How to cut a circle in a tile

How to cut an angle grinder round hole in tile or metal. Overview

You can drill a hole in ceramic tiles with a low-speed drill or an electric screwdriver of sufficient power. It is even acceptable to use a hand drill. the so-called hammer drill. although it is convenient to work only with small holes in the number of one or two pieces.

The diameter of the hole determines the nature of the tool. up to 10 mm, normal twist drill bits with pobedite tips or feather drill bits. also with pobedite or diamond tipped spearheads. are suitable.

For larger holes, it is better to use core bits with pobedite or diamond working edges. If you need to make a large number of holes of different sizes use the so-called ballerina. a device that resembles a compass. It has an alignment drill bit and a cutter that rotates at a given (adjustable) distance from the ballerina axis, cutting an edge in a circle.

Characteristic sharpening of carbide drills

Masters suggest as a last resort, in the absence of other options, to use quality self-tapping screws. Unfortunately, the risk of tile damage in this case is much higher than when using professional tools.

When creating geometrically complex cutouts, in addition to drilling, tile cutting is used with other tools. tile cutters (manual or electric), angle grinder, glass cutter.

If it is a question of creating complex, but consisting of rectilinear and circular sections of the contour, it is recommended to first perform drilling in the required places, and then cut fragments between the individual holes.

Perhaps for a smooth connection of the contour (as in the photo above) will also need nails on metal or grinding wheel.

When working with tiles it is very useful to use the so-called conductor. This is an overlay, usually plastic, which helps center the drill bit and prevents it from deviating from a strict vertical line in relation to the tile surface.

How to cut a tile with an angle grinder without chipping and dust?

Measure the cut surface carefully beforehand. use a marker on the outside of the tile. Since to perform a perfectly straight cut in most cases it is impossible, make a small allowance for trimming with a sharpener or nadfilm.

Straight cutting

The easiest variant of processing, with which even beginners cope. cutting tiles with a corner grinder in a straight line. To begin with, the tool is fixed on a flat surface. You need to position it so that the cutting edge hangs off the table. The cutting direction should remain in the tiler’s line of sight, and the tiles are placed face up.

If the angle grinder involves speed adjustment, at the beginning and end of the work reduce the speed.

Curved cuts

It is more complicated than the first variant, it requires a certain skill. Process tiles with short cuts on a tangential line to the outer contour of the outlined shape (oval, circle). This will cut off small unnecessary fragments, and then achieve the desired configuration.

Also plan small allowances for trimming, and after finishing the contour finish grinding, achieving smooth lines and removing chips.

Making rectangular holes in the tiles

After outlining the borders of the rectangle, steel plates are applied to its outer surface. The longitudinal plate will act as a ruler, and the transverse plate will act as a stopper of the cutting tool movement.

The work can be made easier with a drill. With it drill a few holes with a diameter of about 5 mm inside the contour, and then angle grinder between the perforations create through cuts.

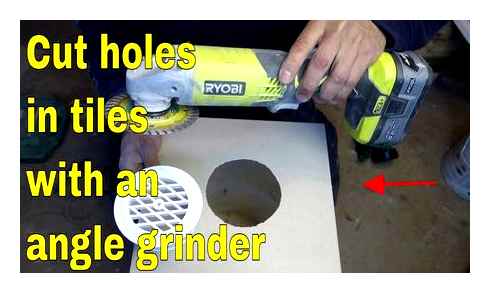

Cutting the Holes

Only large diameter holes are cut with the angle grinder, and small holes are cut with the drill or the rotary table.

- Two straight lines perpendicular to each other are marked through the center of the circle hole.

- Guiding the grinder at an angle, make a small depression along the length of the circle, trying to stick to its inner diameter.

- Gradually move in a circle, evenly sawing the thickness of the tile.

- As soon as there is enough depth, straight perpendicular lines are cut through the center of the circle.

- Carefully remove the first segment to avoid chipping, then remove or knock out the other three.

For smoothing a line of edge use a file, sandpaper wrapped around the bar, a drill with a sanding attachment.

Cutting at a 45-degree angle

Cutting tiles with an angle grinder is necessary when installing plastic or metal corners. This will help form a nice bevel edge when tiling diagonally.

A smooth and fast notch can only be made with a diamond point nozzle. The tile is placed under the edge with the glazed side down. Positioning the angle grinder at a 45-degree angle, grind the back side. As soon as the corner is formed, the action is repeated, moving around the edge of the cut.

