How To Choose A File For Sharpening Chainsaw Chains

Benefits of a branded assortment

In any case, the best result can be obtained using a proprietary chain sharpening tool, the capabilities of which are an order of magnitude higher than cheap analogues.

The practice of working with the brand’s tool shows that the products of the leading manufacturers Stihl, Husqvarna, Oregon and a number of others do not differ in quality characteristics.

Storage rules

Files are made from hard but brittle tool steel. Storage and transportation of several copies in one box may affect their performance.

As part of the factory sets, the files are provided with optimal storage conditions. It is recommended to keep a set of several separate instruments in a sectional case like a cartridge belt.

Files with a dirty or oily cut can be restored to function by scrubbing with a stiff brush and rinsing in a solution of dish grease remover, acetone or unleaded gasoline.

File selection based on saw chain parameters

The quality of the final result largely depends on the correct file diameter. When operating a chainsaw complete with an incorrectly sharpened chain, at best, sawing performance will decrease, at worst, the chain will be hopelessly damaged. Also, there is a high probability of damage to the tool as a whole.

In common use for sharpening chains with a step ¼, 0.325″,3/8″ and 0.404″ files with a diameter of 4.0 / 4.8 / 5.2 and 5.5 millimeters are recommended. Cylindrical counterparts are used for selected exclusive saw chain varieties Ø 3.2 mm. The most convenient file size for manual chain sharpening is 200 mm.

Recommendations for the use of the working chain set

The practice of working with one chain is fundamentally wrong. Experienced sawers are advised to keep several copies in the kit and periodically operate them in working mode.

In this case, uniform wear of the tire and the drive sprocket occurs, the service life of these expensive elements will be equal to the total resource of 3 or even 4 saw chains.

Composition of sharpening kits

The selection of the required round file for the diameter is determined by the pitch of the saw chain. A standard chain sharpening kit consists of several parts. In addition to cylindrical and flat files, the list includes several templates and a headset cleaner.

Both files are used to process each cutting link. In particular, the cutting edge of the tooth, the upper and end blades are formed cylindrically.

A flat file is used to cut the depth gauge. As a result of the dressing of the cutting teeth, the productivity of sawing wood of different species increases significantly.

Chainsaw chain sharpening file features of selection and use

Chainsaw operation with blunt edges of the cutting links of the saw chain reduces the efficiency of the tool by almost half. In the simplest version, the problem is solved with a file for sharpening chainsaws, complete with a guide device.

A simple attachment is inferior in performance to sharpening devices with an electric or mechanical drive, but provides a significant cost benefit. The correct sharpening of the chain with the proper quality can be carried out by the operator directly on the working site.

The list of advantages of manual sharpening:

- Compactness and low weight of sharpening kits;

- Autonomy of work, allowing to bring the circuit into working condition at a distance from power supplies;

- Less intensive saw chain life.

Wear-resistant chains with carbide cutting elements are recommended to be sharpened only with special equipment.

Chainsaw chain file

- How to choose a file for sharpening a chainsaw chain

- Chainsaw chain file diameter

- Stihl chainsaw sharpening files Stihl

- Correct sharpening of the chainsaw chain with a file

The most inexpensive way to sharpen a saw is to purchase a chain sharpening file and do it yourself without assistance. However, this scenario implies a lot of nuances. You need to know how to choose a file, what characteristics are worth focusing on, learn the cutting technique, and, in the end, have patience, sharp eyesight and steady hands. The last three factors are indispensable, because without them it is impossible to sharpen the correct file with a file.

Chainsaw chain sharpening files

Chainsaw chain file diameter

The diameter of a chain saw file is very important in the selection process. The wrong file will damage the chain and cause problems during the sawing process. The saw can get stuck inside the tree, break off, and damage expensive tools.

The diameter directly depends on the chain pitch. When sharpening, 4 main sizes of diameters are used, corresponding to their step:

Step ¼ diameter 4.0 mm;

Step 0.325″ 4.8 mm;

Step 3/8″ 5.2 mm;

Step 0.404″ 5.5 mm.

For some types of chains, files with a diameter of 3.2 mm are also used.

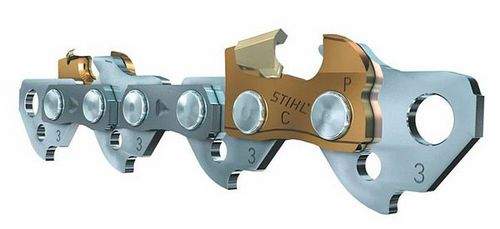

Different diameters of files for sharpening chainsaw chains

How to choose a file for sharpening a chainsaw chain

Most users are wondering: how to choose a file for sharpening a chainsaw chain. The answer to it is complex, because K. It implies a lot of options. But the most correct way to pay attention to the chain pitch. The size (diameter) of the cylindrical file depends on it. But besides it, a second flat one is also required.

Two files are used to sharpen different parts of the same link. If we consider the process in more detail, the saw tooth of the link is sharpened with a cylindrical file, namely the end and upper blades. Use a flat file to cut the depth gauge. It is important that both files can be purchased as a set with a set of templates and a hook for cleaning the saw and bar from the saw set. Some manufacturers of chainsaws and their electric chain analogues even produce similar kits themselves.

