How To Choose A Battery For A Screwdriver

Battery interchangeability

A screwdriver battery that has exhausted its resource can be easily replaced. Typically, manufacturers seek to ensure battery compatibility with all popular brands of power tools. We can recommend batteries of the PowerPlant brand, which are distinguished by their low cost and quite sufficient performance.

There is another option: replacing the batteries in the battery pack with new ones. The block with the battery is disassembled and removed, which requires replacement.

How to implement?

The block bodies have a different connection system. Some are glued, others are self-tapping. In the first case, a screwdriver will help. It is necessary to insert it and carry it out with a separating motion along the gluing perimeter. In the case of self-tapping screws, unwind them.

Before soldering, you should prepare:

- Tin;

- Flux;

- Soldering iron.

Some nuances will help you complete the process correctly:

- Get the job done quickly. Heating the battery will damage it.

- Use in the connection of plates from old elements. They have the required cross-section and resistance.

- It is important to clearly observe the connection of plus and minus. The contacts are connected as follows: the minus of the old battery is soldered to the plus of the new one, and the minus of the new one. to the plus of the next one.

- Then, the potential of each of the batteries is equalized. They may differ. For this, 1 cycle is carried out from charging to absolute discharge of the battery. After the battery is charged (during the night), wait for it to cool down. This takes at least a day. The output voltage is measured on all elements. If all the batteries show the same voltage of 1.3 volts, then the operation was successful.

- The next stage: the battery is discharged as much as possible, loading the screwdriver at full power. At the same time, you need to monitor the engine. you must not overheat it. From time to time it is worth giving him a rest, and so on until the battery is completely discharged. The procedure for charging to full and discharging to the maximum is repeated a couple more times.

Battery types and advantages

Their principle of operation is based on the conversion of chemical reaction energy into electrical energy. The device includes a cathode, anode and an electrolyte, the interaction of which creates repetitive processes of accumulated energy formation, which ensures the operation of the power tool. The type of battery depends on what the three components of the battery are made of.

Nickel-cadmium (NiCd) batteries were invented first. They can last for two decades, thanks to the repetitive charge-discharge cycles. This is one of the advantages of the invention. There are others: independence from temperature conditions and the possibility of long-term storage without recharging.

- The tool is difficult to hold for a long time due to its heavy weight.

- The production of such an energy source releases pollutants into the environment.

- It is better to work until the battery is completely discharged so that it does not have a memory effect. In each subsequent use, it will only work up to the discharge limit that occurred in the previous cycle.

The developers sought to minimize the shortcomings of the battery. This is how the decision was found to manufacture nickel-metal-hybrid batteries.

Nimh has positive properties:

- They are oversized due to their reduced weight.

- Toxicity meets environmental requirements.

- The effect of "remembering" at a low level.

- Mechanical damage is not terrible.

- Charge-charge cycles increased by 1.5 times.

- Capacitive characteristics do not cause complaints from consumers.

But even here it was not about Bosch without flaws:

- Work at negative temperatures NiMH battery is contraindicated.

- You cannot completely discharge it.

- Discharges quickly, charges slowly.

- It is not cheap.

Nimh batteries could not compete with nickel-cadmium batteries, since their performance was seriously reduced.

A significant breakthrough in this area was made by Sony, whose specialists in 1991 began producing lithium-ion batteries (Li-Ion). They are considered a new generation of batteries, which are distinguished by such advantages as:

- Long-term retention of a large charge.

- Complete absence of the "memorization" effect.

- The battery can be recharged without waiting for the battery to completely discharge.

- Screwdrivers and drills based on them have significantly lost weight and dimensions. by almost 40%.

Master builders are happy to choose this type of battery for a screwdriver, as this reduces their physical costs during intensive work.

- Lithium-ion batteries can react with an explosion to strong mechanical impact.

- Complete loss of battery power can damage it.

- Operation in sub-zero temperatures results in rapid discharge.

