How to correctly sharpen a chainsaw chain on the lathe

The chainsaw is indispensable for construction or logging work, as well as for household chores. And like any tool with a complex mechanism. it requires constant maintenance. Each part has a different lifespan, and the number of hours after which it’s worth doing a preventive or replacement. The chain is one such component. Because it bears the brunt of wear and tear during operation. With proper maintenance you can keep your machine running for many years and the chain is always sharp. Depending on how often you use it. You need to check it more or less often between jobs. A dull or defective chain is characterized by atypical behavior in the work, which results in you having to spend much more effort on sawing.

To know when it’s time to have your chain serviced and sent for sharpening, look for the following signs:

- You need to use more force when working;

- the saw often jams because the chain is stretched and sags, which prevents the bar from functioning properly;

- the sawing process itself increases in time and output goes down accordingly;

- it is necessary to pay attention to the form of sawdust: a sharpened saw. shavings look the same size and have an even rectangular shape;

- The appearance of smoke during operation;

- fuel consumption increases by 20-30%.

If you ignore these factors, it will eventually lead to a breakdown, not only the chain, but the entire chainsaw. It is necessary to take into account that all components of the saw are exposed to increased load, and this accelerates its wear. the result is costly breakdowns and even personal injury from defective machines.

Sharpening a chain with a file

This type of sharpening can be used directly in the field. It requires a round file, a file holder (clamp), and a vise for clamping the tire.

To sharpen the file you need to perform the following manipulations:

- Clamp the tire in a vise. If you are on a landing and you didn’t bring a vise with you, then you can clamp the tire by resting it against the log.

- Position the file holder on the chain so that it creates a 30° angle.

- Using light forward (backward) movements, sharpen the tooth. With a new file it is enough to make 5 7 movements. If you have already used the file a few times, it takes more effort.

- Once the tooth is sharpened, remove the file and clamp and turn the chain until the next tooth is sharpened. After passing all the right teeth, turn the saw (or change the position of the file) and sharpen the left teeth.

Some file holders have a sharpening template with the sharpening angle already marked on it. This way you don’t have to “guess” the angle. But from experience let’s say it takes a lot of practice until you get a perfectly straight file to sharpen the chain.

How to sharpen a chainsaw chain

While you’re sawing intensively, the chain’s cutting segments get blunt. And it is not only in interaction with wood. For example, if the tire accidentally slips off a log and hits the ground, the heavy abrasion damages the cutting edges. An indication that it is necessary to sharpen the chains is the decline of productivity: the bar does not go deep into the wood anymore, instead of coarse chips fly fine filings. The user has to put more effort into penetrating the saw into the wood. You can sharpen the cutting segments yourself by sharpening them manually. it is not hard, if you know the geometry of the saw blade and the details of sharpening.

It’s important to know! Sawing with a blunt chain is not recommended. This will not only reduce the productivity of the work and require more effort from you, but will also increase fuel consumption, load on the engine and accelerate the wear of the working units of the tool.

The first part of the chain is the cutting tooth. It has two cutting edges. the upper and the lower (the end blade). As it sinks into the wood, it peels it off just like a planer blade does. Second part is the throat stop. It adjusts the thickness of the wood chip. The upper edge of the cutting tooth is beveled at a certain angle in relation to the mowing line of the saw blade movement. These features of the structure dictate the rules for machining each segment. They need their own approach.

Preparing the sawing equipment

Let us remind you that the chain of a chainsaw is sharpened with your own hands without removing it from the tool. Position the saw comfortably enough by securing the saw headset with a clamp on a hard surface. This will save you from having to hold the tool, and will also help you sharpen with more confidence. Don’t forget: You need safety gloves to protect your hands from cuts on the saw’s cutting attachment. A set consisting of a template, a circular file and a flat file is needed to perform the work. If you work with a jig, you can precisely position the file against the tooth and repeat the sawing action on each of the cutting links. Let’s talk about sharpening in order.

A round file is needed for the cutting edges. It is selected by diameter based on the parameters of the chain pitch. To position the sharpening tool correctly, the following instructions must be observed

- In the vertical plane, its working part should be at an angle of 90 in relation to the tooling;

- on a horizontal plane at an angle of 30 or 10, depending on the features and characteristics of the chain.

To meet these requirements precisely and repeat the same position on each link, a special template can be placed on the bar to enable the sharpener to grind quickly and accurately. Every saw model comes with a specific shape, so it is better to use original tools recommended by the manufacturer. Examples of such fixtures are shown in the illustrations below.

