How to connect a screwdriver from the network. Making a homemade power supply installed inside the battery housing

How to make a network from a battery screwdriver

A screwdriver with a battery is useful in home economic activity, in construction, as well as when assembling a wide variety of structures, power tools. Its main advantage is the ability to perform work autonomously until the nutrition elements are discharged. For various reasons, it may be necessary to alte out a screwdriver for connecting to a 220 V network. Such a modification is relatively easy to carry out independently in various ways, for this you do not need special tools. Depending on the selected option, making changes will require different temporary and financial costs.

The battery screwdriver in power is worthily competes with network analogues, but only while charging its batteries is at a sufficient level. When the battery sits down, he needs recharging from the network. This factor is the first drawback of this power tool.

The second minus is considered limited number of reloading cycles. Over, the cheaper the battery block (battery), the faster its operational resource is exhausted. The acquisition of a new battery at a price is almost comparable to the purchase of a whole power tool. It also makes no sense to buy a new battery instead of the old, if the battery.Type screwdriver itself is outdated and is rarely used. It will be more practical to adapt the power tool for power from the network 220 V network.

Making changes will make it possible to further operate this tool with a minimum level of financial investments. The created alteration will have all Advantages of network devices:

- The need to perform periodic charging will disappear;

- The power of the power tool (torque) will not fall during operation;

- No need to worry about the proper storage of equipment during long.Term non.Working periods: it is enough to put it in a case in a dry place.

These advantages, as well as small expenses, compensate for the inconvenience related to the presence of the cord.

To make a network from the battery screwdriver, you need a power supply (BP), which can be placed in two ways: in the form of an external supply unit or mounted inside the old battery case.

For the practical implementation of any option, the following will be needed A set of tools and materials:

- Screwdrivers with different tips;

- Screwdrivers with different tips;

- Pliers;

- Kusachki;

- Solder with a set for soldering;

- Insulating tape;

- Wiring for jumpers taken, for example, from a multi.Core cable;

- Multimeter;

- Knife.

Power supply options for power supply

There are several options for converting a screwdriver to work from the mains. The task is to write down the device electric motor using an intermediate source.

We use charging from the laptop

You can make a power supply 12 V for a screwdriver with your own hands without even having technical knowledge. It only follows Find an unnecessary charger from a laptop, which has technical characteristics similar to parameters for feeding screwdriver. The main thing is that the output voltage corresponds to the desired (12-14 volts).

13 Products You Should Hide From Your Parents

To achieve a given goal, you must first disassemble the battery and remove faulty elements from there. Then the such manipulations follow:

- Take a charger from a laptop.

- Cut out the output connector, expose and carry out the end of the ends of the wires.

- Save the cleaned wires to the input wires of the battery.

- Isolate the rations to avoid short circuit.

- We make a hole in the housing so as not to squeeze the wire, and we assemble the structure.

Basic. A power supply from a computer

For the manufacture of such a device, you will need a block from a personal computer of format a. T. Finding it is easy, this is an old model of a supply device, which is easy to buy in any radio component market. It is important to know, that you can use a 300-350 watts with a current in a power circuit 12 in at least 16 A.

It is the block format blocks that correspond to such parameters. The power button is located on the housing of this device, which is very convenient when working. The cooling fan is installed inside and the protection circuit from overloads is mounted.

The procedure for the reconstruction of the block:

- Remove the lid of the case b. P. Inside we will see a fee with many wires going to connectors, as well as a fan.

- The next step is to turn off the protection against turning on. We find a green wire on a square large connector.

- We connect this wire with black from the same connector. You can make a jumper from another piece of wire, or you can just cut it briefly and leave in the case.

Read also: Nest for the Internet cable as called

Then, in the output beam, we find a smaller connector (Molex) and make the following operations with it:

- We leave the black and yellow wires, and cut the other two briefly.

- For the convenience of location of the BP, when working, we solder to the black and yellow wires extension cord.

- The second end of the extension cord is attached to the contacts of the empty battery compartment. You need to do this by soldering, you can make a good twist, while it is necessary to strictly observe the polarity.

- We make a hole in the case so as not to squeeze the wire when assembling. The device is ready.

