How to cut a pipe at 90 degrees

Cutting technology

As a rule, the volume and complexity of the work to be done by the home craftsman does not require the use of high-performance and expensive equipment of a production level. When making a greenhouse frame, you can completely cut pipes with an angle grinder or a traditional hand hacksaw.

Each type of cut has its own nuances, and some require special tweaks.

Tapping into a pipe under water pressure

We install the clamp on the pipe and tighten the bolts connecting its halves. When tightening the bolts, distortions between the saddle halves must be avoided. It is advisable to tighten the bolts crosswise.

Как отрезать трубу под 90 градусов.How to cut a pipe 90 degrees.

After that, an ordinary ball valve of a suitable diameter must be screwed into the saddle thread. How to choose a high-quality ball valve and open it if it is jammed, you can see in this article.

It remains only to drill a hole in the pipe through the open ball valve.

First, we determine the diameter of the drill. To obtain a good flow of water, it is advisable to drill the hole with the largest possible diameter. But in this case, the ball valve has its own hole. This hole is smaller than the inner diameter of the valve thread. Therefore, the drill will have to be selected for this hole.

During drilling, it is important not to snag the PTFE seals inside the ball valve with the drill. If they are damaged, the tap will no longer hold the water pressure

For drilling plastic pipes, it is best to use wood drills or core bits. With these drills, the fluoroplastic valve seals will remain intact and such drills will not slide off the pipe at the very beginning of drilling.

During drilling, you do not need to worry about the chips, they will be washed out with a stream of water when the hole is drilled.

There are a few tricks to drill holes safely and easily.

Since there is a high probability of splashing water in the process of making a hole, it is not advisable to use a power tool. You can of course use a mechanical drill or brace. But they will be difficult to drill metal pipes. You can use a cordless electric screwdriver, even if it is flooded with water, the electric shock will be minor. But an electric screwdriver may not have enough power at one important moment. When the hole is almost drilled and the drill has almost passed the pipe wall, it can get jammed in the metal pipe wall. And then the situation will turn out that water is already flowing under pressure to the tool, and the hole has not yet been drilled to the end. It may not necessarily happen, but it’s worth remembering.

Especially desperate people use an electric drill, but they do the work with a partner who unplugs the drill from the outlet when water appears.

To protect the instrument from the flow of water, you can put it in a plastic bag.

Or put a circle with a diameter of 200-300 mm made of thick rubber directly on the drill, which will act as a reflector. You can even use thick cardboard instead of rubber.

There is also a simple and affordable way. A 1.5 liter plastic bottle is taken. A part with a bottom of about 10-15 cm is cut off from it, and a hole is drilled in the bottom. We put this bottom on the drill with the cut part from the drill and with this device we drill the pipe. The bottle should cover the tap. The flow of water will be reflected by a semicircular bottom.

Methods for cutting large diameter pipes

There are a number of reliable tools available for cutting large diameter pipes such as sewers. Next, we will consider some of them in detail:

An angle grinder is an inexpensive and affordable option, but it is not considered the safest when working with such materials. Once you decide to use this method, then be careful and use protective equipment. A roller machine (pipe cutter) is such a tool adapted for such manipulations. The device is attached and material removal begins. Clamping force is mechanically adjustable

It is important to note that the models of the machine differ in shape, so consider the ratio of dimensions to the pipe before use. Flame cutting is the most popular option for cutting larger diameter pipes, sheet metal. The cut occurs due to the action of a high intensity flame, the metal melts and leaves the cut zone with a gas flow

A quick way to cut a pipe lengthwise with an angle grinder:

Pay the main attention to the markup. Use for such a case the painter’s thread, which has found distribution when marking walls.

Before starting work, fix the pipe and with small movements, carefully saw the pipe. Better not to rush, but delicately and slowly process the parts of the pipe, so the cutting disc does not jump off the marking lines. Remember safety.

Thin-walled pipes are made of non-ferrous metals: aluminum, copper. Such work should be done delicately, since there is a high probability of material deformation. Fillers such as sand are used for cutting. Actions can be carried out using an angle grinder, a special machine.

Outdoor system installation

Installation of sewage from plastic pipes outside the building is carried out, in most cases, inside an earthen trench. This is due to:

- the need to protect the plastic sewer structure from the effects of negative temperatures;

- rational use of the surface of the earthen plot; protection from possible mechanical damage.

Installation of sewerage systems outside the trench is carried out:

- in the presence of a high level of groundwater (wetland);

- rocky or frozen ground (permafrost);

- other technical limitations.