After placing the file with the round shank inside the chain link and adjusting it by means of a template, start sharpening in parallel with the edge of the saw blade. Keep the machine horizontal and do not use excessive force. Also, make sure the top of the file does not protrude over the top of the tooth by more than 1/5 of its diameter.

Important! Only move the file away from yourself. Make sure the number of strokes is equal on each tooth. Then after sharpening they will all have the same height. For your convenience, first sharpen the segments of one direction, then change the position of the saw headset and grind the teeth of the other direction.

Finishing the kerf

The process is performed using the same template, but with a different tool. You will need a file with a flat file. The sharpening template has a small window for the kerf. Place the template on the sawing jig so that the limiter comes out of this slot. Then take a file and make a few strokes in the direction from yourself to grind the tip of the segment that protrudes from the window.

How to sharpen a chainsaw chain

Chainsaw chain sharpening is a procedure that gardeners and professional woodcutters regularly encounter. In this article, a master plumber will tell you how to repair damaged saw teeth and quickly return them to their previous working condition.

To understand how to properly sharpen a chain, it is necessary to understand the basic principles of its construction and operation. You can not just sharpen the chain by eye, you need to know the basic characteristics of the chain and its components.

A chainsaw chain is made up of three types of links made from high-alloyed steel:

- Cutting. basic chain elements. A distinction is made between right- and left-handed, which are arranged alternately, their cutting edges are above the plane of the bar. The design of the teeth includes cut depth limiters.

- Power-driven (shanks). serve to transmit torque from the gasoline engine to the chain via the drive sprocket. This feature extends sprocket life and gives the chain a more stable hold on the bar.

- Connecting pieces. connect the chain shanks and cutters.

One of the most important parts of a chain is the cutting tooth that plunges into the wood and removes chips. The tooth depth limiter determines the thickness of the wood chip and limits the depth of penetration into the wood.

Recommended settings relative to the limiter are 0.025″ (0.65 mm) or 0.030″ (0.75 mm), depending on type of chain.

The long life of any chainsaw depends on proper care and use, including that of the chainsaw. Good performance of the latter affects the performance of the device and performance parameters. Failure to sharpen on time may cause some problems with the saw itself. The most common are:

- Curved cuts;

- High loads on the saw, resulting in increased wear of parts of the device, and hence a reduction in the service life of the entire device;

- Increased fuel consumption.

If your saw produces fine, dusty chips and the saw plunges into the cut with too much force, you have a blunt target.

There are other signs of a dull chain:

- The speed of the tool has decreased;

- Uneven and sharp sawdust is produced;

- You have to use a lot of force to cut through the wood;

- The chain is stretched or has become slack.

A chainsaw chain can blunt quickly for the following reasons:

- When working with the saw too often;

- When the operator presses hard on the saw while sawing;

- If the chain is made of poor quality metal or if the steel is not properly heat-treated;

- When sawing raw or resinous wood frequently;

- When sawing hardwood trees such as: oak, birch Karelian, cherry, acacia, elm, ash and others;

- If the chain encounters obstacles in the form of sand or rocks in its path;

- If the chain is not properly sharpened or has insufficient tension during operation.

The design of all chain saws is similar, so the algorithm of actions when removing the chain will be the same:

- First put on protective cotton gloves to avoid cuts from the cutting teeth.

- Remove the protective cover from the chain saw and lay it on a flat surface on its side.

- Unscrew the fastening nuts that hold the housing and the guide bar with a socket spanner of a suitable diameter and remove the upper housing cover.

- Now slide the guide bar all the way down to the sprocket, loosen the chain, and remove the working parts from the fastening bolts.

- Disconnect the chain from the bar.

Sharpening angles and chainsaw tooth configuration

The chain saw chain teeth have the following characteristics:

- Cutting angle for longitudinal cuts should be between 6° and 12°, and between 25° and 30° for cross-cutting cuts predominantly.

- Height of chain profile: professional models have a high profile of 0.762mm, while residential saws have a high profile of 0.625mm.