Some masters start the work with a rectangular tile cutting. Then the nozzle is directed so as to remove the excess ceramic at a given angle. Complete the work by sanding the edge.

Angular cutting ceramic tiles with an angle grinder at home is recommended to perform those models of grinders, where there is an adjustment of the speed of disc rotation.

Ways to drill a tile

When using any method, it is necessary to turn off the percussive mode of the drill/peeler and put the minimum speed to avoid the appearance of chips.

Using special nozzles on the drill

How to make a neat hole in a tile? For this purpose, you can use special attachments on the drill, which include the so-called ballerina. In the design of such a tool, in addition to the central drill, there is one cutter (sometimes two or three), the position of which can be adjusted relative to the center of the created hole.

The sequence of steps in the processing of tiles with ballerina is as follows:

- In the center of the future hole you need to make a small depression, using any drill for this.

- Positioning the center drill bit of the ballerina in the obtained cavity, begin drilling. Set the drill to a low rpm.

- When the glazed tile is drilled along the contour of the future hole to half the thickness, its processing continues to perform from the reverse side.

Using a diamond drill bit is the most effective way to drill a hole in the tile

The hole in the tile for a socket or pipe can be made with the use of drill bits, the cutting part of which is coated with diamond. Let’s consider the sequence of operations when using such a tool.

- On the surface of the tile in the area of the future hole stick a plaster.

- The contours of the future hole are marked with a marker.

- Starts drilling at low rpm.

- In the course of work, the core drill bit is constantly moistened with water, so as not to bring it to overheating, to which it refers quite critically.

When choosing a core drilling tool, it is better not to save on its cost and choose products from well-known manufacturers, which will allow you not only a long time to use such drills, but also to obtain with their help precise and accurate holes.

Using the special bits on the drill

How to make a neat hole in a tile? To do this, you can use special attachments on the drill, which include the so-called ballerina. In the design of such a tool, in addition to the central drill, there is one cutter (sometimes two or three), the position of which can be adjusted relative to the center of the created hole.

The sequence of actions in the processing of glazed tiles with a ballerina is as follows:

- In the center of the future hole it is necessary to make a small depression, using for this purpose any drill.

- Having set the central drill of the ballerina in the obtained recess, begin to perform drilling. At the same time the drill is set to low rpm.

- When the glazed tile is drilled along the contour of the future hole for half the thickness, its processing continues to perform from the reverse side.

Using diamond drill bit. the most effective way to drill a hole in the tile

Hole in the tile for a socket or pipe can be made with the use of core drill bits, the cutting part of which has a diamond coating. Let’s consider the sequence of operations when using such a tool.

- On the surface of the tile in the area of the future hole glued plaster.

- The contours of the future hole are marked with a marker.

- Starts drilling at low rpm.

- In the course of work, the core drill bit is constantly moistened with water, so as not to bring it to overheating, to which it refers quite critically.

When choosing a tool of the core drill type, it is better not to save on its cost and choose products from well-known manufacturers, which will allow you not only a long time to use such drills, but also to obtain with their help accurate and neat holes.

Use of diamond drill bit

Marking

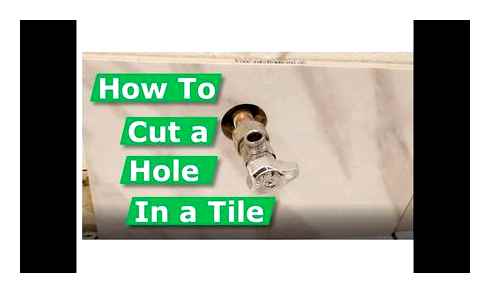

Let’s start with a typical case where you want to drill a hole in the ceramic tile under the pipe outlet on the faucet in the bathroom.

Such things should be taken into account even at the stage of laying, and try to make cutouts for pipes in the center of the tiles. This is done by shifting the layout or changing the starting point of the paving to the right place. If you can not install the faucet exactly in the center, you should try to hide this fact as much as possible, rather than highlight it by installing a number of decors or borders.

Logically, both holes should be at the same height. Therefore, the first thing to do before you drill a tile is to measure the same distance from the floor. To make sure you don’t fall off the vertical, use a plumb line with a weight or a bubble/laser level.

Measuring and marking the wall Next, you need to measure the required horizontal distance between the centers of the points and make two more marks. From the center of each point, measure the radius of the hole so you know where the cutting trimmer line will go.

