How to change brushes on a perforator. Destruction of boyfriends, drummers, trunks, pistons

How to change the brushes on the perforator Makita

Perforators are called drilling devices designed for drilling and exposing holes in particularly durable materials. Two ideas are implemented in the perforator: the working tool rotates and at the same time moves in the longitudinal direction, creating an impact impulse.

Content:

Perforators always work in extreme conditions. The duration of the performers depends not only on the correct operating conditions, but also the reliability of parts included in the product. But no matter how hard you try, over time, punch begin to refuse.

In order to correctly repair the perforator, you need to familiarize yourself with its device.

Repair of the perforator Makita 2470 and 2450 can be performed by a person with a locksmith and knowing the basics of electrical engineering.Remember! Compliance with safety regulations and disconnect the punch from the network during analysis.

Makita perforators 2450 and 2470 are collected in almost the same scheme and from the same details. Their repair is no different. For the convenience of repair, the assembly scheme and the catalog of parts of the Makita perforators are given below.

Makita perforator 2450 and 2470 scheme consists of a mechanical and electrical part.

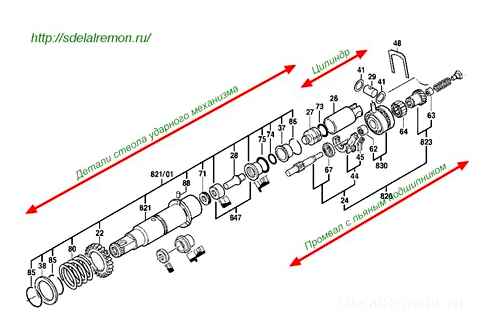

The mechanical part provides the transmission of the rotational moment to the drill-brown, creating simultaneously a progressive movement that creates a blow. The mechanical part consists of a rotation and shock mechanism drive.

The electrical diagram of the makit perforator ensures the conversion of electrical energy into kinetic through rotation of the rotor. The electrical part includes an electric motor, a button for turning with a rotation frequency regulator, a reverse switch, connecting wires.

The main malfunctions of the Makita perforator Malfunctions of perforators are divided into electrical and mechanical.

In this article, we will consider all the malfunctions of the electrical part of the punch Makita 2470 and 2450 and the methods for their elimination:

Electric malfunctions of punch Makita 2450 and Makita 2470 Electric malfunctions are manifested in the fact that when connecting the perforator to the voltage network, the tool does not turn on. The connection diagram of the makit perforator to the network is simple.

The electrical circuit of the Makita punch 2450 is a sequential connection of the electric motor, start.Up buttons and wires.

Makita 2470 punch diagram is similar.

Through the connecting cord pos.72 supply voltage 220 V is fed through the switch pos.68 and electric brushes through the brush holder pos.66 on the lamp of the rotor of the electric motor pos.54, and through the contacts of the reversal switch pos.60 on the stator winding pos.59. The most common malfunction is the lack of contacts in the compounds.

- How to cut gypsum tiles under 45 degrees

- The better to cut plywood 10

- How to cut aluminum 2 mm thick

- How to cut semicircular skirting boards angles

- How to use the Makita 4329 jigsaw

The shock drill is an indispensable assistant for any type of repair work. But, like everything under this sun, it is not forever. Sooner or later you will have to engage in maintenance and repair. And the closer you react to this, the longer it will take.

For example, your hammer has lost strength. What can he talk about? Is the tool repair or “on time” expected? In most cases, this is normal, most likely the time has come to replace the brush in the hole punch.

What are brushes and why they are needed?

The brush is part of the electric circuit for connecting the electric motor, current of the current with the valve collector. Since the anchor rotates due to the electromagnetic field, there cannot be a fixed connection, as in the stature. The output was made using pieces of graphite, which slide along the collector plates, thereby leading the current to the winding of the valve section. In turn, a magnetic field is created in the winding of the latter. According to the law of magnetism, the opposite poles stretch, this creates an anchor movement. As shown below.