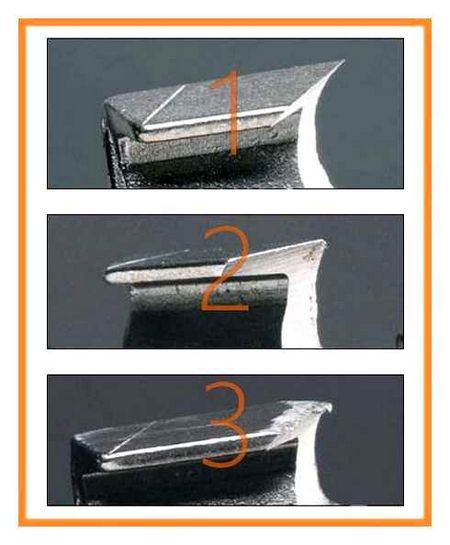

- The shape of the chain teeth can be rounded, half hammered, chiseled, and with carbide plates.

- Drive link thickness. this parameter is the same for most domestic chainsaws, and has a value of 1.27 mm. There are 1.1 mm thick cutters on small power saws which are suitable only for delimbing. Thicker shanks (1.5mm, 1.6mm, 2mm) are typical for semi-professional and professional saws.

- Tooth pitch is the distance between the connecting elements of the chain. Has a value that depends on the power and torque of the tool motor. the higher these parameters, the larger the pitch: 1/4″ (6.35 mm), 0.325″ (8.25 mm), 3/8″ (9.53 mm), 0.404″ (10.26 mm), 3/4″ (19.05 mm).

The pitch is determined by dividing the distance between three rivets by two.

Timely and competent sharpening of the chainsaw chain with your own hands will not only prolong the time of use of the device, but also save efforts and time on wood processing. Signs of a sharp chain is the formation of equal sized sawdust of a regular geometric shape.

- Clean chainsaw chain;

- Inspect chainsaw chain for damage and replace damaged components if necessary;

- Increase chain tension to prevent the cutting teeth from moving during sharpening;

- Secure the chainsaw;

- Find the shortest tooth (for orientation) on both sides;

- Sharpen all cutting teeth on one side, then go to the other side;

- Check the sharpening result: sharpening angle, side edges and top edges;

- Check the height of the depth stop (if necessary, reduce the height with a flat file);

- Remove metal dust;

- Lubricate the chain;

- Adjust the chain tension.

Any chain saw chain sharpening tool, such as any sharpening tool, will work for the right level of sharpness. They are a file, angle grinder, and machine tool.How to sharpen a chainsaw chain with a file

This method is appreciated for the possibility to perform the work in any, even field conditions, simplicity of the procedure and absence of necessity to use expensive tools. To correctly sharpen the chain of a chainsaw with a file the tool has an exclusively round section.

To determine the parameters of the file you need to know the dimensions of the saw itself, in particular you need to determine the pitch of the teeth.

A flat file can be used for the depth stop of the guide tooth.

Depending on the type of chain or tooth and the producer’s recommendation, the position of the file to be filed horizontally against the guide bar is 90° or with a slope of 10°.

While sharpening, take care not to damage other chain components. A file will only mill in a forward direction, so you can’t move it back and forth causing damage to the tooth and the file itself.

In the story. Sharpening the chain of a chainsaw by hand, without removing it from the bar, with a round file

In the story. Chainsaw chain sharpening with a file

Has a small disadvantage of this method. In particular, a great deal of time is needed. But you will not need to buy expensive equipment or special tools.

How to sharpen a chainsaw chain with a chain saw angle grinder

The method of sharpening the saw chain with the angle grinder is the least popular, because of its non-safety. The tooth sharpened in this way can differ considerably from the one sharpened with a file, t.к. While dressing with an angle grinder, it is difficult to control the sharpening angle.

The big disadvantage can be considered a possibility of notching disc angle grinder lug fastening chain link, which will subsequently lead to a break, when carrying out work.

Only a blade specially designed for working with metal is suitable. It must be at least 2.5 mm in diameter. In doing so, it is recommended to choose a disc with rounded edges that has already been used.

Before you start sharpening, you need to insert a wedge of wood between the chain and the bottom of the bar to prevent the headset from moving.

In the story. How to sharpen a chainsaw chain with a grinder

Sharpening a chain saw chain with an electric screwdriver

If you want to sharpen the chain yourself with a drill or an electric screwdriver, you will need a file with a round cross-section. To find it you need to ask for the rounding diameter of the cutting tooth of the chain.Most consumer chain saws can be filed with a 4.8 mm file.

