwdriver, it needs to be disassembled, that is, removing the case and disconnecting the main components from each other.

How to disassemble a screwdriver

The screwdriver is disassembled in the following sequence:

- Remove the battery.

- Remove the screws connecting the two halves of the housing.

The case of the screwdriver consists of two parts connected by a fairly large number of screws. in order to disassemble it, you need to find all the attachment points

The screwdriver button is integral with the switching mechanism, which is connected to the engine, so when separating the button from the socket on the case, you must be careful not to break the wires

In order to disconnect the gear of the screwdriver from its engine, it is necessary to unscrew the four screws located at the contact point of the two plastic casings

Video: how to disassemble a screwdriver

Cartridge Repair

The chucks in different models of screwdrivers may differ slightly from each other. They can be attached to the shaft in three ways:

- Morse cone.

- Threaded connection.

- Threaded connection with fixing screw.

To determine the method of attaching the cartridge, you need to read the inscription on its sleeve:

- the marking “1–6 B10” means a Morse cone. Used nozzles with a shank diameter of 1 to 6 millimeters. The coding "B10" indicates the size of the cone. Take a hammer and knock out a cartridge by striking the body;

- inscriptions like “1,0–11 M12x1,2” or “2–13 mm ½-20 UNF” mean metric and inch threads.

If the cartridge is threaded, you must perform the following steps:

- Release the cams of the cartridge.

- If there is a screw inside, unscrew it clockwise (the screw has a left-hand thread).

- Take a 10mm hexagon wrench.

- Insert the short edge into the cartridge and tightly clamp in the fists.

- At low speeds, start and immediately turn off the screwdriver so that the long edge of the hexagon hits the table. Instead of turning on the device, you can simply hit the key with a hammer. The thread moves and the cartridge is unscrewed.

In order to remove the cartridge, you need to hold the hex key in it and start the engine at low speeds until the key hits the table

Video: how to remove a threaded chuck using a hex wrench

If these methods do not help, disassemble the screwdriver and remove the gearbox assembly. Take the L-shaped tubular wrench (most often 19 ”) and unscrew the chuck, holding the gearbox securing bolts on the back with the cap wrench. She will give the necessary emphasis, with which you can unscrew the cartridge by hand.

Video: how to remove a cartridge with a pipe wrench

To disassemble the cartridge, you need to remove the cap at its base. The plastic plug is gently poked with a knife. Metal. knocked out by hammer blows on the base of the cartridge:

- Take a large bolt, insert it into the cartridge and slightly tighten for alignment. The bolt head should protrude above the cartridge for two to three centimeters.

- Hammer the bolt head. The cartridge will pop out of the case.

Video: removing a plastic plug from a screwdriver chuck

Common cartridge malfunctions:

- crookedly pinches bits;

- play between bits and cams;

- cams jerk out.

To find out the reasons and eliminate them, follow these steps:

- Disassemble the cartridge.

- Remove the flare nut, which consists of two parts.

- Unscrew the clamping jaws.

- Check the condition of the threads on the nut and on the cams, replace the defective parts.

In the process of working on cams or a flare nut that controls their work, a thread may develop or crumble, then these parts must be replaced

Assemble the cartridge in the reverse order of disassembly.

Video: analysis and repair of a cartridge with a metal plug

Battery Repair

Three types of batteries are used in screwdrivers:

- Nickel Cadmium (Ni-Cd). They can be charged many times, but they have a memory effect. If you do not wait for the full discharge and begin to charge the battery, then its capacity will gradually decrease. Swing the battery before first use. Discharge and recharge it three times to maximize capacity.

- Nickel Metal Hydride (Ni-MH). A feature of such batteries is a less pronounced memory effect, but a high self-discharge current. If you intend to store a screwdriver without use for more than a month, be sure to fully charge its battery.

- Lithium-ion (Li-Ion). These batteries charge quickly, but do not tolerate frost. They can be charged when convenient.