Installation of sewer pipes on the site is carried out mainly in the warm season. So it is easier to install sewer pipes. a more comfortable climate and the presence of thawed earth.

Outdoor products. red pipes, made of polymers. You can cut or trim parts in the same way as for indoor structures. Installation of sewer plastic pipes is carried out on its own or with the involvement of a third-party organization.

The way. how to cut the parts when the installation of sewer pipes takes place indoors or outside the building, it is advisable to think over in advance, before starting work. Otherwise, the necessary device or tool may not be at hand, which will significantly complicate the process of installing the line.

How to cut a furniture pipe

When making furniture using pipes, you need to be able to cut them into the required size with an accuracy of a millimeter, while maintaining the cleanliness of the cut, which means you need a suitable tool for these purposes. A profile pipe of rectangular (square) or oval cross-sections can be cut, for example, with a hacksaw for metal or an angle grinder (angle grinder). In the case of a round pipe, we have the opportunity to use a pipe cutter.

Roller pipe cutter. a tool for precise cutting of circular pipes using the principle of narrow-local deformation (indentation) of the pipe wall along a circular, closed mowing line of the cut.

A typical hand-held pipe cutter consists of three rollers: a pair of wide support rollers and one sharp cutter. The distance between the rollers is adjustable, it is changed by rotating the handle, which allows the tool to work with pipes of different diameters, as well as maintain a stable high efficiency of work, by reducing the inter-roller distance as the cutting roller sinks into the pipe wall.

In the furniture industry, pipes of five diameters are used: 16, 25, 32, 50, 60 mm. You can purchase one large and heavy, but universal pipe cutter for working with pipes of any specified diameters, or you can have two tools: one high-quality and small for pipes up to 25 mm inclusive, the second for pipes of large diameters (if necessary). The second option is preferable, since it is rarely necessary to cut pipes over 25 mm in furniture production.

Almost all furniture pipes are thin-walled, with a wall thickness of no more than 1.5 mm. For this reason, cutting them with a pipe cutter is quick. If the cut at the end of the pipe does not look perfect, you can quickly make it so with a file.

Support rollers in the process of working with a pipe cutter can leave circular marks (micro-scratches, indentations) on the surface of the pipe. In cases where any flaws at the ends of the pipe are unacceptable, the working area should be protected with paper tape.

The algorithm for working with a hand pipe cutter is as follows. We install the tool at the place of the intended cut on the pipe, bring the rollers together to a degree of moderately tight rotation of the pipe cutter on the pipe, after several turns (as the resistance to rotation decreases) we bring the rollers together by a fraction of a millimeter and continue to rotate the pipe cutter in a circle, and so on. At the very beginning of the process, you need to carefully monitor that the resulting groove from the cutting roller is closed, otherwise you can get a marriage by cutting a long spiral groove on the surface of the pipe.

The main types of tools cutting propylene pipes

All modifications of equipment manufactured for cutting thermoplastic polymer propylene pipes are subdivided into several design options.

Precision scissors. have a fairly simple, reliable taps-split mechanism. This tool can dissect and fragment products with a diameter of 3.0–41.5 mm. The cutting tool has a steel blade (alloy grade) with a serrated bar, allowing for fairly easy, even cuts in propylene pipes.

Using precision scissors, you can easily cope with one hand, however, with large volumes of fragmentation of the material, fatigue of the muscles of the hand, forearm and shoulder quickly increases. The purchase of a tool implies a one-year warranty, valid only with the correct use of scissors.

The cordless pipe cutter is an automatic tool for ultra-fast (maximum 7.0 seconds), accurate cutting of medium-thickness propylene pipes (8.0–29.5 cm). The compressive force of the cutting surfaces is provided by a small, powerful electric motor.

Roller pipe cutter is an easy-to-use modification of the polypropylene cutting tool. Despite the simplicity of its design, the employee can make an absolutely even cut. In this case, the pipe elements are cut at an even (90 degrees) angle.

Attention! Any deviation in the process of cutting from an even, right angle (90 degrees) can provoke a breakdown of the tool or deformation damage to the lines of the cut!

Roller pipe cutters are available with telescopic extensions. These instruments are equipped with a ratchet device and generally resemble conventional scissors. This pipe cutter has, on the one hand, a C-shaped recess where the pipe to be cut is placed. The opposite side contains a sharpened cutting blade. After closing the handles with a brush, it cuts off the pipe in an even plane.