- Such a battery will last much less time than one based on nickel-cadmium.

- The cost of the consumer also did not please.

Everyone chooses a tool with the battery that suits the operating conditions and frequency of use. If the screwdriver will not be used regularly, and it is periodically sent for storage, it is worth giving preference to a nickel-cadmium battery.

Professionals who constantly use a screwdriver with a battery are advised to opt for lithium-ion batteries. They allow you to work without stopping for breaks for a long time. Recharging of such a battery is done quickly, the main thing is not to wait until it is completely discharged.

Lithium-ion batteries are regularly updated and improved by manufacturing companies. So Metabo came up with the idea of cooling the battery during charging, which accelerated its process by a third. And "Makita" has built a chip into the battery that allows you to record the number of charges, residual power, how often it is used, etc.

Battery for a screwdriver. Which to choose?

The master selects the power tool, guided by several parameters. For example, a screwdriver should work reliably and, preferably, without being tied to the mains. Rechargeable batteries provide this condition. But in order for the screwdriver to work for a long time, without interruptions for recharging and give the desired performance, it is worth carefully studying the parameters of the battery for the screwdriver.

The industry produces several types of batteries. They have their pros and cons, the understanding of which will make it possible to make an unmistakable choice.

How to switch to Li-Ion batteries

It’s not difficult if you remember physics textbooks. The rated voltages are summed up when connected in series. If the screwdriver required a voltage of 14.4 volts to power the screwdriver, then four finger batteries, each 3.3 V, will be enough for replacement. Starting the device does not cause a "drawdown" if it is powered by lithium batteries.

The presence of copper strip elements on the contacts greatly facilitates the soldering process. It is better to replace the soldering flux with soldering acid to minimize overheating of the battery. It is recommended to choose a soldering iron with a power of 65 W.

How to make a charger for a Li-Ion or other type of battery with your own wits?

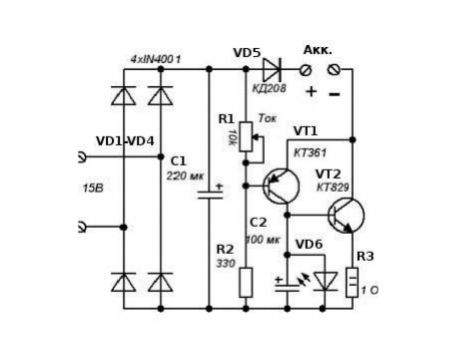

The following scheme will help:

Scheme

Its important element is the transistor VT2, which receives power from the rectifier bridge. The required voltage is supplied to the rectifier bridge connected to this transistor by a step-down transformer. It must have sufficient power to operate without overheating and provide the required current. The voltage above 27 volts should not be output by the transformer, so as not to burn out.

To adjust the charging current, a resistor R1 is used, which monitors the constant current while charging the screwdriver battery. The current should not change during the entire charge. Another resistor R3 monitors the max current limitation. While charging is in progress, the VD6 LED will be on. Gradually, towards the end of charging, it will fade and go out completely with its end.

To charge lithium-ion batteries, it is important to maintain temperature control with accurate voltage values.

To install all the elements indicated in the electronic circuit, a textolite electronic board is used. As diodes, they sometimes use old ones removed from radio equipment, for example, D242 or KD202. When placing elements, make sure that there are no intersections and try to place parts at a distance of 3 to 5 mm. This ensures acceptable conditions for soldering. The transistor is installed on a radiator with sufficient area (20 to 50 cm2). The soldered circuit is placed in the housing. It can be made from plastic by connecting the sides with a glue gun. All necessary radio parts are shown in the table:

Table

Choosing a screwdriver

In this article, we would like to touch on the topic of choosing a screwdriver, take a closer look at their types and, of course, technical characteristics that you should pay attention to when buying this type of tool in order to fully answer a question that has recently arisen more and more often, namely. How to choose a screwdriver for home, cottage or work.