But we can say that this is the weakest place of the engines of collectors, since the brushes are erased during operation, and the collector clogs carbon dust. This leads to a violation of the normal operation of the engine.

The design of the brush itself is very simple: the contact terminal, the wire from the terminal to the working surface of the brush and the spring, pressing the surface to the collector plate.

With the appointment of collapsed brushes, we will now consider their types. There are three types of collector brushes. In fact, there are more of them. But they are not used in perforators. For example, the so.Called “generator” brushes (copper. Graphite, copper. Coal).

- The graphite has a long service life, but due to the stiffness of the graphite “spraying” it is not perfect, and the collector suffers from this;

- Coal brushes for a perforator. Good contact with the work surface of the collector, but a short service life;

- Carleographic brushes as an alternative to the two previous types.

When a replacement is required?

As a rule, the service life of brushes in household perforators is calculated, according to the manufacturer, for 70. 120 hours of work. But it is unlikely that the owner of Poinson will monitor the time of use of the tool. In this regard, it is worth noting the convenience of such a function such as an indicator of wear of the brush for Makita punch. In addition, there is a tool with an automatic shutdown system in case of excessive wear.

But even if you do not have such a top model, there are signs that can be determined by increased wear of the hand. They include:

When a grinding of an electric motor shall

In order to avoid a short circuit and engine breakdown, you should regularly check the condition of the brush holders and brushes. The elasticity of the springs of the brush holders is checked using a lever or spring dynamometer. If the elastic indicator is less than indicated in the one, the brushes will vibrate, and the collector wear out faster.

Indicators of the correct selection and competent installation of brushes are:

- Correspondence of the brushes of the brand of the engine.

- Their free rotation on the axis of the brush holder.

- Full fit of the surface of the parts to the collector.

Similar notes

Bosch Easydrill Bust

Bosch Easydrill 1200 battery.603.9A2.10a) two-speed drills-shurusters with lithium-ion batteries Easydrill 1200 (1 battery) Compactness, lightness, power-wireless execution with a good price ratio and productivity The main properties of the product of the product: the mental system of electrical energy management to ensure good power and the greatest endurance of the memory effect of memory. And self-discharge: unchanged readiness for work thanks to the lithium-ion technology of the malebaric design thanks to lithium-ionic []

Burim ice with a screwdriver Bosch GSR 18 VE-2-Li

Burim ice with a screwdriver Bosch GSR 18 VE-2-Li

When you need a replacement?

Typically, the resource of the work of brushes in household perforators is designed, according to the manufacturer’s assurances, at 70. 120 hours of operation. But it is unlikely that the owner of the perforator will keep records of the time of work with the tool. In this regard, the convenience of such a function as an indicator of brush wear for a punch Makita should be noted. In addition, there is a tool with an automatic shutdown system when you exceed wear.

But even if you do not have such a top model, there are signs by which you can determine the increased wear of the brushes. These include:

Do.It.Yourself repair punch repair

If some details in the tool are damaged, broke or do their function poorly, then they simply need to be changed. If the brushes are and, then when analyzing them are simply replaced with new. A punch cartridge during a slow rotation of the rim, worn an turpentist, failed bearings are also replaced. But there are other malfunctions that you are able to fix. If the winding breaks occurs, then you need to rewind the stator and anchor. You need to look at the lubricant and at times lubricate some parts.

Repair of Bosch 2 26 perforators

Before correcting something in this model, it is necessary to familiarize yourself with the characteristics of the device, the scheme and the principle of the act. The rotary shaft transfers rotation to the shaft of the barrel through the vertical shaft, the bearing of which directs the return movement to the shock piston.

When disassembling the barrel in the shock block, it is necessary to direct increased attention to the fixation of the direct.Toothed of the gear. Before you remove it, you need to pull out 3 pin on which it is fixed in this model.

Replacing brushes: with your own hands or in the service center?

The easiest option is to attribute to specialists to the service center, like Replacing brushes Hitachi perforator, but not the cheapest.