Store all types of batteries separately from the screwdriver and charger. For long periods of non-use, they need to be recharged once a month.

If the battery does not hold a charge, disassemble it. It consists of several batteries. Check the voltage tester in each. The value of the operating voltage is indicated on the housing (it is the same for all elements). Replace broken batteries.

The battery of a screwdriver consists of several elements, which you can call and find and replace those that have failed

Video: eliminating fast battery drain

If the battery cannot be removed, the locking button is most likely stuck. It is necessary to remove the upper part of the case, disconnect the battery, disassemble it and adjust the button.

Charger Repair

Frequent damage to the charger:

- the fuse is on;

- network cable breaks;

- the primary winding of the transformer breaks;

- diodes break through.

If we disassemble the charger of the screwdriver, then we will see a step-down transformer and a board. Through the mains voltage is supplied to the primary winding of the transformer. The thermal fuse is connected in series with the network winding, so it overheats first and prevents the winding from breaking. From the secondary winding, the voltage passes to the diode bridge. If charging transmits current, yellow is formed around the diodes. Transformer windings overheat, diodes break through.

The charger of the screwdriver consists of a step-down transformer and a board with electronics

- Measure the resistance on the primary winding with a multimeter. If it is not there, it means that the circuit is disconnected and the voltage does not reach the primary coil. The fuse is located beneath the transformer insulation next to the wires connecting to the network. Check it with a tester.

- If the fuse is intact, check the power cord; it may be broken.

- If the wire is OK, check the windings. In case of breakdown, replace the transformer.

Video: diagnostics and repair of the charger

Button Issues

A malfunction of the start button can lead to the following malfunctions of the screwdriver:

- self-propelled guns appear;

- the device does not turn on;

- the device is unstable.

From the button, two wires go to the battery terminals and two to the engine. If there is a transistor, then it is connected by three wires. Make sure the problem is in the button:

- Connect the battery. Press the button and tester measure the voltage at its output, it should be absent.

- Remove the battery and remove the upper motor wire from the button housing.

- Connect the motor directly to the battery. To do this, take two wires of the required length and connect them to the battery terminals. Connect the other ends of the wires to the motor housing and to the wire that was inserted into the button. If the engine is running, then the button is faulty.

Video: diagnostics and replacing a screwdriver button

Button repair sequence:

- The wires coming from the button do not need to be soldered. Carefully, so as not to damage the base, remove the push part of the button that does not fall into the interior of the case. This should not be done in a jerk, but slowly rotated and pulled towards yourself.

- Remove the protective cover. Take a knife and a flat screwdriver. Pry and release all latches. Pull out element number 1 and remove the cover of the inclusion compartment under number 2. If the contacts are slightly burnt, they must be cleaned. But if they burn out completely, then the button is best replaced. It is sold complete with wires. If the contacts are intact, then move on.

- Holding the spring, carefully remove the trigger mechanism. Look inside. Perhaps, due to the poor quality of the metal, the contact pads wiped off and dust formed, which settled inside the plastic box. Accordingly, dielectric surfaces began to conduct electric current. This is one of the reasons for spontaneous operation of the device. The second reason is a failed transistor. Remove metal dust with a cotton moistened with alcohol. Contacts can be scraped off with a knife, but not with sandpaper, so as not to spoil their surface. Now reassemble everything in reverse order. Replace the burnt transistor. Turn on the tool.

The cause of the malfunction of the button may be burnt contacts, metal dust or a burnt transistor

Inspection and repair of the force regulator

Behind the cartridge is an adjusting ring with a spring that controls the force and snaps the cartridge away from the gearbox. This spring presses on the balls, which abut against the protrusions of the ring gear of the gearbox. Disassemble the ratchet, check the integrity of all its elements. Remove dirt with a rag dampened with alcohol, grease balls.

Video: ratchet repair

Gearbox disassembly and repair

The main elements of the gearbox:

They are made of metal and plastic. An annular gear is a cylinder with internal teeth along the entire circumference. Satellites move along the teeth.