In addition to the sharpening tool, you will need any bearing that is comfortable to hold with your fingers on the outer rim.Prepare the tool:

- The file shank must first be removed with an angle grinder.

- Insert the file into the chuck and lock it in place.

- Use plastic, cork or a small piece of wood to make a bushing of such diameter that it fits snugly into the bearing.

- To fix the free end of the file in the resulting sleeve, inserted into the bearing.

To sharpen the chain with the resulting device proceed as follows. First you need to fix the saw, the best way is to clamp the bar in a vice, preliminarily loosen the chain for its free movement. It is advisable to mark the first tooth with a marker before sharpening. Now it is necessary to place the file in the rounding of the cutting element blade, focusing on the required sharpening angle, which is usually marked with a ridge on the outside of the teeth. Further, holding the self-made device with two hands (one by the handle of a drill or an electric screwdriver, and the second. by the bearing outer casing), it is necessary to switch on the electric tool and, bringing a file to an edge of a tooth, to make sharpening. Sharpen each cutting link in the same way, gradually moving the chain along the bar of the saw.

In the story. Chain sharpening with an electric screwdriver

No problem copes with the task and the machine for sharpening chainsaw chains with their own hands. There are different options for using such a tool. automatic or manual sharpening.Manual sharpening machine

With such a machine, the optimal sharpening angle is set, fixed. Gives the best results without having to remove the chain from the chain saw.

No effort is required for sharpening: you set the angle, depth and turn on the machine. The work is done quickly and with high quality. vary greatly depending on the manufacturer, the range is large.What sharpening on the manual is inferior to the electric machine:

- Manual sharpening with a mechanical chain sharpening machine is a very long and painstaking process.

- Manual sharpening requires some skill, perseverance, care and accuracy.

- The manual method is less accurate, since there is the human factor.

If you own a professional chainsaw that you use on a regular basis, it makes sense to get an electric automatic sharpening machine. It will save you time and extend the life of your tool.

Oregon’s unique PowerSharp system for sharpening amateur chain saws and power saws includes:

- Plastic box with pressure mechanism and compartment for mounting the sharpening stone;

- A bar with an extra hole for later fixing the plastic sharpening box;

- Low Profile Chain;

- Sharpening stone.

PowerSharp kits are available in various sizes. To find the right size, simply remove the chain headset from your saw, and choose a bar that matches the length of the sample.Install the chain on a new bar, and assemble the saw. This headset can be used in place of the “native” one until the first need for sharpening.To sharpen with the sharpener, place the sharpening stone in the box and fasten it to the bar with the latch, then turn on the saw at full power and press down vertically into a hard surface (stump, log, stone, earth), pressing lightly. So the abrasive stone will touch the teeth of the chain and sharpen them in only 3-5 seconds. After removing the sharpener you can start working again.

In the story. Oregon Powersharp automatic chain sharpening system

The consequences of using a not sharpened chain

If the chain saw chain is not sharpened in a timely manner, it becomes increasingly difficult for the user to work and the cut becomes uneven. Such exploitation will lead to such negative consequences as:

- Reduced efficiency. cutting requires more physical effort and therefore the working speed is reduced;

- Higher fuel consumption. fuel overruns may be up to 30 %;

- Reduced life of the saw. the chainrings wear out quickly and the motor overheats, increasing the likelihood of tool failure;

- Risk of injury to the user. unstable saw chain can break.

Preventing rapid blunting of the chain

It is possible to extend the life of the chain without periodic sharpening, if you pay special attention to careful maintenance of the headset. In particular, it is required:

- Use of specialized oil, which must be added when refilling the chainsaw. To choose the proper oil concentration, it is advisable to consult the instructions for the oil itself.

- The entire unused volume must be discarded.

- During use, it is recommended that the clearance between the stop and tooth edge be checked periodically. Ideally, it should be 0.7 mm.

- To minimize the risk of distortion and single-sided abrasion, the bar can be moved 180 degrees from time to time.

- Lubricate the drive sprocket regularly. This should be done before each use of the saw. You can choose any oil that is diluted with petrol and added to the fuel tank. But the M8 brand offers the best performance.

- Watch the tensioning values. The chain must run straight down the bar grooves.

Chainsaw sharpening school.Your saw will cut faster after this video

Basic mistakes when sharpening a chainsaw

If the saw does not work satisfactorily after sharpening, it is likely that sharpening errors were made:

- Incorrect sharpening angle: more or less than required. To avoid such a mistake, it is necessary to use a special template.