Applications of the screwdriver

- Tightening / unscrewing screws, screws, bolts and other fasteners;

- Drilling holes in wood, metal and brick.

- Stirring building mixtures and paints;

- Drilling holes for winter ice fishing.

There are a huge number of screwdrivers on the market, different in parameters and manufacturers. They are subdivided into professional and household, depending on the nutrient, cartridge size, power, a number of additional functions, delivery set and price. This division, however, is inherent in almost any instrument.

To begin with, let’s analyze the division according to the nutrient. Two types can be distinguished: rechargeable (Li-Ion, Ni-Cd, Ni-Mh) and electric, we will talk more about each of them below.

The most modern and most common, today, type of rechargeable batteries, not only in screwdrivers, but also in many other tools (as well as in portable devices that we all use). Modern Li-Ion batteries are designed for three thousand charge-discharge cycles. The rechargeable battery is lightweight and fast enough to charge; moreover, it has no memory to charge.

The main disadvantages are: battery life, which is three years, the need for constant use to get the most out of it, and significant cost.

They appeared on the market for a long time, they are used in many tools, not only in screwdrivers. Designed for one and a half thousand charge-discharge cycles. The shelf life of such batteries is five years, there is also the possibility of working in the cold, at temperatures up to 15 degrees and it is very important for the average buyer, the lowest price of all types of batteries.

The negative aspects of this type of battery are a rather long, in time, charging process (at best, an hour), the presence of memory for a charge and a significant weight of the battery.

At its core, it is a cross between Li-Ion and Ni-Cd batteries. Found in screwdrivers much less frequently than the types of batteries described above. The number of charge-discharge cycles varies about a thousand. It has practically no memory for a charge, and has the lowest self-discharge among all types of batteries. Of the minuses, one cannot fail to note the weight.

All batteries differ in capacity and battery voltage.

Capacity is measured in amperes per hour (Ah). The higher this indicator, the more the battery is capable of carrying a charge, respectively, more work will be done on a fully charged battery.

Battery voltage is measured in V (Volts). This indicator determines the power that can be obtained from a screwdriver operating on these batteries. Simply put, battery voltage directly affects the maximum possible performance of soft and hard torque, which we will talk about below.

Very similar to drills (don’t miss also the article "How to Choose a Drill"), the main difference is the torque adjustment. Models of this type of screwdriver are represented by only a few manufacturers of household tools. Renowned manufacturers focus on professional drywall screwdrivers, the cartridge of which begins to rotate the bit only after "drowning" it into the material.

Corded screwdrivers are suitable for one-time work around the house or for professional use in repair and construction. Based on the situation, the absence of the need for charging can be considered a plus. Constraints created by the need for an electrical network, low mobility and tangled wires are definitely the main disadvantages of this tool.

Chucks and reducers

Screwdrivers come with either a quick-release three-jaw chuck (clamping range of the tooling from 0.5 to 13 mm), and with a hexagonal tool seat with a 1/4 inch shank. The keyless chuck is more practical and allows you to use any tool of a suitable diameter. Of course, the larger the chuck diameter, the more versatile the screwdriver is.

The hexagonal chuck is convenient for frequent tool changes and when working in hard-to-reach places. For drilling with such a screwdriver, you must use drills with a hex shank. Can be fitted with a conventional chuck with a hex shank.

Rotation from the engine to the chuck is transmitted through a gearbox. The gears inside the gearbox can be made of metal or plastic. Metal gears are most common in powerful professional screwdrivers.

They reflect two parameters measured in Nm (Newtonometer), these are soft and hard torques:

- Soft torque is an indicator of the maximum force of a screwdriver in terms of twisting / unscrewing, the rotational speed in this mode for most screwdrivers varies from 0 to 350 rpm.

- Hard torque, in turn, reflects the maximum force in the drilling mode, in this case, the rotational speed is usually calculated from 0 to 1000 or more rpm.

