How To Correctly Adjust Carburetor On Patriot Petrol Trimmer

lawn mowers, like all gasoline powered tools for the garden, are not difficult to maintain. It is possible and necessary to repair, configure yourself. For example, do-it-yourself carburetor adjustment of lawn mowers is a matter of five minutes.

Lawn mowing carburetor is a unit in the power system. In it, like any carburetors, there is a process of mixing air and fuel (gasoline) for further supply to the engine cylinders.

In this process, the main thing is the correct proportion of fuel and air, for which they regulate the carburetor.

The main problems and malfunctions of the carburetor.

Strainer There are only two problems with this element:

In order to find out the cause of the breakdown, the fuel filter cover is unscrewed to remove the strainer. If dirt has simply accumulated on it, washing with gasoline or blowing will help.

With visible damage to the strainer, it is imperative to install a new one. There may also be damage on the fuel supply pipe (during repair, check this element).

The carburetor starter in most cases does not function due to blockages. Use rinse with acetone or the same gasoline.

Blowing off carburetor parts with a blockage of compressed air is an acceptable and convenient repair practice.

The throttle body, the bundles of carburetor parts, the intake or exhaust pipe. all of these parts are subject to depressurization. You can probably check it in a primitive way. smear the problem area with soap suds.

The device of the carburetor lawn mowers

The basis of the carburetor of the lawn mowers is an aluminum case. It contains a diffuser (a hole with internal contours). Air is blown through this hole. The oxygen (air) flow rate depends on the cross-section (passage opening) of the diffuser.

The diffuser is equipped with fuel channels. Of these, fuel is drawn in using an air stream.

Outside the carburetor is installed:

- fuel pump;

- jet system;

- fuel / air mixture control system;

The principle of the carburetor lawn mowers

The throttle valve determines the amount of air for supply, and engine power directly depends on this.

Fuel is sucked into the carburetor system by a pump (its membrane). Then it passes through the fitting in the carburetor. Further, the fluid moves through the inlet and outlet valves of the pump. Filtered by mesh. The needle valve moves into the membrane chamber.

Phased operation of the device:

- Air supply to the tube with an air baffle (damper). The partition controls the intensity of the air flow.

- The fuel supply system must be narrowed by a diffuser to increase the flow rate.

- Gasoline through the float chamber and nozzle tube with narrowing. A camera with a float adjusts the temporary volume of gasoline. In the float chamber, the pressure level is neutral, and in the tube with narrowing is already low. Due to the pressure drop, fuel enters through the nozzle.

- The acceleration of the air flow contributes to the transfer of fuel (gasoline) and its atomization. As a result, an air-fuel mixture of the necessary proportion or density is formed.

- The air-fuel mixture enters the engine cylinder through the fuel pipe.

The level of air density in the system depends on the area of the open air damper. The wider the flap is open, the greater the fuel consumption and power.

Simply put, adjusting the carburetor on the lawn mower is creating the optimal fuel mixture due to the correct air supply.

How to adjust a carburetor on a lawn mower

Before adjustment, carefully clean the filters according to the maintenance in the instructions.

Do-it-yourself adjustment of the carburetor for lawn mowing is done by adjusting screws. There are three of them:

Right (L). adjustment of the fuel mixture for low revs.

Need to find the maximum idle speed. To do this, slowly turn the screw (L) to the right and left.

To adjust, turn the screw a quarter of a turn necessarily counterclockwise.

Bottom (T). is responsible for adjusting the engine at idle.

- clockwise. increase;

- counterclockwise. decrease.

For proper adjustment of idling, it is typical:

- steady work of the cold engine;

- not overestimated speed of the hot engine;

- a large headroom for the trimmer head;

- stable operation of the engine when changing position (sharp rise or descent of the knife).

Left (N). adjustment of the mixture at high speeds. (The screw is configured last).

The left-hand screw (N) determines the general adjustment of the maximum speed, engine power, temperature and gas mileage.

Setting the carburetor lawn mowers with the last screw is performed as follows:

- Open the throttle to full, while giving out full throttle. Turn the screw clockwise until the speed drops (in this case, they are oriented by ear).

- Turn the screw as slowly as possible counterclockwise until the engine runs unevenly.

- Then turn back quite a bit, barely hearing a stable, smooth operation.

- For a more visual application of skills, it is more convenient to consider the work of an experienced user:

It is interesting that from the point of view of the author of the video, the setting (its correctness) is determined by the color of the candle, and not just by the speed and stability of the engine.