- The front angle of the teeth is tilted forward or backward. This could be due to improper sharpening of the file. It is advisable to use a different type of sharpening, or try to maintain the same amount of pressure while sharpening by hand, and select the correct file diameter.

- The chain teeth are not the same length. To avoid this, mark an approximate tooth before you start sharpening, and “match” the rest of the cutting elements to it.

- The height of the depth guide of the cutting links is too low or too high. In the first case, it is necessary to refine the limiter, using the Kalibr. In the second case, sharpen the cutting links or replace the chain.

Increase the service life by alternating between manual sharpening and a sharpening machine. The latter allows the grinding angles to be aligned as accurately as possible on the machine. The depth of sharpening should not be too deep.

Safety precautions should be observed to ensure that wood of all sizes is sawn with maximum efficiency and minimum risk to personnel:

- Before assembling a chain tool and installing the headset, it is advisable to familiarize yourself with the rules of use. This is because each tool has its own specific characteristics.

- Work with the saw should be performed with gloves and safety glasses.

- For work, it is recommended to choose close-fitting clothes made of natural dense materials and the most reliable shoes.

- To cut wood with a chainsaw, you need to stand in a stable and safe position, and the material itself should be positioned as stably as possible. A toothed stop on the log ensures stability.

- While working the saw needs to be held with both hands and the cutting process needs to be constantly monitored.

Modern chain saws are used in domestic and industrial settings. It is important to maintain the productivity and efficiency of the tool, which is directly related to the condition of the sharpened chain head.

What is sharpening angle and why is it important??

Angle of sharpening is determined by the relative positioning of the blades. Its value influences the cutting performance of the chain saw. The horizontal cutting edge is responsible for plunging the blade into the wood and shaping the cut. The end face blade cuts the wood fibers laterally. Extensive laboratories at the cutting assembly plant work to determine the optimum cutting angle.

It is established by experience that high sawing characteristics are demonstrated by chains with an angle of the upper cutting up to 60 degrees. Side cutter blade is sharpened at an angle of up to 85 degrees. With the highest possible angles the tools are better suited for crosscutting logs. About 10 degrees to be sharpened for the longitudinal cut.

Important: Blade geometry only matters if the depth stop is set correctly. If this element is not sharpened properly, the chainsaw will vibrate while working and come out of your hands. Finish the stop by a template.

How to sharpen a chainsaw chain

Sharpening a chainsaw chain is a procedure that gardeners and professional woodcutters regularly encounter. In this article, the master plumber will tell you how to restore the damaged teeth of the saw headset, and quickly return it to its previous working condition.

To understand how to properly sharpen a chain, it is necessary to understand the basic principles of chain design and operation. You can’t just sharpen a chain by eye, you need to know the basic characteristics of the chain and its components.

A chainsaw chain consists of three types of links made of high-alloyed steel:

- Cutters are essential chain elements. A distinction is made between right-hand and left-hand cutting teeth, which are arranged alternately, with their cutting edges above the plane of the bar. Tooth design includes depth of cut limiters.

- The drive links (shanks) are used to transmit torque from the gasoline engine to the chain through the drive sprocket. This feature extends sprocket life and gives the chain a more stable hold on the bar.

- Links. connects the chain shanks and cutters.

One of the main elements of the chain is the cutting tooth, which cuts into the wood and removes chips. The tooth depth limiter determines the thickness of the wood chip and limits the depth of penetration into the wood.

Depending on the type of chain the recommended settings in relation to the shank are 0.025″ (0.65 mm) or 0.030″ (0.75 mm).

The long service life of any chainsaw depends on proper care and use, including the chainsaw. Good performance of the latter affects the performance of the device and performance parameters. Untimely sharpening can cause some problems with the saw itself. The most common are:

- Curved cuts;

- High chainsaw loads which increase wear and tear and therefore shorten the life of the saw as a whole;

- Increased fuel consumption.

If the cut produces fine dusty chips and the saw plunges into the cut with great force, the target is blunt.

There are other signs of a dull chain:

- The speed of the tool is reduced;

- Uneven and sharp sawdust is formed;

- High forces are required to cut through the wood;

- The chain stretched or began to sag.

