How to check a spark on a chainsaw. Problems with ignition modules (coils) of chain saw

Weak spark on a candle of chainsaw

Our client remains the malfunction of the chainsaws is divided into two main groups: engine failures with its full nodes not systems (ignition, fuel supply system, cylinder-piston group, exhaust system) are not malfunction of other nodes (circuit brake, lubrication system, clutch clutch, tire not etc.).

Engine malfunctions

- The engine will not start;

- Starts, but stalls;

- It works unstable;

- Does not develop power, t.E. It works normally at idle, but stalls under load.

When repairing a chainsaw on its own, you need to act by exclusion. Check in turn that our client has possible to make possible causes of the malfunction, starting with the development of those, the verification of which is not eliminated which takes less time (about the device is not the operation of a two.Stroke engine, see here).

Ignition system. Almost all types of engine malfunctions listed above may be called the ignition system failures. Therefore, when they occur, it makes sense to start searching for a malfunction from the candle. This is all the more justified that the state of the latter can give useful information about the operation of the fuel system. So, when a problem occurs, you need to turn out the candle and inspect it.

The wire is disconnected, and the candle is twisted with a special key.

If the candle is dry, this means that the problem is most likely not in the ignition system, but not admission to the fuel mixture cylinder. You can wrap the candle back and take for the fuel system. If the candle is strongly sprayed with the fuel mixture, then there is its excess. This can happen from the dilution of the carburetor or violation of the launch rules. Ways to eliminate and video repair of a STIHL chainsaw if a spark on a working candle is not. The candle is wiped and dried, the cylinder is drained, the fuel supply is blocked and having worked as a starter. To damage the combustion chamber and remove excess fuel. Then set the candle in place and repeat the launch.

The presence of a large amount of black carrier also indicates malfunctions in the fuel system.

The ratio between oil and gasoline in the mixture may be disturbed, the carburetor is not adjusted or poor.Quality oil is used. The candle is washed in gasoline, cleaned with a needle or an awl from the carbon, clean the electrodes with a small skin and installed in place.

In all these cases, it will not be superfluous to check the gap between the electrodes of the candle. Depending on its brand, it should be in the interval of 0.5-0.65 mm. You need to check the sealing of the candle. With its worn out or damage, the tightness of the combustion chamber may not be ensured, which leads to a decrease in compression in the cylinder and problems in the engine operation.

Even if in the case of checking the candle there is large reasons to believe that the malfunction is in the fuel system, you need to check the candle for the presence of a spark. At least in order to be sure that everything is in order with this. For this:

- Put on the spark plug on the candle;

- Using pliers with insulated handles, apply a thread or a candle nut to the cylinder;

- Pull the header’s handle and watch. There is spark Or it is not.

In the absence of a spark, you just need to replace the candle. If the new candle does not have a spark, you need to check the condition of the high.Voltage wire for the presence of a cliff and contact with the candle.

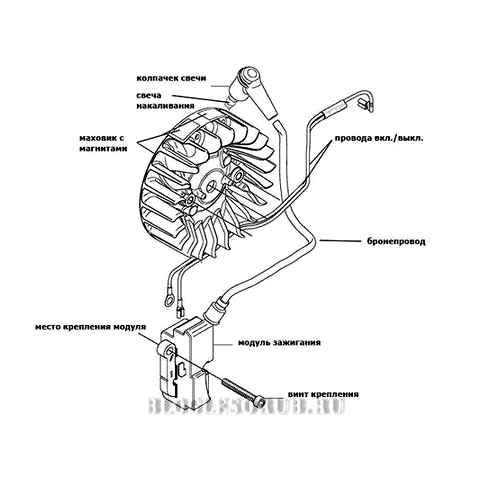

The reason for the lack of a spark can be a faulty ignition module or a disruption of the gap between it and the magneto pipeline of the flywheel. It should be equal to 0.2 mm. The disruption of the gap becomes especially probable if before this was the disassembly of the saw from the filming of the flywheel and the ignition module. The gap is exhibited with a gasket with a thickness of 0.2 mm placed between the boss of the flywheel and the ignition module. Failed ignition module should be replaced.

By checking the ignition system in this way and without finding a malfunction, you can proceed to the fuel mixture supply system.