Guillotine pipe cutter is a device used for cutting large diameter pipes (63.5-350.0 mm). The tool is characterized by the presence in the design of a high-strength, sharp-edged blade covered with Teflon. Smooth pipe installation as well as slow cutting with very sharp blades contribute to the maximum smoothness of the end surfaces. This greatly facilitates the performance of subsequent electrofusion welding without additional processing of the pipe ends.

Gas cutting

This method is best for cutting large pipes. Burning, the fuel melts the metal and removes it with a jet of gas, blowing it out from the cut. When laying pipelines from pipes of very large diameter, the use of manual equipment turns out to be absolutely ineffective and costly. In such cases, large machines are used.

Miter box for cutting pipes

There is a simple tool, often used in everyday life, mainly for working with wood. It is called. miter box. So, the same device is suitable for cutting pipes, and at different angles. The miter box is commercially available, but if you wish, you can always make it yourself and adjust the structure to the required pipe diameter:

- Take a wooden board with a width equal to the diameter of the pipe, 400-500 mm long.

- Take two more boards of the same dimensions, but in width increased by the thickness of the first board.

- From three boards to assemble a structure in the form of an inverted letter “P”, where the first board is installed as a base.

- In the central part of the structure, mark a rectangle, the two sides of which run along the inner boundaries of the side boards.

- Divide the rectangle with diagonals and along the lines obtained on the upper edges of the side boards, make cuts down to the base.

In this way, a template for cutting at an angle of 45º is made. But with the help of a protractor, you can mark almost any angle and make cuts for a pipe cut for a specific angle. The advantage of the miter box is that the tool is suitable for repeated use. Working with the tool is permissible until the walls of the slots are worn to such an extent that they can provide high cutting accuracy. It is recommended to make the walls of the tool from a material of higher strength than wood.

This looks like a possible design of the miter box. a device thanks to which it is also possible to cut pipes at different angles.

However, a miter box, as a rule, is convenient to use for cutting pipes of small diameters and with a small wall thickness.

The advantages of the method are obvious. simplicity, ease of making a tool (miter box), cost-effectiveness, versatility.

The disadvantages of working with this type of equipment are the need to adjust the dimensions of the miter box to the pipe diameter, provided that an accurate cut is made. That is, for each pipe you will have to make your own instrument.

How To Cut Pipe At 90 Degrees || Cut Pipe At 45 Degrees || Notching Pipe

Also, using a miter box, you can only cut a pipe with a hacksaw for metal or pruning shears (for plastic products). This tool is not suitable for working with thick-walled metal pipes under the cut with an angle grinder.

Device for cutting a profile pipe at an angle

about pendulum abrasive cutting machine

Any device that frees your hands from the weight of an angle grinder can be considered the easiest to manufacture. One of them is a cutting machine, a variety of designs of which are in the world network. We offer a few more options.

Such attachments for an angle grinder will allow you to saw off pipes, fittings, cut sheet material, and more. When using any attachment for an angle grinder, such a machine can even cut or grind stone or ceramics (for example, tiles or brooms).

- a frame welded or screwed from a thick plate and squares;

- do-it-yourself triangles from sections of shaped pipes;

- pendulum part, cut and bent from sheet iron;

- handles and fixing unit for the angle grinder;

- corner stopper.

The bed is a regular slotted plate, to which the squares and a ring for the spring are welded.

The movable part is cut from the sheet and bent in the appropriate places. Approximately 1/3 of the length of the pendulum part, an axis is reinforced. a metal rod with a caliber of 10 mm. The axle for the spring is reinforced at the back. screw (bolt) M8 or M10.

An angular grinder with a handle is installed in front. It is welded or screwed onto a movable arm. The assembly must be securely fastened to avoid injury.

The triangles of shaped tubes are welded to the frame. The axis of the movable mechanism of the machine is installed on them. To prevent the axle from slipping off on the triangles, caps are welded or screwed.

Instead of triangles made of shaped pipes, ordinary triangles made and bent from a sheet of iron can be screwed onto the bed. A spring is attached to the frame ring and the bolt on the moving part.

For ease of cutting, attach a vise to the bed.

Precision cutting machines

Among the branded devices that could be used in everyday life to perform an angle cut, you can pay attention to the technique of Italian production. The Mini Cut band saw from the MASS company is a small-sized device with a hand clamp, for working not only with pipes, but also with corners, rods, and profile elements.