Various types of saw chain files

Stihl chainsaw files

There are different files for sharpening Stihl Stihl chainsaws on the market. Despite the external differences, they are all proprietary. Some of them are accessories for sharpening machines and are sold in packs of several pieces. They have no handles, so they are inconvenient to use without a base. Files sold individually can be packaged or sold individually. There are 2 versions of them with and without a sharpening template.

In addition to files, Stihl also produces a range of accessories:

filing gauges;

sharpening mandrels;

templates (holders) of different types;

clamps.

The filing gauges are designed to check the sharpening depth, clean grooves and check corners by hand.

The mandrel is a plate with guides applied on it, indicating the angle of sharpening of the link. By moving in accordance with the guides, it is easier to maintain the correct degree of angle. It is attached with magnets to a metal rail.

The clamp works on the principle of a holder and allows you to sharpen the cutting and limiting teeth of the link in one step.

Stihl chainsaw files

Correct sharpening of the chainsaw chain with a file

It is easiest to start sharpening directly on the bar, but some manufacturers oppose this, citing various arguments, and recommend removing the chain from the device and securing it in a vice. But this is extremely inconvenient, because K. After sharpening each link, you have to dismantle the chain and reinstall it.

If, nevertheless, the sharpening of the chain occurs directly on the saw, the tire can move on the weight under the pressure of the hand with the file, therefore, it is necessary to install a stop for the tire from the opposite edge, for example, a block of wood. It is important to clean the chain from sawdust, grease and debris before sharpening. This will make the job easier.

Sharpening the saw chain correctly with a file

Begin sharpening with the sharpened tooth. It is on it that all the others will be aligned. If the tine is broken, it must be replaced by riveting the chain with a special machine and installing a new element of the appropriate size and type. After the element is selected, start sharpening. The file is moved straight away from you along the semicircular edge of the saw tooth, resting with the template against the edge of the adjacent chain link. In this case, it is necessary to observe the parallelism between the file and the plane of the surface on which the saw or vice is installed, as well as the angle of the guide indicated on the plate template.

Thus, all chain links are processed in turn through one, i.E. Only those that are on one side of it. At the end, they go to the other half of the links and do the same operation, but at the opposite angle, also indicated on the guide in the template. After completion, the file for sharpening the chainsaw chain is set aside, and the chain is swept with a brush, eliminating metal shavings.

File for sharpening chainsaw chains. Sharpeners

A properly sharpened chainsaw chain is one of the keys to successful and productive sawing. A well-sharpened chain does not put unnecessary stress on the saw, easily overcomes the natural resistance of the wood and requires less lubrication, and also lasts longer.

There are two ways to sharpen your chainsaw chain yourself:

- Using a chain sharpener

- With a special file

I have already written about the chain sharpening machines: Chain sharpening machine: is it necessary and how to choose? Today let’s talk about chain files.

How to properly sharpen a chainsaw chain yourself

- The first step is to select the required round file diameter. The above table shows the diameters depending on the chain pitch.

- Before sharpening, be sure to thoroughly clean the chain from sawdust, resin and other unnecessary items. This can be done using a special tool, a soft metal brush or improvised means.

- Sharpening the chain cutting teeth. If you use a round file without accessories, then you need to firmly fix the file and maintain the correct angle (for cross-cutting chains it is 30 degrees, and for longitudinal-10), guide the file back and forth. In this case, it is desirable to press on the file only when moving forward. It is worth starting with the shortest tooth.

- If you have a control device, then after you are sure that the tooth has been sharpened, you need to check it.

- If there is nothing to check the correctness of sharpening, then advice from Stihl will help: no light should be reflected from the cutting edge.

- After sharpening the cutting edges of the teeth, the depth gauges must also be sharpened. It is especially convenient to do this using a control gauge from Calm, but it can also be done manually or with the help of other devices.

Sharpening as a business service what is needed for this

To provide mass sharpening services, that is, to create a business in this direction, a lot of equipment and conditions are required. The following are the main materials, equipment and consumables that will be required to create a mini-workshop:

- Premises, heated, with electricity supply, space for a machine, a chair, shelving (minimum area 2 square meters, mains voltage 220 volts);

- Machine tools with washers for various discs (electric grinder);

- Sharpening discs, including diamond;

- Grinding wheel;

- Mounts for tools such as skates, scissors, chainsaws;

- Touchstone die for manual sharpening;

- Hammers;

- Small tools (hacksaws, screwdrivers, wrenches, etc.);

- Vice;

- Spindle oil;

- Lamps;

- Punch;

- Storage boxes, baskets, furniture.

Clamping holder

This simple tool allows you to sharpen the chain at the correct height and angle. It fits snugly against the tooth and limits the depth of the file. And thanks to the risks involved, you will be able to control the required angle. It is necessary to choose the holder based on the pitch of the chain to be sharpened.

Buy holder with file (3.2 mm; 1/4 PM3)

Stihl FG 2 chain sharpener

When using this tool, the chain must be removed from the chainsaw. This is one of the most accurate tools you can use to sharpen a chain saw for a gasoline saw.

Buy Stihl FG 2 chain sharpener

Popular models of inexpensive sharpening machines

Popular manufacturers of inexpensive chain sharpeners: Dnipro, Einhell, Sadko, Vitals, Forte, Intertool, Eltos, Zenit, Grand, Stern, Temp.

Among the variety of models, each owner of a chainsaw or saw can choose the tool that suits him.

There are many models in this price range that are excellent at sharpening chains for electric and gasoline saws.