How To Check The Coil On A Chainsaw With A Multimeter

How to set the ignition on a chainsaw?

It is required to adjust the clearance between the flywheel and the ignition coil on the chainsaw when the tool does not start. Immediately before adjusting, you need to check the condition of the spark plug. To do this, you need to remove the wires from the head and carefully unscrew the part from the socket with a special key. If the candle is NOT wet, and small light spots of oil are visible on its ceramic walls, then you need to proceed to the next stage of checking.

To do this, you need to put a cap with standard wiring on the candle and pull the starter rope sharply several times. If, at the same time, a spark has not occurred, then you should proceed to adjusting the gap between the flywheel and the magneto.

Infringement of the clearance between these parts of the chainsaw may cause careless handling of the tool. In standard form, the distance between magneto and flywheel should not be more than 0.2 mm. It is quite easy to check this value. To do this, you will need to place a special gasket between the elements. If it freely enters the space between the elements, then the gap is set correctly.

Many craftsmen claim that it is possible to correctly adjust the ignition on a chainsaw only using a template. However, every tool owner can afford to buy a disposable product at a fairly high price. Many gardeners use homemade stripe templates cut from a flat plastic juice container.

Further adjustment of the ignition of the chainsaw is performed in the following order:

- First you need to loosen the system fixing bolts;

- After that, a template should be inserted between the standard ignition coil and the built-in flywheel;

- At the end, the fixing adjustment bolts will need to be tightened.

After adjusting the gap, it remains to assemble the chainsaw and continue its operation.

Overview

Overview of how to set coil gap

Chainsaw gap setting overview

Overview of how to replace the reel on a chainsaw

Semyon Starodubtsev, 54 years old, Krasnodar

“I was cleaning the garden in the spring, the chainsaw began to sneeze, and then it completely stalled. I looked at the candle. it was completely wet, it was obviously flooding. I cleaned the carburetor, changed the spark plug. it won’t start. I looked. there are sparks. I disassembled the ignition and found the reason. the high-voltage cable was completely melted. Why this happened. I still don’t understand. I changed the cable with the module. now everything works fine. “

Chainsaw ignition device:

- Magneto: a device that converts mechanical energy into electrical energy, provides a current pulse to the spark plug of the chainsaw;

- Spark plug: designed to ignite the fuel-air mixture through a discharge that occurs between the electrodes;

- Electric cable;

- Engine shutdown button.

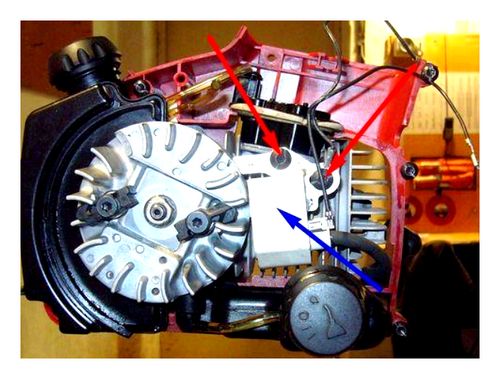

Candles are spark plugs, arc plugs, incandescent plugs and catalytic plugs. Chainsaw devices use spark plugs for 2-stroke engines. A schematic diagram of the ignition of a chainsaw is shown in the image.

Yaroslav Stembitsky, 37 years old, Zhytomyr region

“After the winter the chainsaw didn’t start. For a long time as a starter Dergal. the hand is tired, but It does not start. Then he guessed the candle Vykrut and check for a spark. dull, there is nothing. He took off the protective cover, looked. the gap is normal. Collected everything, and she won’t start again. Day digging, Until I thought of checking the contact on the candle. It turned out that the spring popped out. Why and when. I don’t know. “

Signs of a faulty ignition:

- The chainsaw starts, but it works unevenly (troit), sneezes and shoots often;

- The power of the chainsaw has dropped noticeably;

- With a sharp press on the throttle trigger, dips in the engine are observed;

- The chainsaw does not start well on a cold, strongly troit, Until it warms up;

- Fuel consumption has increased significantly;

If such flaws appear in the work of your chainsaw, then it’s time to diagnose, adjust, and possibly repair the ignition system.

Chainsaw ignition: how to check and adjust

Don’t know how to check the ignition coil on a chainsaw? This procedure is simple. It is rarely necessary to take into account the features of the model, since a system of the same type is installed in all chainsaws. The difference may lie in the type of magneto used to create the structure. The spark is generated by the voltage generated by the magnetic field generated by the crankshaft and flywheel. But what ate something went wrong? How to identify and fix the problem?

Checking the ignition coil of a chainsaw with a multimeter

The ignition coil is one of the most important modules in gasoline power plants. If it turns out to be faulty, then the engine simply does not start. At the same time, computer diagnostics does not always allow you to accurately determine the presence of a malfunction, and in such a situation it is worth checking the ignition coil of the multimeter. Today this method continues to be very effective.

Ignition adjustment

As we have already noted, you can adjust the ignition system both in the workshop and at home. To do this, you need ordinary wrenches, a screwdriver and a 0.4 mm dipstick (you can make a dipstick with your own hands from scrap materials. plain copier paper, a plastic bottle, etc.).

