How to call the stator grinder multimeter. Stepbystep instructions for rewinding the electric motor with your own hands

How to call the grinder with a multimeter

Bulgarian. A construction tool used in cutting and processing the edges of various solid materials, such as stone, metal, wood, etc.D.

The rotor is a part of the grinder engine rotating during the working process, setting in motion other components and parts of an electric tool. The quality of the cutting and grinding tool and the duration of operation of the device depends on the work of this important part.

The rotor control is carried out in two ways. A preventive examination and by determining the cause of non.Service, if the breakdown has already happened.

Dismantling the grinder

How to check the stator angular grinding machine (grinder)? You need to start with disassembling the device. You will need a screwdriver to do the work.

- Remove from the surface on which a disassembly of the grinder will be made, all extra details.

- Remove the working disk.

- Unscrew the screw.

- Unscrew the screws.

- Paste the casing towards the cord.

The stator is located on the outer side of the engine, on top of the rotor. To get the stator first you have to remove the brushes, then remove the gearbox and then stretch the anchor from the grinder after that. The rotor from the stator before checking you need to remove. Inspection is recommended to be carried out in bright light. First of all, you need to carefully examine the winding and make sure that there are no visible breaks on it. If the inspection has not revealed the cause of the stator malfunction, then you will need a special device for verification.

Special check

The most accurate way. Check the stator using a metal ball and a current transformer down. The stator is connected to the terminals of three phases of the transformer. After checking the correct connection, we turn on our low voltage network.

See also: How is it arranged and how the ignition of a chainsaw works their main malfunctions and elimination

We throw the ball into the stator and observe its behavior. If he “sticks” to one of the windings. So it has an intermittent chain. The ball rotates in a circle. The stator works. Quite an unscientific, but effective way to detect chain switching on the stature.

How to check the stator of the grinder. Causes of a malfunction, devices for verification

The stator is the motionless part of the electric motor designed to create an electromagnetic field in which the rotor rotates (the moving part of the motor). The number of possible causes of the malfunction of the angular grinding machine. The “grinder”. Includes a break or short circuit of the stator winding turns (coil).

Possible reasons

Factors causing the stator failure:

Signs by which you can understand that the stator is faulty:

- The smell of burning insulation appears.

- The case overheats.

- Smoke appears.

- The rotation of the shaft slows down or stops.

- The shaft spontaneously spontaneously spaces, the tool is dramatically gaining maximum speed.

The wires of the winding are covered with a protective layer of insulating varnish. When overheating, it burns out and destroys. This causes a short circuit of the turns. The varnish at the same time makes a specific smell. The closure of only one of the wires completely disables the grinder.

Rules that will help to avoid overheating of the Ushm engine:

- Turn off the device after working at low speeds not immediately, but after about one minute.

- When working under load at low speeds, make frequent breaks.

Often you can avoid replacing a faulty stator by rewinding its winding. The rewinding of the spoiled coil of the stator of the grinder can be done with your own hands, but it is recommended to entrust this work to a specialist.

Dismantling the grinder

How to check the stator angular grinding machine (grinder)? You need to start with disassembling the device. You will need a screwdriver to do the work.

- Remove from the surface on which a disassembly of the grinder will be made, all extra details.

- Remove the working disk.

- Unscrew the screw.

- Unscrew the screws.

- Paste the casing towards the cord.

The stator is located on the outer side of the engine, on top of the rotor. To get the stator first you have to remove the brushes, then remove the gearbox and then stretch the anchor from the grinder after that. The rotor from the stator before checking you need to remove. Inspection is recommended to be carried out in bright light. First of all, you need to carefully examine the winding and make sure that there are no visible breaks on it. If the inspection has not revealed the cause of the stator malfunction, then you will need a special device for verification.

Short circuit indicator check

You can detect a shutters of the winding or short circuit in it using an indicator of short.Closed turns (IR). Other names are an interval indicator or indicator of defects in windings of electric machines.

- Power supply;

- Housings with LCD display, nests for connecting accessories;

- Connecting wires;

- Large induction sensor;

- Small induction sensor.

The principle of operation of the indicator is based on inducing an impulse electric motor in the verified winding. In the presence of short.Closed turns, a magnetic field is recorded from a short circuit current flowing on them.

The procedure for checking the stator of the grinder with the Ivvy device:

- Inspect the Interpreter indicator. Make sure that there are no external damage, integrity of the connecting wires and sensors.

- Connect the power supply.

- Press the power button and make sure the device is about.

- If the indicator of the winding defects has been in the cold for a long time, then it needs to be kept at room temperature at least 2 hours.

- Disable Ushm power supply.

- Select from two sensors large or small, depending on the size of the stator.

- If the passport of the corner grinding machine does not indicate the nominal voltage attached to one round of the winding, then it must be determined by the formula: the nominal voltage of the entire coil is divided into the number of turns.

- Turn on the device.

- Install on the indicator the closest to the amplitude of the pulse test voltage that is obtained in the calculation.

- Pressing the sensor to the surface of the winding, sequentially check all the grooves, waiting 3-4 s. If a short circuit is detected, the device will make a sound signal, and an appropriate inscription will appear on the display.

