How to cut a pipe at 45 degrees

How to cut a cast iron pipe

As a result, it will split along the mowing line, forming a fairly even cut that can be further trimmed if necessary.

How to cut a cast iron pipe

If the pipe is made of cast iron, then in order to cut it evenly you will have to apply a certain knowledge. The fact is that this material is characterized by high fragility, which means that before you cut such a pipe, you need to determine the algorithm of actions.

- We mark out the same way as with steel pipes.

- At the place of the sawing it is necessary to put a wooden bar as a support.

- Next, you need to make a saw cut of a few millimeters around the circumference of the screwdriver.

- After that, a chisel is inserted into the groove and a sharp and hard blow must be made with a hammer.

As a result, it will split along the mowing line, forming a fairly even cut, which, if necessary, can be further processed.

SEE the steel pipe cutter on AliExpress →

Marking method using a container of water instead of a template

This method of marking is suitable for small-diameter pipes that are planned to be cut at a certain angle close to the edge. First you need to prepare a deep container of water. The planned angle of inclination is marked on it. Now you need to carefully immerse the end of the product in the liquid, bend it to the mark, and then pull out.

As a result of such actions, a clear line of contact with water will appear on it, it must be highlighted. It is used to cut the pipe at an angle. This method is best suited for jobs where multiple markings are required.

Cutting sheet metal with an angle grinder

To cut metal of different types not thicknesses, use the appropriate cutting discs of different thicknesses not diameters. The algorithm for cutting sheets is as follows.

- For cutting by means of angular grinder sheet metal is laid on an even surface.

- Mark with a chalk (a marker) the exact size of the fragments to be cut through the sheet.

- Carry out sawing along the marked lines, not changing the angle of the initial inclination of the disk to the working surface at the same time to avoid its jamming or damage to the power tool.

If the skills of sawing sheet metal angle grinder does not exist, it is recommended to train on a delicate material. this allows you to feel the work of the tool.

You need to think about what the lower near segment of the blade cuts the metal more effectively.

Performing cutting a sheet of metal, in order to obtain a quality result, you should consider the following recommendations.

- For better cooling it is necessary to water the place of cutting, which also increases the life of the circular saw.

- Start cutting metal only when the disc is rotating: you can not turn on the tool if the stationary disc is in contact with the surface of the workpiece.

- To saw tinplate (thin sheet metal) or cut out different geometric shapes, it is more convenient to use small, worked out circles (“stumps”).

- It is harmful to press the angle grinder with considerable force: cutting must be carried out almost exclusively by the angle grinder’s own weight.

- If the cutting wheel should stop in the kerf (when the power tool is switched off), do not remove it before resuming work.

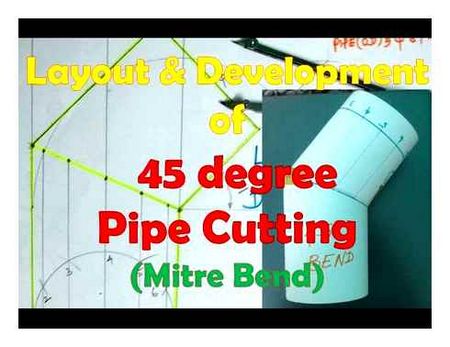

How to cut the pipe at an angle

Sometimes it is necessary to trim the pipe at a certain angle. In this article, the master plumber will tell you how to perform such operations and what are the methods of cutting.

When we look at cutting methods. straight or diagonal. we must keep in mind the different materials that are being cut. So, hoses made of polypropylene or thin copper are easier and easier to cut than thick-walled steel pipes.

Plastic products of small diameters are cut at the desired angle with special scissors. Angles can be controlled with a standard protractor. Polymer pipes can also be cut with an ordinary fine-toothed hacksaw.

It is very common to cut metal pipes during installation. A popular tool for such cases is the so-called angle grinder. This tool is used to cut straight and at an angle.