- – quality, if in an authorized SC;

- – Original Brushes, also if the center is authorized;

- – preserving the guarantee for the tool if its term has not expired;

- – As a rule, a complete inspection of all the “vital” nodes of the tool with cleaning and lubrication is carried out.

There are also disadvantages: you have to wait and if it is not warranty work. Pay. In addition, the service is not always close.

There is another way. Personally. How to change the cartridge on a perforator, for example, replacing the Skil punch stews, this is not difficult, but.

Note. “Attempts to independently repair the tool, outside the authorized service center. The unconditional signs include: torn warranty seals, creases on the slotted parts of the fasteners, parts of the case, etc.P.””. Exposure from the instructions for the perforator.

If the tool is under warranty, it is better to take it to the service. You can do everything right, but who will guarantee that nothing will fail in the perforator? And you have to repair for your blood. But, this is just a warning in order not to open the tool until the end of the warranty period, usually in high.Quality models with moderate operation the brush requires replacement after the deadline.

What are the advantages of replacing with your own hands:

- – speed, tool at hand and ready to work;

- – cheaper, you save on the services of masters;

- – You do not expect a breakdown of the tool, its condition is always under control, just look inside;

- – Improving the level of skill, including the service of power tools.

The disadvantages, perhaps, include the following:

- – There are no guarantees of the work performed;

- – there may be a problem with original spare parts;

- – Fear to spoil something, and this is the loss of nerve cells.

A light and fast procedure, in addition, as a rule, brushes for a perforator go along with the tool.

Disassembling the perforator Intercylla P 30 900er

The procedure for disassembling the intercont punch

In recent years, puncturers of intercol have been especially popular. They are reliable in work, Ordinary in the repair. There just get spare parts there.

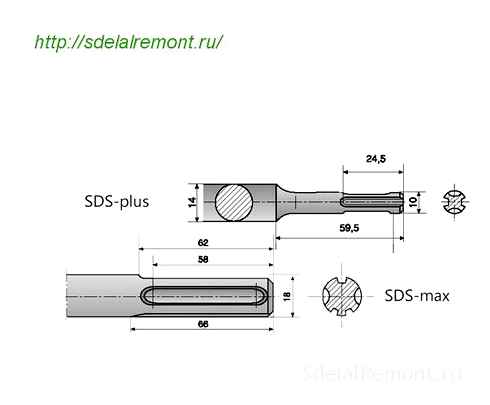

Intercoscol perforators have a wide sample. Tools are conditionally divided into two sectors: perforators component of the SDS-Plus type cartridge, not perforators with a cartridge type SDS-MAX.

Repair of an interforator intercol can be carried out both in service centers, so not without the help of others. In order to carry out repair of intercom punch without the help of others, you need to have the ability of a locksmith not an assignment in electrical engineering in the volume of a secondary school.

Do not remember the observance of safety regulations all the time.

Who has the tool with a corresponding marking sign. Nettle: punch intercosol P-18/450er. Deciphens:

- Bukovka P shows that the instrument belongs to the family of perforators;

- The number 18 shows that with this perforator, the BU is used with a diane of up to 18 mm;

- Number 450 shows the power of the perforator in watts.

The line of the intercont perforators with SDS-Plus by cartridges is represented by 13 models: P-18/450ER, P-20/550ER, P-22/620ER, P-24/700ER, P-24/700ER-2, P-26/ 750EV, P-26/800ER, P-26/800EER-2, P-28/800EV, P-30/900ER, P-30/900er-2, P32/1000E, P-32/1000EV-2.

Perforators Interskol With SDS-MAX cartridges are represented by subsequent models: Interskol P-35/1100E, P-35/1100EV-2, P-40/110EV-2, P-45/1100E, P-50/1200E.

In the field of trade, other models of intercom perforators are considered: Interskol P-600 ER NOT intercol P-710 ER. These models were produced at the beginning of the development of the production of the company Interskol.

Among household users, the most common models are intercont P26/800ER, P30/900ER, P710/ER.