The more these parameters are, the more powerful, productive and practical the screwdriver is. For example, a screwdriver with a torque of 25 to 30 Nm can easily screw a self-tapping screw up to 70 mm long into a tree. To tighten self-tapping screws from 70 to 100 mm, a torque of 40 Nm is required. Longer self-tapping screws require pre-drilling the hole.

Additional features of some screwdrivers:

- The presence of the hammer mechanism is undoubtedly quite a useful feature, especially when working with socket heads or when drilling holes in brick and stone.

- The presence of an impulse, periodically increased torque, is useful for easier drowning of fasteners into the material, when unscrewing a stuck self-tapping screw or even a drill if the hammer drill fails. Particularly useful when there is no way to lean to press the screwdriver tightly.

- The presence of 3 speeds will allow you to fully replace the mains drill at home, since the rotation speed of the chuck in this mode can be more than 3000 rpm, and the first speed will give a decent torque.

- The presence of backlighting is very important when working in hard-to-reach places or with poor, or even completely absent lighting. The most successful version of the location of the backlight above the battery pack, there are models with a backlight located above the start button, which is less effective in most cases.

Summing up all of the above, I would like to note that it is impossible to advise a universal screwdriver for everyone, because many components of the choice depend on your goals and tasks that you are going to carry out with this tool, but finally, I will still share my opinion about the choice, some examples.

Home / cottage screwdriver

For the most part, the network version will be sufficient, due to the availability, light weight and lack of the need for special mobility. If we consider the rechargeable versions, then it is worth paying attention to Ni-Cd and Ni-Mh, if you do not plan to use them often, this will save you money and get a longer battery life.

In cases where frequent use is planned, requiring the continuity of the working process, there is no doubt that choosing a Li-Ion battery will justify itself 100%. Why don’t I advise taking more modern batteries for rare jobs? Everything is very simple, they are more expensive and are designed for stable use, do not forget that their shelf life is 2 years less, and therefore, there will be much more missed opportunities in this case.

For home needs, the maximum torque of 25-35 Nm will be quite enough, of course you can take a more powerful one, it all depends on your desire and financial capabilities. Battery capacity is not so important for occasional use at home, so 1.5-2 Ah will be just right.

Professional screwdriver

When working in hard-to-reach places, it will be logical to choose a more compact model. The peculiarities of frequent and long-term continuous use in many cases justifiably lead to the purchase of a Li-Ion screwdriver with a maximum torque of 40 Nm and more, depending on the type of materials with which to work in the future.

Li-Ion batteries, in this case, are relevant due to the continuity of the working process, provided by fast charging of batteries, and they are simply lighter, which matters for your hand during prolonged use.

The choice of additional features of the screwdriver directly depends on your needs. Try to clearly define for what needs you will use it, decide on a budget. Last but not least, if you have other tools, like a drill or hammer drill, with rare use, these points will allow you to weed out unnecessary functions and highlight the clearly necessary.

In conclusion, I would like to note that the screwdriver market is full of various variations and choosing exactly what suits you will not be difficult. We hope we were able to help you decide on the choice of a screwdriver. We wish you the maximum return from the instrument and more positive emotions.!

How to choose a screwdriver.

Most of us regularly face the problem of choice in our daily life. Today we will try to figure out how to choose the right screwdriver for carrying out all kinds of work around the house or cottage, as well as in everyday life, which are not regular, most often it is repair work or small restoration work in the country. This article will not be the task of choosing a tool for carrying out work at a professional level, which is of a regular nature; this is the subject of a separate article, which we will talk about in the future. In the meantime, let’s talk about screwdrivers for everyday household work. Let’s start by trying to determine what kind of work the screwdrivers are intended for:. Screwing in self-tapping screws, screws, screws and other fasteners;. Removal of screws, bolts, screws and other fasteners;. Drilling in hard and soft wood;. Drilling in metal and tapping in metal;. Tightening anchors and dowels, as well as their removal, during installation work.