Let’s see what tools can be used for cutting at different angles.

To perform a relatively precise cut, you can apply a simple technique, where an ordinary sheet of paper acts as a kind of template. For example, printer paper of A4 size is suitable for creating a template.

The sheet is preliminarily marked as a square using a ruler. The size of the diagonal of the square must be equal to the length of the circumference of the pipe to be cut. Excess parts of the sheet are trimmed.

- Fold the sheet diagonally, aligning the opposite corners;

- Rotate the resulting triangle so that the line of the hypotenuse is perpendicular to the axis of the pipe;

- In this position, wrap the paper around the tube surface, aligning the hypotenuse extreme points together;

- Make a marker mark the cut along the beveled line of any of the triangle’s cathetuses;

- Trim the pipe along the outlined scythe line.

This method is quite convenient to mark and cut pipes at an angle of 45º in the range of diameters from 32 to 63 mm. For more convenient marking, it is recommended to take thick, but soft paper. You can also use paronite and similar materials.

Competently made templates for the figured cutting of the pipe allow for very high precision of the cuts. In this case, the gap between the prepared blanks is not excluded. In the connection of metal pipes, it is “closed” by a welded seam, when connecting plastic parts, a specialized cord for soldering is used.

The technology of cutting according to the templates allows to obtain different cutting angles. But in order to form a template for angles other than 45º, it will be necessary to perform mathematical calculations and according to the calculated data to cut a template from paper or similar materials.

True, there are computer programs designed to save the master from making calculations. Templates for cutting pipes such programs are printed on the printer.

Easy calculation program based on MS Excel application allows you to calculate and create a template for almost any pipe diameter and any required cutting angle.

All the user has to do is enter the appropriate values into the “Outer Diameter” and “Angle of Cut” cells. According to these parameters, a template will be formed, which can be sent for printing.

There is an uncomplicated tool, often used in everyday life, mainly for work with wood. It’s called a plane. So, the same device is suitable for cutting pipes, and at different angles.

The chisel is available for sale, but if you want, you can always make it with your own hands and adjust the design to the desired diameter of the pipe:

- Take a wooden board of width equal to the diameter of the pipe, length 400-500 mm;

- Take two more planks of the same dimensions, but increased in width by the thickness of the first board;

- From three boards to assemble a construction in the form of an inverted letter “U”, where the first board is installed as the base;

- In the central part of the structure, mark a rectangle, two sides of which run along the inner boundaries of the side boards;

- Divide the rectangle diagonally and along the lines obtained on the upper faces of the side boards, make cuts down to the base.

This is how a template is made for cutting at a 45º angle. But you can use a protractor to mark almost any angle and make cuts for cutting the pipe for a specific angle.

Advantage of the power drill. the tool is suitable for repeated use. Work with the tool is allowed as long as the walls of the cuts are worn out, until they can provide a high accuracy of the cut. It is recommended to make the tool walls from a material of higher strength than wood.

The advantages of this method are obvious. simple, easy to manufacture tools (jigsaws), economical, versatile. The disadvantage of working with this type of equipment is that it is necessary to adjust the size of the jig to the pipe diameter if you want to make a precise cut. That is, you have to make a separate tool for each pipe.

Also with a wire cutter, you can cut the pipe only with a metallic hacksaw or secateurs (for plastic products). To work with thick-walled metal pipes, this tool is not suitable for cutting with an angle grinder.

It is convenient to cut round and rectangular metal pieces with rather thick walls at an angle with the help of an angle grinder fixed on the base.

- A rotary mechanism sets the desired cutting angle (e.g. using a ruler and protractor);

- The found position is fixed with clamping screws;

- Between the short and long corner, the pipe is inserted and clamped with the screw of the clamp;

- Voltage is applied to the electric motor;

- Pressing lightly on the cutter disk, the pipe is cut in the right place.

The advantages of this technique are quick work, accurate cut, and the possibility of processing a large number of pipes in a short period of time.

Disadvantages: restrictions on use in domestic conditions, increased noise, work with only small and medium-diameter pipes. In addition, the process of cutting with the tool is carried out stationary at a distance from the place of installation, which is not always acceptable.

The nuances of working with a rectangular cross section

For cutting rectangular section pipes it is recommended to prepare angle cuttings in advance. They can easily be made from a metal angle, pre-marked with the same protractor.

Among the branded devices that could be used in the home to perform cutting at an angle, you can pay attention to the technique of Italian production.

Mini Cut Mini Cut band saw from “MASS” company is a small-sized device with manual clamping for work not only with pipes but also with angles, rods and profile elements.

Cutting angle setting from 0º to 45º is supported on the machine. The procedure is performed by the band blade with a speed of 45 reciprocating movements per minute. The machine is equipped with a 370 watt electric motor, which is powered from a domestic mains supply. Maximum permissible diameter of a round tube to be cut is 65 mm.

Numerous electromechanically and electrically operated pipe cutting machines have been developed for industrial scale. The technically sophisticated machines enable precise thermal, oxyfuel and plasma cutting.

In the story. Cutting of tubes with diameter of 35 mm and wall thickness of 2 mm at 90˚ and 45˚ angle

There are special industrial machines for precision cutting operations at an angle. A good example: Machines produced under the brand name “BSM”. Machine tool manufacturer is German company Rexinger.

True, BSM series machines are designed exclusively for work with polypropylene pipes of rather large diameters. Processing of PP, PVC, PE, PVDF products is supported.

Cutting tool of machine is band saw, thanks to which a cut at angles from 0 to 67,5º is made. Process precision is ensured by the laser cutter.

Despite the configuration of the device for large diameters, you can use a special table, with the help of which you can also successfully cut small diameter pipes (50. 200 mm), which are easier to cut with the pipe cutter. There is a wide range of “BSM” devices.

In the story. Large-diameter pipe band saws GR-BSM series

Besides mechanical sawing methods, it is often the case that thermal methods are used, such as welding and cutting equipment. E.g. an autogenous cutting torch or a conventional welding machine (DC/AC).

With the help of such devices thick-walled metal pipes can be cut. However, it is extremely difficult to obtain a perfectly even and qualitative cut with electric welding or a gas autogenous gas furnace.

Usually after thermal cutting, workpieces undergo additional processing. The cut line is aligned, the required angle is adjusted. Such an approach is not cost-effective, since it entails additional machining costs.Thermal cutting is commonly used in industrial settings. True, utilities often use this technique, too.

Thermal cutting is also used when working with plastic material. There are devices. thermal guillotines. A sharp, thin blade of such devices is heated to a high temperature, and then the cut is made.Thermal guillotines support cutting at an angle, and that’s their advantage. However, these devices cannot be used to work with tougher materials than PVC, wood, chipboard.

For each individual installation it is possible to choose the most convenient and least expensive way of cutting. The concrete choice depends on the pipe material, its diameter, and wall thickness.

Features of working with the angle grinder

Safety precautions when working with a drilling machine

Modern angle grinder allows you to replace the sandpaper when working on metal. To avoid problems, it is helpful to remember a few guidelines when using the tool:

- The angle grinder must be held with both hands when working. In the event of a kickback, firmly fix the disc in such a way that displacement is kept to a minimum. Otherwise, the risk of injury increases.

- Work on a level surface, firmly maintain a good balance.

- Power supply cable must be on the opposite side of the disc. The operating instructions for the angle grinder make these requirements to avoid short circuits and shock wave of the machine.

- When you have finished your work, hold the tool firmly in your hand until the disc comes to a complete stop.

- If the power supply is interrupted, you must unplug the tool from the power outlet. Otherwise, the angle grinder can start working without any control by the operator.

- The work process is accompanied by the heating of the discs. After turning off the tool, they can not be touched until they cool down.

Fixing the material

Rules for cutting pipes of different metal

Angle grinder even in the hands of the master is quite a dangerous tool. When working with it, precautions should be observed, and be as concentrated as possible. Otherwise you can not only damage the metal workpiece, but also injure yourself.

Know how to properly cut the pipe under 45 degrees with an angle grinder, every specialist in working with metal should know. The disk circumference should be set with the drawing upwards, and clamped with a special nut. Pipes of different metal are cut with the observance of some rules.

Working with aluminum workpieces

Aluminum is a soft metal, so a different type of disc is used for cutting with an angle grinder. When working with soft metals, such as aluminum or copper, it is not possible to make the cut in one go. The cutting blade simply gets stuck in the material.

Be very careful when cutting with special discs. Make several passes over the same cut.

How to cut cast iron pipes

Cast iron is very strong, but at the same time it is a rather brittle material. Diamond-tipped discs are recommended for cutting cast iron pipe. Fragile material should only be cut with an angle grinder in a straight line.

Important! Works with sawing cast iron, steel, and aluminum should be performed only with use of personal protective equipment (respirator, goggles and gloves). The cutting process with an angle grinder generates a great deal of dust.

Cutting of big pipes

angle grinder is often used for cutting large diameter pipes. Large metal products have thicker walls and greater weight. It is more convenient to choose large disks for work with large metal workpieces.

Heavy, non-removable workpieces should be firmly supported on low supports or on a flat surface so that they do not change their position when the final cut is made.

When working with large pipes, choose the correct direction of rotation of the wheel of the angle grinder. Otherwise it would be hard to hold the tool in a fixed position and the disc would wear down too quickly.

Cutting at 90 degrees

To cut a round pipeline or a rectangular metal profile evenly across it, you use a sheet of ordinary paper. It is wrapped around the workpiece so that the edges of the paper sheet overlap, and then it is attached to the workpiece with tape or glue. the angle grinder guides a thin line near the edge of the paper sheet and then gradually deepens it until it is completely cut out.

A Simple Process Of Cutting Steel Pipe In 45 Degree Without A Cut Off Machine

Metal profile or round tube can be sawn with the help of a template, putting on them evenly cut element with a large inner diameter.

Collar plunge cut

To obtain the branching of metal pipe lines in the form of T-pieces, a collar cut-in is used, for which it is necessary to cut the edge of the circular tube adjacent to the walls of the other at right angles. To implement the method, proceed as follows

- trim the edges of the workpiece at right angles using the method given earlier.

- On a round end face marker mark four equidistant points located at angles of 90 and 180 degrees to each other.

- Measure the circumference, and divide the obtained diameter by 3. Distance is measured from two diametrically located points and joined to the other two by a straight line drawn with a line marker.

- According to the markings, cut with an angle grinder and separate semicircular segments, after which the piece is ready to be welded. For small inaccuracies in the mating, it can be sealed with a sledgehammer against the round surface of the other element.

Beveled cut

If you change the direction of the pipeline to an angle greater than 90 degrees, manual methods of template making become too complicated. The use of special programs for the calculation and creation of patterns on computer for any angle can be of help. The method is good because it has a high accuracy of paper templates and can be easily implemented if you have a printer.

To obtain a paper template, the necessary data about the bend angles and pipe diameter are entered into the program, then a template is obtained, which is printed out on a printer at full size. All that is left is to cut it, glue it onto the element to be cut and mark its contour.

Further cutting is made with the help of angle grinder in a standard way. An important advantage of mechanical templates is the possibility to cut an unlimited number of them with the same accuracy.

For quality connection of cylindrical elements of piping requires their precise trimming at angles of 45 and 90 degrees. To perform this work special mouldings are used, the shape of the bends are calculated manually or constructed by computer. They are cut out on paper and glued to the pipe surface, then the element is cut along the paper contour with an angle grinder with a small disc. It is thus possible to obtain a high-precision right-angle fit with edges as close as possible.