- If short.Closed turns were not detected, then install the following (larger in value) amplitude on the device and make sure that the reserve of insulation of the winding is available.

- Turn off the device.

The indicator of the winding defects can check the state of insulation between the coils of the stator and the rotor, as well as between the stator winding and the grinder body. If there is no way to buy a ready.Made device, then you can make a simpler indicator of short.Closed turns yourself.

Checking a multimeter

You can make sure that the stator can be used using the device. Multimeter. This is a universal measuring device. They can measure several electrical values: voltage, current strength, resistance. The device consists of a case on which there are a display, a switch and a nest, and two cords with probes (plus and minus). The minus probe is always connected to the lower nest, and the plus to the middle or upper, depending on the current strength in the test device.

To check the stator Ushm (Bulfur), it is necessary to set the resistance value from 20 to 200 Ohms on the multimeter and alternately bring the probes of the measuring device to the windings. If the resistance is the same everywhere, then the coil is working. If the device shows a different resistance at some points, then the winding has a short circuit or a break in one of the turns. On the same principle, the stator is checked by an ohmmeter. Its difference from the multimeter is that this device can only measure the resistance.

Device for checking the anchors and stators of electric machines

Another device with which you can believe the stator of the grinder is a device for verification of anchors and stators of electrical machines PUNS 5. The device has light and sound alarms, allows you to detect an interval closing of windings, break, measure the insulation resistance of the coils.

How to check the collector engine: 3 methods of analysis of the rotor windings

Tomorrow I am going to my first real client and I’m very worried. Why he is the first? Because I only finished my studies and became a certified specialist.

I can do all the work at home, I have a tool. For example, a screwdriver that my father gave me as a child. I take him with me.

But something tells me that it is here that there may be a misfire. The tool with experience. We need to check the engine. At the same time and test my new Mestek MT102 multimeter.

To begin with, we will figure out what a collector engine is, from which my screwdriver works.

How is the screwdriver of the screwdriver

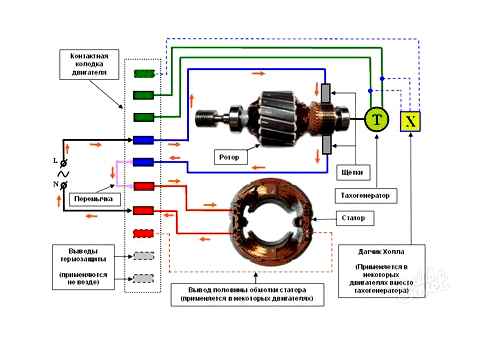

In the electrical circuit of the collector engine of the rotor and stator windings and the stator are connected through the brush-collection node. The scheme of their connection is as follows.

So, we figured out the scheme. Now let’s see where what is. In the assembled state, the electric motor with the collector mechanism looks like this.

The rotor winding consists of sections with the same number of turns. They are sequentially connected to their collector plates, isolated from each other, have exactly the same design and therefore have equal electrical resistance.

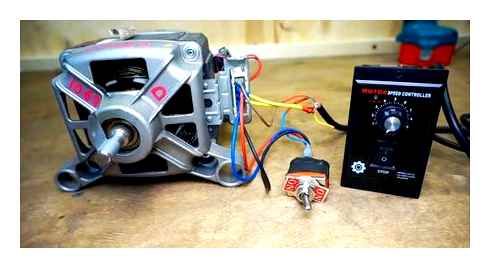

To check the engine, I decided to use a multimeter in an ohmmeter mode, especially since the collector device allows me to do this.

How to check the anchor of the collector engine

There are three methods of such a check. I check them sequentially.

The first method: froze the resistance between neighboring lamellas

In the photo you see a definition of resistance between collector plates in this way.

I put the probe of the multimeter on neighboring lamellas. The place of the first check was marked with a marker, and moved from it sequentially in a circle, checking the collector plates one after another. With this method you need to have great patience, I will tell you.

In my ignorance, I made a mistake from which I want to warn you. When checking, it is necessary to extract brushes from the brush holder, as they create additional connection of electrical chains that distort the real picture. A measurement data is inaccurate.

You should carefully monitor the readings of the multimeter, I had all the same: the accuracy class of the ohmmeter is quite high.

When it is insufficient, it will work difficult to work, since the resistance of these parts. In this case, a different method is used.

Second method: froze the resistance of diametrically opposite lamellas

What I told you about patience, it was flowers. This is where the eightieth level of attention and accuracy will be required.

Ommmeter probes are required not to be put on neighboring lamellas, but on diametrically opposite, that is, to those places that are switched on the engine with brushes. I also marked them with a marker.

Third method: frozen voltage drops with a voltmeter

Overweight resistance by 20 Ohms;

How To Rewind The Field Coil And Armature Of Olympia Mini Angle Grinder 1150 Watt. Part #1

Here I want to make a slight digression and explain that the correctness of the measurement increases the stabilization of the current source due to:

Step by step guide: How to Rewind an Electric Motor (Induction Motor)?