The first carrier has two gears at both ends. The first solar is the engine drive gear. She enters between the satellites of the first carrier. The second solar on the opposite side sets between the satellites of the second carrier. In a two-stage gearbox, the second carrier is connected to the shaft on which the cartridge is worn. The three-stage gearbox has another mechanism. All these parts are located inside the ring gear.

The engine transmits the rotation to the first stage satellites through the sun gear. The first carrier rotates the second stage of the satellites. If there is a third step, then the second carrier will rotate it. Satellites of all stages rotate inside the ring gear. The last carrier rotates the cartridge shaft. With each transmission of torque, the speed drops.

Gearbox disassembly sequence:

- Cartridge removal.

- The unwinding of the body.

- Disconnecting the gearbox from the motor.

- Plate removal.

- Removing all parts from the chassis.

When disassembling the gearbox, all parts are removed sequentially: first satellites of the first stage, and then the second

Arrange all the parts of the disassembled gear in order, so that later it is easier to assemble.

- If a rattle is heard during the operation of the screwdriver or it twitches, then the gearbox has defects. During operation, you have to make lateral pressing and heavily load the tool. Because of this, the gearbox shaft bends and a noticeable runout occurs. In this case, the assembly changes assembly.

- If the support sleeve and shaft bearing are worn, they can be replaced with similar ones.

- Breakage of the pin of the satellite is accompanied by the start and instant stop of the engine. Replace the carrier or gearbox.

- Wearing gear teeth also requires replacing the gearbox.

Often, gearbox repair is reduced only to cleaning and lubrication. Do not overdo it with grease, otherwise the device will work poorly.

Video: disassembling, assembling, cleaning and lubricating the gearbox

Brush replacement

Graphite brushes are located at the end of the engine on the connection side with the button. They can be located inside the engine housing under the rear cover or outside. If at least one of the brushes is worn by 40%, change both. Check your contacts. The following signs indicate wear on the brushes:

- the engine runs jerkily;

- sounds unusual for normal operation are heard;

- sparking;

- the smell of burning.

When removing and installing the brushes, you need to hold the holders, otherwise, under the action of the spring, they can scatter quite far

Video: replacing engine brushes

Engine repair

The screwdriver uses a DC motor in a cylindrical case with magnets. Inside is an anchor with windings and brushes. To check the motor, disconnect the gearbox and the wires leading to the button, and measure the resistance of the armature winding with a multimeter. Lack of readings indicates a break, and a very low value indicates a short circuit. The collector resistance is measured on the shaft and each plate. It must be zero. Faults in the anchor lead to shutdown during operation, loss of power, sparking and smoke.

Video: testing the winding of the armature and collector plates with a multimeter

Often when the engine fails, the gear remains intact. Since in most engines it is pressed onto the shaft, its removal takes place with some difficulties. Buy a special puller or use the tools at hand. Do not try to do this with pliers or a nail puller. you will bend the shaft and spoil the gear teeth.

- Take a piece of profile or channel. Make a longitudinal groove angle grinder.

- Insert the shaft into the groove perpendicular to the profile and pry off the gear.

- Lay the profile on two hard surfaces so that the engine hangs between them.

- Take a nail and gently tap the edge of the shaft with a hammer. The gear will slip easily.

- Put the gear onto the new engine with a hammer and a hard surface.

Video: remove the gear from the engine shaft

The screwdriver is cracking but not twisting

If there is a crack in the screwdriver, first try changing the position of the speed controller. Perhaps he was not involved. If this procedure does not help, disassemble the tool.

- If the engine is spinning, disconnect the chuck. Check the rotation of the gearbox shaft and the condition of the motor gear.

- If the shaft does not rotate and the gear is intact, disassemble the gearbox. Check the condition of the teeth of the satellites and gears.

- If the engine does not work, check the brushes, windings and anchor.

Now you know how to disassemble, assemble and repair a do-it-yourself screwdriver.