Convenient and productive machine for cutting small and medium-sized pipes. The cutter is made on the basis of a strip steel blade, which can be installed to perform an angle cut

The machine supports setting the cutting angle from 0 to 45º. The procedure is carried out using a tape belt at a speed of 45 reciprocating movements per minute. The device is equipped with a 370 W electric motor, which is powered by a household network. The maximum permissible diameter of the cut round pipe. 65 mm.

Programs for calculating cutting angles

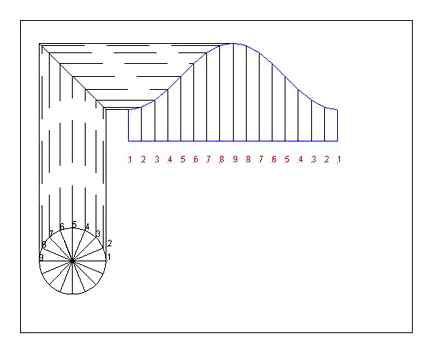

Curve cutting technology allows you to obtain different cutting angles. But to form a pattern at angles other than 45º, it will already be necessary to perform mathematical calculations and, according to the calculated data, cut out a template from paper or similar materials. True, there are computer programs designed to save the foreman from making calculations. Patterns for cutting pipes such programs are printed on a printer.

This is how the window of a computer program looks like, which calculates the cut angle for a circular section. Based on the results of the calculation, a pattern is drawn that can be printed by a printer.

A simple calculation program created on the basis of the MS Excel application allows you to calculate and compose a pattern for almost any values of pipe diameters and required cutting angles.

All the user needs to do is enter the corresponding values into the “Outside diameter” and “Cut angle” cells. According to these parameters, a pattern will be formed that can be sent to print.

An example of a pattern obtained by the calculation method in the popular Excel program. The calculation of the points of the curve is carried out on the basis of only two specified parameters. the pipe diameter and the required cut angle

The disadvantage of the program is that it does not take into account the thickness of the sheet of the pattern, which leads to minor inaccuracies.

Cutting products at an angle

You will not find such attachments for an angle grinder anywhere else. It is very often necessary to cut pipes or squares at some angle with your own hands. The simplest thing is to make a turntable with holes, which is fixed with an axis on the bed.

When fixing the mechanism for the first time, a hole is drilled in the horizontal plate of the bed (straight through the corresponding hole in the circle). This is necessary to fix the circle. A vise is installed on top of the circle with their own hands.

- Turn the circle with a vice to the desired angle.

- Insert a bolt into the holes in the circle and the bed.

- Clamp with a nut.

Tip: To rotate at any angle, make semicircular slots, weld the retainer bolt with the thread upward, and change the nut to a “wing”.

Simple tooling for cutting

Round and rectangular metal products with sufficiently thick walls can be conveniently cut at an angle using simple electromechanical equipment. The cutting element of such a tool is a cutting disc or circular saw attached to the motor shaft. In turn, the electric motor with a cutter is part of the entire equipment, which includes a work table, a pendulum support, a clamp.

Electromechanical device for cutting pipe elements, including at different angles. A disk cutter and a simple mechanical system of fastening the pipe in different positions are used

To install the pipe at the desired angle with its subsequent fastening, a conventional clamp and two metal corners are used. One corner (short) is attached to the base of the swing mechanism. the pendulum. The second corner (long) is in a free state.

- The swivel mechanism sets the required cutting angle (for example, using a ruler and protractor).

- The found position is fixed with clamping screws.

- A pipe is laid between the short and long corners and pressed with a clamp screw.

- Voltage is applied to the electric motor.

- By applying a slight pressure to the cutter blade, the pipe is cut in the right place.

The advantages of this technique are fast work, accurate cut, the ability to process a large number of pipes in a short period of time. Disadvantages: restrictions on domestic use, increased noise, work with pipes of only small and medium diameters. In addition, the process of cutting with equipment is carried out stationary at a distance from the installation site, which is not always acceptable.

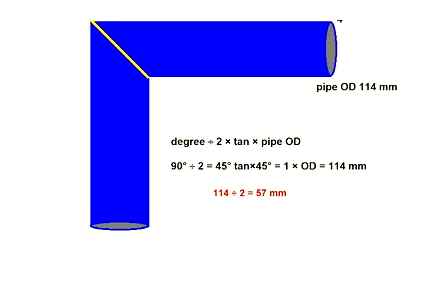

How to make a 90 degree pipe elbow

Pipes are a widespread building material. They are used in the installation of various systems. It is common during the installation process when pipes need to be joined at an angle. However, the technology for the production of such works is not quite common.

