How to cut a corner on a wooden baseboard

How to file a ceiling plinth: methods of cutting corners using a wire cutter, drawing on the table and marking on the ceiling

Classification of baguettes is carried out by the material of manufacture:

- Gypsum. The oldest representatives of ceiling plinths. Special molds have been used for these. Different mortars have been used as an adhesive mounting compound. The name “fillets” also applies to plaster baguettes. In modern construction they are used very rarely because of the high cost and inconvenience of installation. In addition, there are more reliable and inexpensive imitation gypsum skirting boards.

- Polystyrene (polyurethane). The most common type of ceiling plinth. This type of products is characterized by low price, excellent aesthetic characteristics, easy installation and a wide range of choice in terms of design. The width of polystyrene skirting varies in the range of 5-250 mm. They can be used in any type of room, complementing the various interior styles.

- Wooden. Expensive and rather bulky baguettes, which are mainly used to decorate wooden houses with the appropriate interior. To install wooden slats, in addition to glue, often use screws and nails.

- Plastic. An excellent option for bathrooms and other premises with high humidity. Mounting is carried out on special moisture-resistant glue or countersunk self-tapping screws.

When installing the above products, you need to know how to cut the ceiling plinth. This does not apply to plastic products, which are equipped with special corner adapters.

What tool is needed

When installing the ceiling plinth, it must be trimmed to size or in the corners.

To cut the corner of the ceiling plinth, as a rule, the following tools will help:

- A wood serrated knife. Used for working with wooden products.

- Metal saw. This tool is handy for cutting plastic, Styrofoam and plastic friezes. As a result, it is possible to get a fairly clean joint without burrs. It is convenient to use a compound saw when working with saws.

- A box cutter. With its help, you can cut foam baguettes, without using special devices. The main thing is that the knife is well sharpened and has a thin and even blade. If you act carefully, the cut is smooth, without any dents.

When using the saw, it is important not to apply excessive force, otherwise the skirting board will crumple. It’s best to train on some unwanted piece first. This will allow you to further obtain beautiful pieces.

What are the joints to be decorated?

There is a big difference in how to cut the decorative joints of the floor and wall moldings, depending on what kind of connection will be finished. There are two kinds of them:

Naturally, the strips will be cut differently, and the parameters of the cut, which should be used as a guide, will also be different. To orient oneself precisely, as there are, unfortunately, no perfect wall and surface joints in our apartments, and there are always small deviations. Therefore, it is often necessary to deviate from the ideal geometry of the node to get a quality joint.

A small digression: the most ideal option with uneven corners will be the preliminary preparation of the planes in the form of alignment to the ideal of ninety degrees. However, not everyone can afford it, and to perform the work requires certain skills of a plasterer.

It is in this regard, we have to make compromises: not to create a perfect joint, and allow the formation of small gaps or cut strips do not ideal. In this case, it is better to avoid gaps. it looks very ugly. It is better to make a more accurate, though not under forty-five degrees connection of slats, than to leave gaps. In such a situation, you will have to refuse to use special devices and saw everything off with your own hand drawn markings.

Choosing a cutting tool

Before making corners on the ceiling plinths, it is necessary to find out what construction material is used to make the fillets:

- Styrofoam. This material is extremely fragile, it crumbles easily. Its advantage lies in the affordable price for many consumers. When working with polystyrene because of its brittleness should be used a knife or hacksaw. Do not make strong pressure, you must perform the work as carefully and slowly as possible, otherwise the skirting board will break.

- Polyvinylchloride. Products made of it are inexpensive, but they must also be handled with care. PVC skirting boards are highly electrostatic and therefore strongly attract dust. To cut such products use a hacksaw or knife.

- Extruded polystyrene foam. Ties made of this material are durable and reliable, but their cost is higher than previous samples. They are not easy to break, and do not crumble when cut. When choosing what tool to use and how to cut corners on the ceiling skirting boards made of this material, it is best to use a construction knife or hacksaw, which are designed to work with products made of metal.

- Wood. Wood makes the most durable type of these products. This robust product is the most difficult to work with because of the high resistance of the material to physical impact. Use a fine toothed file to cut wooden skirting boards.

- Polyurethane. It is used to produce durable skirting boards for ceiling surfaces. They have a big disadvantage. polyurethane products do not react to temperature differences and are sensitive to heat or cold. Consider these nuances before trimming ceiling plinth in the corners.