Now we will determine the main parameters by which we will choose a screwdriver, in order to simplify the task as much as possible, we will focus on three main parameters, which, in my opinion, are determining: a) torque b) number of revolutions c) power source

Let me remind you once again that we choose an amateur instrument. The maximum torque is the force that the screwdriver can develop or overcome. On average, tools with a torque of 10-15 nm are produced for home use. For professional tools, the torque can be up to 130 Nm. The scope of the screwdriver is very wide, specialist finishers use it to mount drywall, and furniture assemblers generally cannot imagine their work without it.

The next parameter is the number of revolutions of the engine, maximum revolutions per minute means the maximum speed of rotation of the engine or bits, which is the same thing. For a screwdriver, 400-500 rpm is enough, while for a drill it reaches 1200 rpm and more.

Let’s move on to choosing the third parameter by which we will choose a screwdriver, namely the power source. Most of the screwdrivers made today are of the cordless type, but there are also models that operate on the mains. In the overwhelming majority of cases, preference is given to battery-type screwdrivers, since in this case it is not necessary to look for an outlet, cord, extension cord, and work can be done in places where there is still no electricity at all. There are three types of batteries:. Li-ion (Li-ion). Nickel-metal hydride (Ni-MH). Nickel-cadmium (Ni-Cd)

Choose a battery with a higher capacity if you want the screwdriver to work as long as possible without recharging, as well as a model with a spare battery. While you are working on one battery, the second is being recharged, it is very convenient. The charging time for amateur models of screwdrivers is from 1 hour to 7 hours, a professional tool is usually charged within 1 hour, mainly due to an expensive charger. Nickel-metal hydride batteries are currently the most widespread, and all of Europe is now switching to them. They can withstand up to 500 recharges without loss of capacity, have smaller dimensions, but unfortunately they can withstand high currents and negative temperatures worse. I don’t think that this should stop you, not so often and not so much you and I have to work at subzero temperatures. It is advisable to store these batteries in a charged state. They are distinguished by their high price. They are environmentally friendly and easy to recycle.

Nickel-cadmium batteries (Ni-Cd) contain toxic materials and a very strong allergen-cadmium, they can withstand 1000 recharges without decreasing capacity. It is with such batteries that most screwdriver models are equipped today, despite the toxic component. These rechargeable batteries can be stored in a discharged state. They can work at low temperatures. They are distinguished by their low price and have a strong self-discharge effect. Very toxic and difficult to dispose of.

Another type of batteries, although they occupy a small segment of the market, are lithium-ion batteries, they are more powerful than nickel ones, but they tolerate negative temperatures even worse. These batteries can handle 500-1000 recharges without degrading capacity, but they have no memory effect. They have a weak self-discharge effect, increased battery capacity and a very high price. All nickel batteries have a memory effect, which becomes a real problem for their owners. You must always remember that before you put the battery on charge, it must be completely discharged, otherwise its volume will decrease by the amount of the remaining capacity of the battery that you put on charge. This is not very convenient. Batteries are one of the main components of screwdrivers, and their cost reaches 60-70 percent of the cost of the tool. Consider the most important indicators inherent in all types of batteries:. battery voltage. battery capacity. memory effect. self-discharge effect

The battery is a removable unit that consists of several batteries located inside one housing and interconnected by plates. Each battery has its own voltage, in total they show the voltage at the output of the battery, which can be of capacity: 12 volts, 14.4 volts or 18 volts. The voltage of one nickel-cadmium cell is 1.2 volts, a nickel-metal hydride cell is 1.2 volts, and a lithium-ion cell is 3.6 volts. The operating time and battery power depend on the voltage. Battery capacity depends on the type of power supply installed inside the battery case and affects uptime and cycle times as battery capacity decreases over time.

The memory effect is that you have to discharge and charge the battery to the end every time, otherwise it will quickly lose capacity. Even if the battery is not used, it will lose charge over time. When you choose a power screwdriver for your work, pay attention not only to the battery voltage, take into account the ratio of current to time. ampere / hour. Batteries with the same voltage are not the same, batteries with a higher amp / hour ratio, keep charging longer.