The correct setting of the carburetor with your own hands in this case is the combustion of the fuel mixture without residue, the color of the candle should be light brown.

Carburetor adjustment of lawn mowers in practice. video

Despite the high productivity, mobility and unpretentiousness in work, modern lawn mowers are difficult to attribute to complex devices. Over time, any mechanism undergoes wear, and therefore parts and assemblies require special attention of the owner. One of the elements of the trimmer is a carburetor, designed to form a fuel mixture and its supply to the combustion chamber. Increased consumption with proper proportions of gasoline and oil or a drop in engine power indicate the need to adjust the carburetor of the gas trimmer.

Trimmer carb setting

The initial step in restoring the correct operation of the fuel system is to clean the air filter.

Screw trimmer carburetor

Experts recommend rinsing it every 10-15 hours in a solution of water with detergents. Direct adjustment of the trimmer carburetor is carried out by three adjusting screws:

- fuel feed adjustment screw (“L”);

- high speed adjustment screw (“H”);

- the screw responsible for the engine idling (“T” or “AT”).

Adjusting the fuel supply at minimum speed

Before starting the carburetor adjustment of the gas trimmer, it is necessary to warm the engine to operating temperature.

Fuel Adjustment Screws

To do this, start the engine and at idle let him work 10-15 minutes. At the first stage, with the trimmer working, slowly tighten the screw “L” until the beginning of intermittent operation or until it dies. Next, unscrew the screw by ¼ turn and check the speed of maximum speed. If the lawn mower easily and quickly reaches high speeds, this will be the most economical mode. In most models on the market, the fuel screw “L” is screwed in clockwise, however, there are trim tabs where the decrease and increase in the mixture flow occurs in the reverse order.

Trimmer idle setting

Location of carburetor adjustment screws

The screw "T" ("AT") serves as a limiter of the reciprocating movement of the fuel damper and when it is twisted, an increase in engine speed occurs, and unscrewing leads to a decrease in the speed of the crankshaft. Professionals advise adjusting the idle screw of the lawn mowers so that the ICE works a little faster at minimum speed, but the head with the fishing line or knife remains motionless. If it is difficult to start the trimmer “cold” after the manipulations, then it is enough to tighten the “T” screw a quarter of a turn and try to start the engine again.

Video: How To Correctly Adjust Carburetor On Patriot Petrol Trimmer

Adjustment of the propeller

After restoring the fuel supply at minimum speed and adjusting the idle speed, it is necessary to check the stability of the mechanism at an increased speed.

Setting at maximum speed

Adjustment of the motor at high speeds is carried out in order to protect against overheating and reduce hand fatigue when pressing the accelerator key. If the internal combustion engine is unstable at maximum speed, then screw “H” must be slowly turned in to ensure smooth and clear operation.

During operation of the lawn mowers, it may be necessary to adjust the fuel feed screw (“L”) for an optimal set of revolutions.

Tips for repairing a carb trimmer

- Regardless of the manufacturer, there is a factory defect of the carburetor parts of the lawn mowers.

Adjusting screw spring

For example, the adjustment method described above may not give positive results with an excessively large number of turns at the spring of the mixture feed screw and, as a result, the impossibility of optimally reducing the level of gasoline supplied. To eliminate this, you can independently shorten the spring yourself or purchase a new one in accordance with the instruction manual.

Many owners of lawn mowers when buying oil follow the recommendations indicated there for the preparation of the fuel mixture.

Oil for gas trimmer

So, often the information on mixing gasoline and oil indicated on the bank differs from the indications in the trimmer’s passport. As a result, black soot can quickly form on the spark plug, which leads to a drop in power and an increase in fuel consumption. Therefore, when preparing the working mixture, the recommendations specified in the instruction manual should be followed. In most cases, the proportion for a run-in ICE is 1:25. It is worth noting that many owners of the tool prefer to cook fuel “by eye”, which will inevitably lead to rapid wear of the piston spit in case of a reduced portion of oil and the formation of soot on the spark plug with an increased amount of lubricant.

The correct tips for setting up the trimmer carburetor correctly performed above will help to avoid not only engine overheating and increased fuel consumption, but also significantly increase the life of other parts and components of the tool. Pay attention to the operation of the lawn mowers in all modes and timely carry out regulated maintenance and repair of the tool.

The increased fuel consumption and the rapid formation of carbon deposits on the lawn mowing candles when using a properly prepared fuel mixture indicate the need for carburetor adjustment. This describes how to set trimmers with carburetors that have one screw for adjusting the fuel supply.

