How to Correctly Cut Tiles Angle Grinders

One of the tools used for cutting ceramic tiles is a grinder. an angle grinder (angle grinder), commonly referred to as an angle grinder.

The price range of various models of the grinder makes it accessible not only to professionals, but also to home craftsmen, therefore when using a angle grinder it is necessary to know not only the capabilities of this power tool, but also the rules for handling it to avoid personal injury.

angle grinder is best used with adjustable speeds

At home, they use a small grinder, designed to work with disks with a diameter of 100-125 mm and performing many operations. The tool can be equipped with a speed controller.

Safety Precautions During Operation Angle Grinder

To avoid injuries during operation of the angle grinder, the following rules must be observed:

- when working, use personal protective equipment. gloves, protective clothing, safety shoes, glasses, a respirator;

- You can work with a grinder only with a steel protective cover mounted on the tool;

- the length of the grinder’s electric cable should be at least 2 m, which reduces the risk of damage to it by the rotating disc during operation;

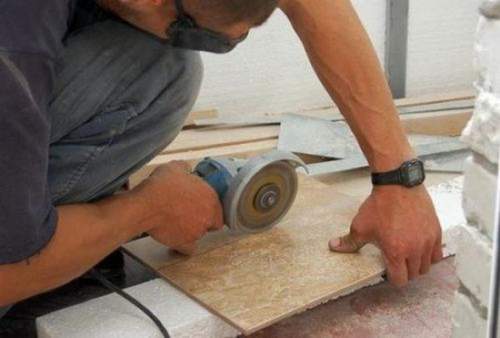

- perform cutting in the direction "away from you", holding the tool with two hands;

- the direction of rotation of the disk should coincide with the direction of translational movement of the angle grinder;

- cut the material by immersing the grinder disc in the cutting line for no more than one third of the radius;

- each material must be processed with an appropriate disk, that is, a ceramic tile cannot be cut with a metal cutting nozzle, and a cutting stone disk is not intended for grinding ceramics (it is possible to grind with a steel “dry cutter”);

- during operation, an angle grinder should be avoided both extremely small and as high as possible revolutions;

- cutting material immersed in water with a grinder in order to reduce the amount of dust generated is prohibited due to the risk of electric shock;

The dust is explosive, so you need to cut or grind the material with an angle grinder in a well-ventilated area.

Ceramic Cutting Discs Angle Grinder

For cutting ceramic tiles, angle grinders use stone or diamond-coated steel wheels (dry cutters). Sukhoreza, in turn, are divided into solid and segmented. The more intense the diamond coating on the dry cutter, the more efficient and more durable the disc will be.

Disks are stone or steel

Stone rims

Stone disks are several times cheaper than dry cutters, but they are worn out during operation and must be replaced with new ones. In addition, they are thicker than dry cutters, so the thickness of the cut line with the stone nozzle is wider and, accordingly, more dust is formed during operation.

In the process of cutting with a stone nozzle, it is necessary to monitor the state of its cutting edge. if a chip or burr has formed on the edge, the disc must be replaced immediately, since such damage is fraught with destruction of the nozzle and causing injury.

Dry cutters

A ceramic cutter can cut ceramic tiles without water cooling, but the duration of one continuous cut should not exceed 1-1.5 minutes, after which the disk is allowed to cool when idling. When buying a dry cutter, a tool with a continuous diamond coating is preferred.

Видео: How to Correctly Cut Tiles Angle Grinders

Stone cutting steel cutters

If during cutting a solid luminous spark-strip appeared on the cutting edge of the dry cutter. the phenomenon of “licking” of the metal, then the temperature at the cut point of the tile in this situation rises sharply, which is fraught with damage to the material. In this case, a rotary dry cutter can make several cuts on any abrasive surface (concrete, plaster), and the disk returns to working condition.

Sukhoreza are divided into 2 types:

Segmented Dryers

This type of nozzles for an angle grinder is a steel disk with evenly spaced slots directed from the cutting edge to the center and dividing the disk into equal segments. A segmented nozzle can cut tiles made of porcelain stoneware and natural stone. The slots between the disk segments are used to increase the life of the nozzle due to improved air cooling of the tool during cutting of hard facing material, but increase the formation of chips.

Continuous dry cutters

With this type of dry cutter, you can not only cut ceramic tiles, but also process the cut edge with a working lateral surface. The absence of tool detonation during operation due to the continuous shape of the disk increases the cutting speed, allows you to cut a fragment evenly and reduces the number of chips.

Direct Ceramic Cutting Angle Grinder

On the front side of the ceramic tile with an alcohol marker, a cutting line is applied. The angle grinder is turned on and given to it a couple of seconds to set the desired speed.

The disk on the grinder must be fixed correctly. using a special key and in accordance with the direction of rotation indicated on it.

The optimal value of the speed of rotation of a disk with a diameter of 100-125 mm when cutting ceramic tiles is 6-8 thousand revolutions per minute. The tile is placed on a flat wooden surface, fixed with a clamp through a sheet of rubber, or you can simply press it against the board with the sole of your foot (shod in safety shoes!).

Ceramic tile cutting can be straight and curly

Exactly along the intended line, an incision is made with a depth of 1-5 mm, depending on the material and the thickness of the tile. From the edge of the material, they begin to cut slowly, then the angle grinder is moved faster. so the cut is smoother. After making an incision, the tile can be broken by placing a pair of nails under it opposite the beginning and end of the incision.

Cutting angle grinder of large diameter holes

The center of the circle is marked with an alcohol marker on ceramics and a through hole with a diameter of 3-4 mm is drilled exactly at the mark with a carbide drill. Then, on both sides of the tile, a circle contour of a given diameter is applied. An angle grinder with a disk makes cuts 1-2 mm deep along the contour of the future hole on both sides of the tile, and then cuts through the inside of the contour and make small pieces of ceramics from it with pliers. The inner surface of the cut along the perimeter of the hole can be treated with rough sandpaper or a file until there are no chips.

Tile cutting angle grinder is performed using a diamond grinding wheel

Grinder cutting in a tile of rectangular holes

Marker and ruler on the front side of the tile mark the contour of the cut and exactly in its corners, without going beyond the boundaries of the contour, drill holes with a diameter of 5-7 mm with a carbide drill. Then, the angle grinder makes through cuts between the holes along the perimeter of the rectangular contour, removes the cut ceramic fragment and finishes the corners and surface of the cut with rough sandpaper or a file.

Cutting tool grinding machine

Tile cutting grinder angle grinder

If an oval-shaped figure is required to be cut out of the ceramic tile, then an angle grinder is cut short along the tangent to the outer contour of the figure in order to cut off small fragments of the ceramic to be removed. At the end of cutting, the surface of the cuts is modified with an abrasive tool until the lines are smooth and there are no chips.

When it is necessary to cut a figured hole in the tile, then the material is cut from the angle grinder exactly along the contour, gradually moving away from it inward and increasing the depth of cut. After cutting the tile through the edges of the hole, modify the rough sandpaper.

Summary

Compliance with safety precautions and the use of the right technology when working with an angle grinder will make this tool not only popular, but also indispensable for home craftsmen.