Take the joint dimensions into account when marking the tiles

Drilling

We switch the drill to the drilling mode and set the RPM to the minimum. Insert diamond drill bit in the chuck. There are different kinds, for example, for concrete, wood or metal. do not confuse them when buying. Also make sure that as much diamond chips as possible are on the workpiece. It is better to get drill bits with a centering drill bit to reduce the risk of misalignment.

Start drilling gently, with a little pressure on the drill, but so that it does not move out of place. When the glaze has been cut, you can increase the speed and the pressure.

During drilling, water must be pumped to the teeth for cooling. Bosch has toothpieces which are filled with coolant (olive oil) inside and can be run dry.

If you are using a small-diameter drill bit without a pilot drill, use a drill bit and conductor to avoid misalignment. You can make it with your own hands in 1 minute from a scrap of board or plywood. Make a hole of similar diameter in it and use it as a conductor, pressing it down by hand.

Using a diamond drill bit

Marking

Let’s start with the typical case where you need to drill a hole in the ceramic tile for the pipe outlet for the faucet in the bathroom.

Such things should be taken into account at the stage of laying, and try to make cutouts for pipes in the center of the tiles. This is done by shifting the layout or changing the starting point of installation in the right place. If you can not install the faucet exactly in the center, you should try to hide this fact as much as possible, and not to emphasize it by installing a number of decors or borders.

Logically, both holes should be at the same height. Therefore, the first thing to do before you drill the tile. measure the same distance from the floor. In order not to fail the vertical, we use a plumb line with a weight or a bubble/laser level.

Measuring and marking the wall Next, you need to measure the horizontal distance between the centers of the points and make two more marks. From the center of each point, measure the radius of the hole, so you know where the cutting trimmer line will go.

When marking the tiles, take into account the size of the joint

Drilling

Switch the drill to drilling mode and set the minimum speed. Insert diamond drill bit into the chuck. They are available in different versions, e.g. for concrete, wood or metal. do not confuse when buying them. Also make sure that there is as much diamond chip on the working part as possible. It is best to get drill bits with a centering drill bit to reduce the risk of misalignment.

Start drilling carefully, pushing the drill a little, but make sure that it does not move out of position. When the glaze is cut through, you can increase the speed and the pressure.

During drilling, it is necessary to supply water to the working part of the drill bit to cool it. Bosch has bits that have coolant (olive oil) inside and can be run dry.

If you use a small diameter drill bit without a center drill bit, use it together with a conductor to avoid displacement. You can make it with your own hands in 1 minute from a scrap of board or plywood. Make a hole of similar diameter in it and use it as a conductor, pressing it down with your hand.

Processing of tiles with improvised tools

The question of how to cut a hole in the tile, if there is no handy electric jigsaw, or angle grinder, you can solve with improvised means. A regular glass cutter, pliers or pliers can be used as such tools. To make a hole in a tile when using them, you can use the following algorithm:

- Pre-mark the contours of the future hole.

- To make the tile material more pliable, you can hold the product in warm water for a while.

- Using a glass cutter, a groove is made along the outlined contour. When doing this, the working part of the tool must not be torn from the surface of the tile. Cutting a groove, considerable pressure is exerted on the tool, taking care not to damage the workpiece.

- The cut made on the tile surface must be punched with the head of the glass cutter, so that the groove becomes deeper.

- The cut section of the tile is removed with pliers or pliers, piece by piece, until a hole with relatively smooth edges is formed inside the cutting line.

- You can use a fine grit emery cloth to even out the edges of the cut.

Use a wooden block with sandpaper wrapped around it for grinding

Dupel hole in the wall tile

To drill a tile, use special so-called feather drill bits with a hard-alloy plate fixed as a sharp tip. Drills with two cross-shaped plates are impractical because they cannot be sharpened.

To make a marking for cutting or drilling on the smooth surface of the tiles it is convenient to use a spirit marker of contrasting colors, traces of which are easily removed with an alcohol solution.

The material of the tip is harder than the glaze and does not slide on it. To ensure a secure fit of the drill bit, a piece of masking tape or duct tape is glued to the tile, the place for the dupel is marked and drilling is performed. After passing a layer of ceramic tiles, the feather drill bit should be replaced with a concrete drill bit with a pobedite tip.

Drill holes with a diameter of 3-12 mm can also be drilled with a concrete drill, more common among home craftsmen. Make a marker on the tile, put a dowel or tap to it, and a light hammer blow make a dent in the ceramic glaze, to fix the drill in it before drilling. Drilling is performed at low rpm, the chiseling mode is applied only after the drill has penetrated the clay layer.