Carb adjustment

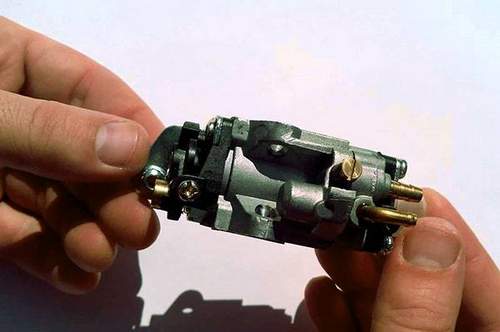

Flush the air filter before adjusting the carburetor. It is recommended to rinse it after every 10 hours of operation. After that, you can begin to adjust. The example photograph shows the carburetor of the gasoline trimmer PRORAB-8406. The numbers indicate the adjusting screws that we will use.

PRORAB-8406 gas trimmer carburetor adjusting screws

Purpose of adjusting screws:

- Fuel mixture adjusting screw.

- Idle adjustment screw.

- The screw limits the maximum speed.

Start the lawn mower and wait until it warms up.

Fuel adjustment

Start slowly turning the fuel mixture adjusting screw until the engine stalls or stalls unless you catch the moment. After that, unscrew the screw a quarter of a turn if the engine is not dead, or half a turn if it is dead. Start the stalled engine. Check, by opening the throttle, how the engine accelerates. Continue to unscrew screw No. 1 a quarter of a turn until the engine starts to confidently gain increased speed when it is progazovaniya. This will be the moment of the most economical stable engine operation. At the PRORAB-8406 gas trimmer, the adjusting screws are turned clockwise, unscrewed. counterclockwise, for some other brands the lawn mowing may be vice versa.

Idle adjustment

We proceed to adjust the low speed. Screw number 2 restricts the return movement of the throttle lever. by wrapping it, we increase idle speed, unscrewing. reduce it. Adjust so that the engine runs confidently at low speeds and even slightly faster (for a better start), but so that the reel with fishing line or knife does not rotate, and before starting to rotate, there is a sufficient margin of speed. If the engine starts poorly, still increase idle speed.

Maximum speed limit

After adjusting the flow of the fuel mixture and low revs, check how the lawn mowing engine will operate at maximum speed. If necessary, limit the maximum speed to the required level using the No. 3 hollow screw. Loosen the locking nut and screw in to decrease the maximum speed or unscrew to increase. After adjusting, tighten the nut. Setting the maximum speed is necessary to protect the trimmer motor from overheating and the ability to use the release key lock to reduce fatigue of the right hand.

In the future, it may be necessary to adjust the trimmer carburetor. For example, if the engine, when operating at full load, starts to pick up poorly, loosen screw No. 1 by another quarter of a turn. If it is difficult to start, increase the idle speed. Weather conditions and the quality of the fuel mixture can affect the operation of lawn mowers. The vibration can even make the adjusting screws rotate.

The spring may interfere

My first attempt to adjust the carburetor of the lawn mowers did not work, as the spring of the fuel mixture adjustment screw prevented it. The factory spring turned out to be too thick in a compressed state and did not give the opportunity to reduce the fuel supply to the required level. I had to pick up another spring and continue adjusting after replacing it.

Spring mixture adjustment screw

In the photo above, the factory spring, below the adjustment screw with a selected spring. I am writing about this, because I’m not sure that this is an isolated case, and someone else may encounter the same situation.

From personal experience

lawn mowing or trimmer

A trimmer is a broader concept than a lawn mow (lawn mow), as it can also be electric. A gas trimmer and a lawn mower are one and the same.

Some authors claim that the trimmer is a weaker tool, in contrast to the more powerful lawn mowers, which can be used to mow shrubs. Personally, I have a tool with a maximum power of 1.7 kW and capable of mowing a small shrub up to 10 mm thick, as stated in the instructions. The user manual is called “Petrol trimmer. ".

Fuel mix ratio

I read somewhere that if in the instruction manual for lawn mowers and on the canister with oil different proportions of the preparation of the fuel mixture are indicated, the proportion indicated in the manual should be used.

This has been the case for a long time. excess oil flowed from the engine to the gas tank and soot was constantly forming on the candle, since the manual indicated the proportion for the engine being run in 1:25, and on the canister. 1:50. After the transition to a proportion of 1:50, the appearance of oil drips stopped. The candle continued to burn, but with less intensity (the carburetor was not yet adjusted).