Power from the charger of the car

Having charging for a car battery, it is quite easy to make a screw for power supply. To make alteration, you just need Combine power terminals output of the charger with power engine power.

If there is a charge for charging with a smooth adjustment of the output voltage, then it can be used as an 18 volt power supply unit for a screwdriver.

Advantages and disadvantages of alteration

Removing the screwdriver into a network model has a number of advantages. Among the main advantages, the following can be distinguished:

- Do not have to periodically recharge the device;

- The power of the tool will not worsen due to a weak battery;

- I will not need to change the batteries.

However, such remakes have their own shortcomings. The main minus is that it is more difficult to use such an instrument in hard.To.Reach places. Will have to buy a special extension cord.

How to redo the battery screwdriver for working from a 220 volt network?

The methods for alteration of the battery screwdriver for work from the network differ in complexity, most often this is necessary connect a screwdriver directly to the charger. Connecting charging from a laptop almost does not require knowledge, to install a computer power supply, you need to be friends with a soldering iron, and for the reconfiguration of the Chinese unit the master must be able to handle measuring devices. Keep in mind that the native power supply unit is usually not intended to connect the screwdriver directly, its power is designed only for charging batteries.

How to connect a screwdriver directly charging from a laptop

This method will require you at least technical knowledge. If there is a need to remake a screwdriver in the network, unnecessary charging from the laptop will be able to help you, as it has similar characteristics and can easily be found in any house. First you need to see what output voltage has a charge. Charging devices for 12-19v are suitable.

It is important to check the voltage and current of the charger

It will be necessary to finalize the battery block, for this you need to disassemble it and get out of the system of batteries.

- Take charging from a laptop.

- Cut off the connector and clean the wires from isolation.

- Take the bare wires and solder them. If there is no such possibility, to wind them with island.

- Make a hole for the wire in the housing and collect the structure.

We use the external power supply from the computer

So, you will need a power supply “AT” format. It is likely that you will find it at home, but you can easily purchase an old working power supply in any radio market. Its cost is unlikely to be great. It is very important to remember that the power supply is suitable, the power of which is 300-350 W, and the current in the chain of 12 V is not lower than 16 A.

AT computer unit is buried with a screwdriver

In this regard, the same power supply unit format, which is located in the building of any stationary computer, is good that it always honestly indicates the power. Such power supplies always have a power button, as well as a fan for cooling, and a system of protection against overload.

- Spin the power of the power supply. Under the case you will see a fan, a fee and many wires that go from the board to the connectors.

- It is required to remove the protection against inclusion. To do this, you need to find a green wire on a large square connector.

- Connect the green wire with any black wire from the same connector. For convenience, you can cut it shorter and leave it inside the case. As an option, you can use a jumper from a small piece of wire.

Next, we need a smaller connector (Molex), with it we need to do the following:

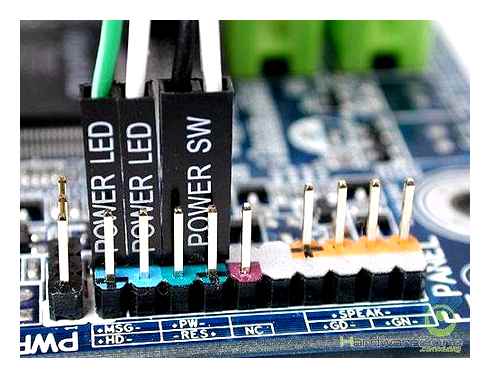

Connector contacts: yellow wire 12 V, red wire: 5 V, black. Earth

- Cut out unnecessary wires, leaving yellow and black.

- Using a piece of wire as an extension cord so that the power supply during operation can be in a convenient place, we solder it to yellow and to black wires

- The other end of the wire is attached to the terminals of an empty battery compartment, as in the previous instructions.

Using a car battery

The principle of such alteration does not differ from the method using charging from the laptop. Thanks to the current trends on compact impulse charges, linear analog appliances with manual control can be bought at the car market at a very attractive price. If the voltage on the battery changes in a smooth way, then it will approach absolutely any screwdriver, and the alteration of such a tool is carried out as follows:

- To connect a screwdriver to a car battery, inexpensive wires with a small section should be used, car wires are suitable for lighting.