Dismantling Percol perforators models P18, P22, P26, P28, P30, P600, P710

The principle of operation for all perforators is the same.

The rotational moment from the rotor is transmitted to the shaft of the barrel and the working tool fixed on it. At the same time, with the help of a swinging bearing, the “drunk bearing” called the people, a torque, is converted into a reciprocating movement that transfers an impact pulse to a working tool.

All interforators of intercol are collected according to one general scheme and consist of the same blocks.

Conditionally, intercont punch consist of three blocks:

Repair Percol perforators You should start by studying the tool circuit, preparing tools and workplace.

Drum Lesson. Cool Brush Lick For Swing Beats

These blocks of these models have their own design features.

For the convenience of consideration, we divide the presented perforators into groups.

- In the first group, we include the punch punch P-18, P-22, P-24, P-26, P-30.

- In the second group, we consider the disassembly of the piercing of the intercol P-600 and P710.

Design features of a fast-packed cartridge type SDS-Plus

Let’s start with the differences in the design of the fastening node of the fast.Packed cartridge.

The principle of disassembly of fast.Packed cartridges in all perforators is almost the same.

Intercker perforators use a fast-and-packed cartridge type SDS-Plus. To work with an intercont punch, you need to use a tool with a sds-plus shank.

Dismantling of a quick.Linking cartridge

We will consider disassembling a fast-packed cartridge on the example of an intercont P-26/800er.

Having set the punch on the back of the handle, it is necessary to remove the protective sleeve pos.1, remove the puck pos.2 and get the locking ring pos.3.

Then the puck is removed.4 and stop ring pos.5. At the next stage, the pressure sleeve of poses is removed.6.

To free the fixing ball pos.8 must click on a special puck pos.Nine. Remove the ball, take out the conical spring pos.Ten.

The design of the fast-and-packed cartridge of the P-30/900ER intercont contains less details. But the disassembly order remains the same.

Quick-collapsible cartridges for punch p-600ER and P-710ER are almost the same and are disassembled in identical sequence.

Quick-packed punching cartridge Intersol P-30/900ERER

Details of the fast.And.Packed cartridge of the punch P600ER and P710ER are dismantled in the following sequence:

- A special ring post is removed.One;

- The sleeve liberating the posture is released.2;

- A special ring is pressed.3 and gets the ball pos.4;

- The spiral spring spring is extracted.5.

Repair of the perforator P30/900ER Part 2

Continuation of repair punch p30/900er intercol. Recovery punch from scratch. What survived, the case.

Review from analysis of the punch of the P-24/700ER intercont // How to disassemble the punch //

If you liked the reviews, we subscribe to the channel, for me it is important /// The next review will be on the bison.

For all perforators, the intercol to remove the gearbox housing must first remove the modes switch.

Dismantling the mode of switching modes in the perforator of the Interskol P-26

Tilt the perforator to the side, turn the handle of the postm.28 counterclockwise until it stops when the button is pressed.26. Remove the handle from the perforator body.

Never switch the handle of the modes with a operating perforator.

Dismantling block shock mechanism Perforator Interskol P26/800Er

The main number of differences is contained in the design of the shock mechanism.

The shock mechanism consists of several nodes:

The stroke mechanism in the puncher Intercker works according to the same principle. Differences in constructive features.

Dismantling of the strike mechanism of the punch intercol P-26/800ERER

In the perforator, the P-26/800er intercol consists of the following components:

Dismantling the tool receiver

Tool receiver pos.12 is disassembled after removing from it the parts of a fast.Packed cartridge.

At the first stage, four videos of poses are carefully removed.Eleven. Then the receiver is taken out of the case pos.18, in which the needle bearing of poses is inserted.20.

In the needle bearing the barrel poses.36.

Malfunctions and their causes

When analyzing the node, carefully inspect the details for the presence of cracks and chips.

Replacing the power button

Before replacing, mark the wiring and contacts of the button so as not to confuse the connection order.