To create such a joint configuration, bevel cutting of the pipe is required. Consider how such operations are performed and what cutting methods exist.

Cutting at 45 degrees

Usually, in order to turn the pipe by 45 degrees, fittings are used, bends with a 45-degree rotation angle, made of the same material as the pipes themselves, if the pipes are steel, then the turns are welded from steel. For HDPE pipes, there are electrically welded or cast bends at 45 degrees (note that it is almost impossible to find compression fittings with such an angle of rotation in Russia).

But, if you still need to cut a round pipe made of steel or various types of plastics, then for this you need a piece for cutting pipes at an angle, the shape of which is calculated manually or by machine. The task is greatly simplified if at an angle of forty-five degrees it is necessary to cut a metal profile of a square cross-section.

For a quick cut, you can use a regular sheet of paper folded diagonally to mark the surface for the future cut. Using folded paper, proceed as follows:

- carried out on a straight surface of the profile in the place where the cut is made, strictly perpendicular to the line;

- apply a diagonally folded sheet of paper to the side surface with the sharp end to the mowing line so that the top edge of the paper triangle is flush with the top side of the metal profile.

- draw the line with a pencil along the side of the sheet at an angle of 45 degrees, after which the paper corner is applied to the other side and outlined with a pencil (it is better to use a thin marker).

For sawing, you can use an angle grinder with a disc for metal, drawing a thin line at the beginning along the markings, and then gradually deepening it until the edges are completely separated.

When working with an angle grinder, the following factor must be taken into account. if the edges are completely cut off, the disc can be damaged by an acute angle, which will lead to its failure, and in the absence of protection on the angle grinder, even to employee injuries. Therefore, it is advisable not to cut the corner edges to the end, but to leave a narrow groove and then break off, subsequently grinding the protrusion.

If you need to cut a large number of pipes, you can make a template from a metal profile of a larger diameter on a paper sheet in the above way. The angle of inclination is checked with a protractor or a construction square. in this case, the two edges of the trimmed parts of the template are connected.

When working on the part to be cut, a template is put on in the right place and pressed tightly, the markings are applied with a sharpened scribe when tracing the template contour. The part is cut in several passes with a gradual deepening of the groove.

Miter box for cutting pipes

There is a simple tool, often used in everyday life, mainly for working with wood. It is called. miter box. So, the same device is suitable for cutting pipes, and at different angles. The miter box is commercially available, but if you wish, you can always make it yourself and adjust the structure to the required pipe diameter:

- Take a wooden board with a width equal to the diameter of the pipe, 400-500 mm long.

- Take two more boards of the same dimensions, but in width increased by the thickness of the first board.

- From three boards to assemble a structure in the form of an inverted letter “P”, where the first board is installed as a base.

- In the central part of the structure, mark a rectangle, the two sides of which run along the inner boundaries of the side boards.

- Divide the rectangle with diagonals and along the lines obtained on the upper edges of the side boards, make cuts down to the base.

In this way, a template for cutting at an angle of 45º is made. But with the help of a protractor, you can mark almost any angle and make cuts for a pipe cut for a specific angle. The advantage of the miter box is that the tool is suitable for repeated use. Working with the tool is permissible until the walls of the slots are worn to such an extent that they can provide high cutting accuracy. It is recommended to make the walls of the tool from a material of higher strength than wood.

This looks like a possible design of the miter box. a device thanks to which it is also possible to cut pipes at different angles.

However, a miter box, as a rule, is convenient to use for cutting pipes of small diameters and with a small wall thickness.

The advantages of the method are obvious. simplicity, ease of making a tool (miter box), cost-effectiveness, versatility.

The disadvantages of working with this type of equipment are the need to adjust the dimensions of the miter box to the pipe diameter, provided that an accurate cut is made. That is, for each pipe you will have to make your own instrument.

Also, using a miter box, you can only cut a pipe with a hacksaw for metal or pruning shears (for plastic products). This tool is not suitable for working with thick-walled metal pipes under the cut with an angle grinder.

How to cut a pipe at 45 degrees: all possible options

When carrying out work on the installation of gas or water mains, it is often necessary to change the direction of the mowing line, while the pipeline is cut and then welded at the desired angle. Most often, the direction changes by 90 degrees, and the question arises. how to cut the pipe at 45 degrees in order to accurately connect the joints when welding.