A chainsaw chain can quickly become blunt for the following reasons:

- If you work with a chain too often;

- When the operator presses hard on the saw while sawing;

- If the chain is made of low-quality metal, or if the steel has undergone an improper heat treatment;

- If you frequently saw raw or resinous wood;

- When sawing hardwood trees such as oak, birch, cherry, acacia, elm, ash and others;

- If the chain is blocked by sand or stones;

- If the chain is not properly sharpened or has insufficient tension when working.

The design of all chain saws is similar, so the algorithm for removing the chain will be the same:

- Wear protective cotton gloves first, to avoid getting cut by the cutters.

- Remove the protective cover from the chain saw and lay it on its side on a flat surface.

- With a socket wrench of the required diameter, unscrew the fixing nuts that hold the housing and the busbar, remove the upper cover of the housing.

- Now slide the bar all the way down to the sprocket, loosen the chain, and remove the working elements from the fastening bolts.

- Disconnect the chain from the bar.

Sharpening angles and chainsaw tooth configuration

The chainsaw chainrings have the following characteristics:

- Sharpening angle for longitudinal sawing should be between 6° and 12°, and between 25° and 30° when a cross-cutting cut predominates.

- Chain profile height: professional models have a high profile of 0.762 mm, while residential saws have a high profile of 0.625 mm.

- Shape of chain teeth can be rounded, semi-hammered, chiseled and with carbide plates.

- Thickness of the drive links. this parameter is the same for most household chainsaws, and has a value of 1.27 mm. There are 1.1 mm thick edges on small saws that are suitable only for delimbing. thicker shank (1.5 mm, 1.6 mm, 2 mm) for semi-professional and professional saws.

- Tooth pitch is the distance between the connecting elements of the chain. Has a value that depends on the power and torque of the engine of the tool. the higher these parameters, the greater the pitch: 1/4″ (6.35 mm), 0.325″ (8.25 mm), 3/8″ (9.53 mm), 0.404″ (10.26 mm), 3/4″ (19.05 mm).

The pitch is determined by dividing the distance between three rivets by two.

Timely and competent sharpening of chain for a chainsaw with your own hands will not only prolong the time of use of the device, but also save efforts and time on processing wood. Signs of a sharp chain saw are the formation of equal-sized sawdust of a regular geometric shape.

- Clean the chainsaw chain;

- Check the chainsaw chain for damage and replace damaged components if necessary;

- Increase chain tension to prevent the cutting teeth from moving during sharpening;

- Fix the chain saw;

- Find the shortest tooth (for orientation) on both sides;

- Sharpen all the cutting teeth on one side, and then move on to the other side;

- Check the sharpening result: sharpening angle, side edges and top edges;

- Check the height of the depth stop (if necessary, reduce the height with a flat file);

- Remove any metal dust;

- lubricate the chain;

- Adjust the tension of the chain.

Any chain saw chain sharpening tool, such as a chain sharpening tool, will work for the sharpness of the teeth. These include a file, angle grinder, and machine.How to sharpen a chainsaw chain with a file

Appreciate this method for the ability to perform work in any, even in the field, the simplicity of the procedure and the lack of need for expensive tools. To correctly sharpen the chain of a chainsaw with a file only a tool with a circular cross-section can help.

To determine the parameters of the file it is necessary to know the dimensions of the saw itself, in particular it is required to determine the pitch of the teeth.

A flat file can be used for sharpening the depth guide of the sawtooth.

Depending on the type of chain or tooth and the producer’s recommendation, the position of the file to be sawed horizontally against the guide bar is 90° or with a 10° slope.

While sharpening, take care not to damage other chain components. The file will only mill in a forward direction, so it is not allowed to move it back and forth causing damage to the tooth and the file itself.

In the story. Hand saw chain sharpening without taking it off the guide bar, using a circular file

In the story. Sharpening a chainsaw chain with a file

This method has a few disadvantages. Time-consuming sharpening in particular. But you will not need to buy expensive equipment or special tools.

How to sharpen a chainsaw chain with an angle grinder

The method of sharpening a saw chain using an angle grinder, the least common due to its non-safety. A tooth ground in this way can differ considerably from one ground with a file, i.e.к. During dressing with an angle grinder, it’s hard to control the sharpening angle.

A big disadvantage can be considered the possibility of cutting the disc angle grinder lug attachment chain link, which will subsequently lead to a break, when the work.

Only a special disk for working with metal is suitable. It must be at least 2.5 mm in diameter. In doing so, it is recommended to choose a disc with rounded edges that has already been used.