- To replace the button, just unscrew the contact screw screws. But buttons can meet without cogs. There are holes next to the contacts in which the needle or thin awl is inserted. Pack into the hole, press and pull out the wiring. Do not pull the wire, you can damage the button.

- The wires must be cleaned and tuned.

- Take the old button and buy a similar.

- On the new button, insert the awl into the hole, slightly press and insert the wire. It will automatically light up contacts.

Replacing brushes

Brushes must be periodically checked. With a wear of one by 40%, change both. Also, clean the brush holders.

Replacing and connecting the stator

- Eliminate the stator from the electrician body. Put a new one in his place.

- Screw the fasteners.

- Install air intake.

- Start connecting windings. Connect the two ends of different windings with each other and connect to the nearest brush. Connect the other two connected ends to the start button. The wire from the second brush also connect to the button.

Replacing bearings

There are several bearings in the perforator. They will need a shooter to dismantle them. In some cases, it is necessary to remove the locking ring. If there is no shooter, hang a shaft with a bearing and knocked out a piece of wood. Plant the bearing with the help of an infusion from a polypropylene tube tapping it with a hammer.

Replacement of the cartridge

Cartridges in perforators change very simple. Remove a rubber boot, a locking ring, a plastic boot, a washer, clutching balls, fixing plates, a spring. In different models, the number of rings and plates differs. Put a new set in their place.

Repair of a drunk bearing

Prepare a flat screwdriver, clean rags and lubricant for the gearbox, recommended in the instructions.

- The bearing is kept due to the bracket. Disconnect it with a flat screwdriver.

- Remove the drunk bearing from the aluminum gearbox body.

- Remove the needle bearing.

- Get the gear and spring.

- Remove plastic centering from the spring.

- Replace the worthless spare parts.

- Take the aluminum body of the gearbox and carefully clean it with a dry rag. Clean all spare parts too.

- Lubricate the bearing from the inside. Insert a needle bearing into it and also grease.

- Insert the gear, grease from the inside and insert the spring into it. Put on the centering.

- Lubricate the intermediate shaft and put the switching bracket on it. Install the shaft in a drunk bearing.

Repair of a raster sleeve and shock bolt

To disassemble the ragged sleeve, you need to squeeze the spring, remove the locking ring and gear.

Rodbar’s sleeve assembled and without a gear

Rodbar’s sleeve assembled and without a gear

The shock bolt is repaired by replacing parts or changes completely if it falls apart.

-

There are holes in the raster sleeve on both sides, in which the locking ring is clearly visible. Small a small flat screwdriver and move the ring on both sides.

Replacing the sleeve

The sleeve wears out less often a raster sleeve, but with a frequent overheating of the tool, it also fails. From the aluminum body of the gearbox, remove the sore sleeve and sleeve. Put a new one in its place.

How to change brushes on a perforator

Do not confuse ordinary small sparks that are at work, with partial gliding of sparks in a circle, this is permissible when loading and with a new tool until the brushes are grounded.

The first signs of wear of the brush are a strong spark and an extraneous sound. Stop work immediately!

Timely replacement of coal brushes prevents the failure of more expensive parts of the perforator. The cost of a set of coal brushes is not comparable with the cost of a rotor or stator of any power tool. Do not save on small so as not to lose more. The conclusion is simple: often change coal electric brushes. Remember that if one brush is faulty, the other should change automatically.

The critical length of the coal brushes of the Makita perforator cannot be less than 8 mm.

When replacing, you must carefully look at the anchor, which is the development of the collector.

With a noticeable deepening, the collector must be polished to a smooth state, if this is not done, even the original original brushes are sparkling, which will lead to even more burning out the collector.

After installing new brushes, do not forget to let it work for 10 minutes without load.

The brush is part of the electric motor circuit of the electric motor, the current conductor for the anchor collector. Since the anchor rotates, due to the electromagnetic field, the motionless connection, as in the stature, cannot be. The way out of the situation was realized using pieces of graphite, which glides along the collector plates, thereby applying current to the terrified winding of the anchor. In turn, a magnetic field is created in the winding of the latter. According to the law of magnetism, the opposite poles are attracted, and this creates the movement of the anchor. As shown below.