It is possible to cope with the problem with cut edge angles of 45 or 90 degrees with the appropriate knowledge and techniques that will help save not only time, but also materials during work. At other angles of rotation, it is impossible to solve the problem with a ruler and a sheet of paper. you will have to call computer equipment for help.

Paper mold for pipe

To perform a relatively accurate cut, you can use a simple technique, where a regular sheet of paper acts as a kind of pattern. For example, A4 printer paper is well suited for creating patterns. Previously, the sheet is marked out under a square using a ruler. The size of the diagonal of the square must be equal to the circumference of the pipe to be cut. The excess parts of the sheet are cut off.

The easiest way to get a mowing line marking on a pipe is to make a 45-degree cut. A regular sheet of paper is used, which is superimposed on the pipe body in the cutting area

- Bend the sheet diagonally by aligning opposite corners.

- Turn the resulting triangle so that the hypotenuse line is perpendicular to the pipe axis.

- In this position, wrap the tubular surface with paper, aligning the extreme points of the hypotenuse together.

- Use a marker to mark the cut along the mowing line of any of the legs of the triangle.

- Cut the pipe to the intended mowing line.

This way it is quite convenient to mark and cut pipes at an angle of 45º in the range of diameters from 32 to 63 mm. For better markup convenience, it is recommended to use thick, but soft paper. Paronite and similar materials can also be used.

Simple tooling for cutting

Round and rectangular metal products with sufficiently thick walls can be conveniently cut at an angle using simple electromechanical equipment. The cutting element of such a tool is a cutting disc or circular saw attached to the motor shaft. In turn, the electric motor with a cutter is part of the entire equipment, which includes a work table, a pendulum support, a clamp.

Electromechanical device for cutting pipe elements, including at different angles. A disk cutter and a simple mechanical system of fastening the pipe in different positions are used

To install the pipe at the desired angle with its subsequent fastening, a conventional clamp and two metal corners are used. One corner (short) is attached to the base of the swing mechanism. the pendulum. The second corner (long) is in a free state.

- The swivel mechanism sets the required cutting angle (for example, using a ruler and protractor).

- The found position is fixed with clamping screws.

- A pipe is laid between the short and long corners and pressed with a clamp screw.

- Voltage is applied to the electric motor.

- By applying a slight pressure to the cutter blade, the pipe is cut in the right place.

The advantages of this technique are fast work, accurate cut, the ability to process a large number of pipes in a short period of time. Disadvantages: restrictions on domestic use, increased noise, work with pipes of only small and medium diameters. In addition, the process of cutting with equipment is carried out stationary at a distance from the installation site, which is not always acceptable.

The nuances of working with a rectangular section

To perform cutting of products of rectangular cross-section, it is recommended to prepare template cuts of the corners in advance. They are easy to make from a metal corner, having previously marked with the same protractor.

Cutting rectangular pipes (profile elements) at the desired angles is usually done according to templates. These templates are made from metal corners of different sizes.

Marking can be done at different angles. To use a template in business, it is enough to attach it to a rectangular pipe in the right place and mark the cutting line. Then, with any suitable tool, cut along the intended mowing line.

Pipe marking and cutting

The very process of marking the cut-off workpiece seems to be quite a simple matter. But it should be noted that the rounding made during the manual marking process will create an irreparable error after cutting, which will lead to inconsistencies and the formation of defective products. In order to eliminate such defects, it is required to make a simple tool for clear marking of the profile parts. This makes cutting products at an angle of 450 much easier. A regular 45-degree U-shaped steel section is a reliable tool for accurate pipe cutting. In this case, the size of the profile for the ruler must be selected so that it becomes possible to easily position the cut profile pipe in it.

Manual pipe cutting tool

To perform such a tool marking the correct angle, you must also have the following additional tool:

- Protractor;

- Scraper for metal;

- angle grinder;

- Cutting disc;

- File.

Tool for cutting pipes at an angle How to cut a pipe at an angle

BRILLIANT Idea For PIPE 90 degree Joint WITHOUT CUTOFF MACHINE

It is not difficult to make a measuring tool for cutting pipes. To do this, cut a segment 20-30 cm long from the profile blank. By means of a goniometer, at any end of the segment, it will mark an angle of 45 degrees. Next, cut off the profile with an angle grinder. The resulting template needs to be tested for accuracy. In case of deviations, file the measuring tool.