The moment has come when we can discuss the design of this or that model of the screwdriver. A screwdriver consists of several structural units:. An electric motor that produces a rotary motion. The planetary gearbox carries out mechanical transmission from the motor to the spindle on which the chuck is attached. The torque regulator clutch is adjacent to the planetary gearbox. The chuck is needed to connect the bits (bits) to the spindle or torque shaft. Electronic control unit with start button and reverse switch. Rechargeable battery (power supply).

Screwdrivers are produced in various configurations, both as an independent tool and with a set of attachments. If the set of nozzles is complete, then with its help you will be able to tighten screws with a wide variety of head shapes, from straight to four-sided. Now, when choosing, pay attention to the handle of the screwdriver. The handles are pistol grips or center-of-gravity balanced. The handles are balanced in the center of gravity due to their ergonomic parameters are the most common. In this case, the screwdriver is conveniently located in the hand, like any other tool, and the hand is less tired. Pay attention to the gearbox, it provides the rotation of the working shaft of the screwdriver at a certain angular speed. Usually, in cordless screwdrivers, planetary gearboxes with plastic planetary gears are installed, with different gear ratios. They give an output of 500 turns for screwing and 1200 turns for drilling. There are mains-powered screwdrivers, they are usually heavier than battery-powered ones, their access area is limited by the length of the cord, and we agreed that we will not describe them in this article.

If they touch upon all sorts of additional functions of the screwdriver, then their presence or absence depends on the personal preferences of each owner of the screwdriver and his material capabilities. But the key difference between all screwdrivers from another tool is the presence of a torque limiter. At the screwdriver, right behind the chuck, there is an adjusting ring, as soon as the self-tapping screw is screwed in, the chuck stops, while the engine continues to work (you will immediately hear the crackle of the ratchet), this prevents the slot on the screw from breaking off (either the self-tapping screw goes into the depth, or the wear of the bit). The number of steps for adjusting the torque limiter is from 5 to 22. To protect the engine, all modern couplings are equipped with a so-called ratchet or the ability to slip when the load is exceeded. This is a limitation or maximum torque, it is quite enough to tighten the tightest self-tapping screw and protect the engine from overloads. High torque screwdrivers are versatile, they can drill and screw in self-tapping screws. There are 2 types of torque: hard and constant. The hard moment is the power at the moment of starting the engine, at this moment starting currents are triggered that exceed direct currents and are necessary to start the engine. The torque affects the diameter and length of the screw to be screwed in, the drilling diameter of the material and depends on the density of the material. The more power, the thicker in diameter and longer the self-tapping screw can be screwed into a denser material.

The number of spindle speed modes can be different:. one, with a speed of approximately 0-800 rpm of idle. two, switching from about 0-400 rpm to 0-1300 rpm. The first mode is used for loosening and twisting, the second for drilling.

A very useful feature is the ability to adjust the engine speed. However, almost all modern models are able to do this. This feature comes in handy when you are just starting to drill a hole, as the slower the drill rotates, the more accurately you can position the hole and the less likely the drill will jump off.

The clamping chuck according to the method of fixing the attachments can be:. quick-clamping, it allows you to clamp the bit holder or drill without using a clamping wrench. key, to fix the part in such a chuck, a toothed clamping wrench is required.

According to the number of couplings, the chuck can be:. single-sleeve, it is used with the function of blocking the spindle from rotating during the change of nozzles. Double-clutch, it is used in screwdrivers that do not have a spindle lock function. One sleeve holds the chuck, the other is used for clamping.