But we can say that this is the weakest place of collector electric motors, since the brushes are erased in the process, and the collector clogs carbon dust. This leads to a violation of the normal operation of the electric motor.

Drums. Brush Techniques. By Zack Albetta

The very structure of the brush itself is very simple: the contact terminal, the wire from the terminal to the working surface of the brush and the spring, which presses the surface to the collector plate.

We figured out the appointment of the brush, now consider their types. The current brushes are three types. In fact, there are more of them. But in the perforators they are not used. For example, the so.Called “generator” (copper. Graphite, copper. Coal) brushes.

In the perforator there are brushes of such types:

- Graphite. A long service life, but due to the hardness of the graphite “grinding” is not perfect, and the collector suffers from this;

- Coal brushes for a perforator. Good contact with the work surface of the collector, but a short life;

- Coal. Graphite brushes as an alternative to the previous two types.

When you need a replacement?

Typically, the resource of the work of brushes in household perforators is designed, according to the manufacturer’s assurances, at 70. 120 hours of operation. But it is unlikely that the owner of the perforator will keep records of the time of work with the tool. In this regard, the convenience of such a function as an indicator of brush wear for a punch Makita should be noted. In addition, there is a tool with an automatic shutdown system when you exceed wear.

But even if you do not have such a top model, there are signs by which you can determine the increased wear of the brushes. These include:

If something similar is observed. It’s time to look at the condition of the brushes and collector.

If you remove the brushes from the brush holder, you observe wear, both brushes change without fail, even if wear is not uniform. When replacing brushes, it is strongly recommended to clean the collector from graphite dust and soot. The collector can be cleaned with gasoline (preferably for lighters, its quality is higher) or ethyl alcohol. When replacing the brush, you should definitely be wiped to the collector. This will reduce the electric arc (sparking), which will have a beneficial effect on both the collector and the engine power. Lice is carried out with soft sandpaper, fixed on the collector. When the anchor rotates, sandpaper smoothes out the irregularities of new brushes.

Another important nuance when replacing brushes is the degree of hardness, both brushes and collector. If you put soft (carbon) brushes on a hard manifold. It will quickly erase. Therefore, it is important to use branded brushes from the tool manufacturer for replacement.

When replacing, you should also pay attention to the node of the brush holder. It consists of a profile, a clamping device and a contact group. At the same time, pay attention to the condition of the spring of the clamping device, if you suspect in serviceability and reliability, it is better to replace it with a new. Fortunately, it is not expensive. For example, if the spring is weakened, this will lead to an insufficiently tight fit to the collector, which will cause increased sparking. And this, in turn, leads to premature wear of the collector plates. And if she jumps up, he will have time to do things in the electric motor for a good repair of the tool.

By the way, if only one brush sparkles, perhaps the stator has burned down. This is easy to determine, it is important to have a device for measuring resistance. The stator has two windings, on average they have a resistance of 4 Ohm each. If the resistance of both windings is the same, the stator is.

The replacement process itself should not be described, it is easy and for most perforators the design provides for a quick and easy replacement of brushes like the Bosch punch, or any other, as can be seen in the video given at the end of the review. Look for a special window on the case, it is usually closed with a plastic lid.

The procedure for obtaining charcoal from other brushes

The process of manufacturing coal brushes for the rotating hammer Makita

Work begins with the preparatory stage. You must choose the correct transverse section of the harvesting of a carbon rod. Here are the dimensions of the factory coal brushes CB-419A in mm (6x9x12). Selected carbon rods should be larger or the same size as Makita perforators.

If you choose a larger section, they are served with files or sandpaper. But you can use a fairly simple device. A special device called “fungus” is clamped in an electric drill. Almost every master has this device. Used in the process of grinding surfaces. The device is a Velcro circle, to which a grinding circle of the desired diameter is attached.