Special fittings are available that facilitate the process of installing the fillets. These are the corners for the ceiling plinth. They help to hide all kinds of errors that occur during installation. These corners should be simply inserted into the skirting boards. You only need to cut the fillet at right angles. Corner will cover the existing errors.

Ties made of foam plastic. this is one of the cheapest options. However, the advantage in the form of low cost is offset by a lot of disadvantages. In particular, the foam itself is very fragile and soft material that is very easy to break. Even if you just squeeze such a product in your hand, it can deform.

Due to the low strength of the foam skirting boards is very difficult to handle. If there is little experience in cutting such parts, then most of them in the process of work will be destroyed, so all the benefit of the cheapness of the skirting boards will be leveled. To cut the foam strips, you usually use a hacksaw or a well-sharpened knife.

Styrofoam

By and large, Styrofoam is a type of foam that has an increased margin of safety. The cost of products from extruded polystyrene foam is somewhat higher compared to the foam, but the reliability of such skirting boards is much higher. Breaking such a part is already problematic.

To cut the polystyrene skirting boards requires any sharp tool, such as a construction knife or hacksaw. Thanks to the high strength of such products is much easier to work with. they are almost never broken or deformed in the process of work. There will be less waste in the end.

How to correctly join the baseboards in the corners

Corner angles that are formed correctly look attractive

As a rule, the design of corners, both internal and external, takes most of the time. Due to the fact that the ceiling skirting boards are characterized by a very complex shape, it is not easy to just take and cut them at the right angle. It is necessary to cut so that they dock in the corner without visible gaps. To get the corners literally perfect, there are several ways.

Using a power tool

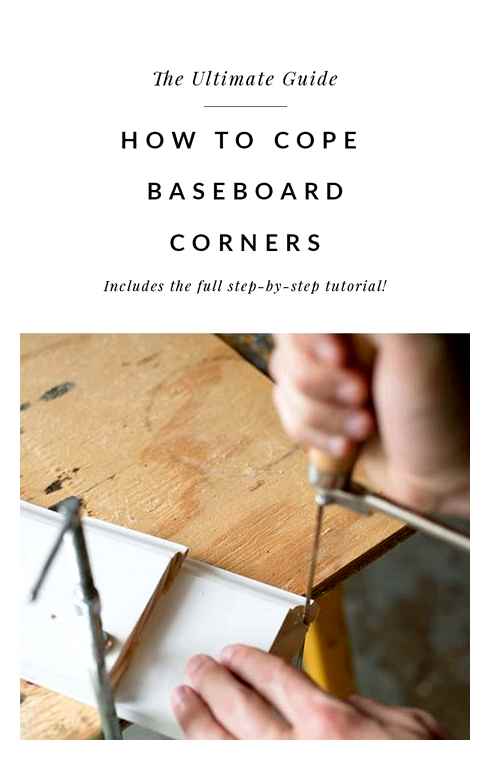

The chisel, as a tool, is suitable if the corners of the room are joined at an angle of 90 degrees. The tool is a groove, in the shape of the letter “U”, turned upside down. On the walls of the gutter made cuts at different angles. To evenly cut the decorative element, it is placed inside the gutter, after which the element is cut at the desired angle with a hacksaw.

This is what the jig looks like. Can be plastic, wood or metal

Due to the fact that the skirting boards have a complex shape, they must be placed in the gutter so that they simultaneously pressed on two surfaces. the bottom and side. Depending on which corner is formed, the baseboard is pressed to the bottom and side, or opposite, or the near surface.

As a rule, corners are trimmed at an angle of 45 degrees. First of all, you need to determine the length of the skirting board, placing certain marks on it. After that, the decorative element is placed in the chair so that the mark corresponds to the maximum length of the element, and then the element is cut off. You must also remember that the left side of the baseboard is placed on the left side of the jigsaw, and the right side of the baseboard is placed on the right side of the jigsaw.

How to cut a corner on the ceiling plinth: properly install it in the jig

Ceiling skirting boards are attached to the ceiling with one side and to the wall with the other, so the part that is attached to the ceiling is placed on the bottom surface of the skirting board. It is very important to hold the skirting board firmly and securely during the cutting process, as otherwise the cut surface is unlikely to be flat and smooth. After cutting off the left and right side in this way, either the inner corner or the outer corner is obtained.

How to cut a corner on the ceiling plinth: properly install it in the jigsaw

First, both parts are applied to the attachment point without glue to check the quality of the work. If the corners do not match, they are corrected with a suitable tool. The advantage of polystyrene ceiling plinths is that small errors can be hidden by covering them with putty.

After final inspection, a thin layer of special glue is applied to both surfaces of the skirting board.

How to make the inside corner of the ceiling plinth with the use of the jigsaw

The technique of fitting ceiling skirting boards in the corners is almost the same, regardless of which corner it is, internal or external. After the glue has been applied, the skirting board is pressed against both the wall and the ceiling. Naturally, the effort must be controlled, especially if the decor elements are made of Styrofoam. over, it is necessary to work with gloves on, so as not to smear the surface of the skirting boards, which can easily get dirty.

How to cut a corner of a skirting board without a jig

skirting inside corner

- A profile is placed in the installation area and must be set against the adjacent wall;

- on the floor base with a pencil (marker) is carried out the control line for the trimmer;

- similar actions are performed near the other wall;

- The intersection point of the two control segments. the bottom cut, the junction point in the corner. the upper cut.

Finishing the outer corner

- in this case, similar actions are performed, only the profile is led out of the corner of the converging walls;

- Where the reference segments cross. the lower cut, the upper cut. the corner edge.

Important! When trimming the skirting boards you should try to keep the hacksaw at a 45º angle when sawing.

Note! We strongly advise to buy a crossbow for cutting corners. it costs not expensive, and to spoil or make an uneven and ugly angle without it is quite realistic!

Connecting plastic skirting boards

Today, for plastic baseboards produced additional elements: connectors, plugs, corners, which help close the slices of strips. That is why there is no need to trim the skirting boards when finishing corners.

Connecting elements for a plastic skirting board

- Measured length of both walls, by which the slats are cut.

- The skirting boards are screwed to the wall with self-tapping screws (read more about how to fix the skirting board).

- At the corner of the plastic skirting boards are connected by a special device, also made of plastic.

- Next, the corner of the skirting board is closed zaklushkoy corner, which simply must be put on the edges of the strips.

Photo example of fastening a plug to a plastic skirting board

Important! When using different plugs for corners and joints plastic skirting boards advise you as well mount them (in addition to standard fasteners) on a small amount of glue or liquid nails. this will “firmly” fix the corner, and with a small physical impact (for example, caught his little finger on the outside corner))))) ) plug will not pop out (less likely to break the fasteners or the plug itself with the baseboard).

Nuances of trimming internal corners

Work related to how to make the inner corner of the ceiling plinth, begins with the fact that the product is attached to the ceiling. This is necessary to measure the required length of the part.

When the measurements are completed, the skirting board is placed in the prepared jig. It is placed so that the location of the product in it turned out exactly as on the ceiling.

You need to hold the skirting board with your left hand and make sure it fits snugly against the wall of the appliance. The piece, which is intended for installation on the ceiling, should be located at the top, and the lower part is pressed to the bottom of the chair.

The blade of the hacksaw is turned at an angle of 45 degrees and begin to cut. The tool itself should be held as close to the left hand as possible and while cutting it should not be pressed hard. After cutting the inner corner of the ceiling plinth number one has succeeded, proceed to work with the adjacent product. It is cut in a similar way, but in reverse, as if in a mirror image.

If the skirting boards are made of polystyrene or PVC, the work should begin on the front side, so that the result is more accurate.

Creating the outer corner

Before you make the outer corner of the ceiling plinth, you need to make appropriate calculations and measurements to perfectly cut the product. To do this, measure the distance the piece takes from the corner on the outside to the nearest wall.

On the reverse side of the product spend a trimmer line, outlining the required length, not forgetting that its top slightly protrudes outward. After completing measurements and calculating the outside corner of the ceiling plinth, proceed to further work.

Tutelage is placed in the wire cutter and carefully cut off. The adjacent skirting board should be measured in the same way as the previous one, not forgetting to leave a reserve. Trimming must be done in a mirror image to the first piece.