- On all sides of each of the wires, cut off the so.Called “crocodiles”, at the free end, clean the wire from isolation by 2-3 cm. Cut the clamps and clean the wires

- Next, attach the wires. To join the wires to the terminals, the part of the one part that is cleaned, and then pass them inside the terminals to get a kind of hook. Crochet wires to connect to terminals

- For a more reliable fixation, tighten all the compounds with plastic clamps or solder them. Do not forget about polarity, usually the “crocodiles” are marked.

- The next step is the assembly, you need to insulate everything. To begin with, it is better to wrap each connection in such a way that the metal parts do not protrude, and after wrapping everything together, the terminals should not come into contact.

Having taken the Chinese power supply unit

So, we are talking about a power supply with an output voltage of 24 V and maximum current 9 A. Screwdrivers are usually designed at 12 V or 18 V, so first you have to lower the voltage to an acceptable level.

To change the output voltage, you need to finalize the feedback circuit. The resistor under position R10 is responsible for the output voltage. Its face value is 2320 Ohm. Instead of the resistor, we set the tuning resistor, this way it will be possible to change the output voltage of the power supply for our needs, the denomination of the tuning resistor 10 kom.

- Get a permanent resistor. It is necessary to drop a permanent resistor

- Before installing the tuning resistor, it is recommended to set its resistance approximately 2300 Ohms. This is done so that the output voltage of the power supply is approximately 24 volts, and the power supply does not go into protection from excessively high or low output voltage.

- Save up the tuning resistor. Save in a fee in a tuning resistor instead of constant

- Turn on the power supply and configure the voltage rotating the tuning screw. After changing the output voltage, check the characteristics of the power supply: the maximum output current and power. At a current of more than 7.6 and the power supply goes into overload and sharply lowers the output voltage. Configure the output voltage and check the characteristics of the block

- Check what will happen at a voltage of 12 V. Configure the output voltage. The maximum output current is more than 9 A, excellent!

Installation of the finished power supply in the body of the old battery

If you managed to purchase a power supply in the market with appropriate indicators, installation and alteration is carried out by several simple steps:

- Dismantle the old battery building, the extraction of the developed elements.

- Install a new power supply so that it is tightly located with the case, if necessary, you can glue, connect the wires of high voltage (exit from the 220 volts outlet).

- Connect low voltage terminals to the power supply of the Gaikovert electric motor, in the absence of contacts, the wire will have to be soldered.

- Assemble the case after alteration and install the block on a screwdriver.

Installation of the finished power supply in the body of the old battery

It must be remembered that compact power supplies are warming in a closed space, so it is necessary to drill several holes from different sides of the body for ventilation.

Why redo?

The battery screwdriver has a lot of advantages over the device of the network type. It can be used even where electricity is not affected, you can tighten the fasteners in hard.To.Reach places, the movements of the master are not limited by the length of the wire or extension cord. In a word, it is this option that is often chosen for homework.

But the battery screwdriver is limited by the time and quality of the installed battery. You can use it until it sits down. Over, if the battery failed and stopped holding the charge or completely charged, then the screwdriver itself will not work. You need to either replace the battery, or redo it into the network version. In some cases, it is impossible to replace the battery. And the new costs almost as much as the new device. Of course, in this case, most people will decide to buy a fresh screwdriver model.

A new battery for a screwdriver sometimes costs as much as a new tool

But, as practice shows, in some cases it is easier and cheaper to redo the battery screwdriver into a 220 in working network. You will give the tool a new life and save money. The only restriction that such an updated screwdriver will appear is the need to include it in the outlet before use. But there is an opportunity not to interrupt the work during the recharge of the battery.

How to redo it with your own hands

Before remaking a screwdriver, it is necessary to clearly determine what power and what voltage is necessary for the tool to work. From this it will be necessary to proceed.

It is important to choose a power supply of not very large sizes and relatively non.Minor, so as not to make work with a screwdriver completely uncomfortable. If the block is planned to be installed directly in the screwdriver itself, it is important to observe the size.

Then the tool body opens. Two halves of the case can be fastened with screws or with glue. When disassembling, a knife can be very useful.