Read how to pull a broken drill from a perforator cartridge

Try to securely fix the electric drill on a bench or table. The drill can be fixed using clamps, clamps or temporary fastening. Insert the fungus into the pipe, attach a circle of sandpaper No. 100 to it.

After turning on the drill, adjust the speed of the cartridge. It is preferable to start grinding at low speeds. This will allow you to properly control the grinding process.

Replacing brushes on the perforator Kolner 820ns

If yesterday you thought that you once bought a hammer or shock drill, you can use them for several generations without warning, and today the tool does not work, then everything is in order, it should have happened. Any equipment needs to be maintained, otherwise disappointment will occur at the most inappropriate time. One of the reasons for the inoperability of the tool is the wear of its graphite brushes, and today we will tell you how to replace brushes on a perforator, and briefly explain what it is and why they are needed.

The second way, how to dismantle the bearing by heating

Apply the effective laws of physics related to metal heating. After all, it is 100%known that the metal expands at high temperatures, so there is a possibility that the bearing will jump out of its nest on its own, and it will not be necessary to use physical force, sometimes destructive for the entire system.

Instrument for installation and dismantling of bearings

How to repair or replace the brushes of the perforator Makita 2450 and 2470

The fact that the replacement of the punch brush is required is indicated by increased sparking in the area of the rotor collector, the smell of Gary, and the heating of the brush holders. The new or renovated perforator of the spark under the brushes costs evenly, constant length and there is no breakdown of the spark in a circle. To wear the bearings, damage to the insulation of the rotor or stator clearly indicates the spark over the entire circle of the collector. The appearance of this kind of spark indicates the burning of collector plates, failure of the rotor or stator.

Anchor. This is a rotating unit of any asynchronous engine. Given that during operation, the punch experiences significant resistance to the material that he destroyed, the load on the rotor often reach extraordinary values. Sometimes they cause a significant decrease in the speed of the valve rotation, which leads to the immediately output of the engine.

The resistance of the fittings on the perforator from combustion is determined by its design. There are two types of perforations:

A short circuit of the anchor winding is formed by the rods, which, when assembling the rotor, fit into the grooves of its core. In this case, the ends of the rods are connected by a special rotor ring. This design does not have mobile contacts, which positively affects the durability of the assembly.

The disadvantage of the anchor of this design is a limited starting point, which in relation to perforators requires limiting the intensity of use at the initial time after the tool is turned on. Of course, this is impossible to keep in mind, therefore, if you carefully use the punch, the durability of the protein-cell motor will be low.

The problem is solved by installing the electric motors of protein cells for all rotating hammers. The number of poles of the anchor winding in this case is fully consistent with the same stator parameters, and the contacts of each phase are displayed into the external circuit using carleographic br. Replacing the brush. This is a relatively simple process that you can perform (for non.Warranty equipment) yourself. In other cases, you should use the services of specialists. Often the price of this type of service is associated with the need for static and dynamic balancing of the anchor at the drill, which uses special technologies and equipment.

Read what power is a screwdriver for ice discovery

Other mechanical breakdowns and their elimination

In addition to breakdowns associated with the shock mechanism, other mechanical breakdowns may occur in the perforator.

Switch of modes

There are times when the unit switch is out of order. This is mainly due to Flowing dust this node. To fix the switch, you will need to disconnect it from the body (how to do it for cam. Above) and clean from pollution. If you find any breakdowns of the plastic parts of the switch, then it will have to be replaced.

Gear with a slanting tooth

The reason that the device ceased to work normally, namely, stopped drilling and hammering, it can lie in worn teeth on the Rotor shaft.

If this happened, then the teeth will be worn out on an intermediate Skewers of the gear.

This problem occurs when the tool is jammed or a malfunctioning clutch coupling. The breakdown is eliminated by the replacement of the intermediate gear and the engine rotor.

The drill does not hold in the cartridge

The reason that the punch does not hold the drill lies in the breakdown of the cartridge and the wear of the parts included in its composition: