How to cut a pipe at a 90 degree angle

Cutting the pipe at a 90 degree angle

You can use a standard A4 sheet of paper, wide electrical tape, or construction tape to mark the [water and gas pipe] cut at a right angle. If you wrap a wide enough material around the pipe so that its edges coincide exactly when you overlap, you will get a perfect cutting line. If the tape or tape is tightly glued to the metal, you can go straight to the edge.

It is important to know how to use the grinder correctly, hold it with a certain force and follow the safety rules. The described technique is the simplest, it is also suitable for cutting a large-diameter pipe.

What tools are available

The tool for cutting pipes, as well as most of the existing tools, can be manual and electric. In both of these niches, in turn, there are specialized professional and applied amateur tools (learn here how to thread a pipe at home).

For example, the question of how to cut a plastic pipe can be solved in two ways.

On the one hand there is a professional secateurs, but on the other hand, you can use an ordinary hacksaw.

- If we talk about pipes from different types of plastic, then for the material with a cross-section of up to 75 mm, a mass of special scissors is produced, professionals call them secateurs type cutters. Since plastic is a rather dense material, all secateurs are equipped with a toothed mechanism that serves to increase the compression force. The price of such scissors starts at 10 and, depending on quality, can go up to 150.

- The next pro in cutting plastic is the disc pipe cutter. If the secateurs work on the principle of conventional scissors, here the cut is made with a sharp, heavy-duty disc. It presses against the wall and makes the cut by rolling around it.

The pipe cutter is indispensable for thin-wall products, because it is difficult to cut thin-walled plastic pipe with a pipe cutter because it crumples.

- The question of how to evenly cut a large-diameter pipe in professionals is solved simply, for this purpose there is a guillotine, adapted to the cutting of round products. It works in a classical way, with a knife on top and a semicircular bed on the bottom.

The machine can be electrically powered and cut with hydraulics. There is also a guillotine with manual, screw drive.

- In addition there are many specialized machines. So for a perpendicular cut, lathes are used. If the question arises as to how to cut the pipe at 45 degrees or any other angle, then here, as a rule, you need band saws.

Important: the main difference between professional and amateur tools is that the cut is made with particular precision. Plus the edge doesn’t need any additional machining after the job is done.

- But the right device is not always at hand, and buying it separately is expensive and not always makes sense. The leader among amateur tools is considered an ordinary hacksaw for metal. It can easily cope both with metal and plastic, the main thing correctly mark, but about this a little later.

- Every good owner always has an angle grinder. With its help, having a certain skill, it is possible to dissolve small and medium-diameter pipes accurately enough. A big plus of angle grinder is that it can be used to work on any material, from polyethylene, to cast iron or steel.

- At the end of our ranking is an electric jigsaw. It is undoubtedly possible to work with it, but it is difficult to make precise cuts, plus the edges of the pipe need additional work.

Power tool for large diameter pipes.

Cutting at a 45 degree angle

Usually in order to turn the pipe in 45 degrees use fittings, elbows with an angle of rotation of 45 degrees, made of the same material as the pipe itself, if the pipe is steel, then the turns are welded from steel. For HDPE pipes there are electric welded or cast 45 degree bends (note that the compression fittings with this angle in Russia find almost impossible).

But if you still need to cut a pipe with a circular cross-section made of steel or various types of plastic, you will need a template for cutting pipes at an angle, the shape of which is calculated by hand or machine. The task is greatly simplified if the angle of forty-five degrees to cut a metal profile with a square cross-section.

For hasty cutting, you can use an ordinary piece of paper folded diagonally, with which to mark the surface for the future cut. Using folded paper, do the following:

- draw a line strictly perpendicular to the straight surface of the profile in the place where the cut is made;

- lay the paper folded diagonally to the side surface with the sharp end to the mowing line so that the upper edge of the paper triangle is flush with the upper side of the metal profile.

- spend a pencil line on the side of the sheet at an angle of 45 degrees, then the paper corner is attached to the other side and trace it with a pencil (better to use a thin marker).

For sawing, you can use an angle grinder with a disc for metal, first conducting a thin line on the marking, then gradually deepening it to complete separation of the edges.

When working with an angle grinder must consider the following factor when fully cutting the edges of the disk can be damaged on a sharp angle, which will lead to its failure, and in the absence of protection on the angle grinder even to injury to the employee. Therefore, it is desirable not to cut the corner edges all the way through, but to leave a narrow groove and then break it up, sanding down the projection afterwards.

Making a template for cutting metal profile

If it is necessary to cut a large number of pipes, you can make a template from metal profile of a larger diameter using a paper sheet in the above way. The angle of inclination is checked with a protractor or a construction angle piece in which case the two edges of the cut parts of the template are connected.

At work on a detail in a necessary place put a template and it is tightly pressed, the marking is put by sharply sharpened eraser at outlining of a template contour. The piece is cut in several steps with a gradual deepening of the groove.