Until now, some users of gasoline tools determine the proportion of the fuel mixture “by eye”. If during the preparation of the mixture the amount of oil is underestimated, after some time an extraneous sound may appear immediately after the engine starts, gradually disappearing during warming up, and the engine stops with a sharp jerk. Continued operation of the trimmer in this mode will lead to its failure.

Candle cleaning

In the worst times of working with a trimmer with an unregulated carburetor, the engine stopped starting after using each fuel tank. And only after cleaning the candles from soot could we continue to work.

To clean the electrodes, fine sandpaper was used, and to clean the space between the insulator and the case, a thin clerical clip with a bent end was used. First, the electrodes were wiped from a large dirt with rags, then they were cleaned with sandpaper. After that, the candle was lowered into diesel fuel and the moistened soot was scraped off with a paper clip from the surfaces of the insulator, the inside of the housing and between them. Next, the candle was lowered several times in diesel fuel, which was then shaken off with the dirt. Sometimes the cleaning procedure with a paper clip and rinsing were repeated. After that, the candle was wiped dry and was ready for further use.

Incredibly, one tank of the fuel mixture with an unregulated carburetor can be consumed in less than 10 minutes. it was tested in practice when the trimmer was started and operated at high speeds with maximum fuel supply (the adjusting screw was unscrewed much more than normal).

Carburetor trimmer trimmer trimmer: 57 comments

Explainably, concisely and clearly. Thanks!

Thanks, I would also find a Chinese screwdriver and everything is clear to the gas. I give it it’s not gaining momentum. The carburetor is new.

Hello Eugene, can you tell me why the vibration appeared on the gas trimmer when mowing, thank you in advance

Hello Oleg. If your trimmer has been in use for more than a year, then it may need to lubricate the shaft shaft. Pay attention to the condition of the bearings.

He greased the shaft, began to calm a little, and which bearings should I pay attention to?

Oleg, since you did not notice the bearing, as in the video in which the coupling is pressed in, then you do not have it. My trimmer does not have one either (the shaft is freely removed from the top of the rod in the direction from the engine, as in the video, but only after removing the retaining ring from the shaft from the engine side, and the coupling is an extension of the shaft). Four more bearings in the lower gear.

See if there is any side play on the gear shaft to which the drum with fishing line or knife is attached, or if there are any extraneous sounds during rotation. If you use a knife, it can be unbalanced from the uneven distribution of damage on the blades or their deformation, which leads to increased vibration.

Oleg, if you can find and eliminate the cause of increased vibration, write what it was.

I can not help but give a link to the video Dismantling and repair of the lower gear of the lawn mowing, trimmer, where the problem bearing is removed using a loaf of crumb. This is the know-how!

There, in the comments, there is advice when disassembling the lower gearbox, first remove the drive shaft, the gear of which prevents the output of the output shaft bearing. Then, if the seat on the driven shaft is not broken, the problem bearing is removed along with the shaft.

Well, if I find something, unsubscribe

Eugene, sorry for the importunity, another question, the upper gearbox, where does it need to be lubricated?

Oleg, I’ve never taken it apart and I think it’s not worth it until the bearing breaks or the clutch breaks down. There, in front of the cover, there is only a bearing and a coupling (sleeve) with splines, into which the shaft is inserted and which is lubricated with it, it is accessible without dismantling. Next comes the clutch.

Thanks, everything is clear

How to set up a carburetor if not 6th what are the adjustments on it?

Alexander, specify a question.

Hello, I have a Patriot 5555 trimer, the problem is that when you type gas, you can hear it sounding like something, what’s it, tell me what it is?

Hello, Nikolai. Have you tried to change a candle?

I tried everything as well.

Nikolai, I have all the problems with the difficult start of the trimmer and interruptions in the engine’s operation were connected with the ignition system, or rather, with the breakdown of the spark plug insulator and the breakage of the high-voltage wire in the cap. They also write that the ignition coil may fail.

To make sure that your problem is related to ignition or not, check for a spark on a cold engine and after a little warm-up (the candle should be hot, but it should be free to twist). If in both cases the spark is interrupted, then the cause is in the fuel system.

Hello Eugene, I found the reason, the vibration during mowing was due to the breakdown of the coil, there was an uneven ejection of fishing line, but there was still a problem when starting up at idle, the trimmer began to shake a lot, what could be the reason?

Good afternoon, Oleg. Check all engine mounts, including the rod mount to the clutch housing (upper gearbox).

It’s clear, but why the boom mount, it shakes at idle, the clutch does not work at this moment