Fuel supply system. If the candle with a candle was established that the fuel does not enter the cylinder, you need to consider all the possible causes of this. It can be:

- Not the intake of the fuel from the tank due to the clogged hole in its lid (sapuna), while a vacuum is created in the tank that prevents fuel from flowing;

- Pollution of the fuel filter installed in the tank;

- Non.Admission or insufficient receipt fuel mixture from carburetor to cylinder.

To diagnose the first two reasons, it is enough to disconnect the fuel hose from the carburetor and see if the fuel flows from it or not. If it flows with a full stream, the sappan and the filter can not be checked, if it does not flow or flows weakly, we can assume that the cause of the malfunction is found. The sapun is cleaned with a needle. The fuel filter is extracted through the flood hole of the emptied fuel tank, with a wire hook, along with the suction hose, from which the filter is disconnected and cleaned or replaced by a new. Mastery manufacturers recommend changing the fuel filter every three months.

There is no spark in the chainsaw, replacement of the ignition coil/No Spark in the Chainsaw, Ignition Coil Replaceement

In this video, a breakdown of the ignition coil is considered, its replacement and launch chainsaws. And also watch mine.

Insufficient receipt fuel mixture From a carburetor to a cylinder or a violation of the correct ratio between fuel and air mixed in a carburetor, it can occur for several reasons: due to clogging the air filter, the unresolved carburetor, clogging its channels or a mesh-filter.

As a rule, the repair of the chainsaws is not complete without cleaning the air filter, since it is polluted quite quickly. When this happens, the flow of air into the carburetor decreases, the fuel mixture at the exit from it is too enriched, which violates the normal operation of the engine. Removing a dirty filter for cleaning must be carefully so that the dirt from it does not get into the carburetor. The filter should be cleaned or washed in water with some detergent, dried and installed back.

Carburetor’s resolution is eliminated by its adjustment. This is usually done using three screws. Maximum and minimum revolutions and a blank screw. Adjustment should be carried out in strict accordance with the instructions, the non.Compliance of which can lead to engine breakdown. Some saw manufacturers leave only one adjusting screw (idle turnover). To exclude the unwanted intervention of inexperienced users in the carburetor work. An example of adjustment Carburetor of the chainsaw See in the article the work of a chainsaw.

The consequences of filling

The element responsible for ignition of the fuel mixture is the candle. It consists of a case and central electrode. A side electrode is welded to the “skirt” of the details, which has an electrical connection with the “mass” of the car. Due to the presence of a ceramic insulator, the electrodes do not have contact with each other. The high voltage attached to the contact output of the candle leads to a break in the air gap. The spark slides between them.

The main condition for sparking is the lack of an electric bridge between the electrodes. If the candle is wet, then a chain that has low resistance is created. This leads to a sharp failure of the tension due to the leakage to the case.

If a chainsaw is not started after a long rotation of a manual starter, then there is a high probability of a candle bay. The wet candle is wiped with a clean rag and blown with air. It is not recommended to pump it on fire, t.To. This leads to the formation of microcracks on the insulator. After cleaning, the element performance is tested. If there is a spark, then it is installed in place and the engine is being started. In the event that there is no spark on the candle, then it is replaced with a working.

Ignition malfunctions

Most often we think about repair after the chainsaw stopped starting, or visual signs of serious breakdowns appeared.

Signs of ignition malfunction:

- The chainsaw is started, but it works unevenly (troit), often sneezes and shoots;

- The power of the chainsaw fell noticeably;

- With a sharp press on the accelerator, failures are observed in the operation of the engine;

- The chainsaw is poorly started on cold, very troit until it warms up;

- Fuel consumption has increased significantly;

If such flaws appeared in your chainsaw, then it is time to conduct diagnostics, adjustment, and possibly repairing the ignition system.

Determining the localization of a malfunction:

First of all, it is necessary to inspect the candle, if a lot of soot has accumulated on it, then the cause of the malfunction is most likely associated with the work of the carburetor, the piston group or the quality of the fuel. If visually the candle looks good, it does not throw it and it is dry. Make sure there is a spark.

- Remove the candle, put the ignition cable on it;

- Using pliers with isolated handles, press the candle thread to the motor body;

- Sharply pull the starter handle and make sure there is a spark;

If there is no spark, we change the spark plug to a new one and test again. After making sure there is a spark, start the engine. But what to do, even if there is no spark on a good candle? We continue the search:

- Test an electric cable for a cliff and insufficient contact with the spark plug. We check the serviceability of the spring in the cap of the nursing and the presence of contact with the armored vehicle;

To check the serviceability of the wiring, it is best to use the tester.