Round holes of smaller diameter in ceramic tiles can be made by screwing in self-drilling screws. Consumption of self-tapping screws for one such hole is 2-3 pieces.

Holes in the tile for faucets, outlets and pipes

To drill socket holes in a wall tiled with ceramic tiles, diamond-coated core drills are used. Drill bits can also be used to drill metal and wood, so it is important to use a drill bit specifically for tile. Core bits can be either with a pilot drill bit, which makes drilling easier, or without it. In the first case, the center of the circle to be cut is tapped, the center drill bit is positioned in position and drilling is performed.

Through the “ballerina” you can easily adjust the size of the hole

As the center drill bit deepens, the core drill bit is drilled. If the drill bit is not centered, the contour of the circle is drawn on the ceramic tile, the drill bit is placed against the contour, low rpm is turned on and by pressing alternately on the opposite edges of the drill bit, the groove is cut along the contour and then drilled. You can make a conductor out of plywood, which is a cut stencil of a circle of the same diameter as the crown. The stencil is applied to the wall, the crown is placed in the circle, and drilling is performed, in which the stencil will not allow the crown to move.

When drilling, the crown must be cooled periodically in water to prevent overheating and deterioration. Core drills are also suitable for drilling porcelain tiles.

Around the mounting box for the socket in such a hole should have room for cement-sand mortar. This is necessary for a firm fixation of the box and socket.

Special nozzles on the drill

There are specialized devices, designed to work with tiles, which allow you to cut a hole of large diameter. One of these is a ballerina. It is a drill bit with an additional cutting element.

How to cut a round hole in a tile with a ballerina:

- Make a small hole exactly in the middle by any means.

- Place the ballerina on the drill and the center drill bit in the hole.

- With slow revolutions, begin to deepen. The side pieces will begin to scratch the tile, outlining a circle like a compass.

- When half of the job is done, turn the tile over and do the same on the back side until the center falls out.

Another type of bit is the diamond drill bit. Find the right diameter for the specific size.

How to make a hole in a tile with a drill bit:

- Put masking tape on the ceramic tile.

- Mark the contours of the hole.

- Position the drill and start to go deeper at a slow speed.

- Wet the bit with water to avoid overheating.

When buying drill bits, pay attention to their price and quality. Only work well if you have a good tool.

Sawing a hole with an angle grinder

Most of the time, it is necessary to make a hole in the tile during installation. As long as the tile is not fixed to the surface, it is easiest to do it with an angle grinder. This tool comes in handy many times during floor and wall tiling. It is suitable for cutting along the edge of the tile.

How to make a hole in a tile with an angle grinder:

- Mark the contours.

- Take a diamond wheel for dry cutting.

- Start cutting from a comfortable edge. Move the tool smoothly away from you. Hold the tile with your hand, do not forget to protect your fingers.

- If the working area is not too comfortable, stop in the middle and finish with an angle grinder from the other edge. But there is a risk of divergent cut lines.

Work on the face side of the tile to avoid chipping.

The diamond disc is used for cutting the tiles

Using a jigsaw

This tool can be used to cut any shape, both on the edge and in the center of the tile. But in the latter case you need a drill to get the initial hole.

How to cut ceramic tiles with a jigsaw:

- Draw the contours on the front side.

- If the work area is close to an edge, start cutting.

- To make a hole in the center, use a drill to pre-drill a small hole. Pass the cutting thread through it and set the jigsaw on the edge of the cutout.

- Slowly guide the tool according to the markings. Cut inward a little from the line so you don’t cut too much out.

The necessary holes are made in the tile in advance. before laying

Selecting a drill

Tile drills come in the following types:

- Diamond drill bit. This is the most commonly used, and it is considered the most effective. But it is expensive. Therefore, it is not always rational to buy it for one-time work. It is used by professionals who work in the construction business;

- drill bit with pobedite tip. It is very popular in the home, cheaper than other types and quite effective;

- tile drill bit. Its price is high, but if funds allow, it will not hurt in the household;

- Tungsten carbide drill bit. The design of such a drill allows you to drill holes of large diameters.

How to make a hole in the tile with a special saw and hacksaw for metal

This method is good for holes on the edge of the tile. You will need a special tungsten tungsten wire saw.

Drill a 8mm hole in the tile to fit the wire saw. Insert the string into the hole and load it into the hacksaw. With calm movements, make a circular hole in the tile. Grind the edges with a.10 abrasive emery cloth.

That’s all! I hope that these simple tips, How to make a large diameter hole in a tile, will help you.