Using such a hand-made marking tool, the process of cutting pipes is much easier, especially with a large volume of pipes. To mark, it is only necessary to place the cut profile pipe in the made device and draw the correct angle with a scribe. During the marking process, the length of the products is controlled. Next, you need to cut the pipe clearly along the marking lines using an angle grinder. It is worth noting that at first the pipe is cut along the diagonal marks on both sides, then the straight, marked mowing lines are cut. These 45 degree pipe cutting templates will save you a lot of time and money.

Methods for cutting large diameter pipes

There are a number of reliable tools available for cutting large diameter pipes such as sewers. Next, we will consider some of them in detail:

- An angle grinder is an inexpensive and affordable option, but it is not considered the safest when working with such materials. Once you decide to use this method, then be careful and use protective equipment.

- A roller machine (pipe cutter) is such a tool adapted for such manipulations. The device is attached and material removal begins. The clamping force is adjusted using mechanical devices. It is important to note that the models of the machine differ in shape, therefore, before use, consider the ratio of dimensions to the pipe.

- Flame cutting is the most popular option for cutting larger diameter pipes, sheet metal. The cut occurs due to the action of a high intensity flame, the metal melts and leaves the cut zone with a gas flow. This method is convenient and effective.

A quick way to cut a pipe lengthwise with an angle grinder:

- Focus on the markup.

- Use for such a case the painter’s thread, which has found distribution when marking walls.

- Before starting work, fix the pipe and with small movements, carefully saw the pipe.

- Better not to rush, but delicately and slowly process the parts of the pipe, so the cutting disc does not jump off the marking lines. Remember safety.

Thin-walled pipes are made of non-ferrous metals: aluminum, copper. Such work should be done delicately, since there is a high probability of material deformation. Fillers such as sand are used for cutting. Actions can be carried out using an angle grinder, a special machine.

Summing up, we emphasize that cutting metal pipes is a complex process, but anyone who wants to enhance it can enhance it. With the advice of a professional, you can easily cut pipes in a variety of sizes and materials. Also remember to file or sandpaper the edges of the pipes after cutting. And the most important thing to remember when starting such actions is safety precautions. Wear a special suit (casing), mask or goggles when getting started. Hands should also be reliably protected from sparks, so use thick gloves.

In various situations, household-level masters often come to the issue of correct marking for accurate cutting of pipe blanks at an angle of 45 degrees. Today there is a huge selection of tools, both for the domestic and industrial process of cutting pipes at any angle. The cost of such devices can be quite high.

It is proposed to consider methods of marking workpieces for cutting at an angle of 45 degrees in a domestic environment without the use of expensive professional equipment.

Making a template for trimming a metal profile

If you need to cut a large number of pipes, you can make a template from a metal profile of a larger diameter on a paper sheet in the above way. The angle of inclination is checked with a protractor or a construction square. in this case, the two edges of the trimmed parts of the template are connected.

When working on the part to be cut, a template is put on in the right place and pressed tightly, the markings are applied with a sharpened scribe when tracing the template contour. The part is cut in several passes with a gradual deepening of the groove.

How to cut a pipe at a 90 degree angle

When carrying out work on the installation of gas or water mains, it is often necessary to change the direction of the mowing line, while the pipeline is cut and then welded at the desired angle. Most often, the direction changes by 90 degrees, and the question arises. how to cut the pipe at 45 degrees in order to accurately connect the joints when welding.

It is possible to cope with the problem with cut edge angles of 45 or 90 degrees with the appropriate knowledge and techniques that will help save not only time, but also materials during work. At other angles of rotation, it is impossible to solve the problem with a ruler and a sheet of paper. you will have to call computer equipment for help.

DIY pipe miter box

Using the template is not very convenient. you have to make a cut along the mowing line, keeping the angle grinder suspended, which leads to large errors. If you have a welding machine, you can make a simple miter box. guides for the disc of an angle grinder, which do not allow it to go to the side.

For this, a previously made template is used, in the side of which a hole is drilled and a nut is welded. When working, a homemade miter box is put on the profile, a bolt is screwed into its nut and the device is pressed against the profile surface. An angle grinder with a disc for metal makes a cut, slightly pressing the disc to the side surface of the device. It is clear that with long-term work, the edges in the miter box are gradually grinded, and although the process occurs simultaneously on all edges, some errors will appear over time. Therefore, it is better to make the device from hard wear-resistant metal in order to increase its service life and get a more accurate tool.

When dealing with construction or plumbing tasks, you need to know how to cut the pipe straight with an angle grinder. In the article, we will consider quick and easy ways of how to properly cut a pipe with an angle grinder so that the result is perfect.