You can set the right gap with a probe, they are not a deficit and are available for a small fee.

Diagnosis of a malfunction multimeter

It is possible to determine the malfunction of the ignition coil can be determined by the so.Called hardware method. However, for this you must have a multimeter with which diagnostics is carried out.

Step.By.Step diagnosis of ignition by multimeter:

- We set the multimeter to the position in which the arrow is at a mark of 200 Ohms.

- We study the instructions of the chainsaw. We find out the optimal resistance for the coil winding installed on our model (in most modern chainsaws this indicator ranges from 3-5 Ohms.);

- We connect the multimeter to the primary winding of the coil and measure the resistance, if it is normal. Continue testing;

- We connect the multimeter to the secondary winding of the coil, compare the obtained readings with the operation manual;

- We connect the multimeter to the coil hole into which the wires are inserted. If the device gives normal indicators, we come to the conclusion that the coil is serviceable. If the measurement results are far from optimal, you will have to replace the node (coil) with a new one;

Ignition adjustment

As we have already noted, you can adjust the ignition system both in the workshop and at home. To do this, you will need ordinary wrenches, screwdriver and probe 0.4 mm (you can make a probe with your own hands from improvised materials. Ordinary photocopy paper, plastic bottle, etc.P.).

Step.By.Step adjustment of the fuel of the chainsaw:

- Diagnose a malfunction;

- We dismantle the protective cover;

- Remove the module with a nursing and electric cable. We conduct their visual inspection, if necessary, replace with a new one;

- Install the ignition module, but do not tighten the mounting screws to the stop;

We determine a plot with a magnet on the flywheel;

STIHL 028 ignition/ spark fix

You should also check if the flywheel clings to the module counterweight. If this happens, perhaps you have failed a bearing or a backlash has formed on the shaft.

User manual

We offer to get acquainted with the original guide to the Husqvarna 236 chainsaw: your browser does not support frames download the operating guide of the chainsaw Husqvarna 236

This document is necessarily present in the configuration to the original chainsaw “Khuskvarna” 236. Its purpose is to familiarize the owner of the gas tool with the structure of the chainsaw, the principles of working with it, the rules for caring for the tool and a list of typical malfunctions of this model.

The instruction includes the following points:

- Acquaintance with the gasoline saw “Khuskvarna” 236, its device, assembly.

- Equipment.

- Table with technical characteristics of modification 236.

- Security measures.

- Acquaintance with the methods and techniques of sawing a chainsaw Husqvarna.

- Description of the procedure for preparing to launch the saw and start the tools of the tool.

- All about the current period.

- Serving work, adjustment of benzo.Tools, repair work.

- Problems, their causes and methods of elimination.

Safety measures during a chainsaw:

- Use personal protective equipment when working with a chainsaw Husqvarna 236.

- Ensure the absence of people and animals in the zone of sawing work.

- Do not work with a faulty saw (the brake does not work, oil is not supplied, etc. D.).

- Refill a chainsaw far from the working area.

- Do not smoke in the work area, when refueling a saw and during the preparation of the fuel mixture.

- Speaking of a chainsaw in the room is prohibited.

- Follow the rules when refueling.

- To avoid the rebound, it is necessary to cut the whole bus, and not its end.

- Do not carry out repair work when the engine is included and connected in/in the wire.

First launch and running.In

Preparatory actions for the work of the chainsaw:

- Installation of equipment, tension of cutting circuit.

- Cooking fuel from 2t oil for Husqvarna and AI-92 gasoline (50/1).

- Huskvarna chainsaw 236 is seasoned with fuel mixture and chain oil into the corresponding containers.

- Checking the reliability of fasteners.

- The procedure for launching a chainsaw (follow clear instructions in the manual).

- Status check:

- Idling;

- Lubrication supply;

- The operation of the brake.

The beginning of the running.In. The production of 10 hours lasts. Load no more than half of the power of the internal combustion engine. The purpose of the running.In is the grinding of moving elements of the motor, gearbox. The result is an increase in the development resource of the saw.

Maintenance

- Cleaning the chainsaw

- Lubrication of the main nodes of the chain saw.