A large battery capacity, which creates a constant voltage level during a short.Term check;

The increased power of the resistor, which does not allow it to heat up and retains the accuracy of the parameters at a current strength of less than 1 A;

I brought the first connecting wire directly from the accumulator terminal to the collector plate. In the second, he inserted a current.Limiting resistor, which limited high current. In parallel with collector plates, he installed a voltmeter. It turned out so.

Then I sequentially put the probes on the pairs of the collector lamella and took the voltmeter readings. The battery through the resistor and the connecting wires during the measurement produces the same voltage. Therefore, the testimony of the voltmeter according to the law of OMA depends only on the resistance of the circuit.

The same method allows you to measure the current strength through collector plates with a milliammeter and compare it.

But what about my new multimeter? Let him have his own flaws, but he coped with the task.

The final conclusion about the serviceability of the collector engine can be made after checking its stator.

This process is described in more detail in an article on checking electric motors of all types by multimeter.

The article was written for you by Rogozhnikova Elena. You can contact her at the following addresses:

How to check the generator rotor

The first step will be the rising of the winding of excitation. To do this, on the multimeter, set the mode to check the resistance and measure it between the contact rings. The winding resistance should be in the range of 2.3-5.1 ohms. When it is from above. Either a break or just a bad contact between the rings and the winding conclusions. Small resistance speaks of Interpretation circuit.

Using the ammeter mode on the multimeter, you can also check the current consumed winding. It is necessary to apply 12V on the contact rings and measure in the rupture of the circuit-the winding of the excitement should not consume more than 3-4.5 am.

You can also add to the complete complex and check the resistance of the insulation of the rotor. To do this, you will need a 40-piece bulb and wires (one wire from the outlet on the ring, and the other through the light to the case-if everything is normal, then the light does not light up, if the thread is barely encouraged, then the current leaks for the mass).

Adhering to all the recommendations and the sequence of verification, in most cases, you can easily check the generator of the car and its performance on your own, having at your disposal only one multimeter. But in order to repair it, having determined the faulty node, it is necessary to replace the failed part. Control the belt tension, the state of contacts, monitor the generator light on the dashboard and the generator will last you longer.

There are two power sources in the car. This is the battery and generator. The first nourishes an electric circuit when the engine does not work. Second. When the engine is already launched. In this case, the battery goes into the consumer mode of the electric current and replenishes the spent energy to start the engine.

In practice, the malfunctions of a particular power source are quite often found. They often appear the same. The starter refuses to promote the engine, as a result, the engine does not start. With a neglected engine, the control light lights up on the instrument panel with the battery icon. She indicates that a malfunction appeared and the battery does not charge.

Bulgarian. Rules for working with an electric grinding tool

The corner grinding machine is called the “grinder” only on the repair spaces of the former USSR for prosaic reason-the Eltos Bulgarian plant was single-handedly engaged in its production. Pilaf. The high.Speed cut.Out circle is an indispensable assistant in the processing of the most durable metal, when arranging siding for the ceiling, with cutting reinforcement, sheets, profiles and many other repair operations. The grinding capabilities of the Bulgarians are no less popular. They allow to eliminate burrs, roughness from both metal and from stone or marble.

Over the past 40 years, the assortment of the Bulgarians has grown tremendously, but the rules for handling this convenient and multifunctional tool have not changed much. Over, repairs are often prevented by compliance with simple operational recommendations:

Motor Rewinding

- Do not remove the casing above the abrasive circle without extreme necessity. If this cannot be avoided, be sure to work in a goggles and protect the tool from any side touches;

- Do not process wood, chipboard, MDF and similar materials. There are saws and hacksaws for this;

- Keep the grinder tightly and confidently. When jamming the disk, the entire tool can tear out of your hands, it will receive severe damage and entail the danger of serious injuries;

- The work of any grinder is accompanied by the presence of characteristic sparks. Beware of their hitting electrical wiring, power cord and any other combustible materials;

- Any workpiece. Cut or ground. Must be securely fixed. Even if there is a cutting of a reinforcing rod that was walled up in concrete during the construction of a strip foundation from the corrugated board, you should make sure that the entire structure is pressed before pressing the Start button on a grinding machine;

- Do not press on the detail to accelerate the work. The principle of operation of abrasive circles is to erase the material of the workpieces and does not need a large clamping effort. The accuracy of movements when working with a grinder is just as useful as the gross force is harmful.

Checking a multimeter

You can make sure that the stator can be used using the device. Multimeter. This is a universal measuring device. They can measure several electrical values: voltage, current strength, resistance. The device consists of a case on which there are a display, a switch and a nest, and two cords with probes (plus and minus). The minus probe is always connected to the lower nest, and the plus to the middle or upper, depending on the current strength in the test device.

To check the stator Ushm (Bulfur), it is necessary to set the resistance value from 20 to 200 Ohms on the multimeter and alternately bring the probes of the measuring device to the windings. If the resistance is the same everywhere, then the coil is working. If the device shows a different resistance at some points, then the winding has a short circuit or a break in one of the turns. On the same principle, the stator is checked by an ohmmeter. Its difference from the multimeter is that this device can only measure the resistance.