Another useful characteristic is reverse or reverse. With its help, you can not only free the stuck drill, but also unscrew the tight screw. The reverse in screwdrivers is usually electronic, that is, switching occurs by changing the electrical polarity. To control the reverse, there is a two-position switch next to the start button; it can additionally have the function of blocking it from being pressed when the switch is in the middle position. The property of blocking the rotation of the spindle, if the rotational movement is applied from the side of the chuck, makes it convenient to change the attachments in the chuck, since it is necessary to hold the chuck with only one hand. The blocking depends on the design of the gearbox. For clarity, we present several models of screwdrivers from leading manufacturers.

Choosing a screwdriver: for home and for work

The difference between home and work screwdrivers is power and functionality. Accordingly, their tasks are different.

- With the help of household models, you can change the lock, hang a mirror or assemble furniture. They are designed for tightening bolts, screws and self-tapping screws. Designed for short-term operation.

- Professional screwdrivers, in addition to screwing, are equipped with the function of drilling hard surfaces. They are tough: able to work non-stop for eight hours, five days a week.

Choose screwdrivers for two parameters.

Screwdriver power

The capacity of cordless models depends on the operating voltage of the battery. It ranges from 1.2 to 36 V.

- For simple work, 3-6 V (Volts) is enough.

- For screwing into wooden beams, plastic and drywall, optimal 10-15 V.

- For drilling hard materials. 18 V minimum.

The more power, the more functionality the screwdriver has. Powerful models are heavier than their "brothers".

Tool performance is directly related to the work of torque (force). The more powerful it is, the more tighten the screw or drill the hole deeper.

For homework, screwdrivers of three powers are chosen.

- Stronger: torque 30-40 Nm (Newton meters) and above. Professional models are equipped with torques up to 130 Nm. In addition to screwing, they are equipped with the function of drilling hard surfaces.

- Normal: with a force up to 20 Nm. It is easy for them to unscrew / tighten the bolts and screws on drywall and plastic.

- If only twisted. this is a cordless screwdriver. Its torque is about 10 Newton meters. Suitable for work with small fasteners: repair children’s toys or tighten loosely clamped furniture bolts.

In most screwdrivers, the maximum torque is adjusted using a limiter. a ring with digital divisions located behind the chuck. You will be able to set the optimum torque to tighten the screw. The more graduations the limiter has, the more accurately you can meter the torque element.

Sparky BUR2 10.8li-C HD: 20 torque steps drilling

A separate division is provided to determine the drilling coverage. Therefore, the rotation speed in screwdrivers is indicated in two ranges:

- Unscrew the screws on the low one. It ranges from 400 to 800 rpm.

- Drilled on a high. In professional models, the rotation speed reaches 1300 rpm.

How to choose a screwdriver

Battery type

The battery determines how quickly the instrument is discharged. And if the question became an edge: "How to choose a cordless screwdriver?". it is worth dealing with the types of batteries.

- Li-Ion (lithium-ion). they have the highest power and, in comparison with other batteries, the largest number of charges. up to three thousand times. They are lightweight, fast charging and have no memory effect. To extend the life of the battery, do not fully charge / discharge it, keep it half charged. There is only one drawback:

- Works intermittently in the cold.

Which battery for a screwdriver is better to choose

A cordless screwdriver is a fairly convenient and popular tool. The independence of the power supply makes this device mobile and allows you to work in hard-to-reach places. But despite all the advantages, the rechargeable battery (AKB) is the weak link in a screwdriver. Therefore, when choosing a power tool, you first need to understand what types of batteries exist, what is their difference, the pros and cons of different types of batteries.

Nickel-metal hydride batteries

Nimh batteries have been designed to overcome the disadvantages of nickel-cadmium batteries. The positive characteristics of nickel-melall hydride batteries are as follows:

- Have smaller dimensions and weight;

- Low toxicity;

- The “memory effect” is poorly expressed;

- They have high capacitive characteristics;

- Resistant to mechanical damage;

- The number of charge-discharge cycles has increased (up to 1500).