- Sharpening of the chain.

- Repair of the chainsaw “Khuskvarna”.

- Setting a carburetor, oil pump, etc. D.

The main problems and their elimination

- The fuel tank is empty;

- Water fell into the fuel;

- The quality of the mixture does not meet the requirements;

- There is no spark on the candle;

- The candle was wet, burned, smoked;

- No compression, piston wear;

- The carburetor is clogged or lost from the settings;

- Disconnected or torn to the wire;

- Filters require cleaning;

- The ignition does not answer;

- The start procedure is done incorrectly, repeat it.

How to check ignition timing chainsaw

Basil “Khuskvarna” 236 starts and stalls:

The ignition coil of the chainsaw. We perform the check, replacement, adjustment

Checking the ignition coil is performed in the following ways:

- Measuring the resistance of the coil (for this method, the multimeter device is used), the disadvantage of this method is its relative complexity, because the cold semiconductor elements will not show the coil malfunction, their heating and special conditions for verification are required;

- Spark. This device is inserted between the high.Voltage wire and the candle. Typically, such devices are available only in service centers, in everyday life, due to the high price, are not used.

- With the help of a candle turn. In this way, the presence of a spark is checked, but it does not give an accurate idea of the state of the ignition coil.

You can adjust the ignition coil of the chainsaws as follows:

- After weakening the bolts holding the ignition system, the magnets should be brought to the coil;

- Between the coil and the flywheel, the adjusting plate is clamped, then the bolts are tightened;

- The plate is taken out;

- The flywheel is scrolling with a full turn 2-3 times, controlling so that it does not cling to the coil, after which the chainsaw is assembled.

How to check the ignition on the chainsaw. On the example of the fuss “Friendship”:

How to check the ignition coil by a multimeter. Video

Tips for eliminating faults

Fuel transfusion and filling of the chainsaw candles can be single and random. For example, the “perry” with a cap of the pump (primer): the engine did not start right away, the operator presses his finger on the cap again and again, tries to start, pumps up again.

In this case, the reason is not at all in the carburetor. You need to turn out the candle and blow the combustion chamber, pulling the starter cord several times, as when starting. They wipe the candle, dried on the flame of a gas burner or burner, or use another. Check the spark, put the candle in place. Try to start first without suction.

Chainsaw Won’t Start. No Spark. How to DIAGNOSE. TEST INSTALL an IGNITION COIL

If you do not start after 3-4 jerks, press the pump cap 2-3 times. Try again. That is, after overflow, it is first better not to pump fuel, but to pump it on an increase in. Until the engine starts.

Candles sometimes require their maintenance and care.

- Inside, around the insulator, there should not be a carbon or dirt categorically.

- Contact of the electrode and records from the body of the candle is cleaned with sandpaper “nulevka”. Neatly, without twisting the end of the electrode.

- You need to know the recommended candle clearance indicated in the instructions for each chainsaw model (from 0.5 to 0.65 mm or more).

- For accurate adjustment of the candle clearance, special probes are used. A fan set of plates of different calibrated thicknesses that are folded in the handle, like a folding knife. Sold in auto tools and spare parts.

- When working in winter and store a chainsaw is better at low temperature. When removing from heat to the frost from a sharp temperature difference, condensate can form everywhere, including in the ignition system, which is harmful.

One of the reasons for the lack of a spark in the chainsaw is told in the next video, where they also say how to fix the breakdown:

Modern ignition systems of chainsaws are quite compact and reliable. It is only necessary to protect them from direct moisture, strokes, exposure to extreme temperatures. And then there will be no problems with the lack of a spark during the launch. Also, obviously serviceable 1-2 spare candles will not be superfluous.

Ignition malfunctions

Most often we think about repair after the chainsaw stopped starting, or visual signs of serious breakdowns appeared.

Signs of ignition malfunction:

- The chainsaw is started, but it works unevenly (troit), often sneezes and shoots;

- The power of the chainsaw fell noticeably;

- With a sharp press on the accelerator, failures are observed in the operation of the engine;

- The chainsaw is poorly started on cold, very troit until it warms up;

- Fuel consumption has increased significantly;

If such flaws appeared in your chainsaw, then it is time to conduct diagnostics, adjustment, and possibly repairing the ignition system.