How does the ignition of a chainsaw work and how does it work?

The carburetor engine design does NOT depend on the tool model. Therefore, we can talk about a standard chainsaw ignition system. It consists of the following elements:

- Magneto. It is an alternating current generator. Required to supply the spark plug with electrical current. Outwardly, this part looks like a stationary winding of an inductor and a permanent magnet, which is fixed on the flywheel. The latter rotates simultaneously with the engine crankshaft.

- Spark plug.

- An electrical cable that connects the 2 previous elements.

- Disconnect buttons.

The chainsaw ignition scheme is simple. After starting the tool, a rotating magnetic field is generated by the movement of the flywheel and crankshaft. It creates a moving force in the existing winding, which is transformed into voltage. This potential is enough to create a spark.

Differences in different models of chainsaws may only be in whether a contact or non-contact magneto is used. In the first case, one terminal of the winding goes to the candle, and the second goes first to the shutdown button, and then through it to the ground. In the second case, the device has a capacitor, which, when discharged, forms a current.

Basic malfunctions and their elimination

If the dust starts the first time it fails, there may be several reasons. The most common problem is with the spark plug:

- Worn electrode or damaged ceramic insulator;

- Loose fitting of the removable cap (if any);

- Spark flickering along the ceramic winding, as evidenced by a brown residue on the outer shell;

- Cracks in the candle cap (a saw with such a problem will continue to work, but it may cause pain to the user when touched).

If no problems were found with the spark plug, it is recommended to inspect the wires coming from the coil. They can be cut off or have other mechanical damage. There may be wire breaks inside the insulation, so sometimes these violations cannot be detected during visual inspection.

The cause of the breakdown may lie in the shutdown switches. It is not difficult to check them. To do this, you need to disconnect the wires from the module, and then check the ignition. If a spark appears after shutdown, the switch must be replaced.

Check the ignition coil on the chainsaw

If the preliminary actions did not help in identifying the cause of the chainsaw malfunctions, then it is necessary to check the saw ignition coil. Diagnostics is performed in several stages:

- Measure the resistance of the coil using a multimeter. To do this, you should know the optimal parameters, which are indicated in the operating instructions. However, due to the use of semiconductor elements in the system when trying “ringing” coil, the result will be “Breaking the chain”. This is normal. A positive test result is a sign of a malfunction. T.E.If it was possible to determine the resistance of the coil using a special tool, then it is definitely faulty.

- Check for spark with a special device. This device should be installed in the open circuit located between the spark plug and the high voltage terminal of the saw ignition coil. The readings will be visible on the display. This verification method is more often used in service centers, since the device required for this is expensive and the costs will not be comparable to the benefits rendered.

- Testing the coil with a spark plug, i.e., perform a homemade ignition. To do this, it must be turned out, and then the body must be attached to the cylinder. Now you need to pull the starter and watch the spark. But this method gives only approximate results, since the flywheel turns faster due to the unnatural position of the candle.

If none of THESE methods work, or if you need to perform a check in the field, you can proceed as follows:

- Remove the cap from the candle, insert a nail without a cap into the core at a distance of 6-7 mm from the cylinder. This must be done as carefully as possible so as not to damage the part.

- Carry out the steps to be done when the tool is manufactured. Now you need to look at the presence of a spark and its color. If there is a fault, the spark will be strong and the color is bright blue.

This method can be used as a last resort and only if there are no electronic components, while it is important to follow the rules:

- It is impossible to completely unscrew the plug, as this can lead to a faster rotation of the flywheel, which is NOT the correct mode of engine operation;

- It should be located at a distance that corresponds to the compression model and the dielectric properties of the fuel mixture, therefore this parameter can be viewed in the instructions (the value of 6-7 mm is averaged).

How the ignition of a chainsaw works and how it works, their main malfunctions and elimination

Petrol saws must be equipped with an ignition system. It is necessary for the timely ignition of the fuel mixture in the engine cylinder. Therefore, it is so necessary to install the ignition on a chainsaw and its periodic adjustment, since the tool simply will not start without a spark.

How to set the ignition on a chainsaw

The ignition of the chainsaw should be adjusted periodically. This action involves setting the correct spark plug gap between the coil and flywheel. The parameter depends on the model of the chainsaw. It is indicated in the instruction manual. The average value is 0.2-0.4 mm. Having the correct gap is important to ensure that the spark appears at the right moment, i.e. NOT before and NOT much later than the fuel supply.

Special templates will help to adjust the ignition on the chainsaw, but it is not always advisable to purchase them for one-time use. Therefore, they can be replaced with a homemade one. To make it, you need to cut a strip from a plastic bottle. A part of the container where there is no embossing is also suitable. After that, you can install the ignition, proceeding in the following sequence:

- Unscrew the ignition bolts slightly to loosen.

- The magnets, which are located on the flywheel, lead to the ignition coil.

- Clamp the plastic plate between the flywheel and the spool and then screw the bolts back.

- Remove the strip.

- Scroll the flywheel in full turn several times in a row, while you need to make sure that it does NOT cling anywhere.

If during the diagnostics any coil malfunctions were identified and it did not work out, then the part needs to be replaced, since repair is inappropriate.