However, NiMH batteries have their drawbacks:

- It is forbidden to use them at negative ambient temperatures;

- The battery tends to discharge quickly;

- Shorter battery life when compared to nickel-cadmium batteries;

- High price;

- It takes a long time to charge;

- The battery does not “tolerate” deep discharge.

Thus, although NiMH batteries were designed to compete with nickel-cadmium batteries, they are significantly inferior in performance to the latter.

Nickel-cadmium batteries

This type of battery is the most common, although it is over 100 years old. Nicd batteries have good capacity and low cost.

Nickel-cadmium batteries have the following advantages.

- Durability. With proper operation, the battery can last 8-10 years.

- Ability to work at low temperatures. The battery power is practically not reduced, which allows you to use the tool in the winter outdoors.

- High degree of reliability and unpretentiousness to working conditions.

- The battery can withstand a thousand charge-discharge cycles.

- The battery can be stored for a long time in a discharged state.

Since NiCd batteries are not “afraid” of full discharge, you can work with the tool until it stops completely, that is, until the battery is deeply discharged. Only then can you put it on charge without fear that the battery capacity will decrease.

However, nickel-cadmium batteries are not without their drawbacks. Toxicity of internal battery filling causes disposal problems.

Batteries of this type are quite heavy when compared to other types of batteries. In addition, they have a “memory effect”. This phenomenon occurs in a nickel-cadmium battery when it is prevented from fully discharging. If you turn on such a battery for recharging, then it will “remember” this value and during further work it will discharge exactly to this mark. This will lose a significant portion of the battery’s capacity. The figure below clearly demonstrates how the "memory effect" appears.

Varieties of batteries for a screwdriver

There are 3 types of rechargeable batteries on the power tool market:

- (NiCd) nickel-cadmium;

- (NiMH) nickel metal hydride;

- (Li-Ion) lithium-ion.

Replacing batteries with similar ones

On some units, you can see the mounting screws that need to be removed. But on most battery blocks there are no self-tapping screws, since the body is glued together. To open such a block, you need to carefully insert a screwdriver into the gluing place (shown by an arrow in the photo) and press lightly so that the walls of the case are detached. The same actions need to be done around the entire perimeter.

After opening the block, you will see the batteries in it.

- You need to solder quickly, not allowing the battery to heat up, as it may become unusable.

- For connections, you need to use the "native" plates, desoldering them from the old batteries (they have the desired cross-section and resistance).

- It is important to correctly connect the plus and minus of the battery. The elements must be connected in series: the minus of the previous battery must be connected to the plus of the new one, and the minus of the new battery to the plus contact of the next battery.

After connecting all the elements, it is necessary to equalize the potentials on all batteries, since they are different. Carry out one charge-discharge cycle: connect the charger to the battery overnight, then let it cool down for a day and measure the output voltage in turn on all cells. If everything went well, then on all batteries the indicator will be the same. within 1.3 V.

Now the battery needs to be discharged by inserting it into a screwdriver and loading the latter to the maximum. The main thing is not to overheat the engine of the tool. Give him a little rest. Bring the battery to full discharge. Repeat this procedure 2 more times (full charge and full discharge).

Replacement with lithium batteries

Replacing NiCd cells with Li-Ion is also not difficult. It is known from the school course that if the batteries are connected in series, then their voltage ratings will be summed up. For example, your screwdriver runs on a battery with a voltage of 14.4 V, which means that it can be replaced with four 3.3 V finger batteries. This voltage will be enough, because the lithium batteries do not "sag too much" when starting the device.

It is recommended to buy batteries from reputable manufacturers, for example, Sistem A123. The LiFePO4 battery of this company has a capacity of 2400 mAh, sufficient for the normal functioning of the screwdriver. If you buy batteries via the Internet, then they will cost you less. around 900 rubles for 3 pieces.

You will also need to purchase soldering acid instead of alcohol flux. In this case, overheating of the batteries will be minimized. The soldering iron must have a power within 65W.

You can learn more about how batteries are replaced with lithium batteries by looking at this.