Pipe cutting at an angle of 45 and 90 degrees

If you need to cut the pipe at an angle of 45 degrees, which is more often required when laying water, heating pipes. Steel, cast iron pipes that are cylindrical in shape are often used. In installation work, rectangular or shaped pipes are used. However, you should properly cut the pipe with an angle grinder, so that later it can be easily connected. Therefore, you should carefully mark the pipe.

Some craftsmen try to mark the place of the cut using a tape measure, but we warn you that the result is likely to be negative. And for a positive result, consider the following professional recommendation.

Take a sheet of paper or cardboard, preferably A4, fold it diagonally and wrap it around the pipe where you plan to cut it evenly. The edges of the paper should be exactly aligned with each other. And the side of the paper that is closer to the end of the pipe was perpendicular to the axis. Then mark the cut line in a circle.

If you need to cut exactly at an angle of 90 degrees, then solve the problem quickly using paper or masking tape again. Wrap around the pipe so the ends match. Make even lines and saw off.

Masters advise using a square when cutting a profile pipe. To do this, apply the square in turn to the sides, and turn and mark with smooth movements. After action, fix the pipe and cut. Prepare yourself a template that will come in handy in the future and save time. It is better to do the action with an angle grinder, so the cut will be smoother.

When working with a cast iron pipe, keep in mind that it is a brittle material. Therefore, we will point out a method with which it will be possible to cut such a metal without damage.

Before starting work, make notes for the cut, just like with steel pipes. Place a piece of wood for support. Run an angle grinder around the circumference of the pipe making small cuts. Then take the chisels, insert into the groove and hit hard with a hammer. Note that bakelite-based cutting discs are used to cut cast iron pipes.

If you do not have an angle grinder at hand to cut a cast-iron sewer pipe or other purposes, use a metal hacksaw, chisels or special pipe cutters.

Cutting a gas pipe is dangerous, so it is best to entrust it to professionals. But if you are confident in your strength, then to cut the metal, take an angle grinder, welding, hacksaw, gas welding.

- Shut off the gas riser before work. Then release the rest of the gas from the pipe. To do this, set fire to the gas in the burners and wait for it to go out.

- After the actions taken, cut. Using the welding method, the metal base burns out when exposed to high temperature. The result is fast and effective. But remember that cutting or rooting gas pipes again requires experience.

Cutting at 45 degrees

Usually, in order to turn the pipe by 45 degrees, fittings are used, bends with a 45-degree rotation angle, made of the same material as the pipes themselves, if the pipes are steel, then the turns are welded from steel. For HDPE pipes, there are electrically welded or cast bends at 45 degrees (note that it is almost impossible to find compression fittings with such an angle of rotation in Russia).

But, if you still need to cut a round pipe made of steel or various types of plastics, then for this you need a piece for cutting pipes at an angle, the shape of which is calculated manually or by machine. The task is greatly simplified if at an angle of forty-five degrees it is necessary to cut a metal profile of a square cross-section.

For a quick cut, you can use a regular sheet of paper folded diagonally to mark the surface for the future cut. Using folded paper, proceed as follows:

- carried out on a straight surface of the profile in the place where the cut is made, strictly perpendicular to the line;

- apply a diagonally folded sheet of paper to the side surface with the sharp end to the mowing line so that the top edge of the paper triangle is flush with the top side of the metal profile.

- draw the line with a pencil along the side of the sheet at an angle of 45 degrees, after which the paper corner is applied to the other side and outlined with a pencil (it is better to use a thin marker).

For sawing, you can use an angle grinder with a disc for metal, drawing a thin line at the beginning along the markings, and then gradually deepening it until the edges are completely separated.

When working with an angle grinder, the following factor must be taken into account. if the edges are completely cut off, the disc can be damaged by an acute angle, which will lead to its failure, and in the absence of protection on the angle grinder, even to employee injuries. Therefore, it is advisable not to cut the corner edges to the end, but to leave a narrow groove and then break off, subsequently grinding the protrusion.

Marking and Cutting Circular Pipes

When cutting round pipes at an angle of 45 degrees, the tool made for rectangular pipes is not quite suitable. For a more accurate. streamlined drawing of the mowing line of the cut at an angle, it is recommended to use a paper template, which is wound around the workpiece.

Patterns are developed in the modern world using computer programs.

the cut line changes depending on the angle and diameter of the pipe set in the program. Common patterns can be found on the Internet or remember our painted rulers from the school bench.