Before you start sharpening, you need to insert a wedge of wood between the chain and the bottom of the bar to prevent the headset from moving.

In the story. How to sharpen a chainsaw chain with an angle grinder

Sharpening the chain with a chain saw with an electric screwdriver

To sharpen the chain yourself using a drill or an electric screwdriver, you will need a circular file. To pick it up, it is necessary to specify the value of the diameter of rounding of the cutting tooth of the chain.Most domestic chain saws can be sharpened with a file with a cross sectional diameter of 4.8 mm.

In addition to the sharpening tool, you will need any bearing, which will be convenient to hold with the fingers on the outer cage.Let’s prepare the tool:

- First you need to remove the file shank with an angle grinder.

- Insert the file into the chuck and lock it.

- Use plastic, cork or a small piece of wood to make a bushing of such a diameter that it fits snugly into the bearing.

- Engage the free end of the file in the sleeve that is inserted into the bearing.

To sharpen the chain with the resulting tool, proceed as follows. First you need to fix the saw, the best way is to clamp the guide bar in a vice, preliminarily loosen the chain for free movement. Before sharpening, it is advisable to mark the first tooth with a marker. Now you need to put a file in the rounding of the cutting element blade, focusing on the required sharpening angle, which is usually marked with a ridge on the outside of the teeth. Next, holding the homemade device with two hands (one by the handle of the drill or electric screwdriver, and the other. by the outer casing of the bearing), you should turn on the power tool and, bringing a file to the tooth edge, make the sharpening. In the same way sharpen each cutting link, gradually moving the chain along the bar of the saw.

In the story. Chainsaw chain sharpening with an electric screwdriver

No problem copes with the task and a machine for sharpening chainsaws chains with their own hands. There are various ways of using such a tool. automatic or manual sharpening.Hand sharpening machine

With such a machine the optimum sharpening angle is set and fixed. Gives the best results without removing the chain from the chain saw.

No sharpening effort required: just set the angle and depth and start the sharpening machine. The work is done quickly and with high quality. High price range depending on the manufacturer.How manual sharpening is inferior to an electric machine:

- Manual sharpening with a machine tool is a very long and laborious process.

- Manual sharpening requires some skill, perseverance, care and accuracy.

- Manual method is less accurate because of the human factor.

If you own a professional chainsaw that you use on a regular basis, it makes sense to buy an electric automatic sharpening machine. It saves you time and prolongs the working life of your tool.

Oregon’s unique PowerSharp hobby chainsaw and power saw sharpening system includes:

- A plastic box with a pressure mechanism and a compartment for setting the sharpening stone;

- The bar with an extra hole for the subsequent fixation of the plastic box of the sharpener;

- Low Profile Chain;

- Sharpening abrasive stone.

PowerSharp kits are available in a variety of sizes. To find the right size, simply remove the chain headset from your saw, and select a bar that matches the length of the sample.Install the chain on the new bar, and assemble the saw. This headset can be used in place of the “native” headset until the first need for sharpening.To sharpen with the sharpener, place the sharpening stone in the box and secure it to the bar with the latch, then turn on the saw at full power and push the unit’s pressure mechanism vertically down into a hard surface (stump, log, rock, earth), pressing lightly. This way, the abrasive stone will touch the chain teeth and sharpen them in just 3-5 seconds. After removing the sharpening machine you can start sharpening again.

In the story. Oregon Powersharp automatic chain sharpening system

The consequences of using a chain that is not sharpened

If the chain saw chain is not sharpened quickly, the operator will find it increasingly difficult to work and the cut will become uneven. Such operation will lead to such negative consequences as:

- Reduced efficiency. sawing requires more physical effort, respectively, the speed of work falls;

- Higher fuel consumption. overruns can reach up to 30%;

- Reduced saw life. the chainsaw will quickly wear out and the motor will overheat, increasing the likelihood of tool failure;

- Risk of injury to the user. the chain can break if the saw becomes unstable.

Prevention of premature dulling of the chain

Extend the life of your chain without the need for periodic sharpening by paying special attention to careful maintenance of the bar. In particular, it is required:

- Use of special oil to be added when filling up the chain saw. To choose the proper oil concentration, it is recommended to consult the instructions for the oil itself.

- All of the unused fluid must be discarded.

- during use, it is recommended that the clearance between the stop and the tooth edge be checked periodically. Ideally, it should be 0.7 mm.