Determining the localization of a malfunction:

First of all, it is necessary to inspect the candle, if a lot of soot has accumulated on it, then the cause of the malfunction is most likely associated with the work of the carburetor, the piston group or the quality of the fuel. If visually the candle looks good, it does not throw it and it is dry. Make sure there is a spark.

- Remove the candle, put the ignition cable on it;

- Using pliers with isolated handles, press the candle thread to the motor body;

- Sharply pull the starter handle and make sure there is a spark;

Spark plug with a nut for a chainsaw

If there is no spark, we change the spark plug to a new one and test again. After making sure there is a spark, start the engine. But what to do, even if there is no spark on a good candle? We continue the search:

- Test an electric cable for a cliff and insufficient contact with the spark plug. We check the serviceability of the spring in the cap of the nursing and the presence of contact with the armored vehicle;

To check the serviceability of the wiring, it is best to use the tester.

You can set the right gap with a probe, they are not a deficit and are available for a small fee.

Diagnosis of a malfunction multimeter

It is possible to determine the malfunction of the ignition coil can be determined by the so.Called hardware method. However, for this you must have a multimeter with which diagnostics is carried out.

Step.By.Step diagnosis of ignition by multimeter:

- We set the multimeter to the position in which the arrow is at a mark of 200 Ohms.

- We study the instructions of the chainsaw. We find out the optimal resistance for the coil winding installed on our model (in most modern chainsaws this indicator ranges from 3-5 Ohms.);

- We connect the multimeter to the primary winding of the coil and measure the resistance, if it is normal. Continue testing;

- We connect the multimeter to the secondary winding of the coil, compare the obtained readings with the operation manual;

- We connect the multimeter to the coil hole into which the wires are inserted. If the device gives normal indicators, we come to the conclusion that the coil is serviceable. If the measurement results are far from optimal, you will have to replace the node (coil) with a new one;

Ignition adjustment

As we have already noted, you can adjust the ignition system both in the workshop and at home. To do this, you will need ordinary wrenches, screwdriver and probe 0.4 mm (you can make a probe with your own hands from improvised materials. Ordinary photocopy paper, plastic bottle, etc.P.).

Step.By.Step adjustment of the fuel of the chainsaw:

- Diagnose a malfunction;

- We dismantle the protective cover;

- Remove the module with a nursing and electric cable. We conduct their visual inspection, if necessary, replace with a new one;

- Install the ignition module, but do not tighten the mounting screws to the stop;

We determine a plot with a magnet on the flywheel;

You should also check if the flywheel clings to the module counterweight. If this happens, perhaps you have failed a bearing or a backlash has formed on the shaft.

Video on the ignition of a chainsaw

Video on the ignition device of the chainsaw. Which components consists of, for which one or another is needed.

HOW-TO Check For Good Spark On A Chainsaw

The next video tells how to replace the ignition on a modern chainsaw. This video tutorial is suitable for almost all chainsaws. Of course there may be nuances, but the general meaning is the same.

Block: 4/4 | Summer characters: 329Source: https: // Benzopilatut.Ru/zazhiganie-benzopily-ustrojstvosxemyneispravnosti/

The main causes of the problem

Search for the causes of a bad chainsaw plant should begin with diagnostic measures

To conduct diagnostics, it is not necessary to understand the device of the tool, since the problems are mainly similar.

Most often, a bad plant is associated with the faulty operation of the following systems:

- Fuel highway. The fuel drive and membrane, acting as a pump, are responsible for the flow of gasoline in the carburetor. If these nodes are faulty, fuel does not enter the desired node, and the saw does not start.

- Ignition system. Candles giving a spark tool have a certain work resource. With frequent operation, the system begins to give a spark with failures.

- Filters. Fuel on the supply drive and airy, located on a carburetor, clogged during operation of the tool with chips and sawdust.

- Breather. If the saw stalls with active work, the sapuna is out of order, that is, the pressure equanist.

- Muffler. Settlement of soot on the internal surfaces of the exhaust system leads to a violation of the outflow of exhaust gases.

- Carburetor. The engine does not start when clogging jackets or channels.

- CPG. TSPG wear. The most serious breakdown. You can make sure that this node is about the service of the engine compression.

To identify and eliminate the cause of the poor launch of the chainsaw, you need to check the work of all of the listed nodes. Often several details breaks at once, so it is impossible to work with the tool without repairing them without their repair.