After opening the case, a power supply or wire is inserted inside, the contacts of which must be soldered to the charger. Soldering should be as effective as possible, using special solutions.

The second end of the wire should be intended for recharge from the network. So there should be a fork. It is recommended to make a hole in the case in advance, through which the cable will pass.

F1TP ACK-E10 AC Power Adapter LP-E10 Dummy Battery for Canon T3 T5 T6 T7 1100D 1200D 1300D Cameras

A homemade power supply can be obtained in several ways. In any case, you get a full.Fledged tool that can be done after connecting to the network. It is advisable to pre.Prepare a scheme that will help not be mistaken when creating a block.

Alteration of the Chinese.Made power supply unit

Excellent for creating a power supply for a 12.Volt screwdriver with your own hands, ordinary Chinese power supplies with a output voltage 24 V are suitable with your own hands, and the current strength 9 A. But since the tools use less voltage, it is necessary to reduce it first.

To achieve the goal, you need to replace the initial resistor R10 with a customizable resistor, with which it will be possible to achieve the desired voltage. This is done in several stages:

- A permanent resistor is removed;

- A pre.Prepared adjustable resistor is inserted into its place, on which a resistance of 2300 Ohms will be set;

- So far, the voltage is still 24 V;

- Using the resistor settings, you need to achieve the required voltage at the contacts.

After all manipulations, it must be checked that the output voltage is the desired value (12 V, 14 V, etc.D.), as well as that the current strength exceeds 9 A.

Alteration of purchased blocks

You can also be powered from any other purchased power supplies. The process of alteration in this case will be almost the same, however, in addition to the resistor, you may need to plow additional diodes. Most importantly, to achieve the necessary output parameters. And this can easily be done using a combination from components.

After alteration, it is important to ensure a good air current in a box with a power supply. For this, holes are drilled. Do not allow the device to overheat.

We use charging from the laptop

A great option is the use of charging from the laptop. Such devices usually work with a voltage of 12 to 19 V. This is enough to ensure the quality of the screwdriver work. But do not neglect the output current indicators. The closer it is to the required, the better.

In this case, the alteration of the screwdriver for power from the network is reduced to the elementary piece of wires from the charger to the board in the tool. It is advisable to isolate everything with island or other similar materials. After that, the wire is displayed and the tool can be used.

Computer power supply

You can make a screwdriver from the network using an unnecessary power supply from the computer. There are many varieties of such devices, but almost all of them are suitable for a screwdriver. The necessary wires can be found by color by instilling inquiries on the manufacturer’s website.

Food blocks from computers are durable, advanced protection from overloads and a mass of other advantages. They may not be very convenient because of their dimensions, but a long wire will help to solve this problem.

The procedure for connecting a computer power supply to the screwdriver:

Homemade digital power supply with Arduino

- Disassemble the block;

- Remove protection against inclusion by disconnecting the green wire from the board;

- This wire must be connected to a black connector on the device;

- Separate all wires except yellow and black;

- These two wires are soldered to the extension cable;

- The second end of the cable is directly connected to the screwdriver;

- All open contacts are isolated if possible.

Thus, from the computer device you get a power supply for a screwdriver 14 volts.

Power from the charger of the car

Power blocks converted from charging devices for automobile batteries are still quite common. The principle of alteration is approximately the same as that of the computer power supply, but there are several features.

The main feature is that usually such devices allow you to easily adjust the voltage and current strength. This greatly simplifies the use procedure, and also allows you to apply a method for all screwdrivers.

The use of automobile chargers is reduced to several simple actions:

- It is necessary to prepare special wires with which the power supply and screwdriver will be connected;

- The edges of the wires are cleaned and inserted into the terminals on the instrument (for better retention, you can use the clamps);

- When connecting, it is necessary to observe polarity, which is usually indicated on mounts or the wires themselves;

- Now all compounds are thoroughly strengthened and isolated.

After all these procedures, the user will receive a functional screwdriver that is capable of working from a 220 volt network.

All of these methods are quite effective for creating a network tool from the battery. But do not forget that in this case the mobility of the screwdriver will decrease significantly, which can affect the quality of work. But if the battery is out of order, and the work needs to be continued urgently. It is logical to connect external power sources.