How to properly cut corners in a ceiling plinth. How to cut a corner with the jigsaw

In rooms with even corners and walls, cutting a ceiling plinth with a wire cutter is usually not very difficult. The tool has a U-shaped trough with 90 and 45 degree saw guides. Placed inside the device required to cut the element, insert the saw into the guides. The baguette must be held firmly in place during cutting, to avoid defects. It is quite difficult to cut the skirting board, as it is necessary to achieve its simultaneous adjacency to two planes. If the width of the baguette is small, it is more convenient to press it to the near side. ” How to cut ceiling plinths. tools and cutting rules “.

How to cut the corner of the ceiling plinth, if you make out an outer corner:

- Before you cut the corners of the ceiling plinth with a wire cutter, a 45-degree angle saw is made.

- The chair is aligned in a comfortable position. This will make it possible to determine the exact position of the skirting board: first of all it concerns that edge of the product which will adjoin to the ceiling. To avoid confusion, it is most convenient to place the right-side plank on the right, and the left-side. on the left.

- The surface is pressed to the underside of the chair. In this case, the second part is lifted, being the closest. It must be so put to the wall of the jig, so as to avoid its wobbling during the work. In this arrangement, the front side of the product is turned to the opposite side.

- The cut must be made at a 45 degree angle away from yourself. If everything is done correctly, when you fold the two halves, you get a beautiful outside corner.

Once the correct sawing of the ceiling plinth in the corners is completed, both pieces should first be attached to the ceiling “dry” to check the geometry of the corner match. If necessary, adjustments are made by trimming with a knife. Small gaps are easier to cover with putty, which, after drying, must be processed with sandpaper. As for the inner corner, it is much easier to make it.

The procedure, how to cut the ceiling plinth in the corners of the interior type is much like the above described. The first thing to do is to determine the side that will be adjacent to the ceiling. It is placed on the bottom of the jigsaw. The back side must be leaned against the near wall. After sawing the plinth on the ceiling is finished, the obtained fragments should be dryly attached to the corner, checking the quality of the junction. If necessary, adjustment is carried out. After that, the installation of one and the second skirting board on the mounting compound. Small gaps in the corner can be filled with a special putty.

Different materials and their characteristics

The most durable material in comparison with the other two, listed below, whose advantages are the hardness, impact resistance and the ability to withstand certain mechanical loads. However, wooden skirting boards (another name. tacks), glued to the ceiling, is also relatively easy to handle. they can be cut (for this purpose, a wood hacksaw), covered with varnish. Wood will give warmth to the interior. Of the disadvantages can be called a higher cost than that of Styrofoam. However, the appearance of wooden fillets lasts longer than the foam ones.

Styrofoam. Perhaps this material is the most fragile. it is not resistant to mechanical damage, scratches, and even minor impacts. Of the pluses. the light weight, the ability to paint in different colors and ease of handling (it can be cut with a box cutter. but very carefully).

Styrofoam foam. This material can be considered a kind of Styrofoam, although its strength characteristics are somewhat higher (extruded polystyrene foam is more dense than Styrofoam). As for processing. styrofoam is just as easy to cut with a common sharp knife, and also has a small weight, which is an important factor when taking into account the load on the walls.

Exterior types of joints

Strangely enough, but with the general identity of the work with the internal joints, external ones cause more problems. Here the joining of elements takes place exactly as in the case of internal connections. The only difference will be the position of the sawed off strip when sawing. it is necessary to consider that the sawed off blanks should be joined together projecting outwards, instead of connecting inwards. The rest is done in the same way. with a plane, a saw, and trimming the cut.

Uneven corners

Unfortunately, this situation will be more common than perfectly even corners. Figuring out how to cut the corners of the floor plinth in this case can be difficult, and the technology of cutting ceiling moldings will help. Here is how it will be done:

- We put the first piece so that one side was tight to the wall, and the end of it rested against the adjoining wall.

- Run the trimmer line on the floor along the edge of the piece.

- Take the second piece and press it firmly to the perpendicular wall, also flanking the adjoining surface.

- Draw the second trimmer line on the floor.

- The point where our drawn lines will intersect is transferred to the bottom of the two slats to be trimmed.

- We draw a fishing line for a trimmer from the point transferred to the workpiece to its edge and cut the workpiece by it.

- Repeat with the second piece.

The described algorithm is applicable to the inside corners, but, with external all will be about the same, except that the skirting boards will not stop anywhere, and will protrude to the width of the cut outside the walls. The photo below shows how you can dock moldings on the ceiling, but it is even easier to work with elements of the floor decor, and the principle will be the same.