- To minimize the risk of distortion and single-sided abrasion of the teeth, the bar can be periodically repositioned 180 degrees.

- Lubricate the drive sprocket regularly. This should be done before each use of the saw. Only oil that is diluted with petrol and added to the fuel tank should be chosen. But the M8 grade gives the best performance.

- Watch the tensioning values. The chain must fit exactly into the grooves of the guide bar.

Top mistakes when sharpening a chain saw

If the saw does not work satisfactorily after sharpening, it is most likely that sharpening errors were made:

- Incorrect sharpening angle: more or less than required. To avoid this error, it is important to use a sharpening template.

- Front tooth angle is tilted forward or backward. This may be due to improper sharpening of the file. It is advisable to use a different sharpening method, or try to maintain the same pressure when sharpening by hand and select the correct file diameter.

- The chain teeth are not the same length. To avoid this, mark an approximate tooth before sharpening, and “match” the remaining cutting elements to it.

- The height of the cutting depth limiter of the cutting links is too low or too high. In the first case, it is necessary to refine the limiter, using a filing Kalibr. In the second, to sharpen the cutting links or replace the chain.

Increase operating life by alternately sharpening by hand and using a sharpening machine. The latter allows the most accurate alignment of the sharpening angles on the machine. The depth of stitching should not be great.

It is necessary to comply with safety measures that allow you to perform wood sawing of any size with maximum efficiency and with a minimum level of danger to humans:

- Before assembling the chain saw and fitting the chainsaw, it is recommended that you familiarize yourself with the following usage guidelines. This is due to the fact that each tool has its own characteristics.

- Always wear gloves and safety glasses when working with this saw.

- For work, it is recommended to choose close-fitting clothes made of natural dense materials and the most reliable shoes.

- When cutting wood with a chainsaw, it is necessary to be in a stable and safe position, and the material itself should be positioned as stably as possible. A toothed stop on the log ensures stability.

- Hold the saw with both hands while working and keep both hands on the saw at all times.

Modern chain saws are used today in both domestic and industrial settings. In doing so, it is important to keep the performance and efficiency of the tool high, which is directly related to the condition of the sharpened chainsaw headset.

General rules for sharpening chains

The general rule for this manipulation is to precisely position the tool in relation to the cutting teeth. Their internal configuration is a circle, so a circular file must be used for sharpening. Tool cross-section is determined by the size of the chain. Its pitch usually varies from four to five and a half millimeters, based on this, the desired cross-section of the file is selected.

The rules of sharpening provide for the location of the tool at right angles to the vertical plane of the processed surface, the value of the angle of horizontal direction can be ten or thirty degrees, depending on the configuration of the cutting tooth. A file should protrude over the cut of the chain by about twenty percent of its diameter.

It is rather difficult to achieve these conditions using only one file, that’s why special kits are often used for this operation. They are often included in the machine set or purchased at specialized stores.

Specifics of chain saw teeth

Saw teeth have their own specifics, so in order to understand which part of the teeth should be sharpened, it is necessary to know how the process of sawing wood is arranged. In essence, this process can be compared to a planer.

The cutting link of the teeth is arranged as follows:

During the manual sharpening procedure, it is necessary to control such parameters as the sharpening angle and the height of the limiter. These parameters should remain close to those stated by the manufacturer. Correct sharpening ensures that the tool works at the proper level.

It is not recommended to grind the links too much or change their order. Correct alignment is essential for proper tool operation; otherwise, there is a chance of straining the body and engine of the appliance. There is a possibility of tearing the links, as well as a guarantee of a crooked cut.

The main thing to pay attention to when carrying out the process at home and with your own hands is the following: the higher the angle, the stronger the performance of the saw. That’s why the process of bringing the saw into working condition should be performed at an acute angle between 25 and 35 degrees. The exceptions include cases where it is necessary to perform a longitudinal cut, then the angle is 10 degrees.

Anyone who has ever worked with a sharp chainsaw quickly knows when a chain needs sharpening. There are several ways to determine this:

- Instead of shavings when cutting wood, there is practically dust;

- the time required for the sawing operation is increased;

- the load on the hands is felt;

- Fuel consumption increases;

- the saw jams and falls out of your hands;

- The cuts are crooked.

You need to sharpen it as soon as possible, and not only because it becomes hard to work with the tool. Unsharpened chain shortens its service life and the chainsaw mechanism itself wears out sooner, fails earlier than it is supposed to.