The chair for cutting pipes with your own hands

Using the template is not too convenient you have to make a cut on the line, holding the angle grinder on weight, which leads to large errors. If you have a welder, you can make a simple jigsaw guide for the disc of the angle grinder, preventing him from going sideways.

To do this, use a previously made template, in the side of which a hole is drilled and a nut is welded. When working, a homemade jig is put on the profile, a bolt is screwed into its nut and the device is pressed against the profile surface. Angle grinder with a metal disk to make a cut, slightly pressing the disk to the side surface of the device. It is clear that with prolonged work, the edges in the grinding mill gradually grind, and although the process occurs simultaneously on all edges, over time there will be some errors. Therefore, it is better to make the device from hard, wear-resistant metal, to increase its service life and obtain a more accurate tool.

How to cut a profile tube evenly across

Most often in the household use rectangular or square tubular metal profile with a wall thickness of no more than 3 mm, and cutting into separate sections is necessary when carrying out work on the assembly of welded frameworks.

In order to properly cut the pipe, additional devices are used to mark and mark the cutting line, some of the devices act as a supporting edge for the cutting disc.

Nuances of working with rectangular section

Blanks of rectangular cross-section is much easier to cut along and across with any angles than cylindrical elements, which are difficult to hold stationary on an even surface. Cross cutting of blanks under any angle does not represent any special difficulties. a line of the necessary angular slope is carried out on a side face and always coincides with the calculated (round elements require the use of special molds, calculated on the computer, to match their faces at an angle different from the right angle).

The wall thickness of metal profile when used in the household is rarely more than 5 mm it is easy to cut with an angle grinder any disk on metal.

What tool is used

As noted above, the main tool for cutting metal parts in domestic conditions is an angle grinder, in its absence you can use a hand saw for metal or electric jigsaw, which can also cut metal materials with a special diamond-coated blade.

For cutting with an angle grinder, electro-corundum cutting discs that are not designed for grinding operations are used. As an auxiliary tool a tape measure, a metal ruler, various types of clamps, pencils and markers for marking are useful.

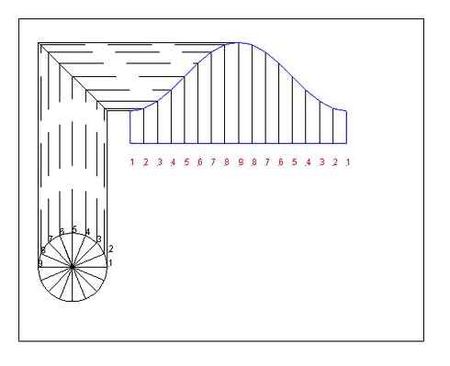

A paper template for a pipe

Using a paper sheet is a simple method of marking a rectangular or square profile for precise trimming at an angle of 90 or 45 degrees in the direction of its axis.

To make a marking for cross-cutting at an angle of 90 degrees, they take a sheet of paper and wrap it around the pipe until the exact alignment of the edges, and then they are glued. In this way the cutting line is very well visible, unlike drawing it with a pencil or marker on the edge of the template.

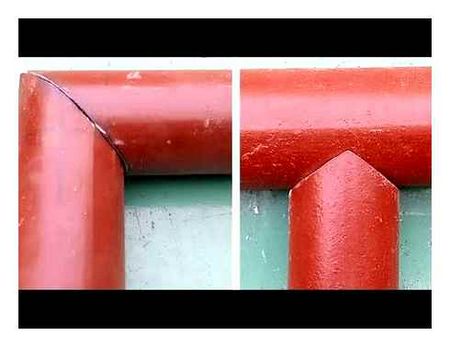

After that cut the profile along the template edge alternately on all sides, trying not to allow complete cutting through the finish sections this may lead to the disc hitting the sharp corners and destroying it.

A sheet of paper can also be used to mark the sides of rectangular or square pipes. To do this, the paper sheet is folded diagonally, and the resulting angle of 45 degrees is applied to the side walls and make the appropriate markings. To ensure that the sides of the mowing line are at the same level, a sharp angle is applied to the transverse mowing line placed at a 90 degree angle to the axis, which is pre-applied in the above manner.

The pipe cutter

It is very convenient to cut a profiled tube using a special template, which is analogous to a construction chisel for cutting construction materials at different angles.

To do this, the above or other way to make a metal template from a piece of cut lengthwise profile pipe, it can be designed to obtain a straight or 45 degree angle.

To cut the metal profile, the template is attached to it and a line is drawn with a scraper, which is then used to make the cut. In other cases the template is retained and the angle grinder guides the fishing line along the surface of the workpiece, taking care not to press the side surface of the disk firmly against the attached metal template. Then the template is removed and the cutting continues along the clearly visible indentation on the facets of the workpiece.

The template can be used to produce a very even cut line if it is not held by hand, but secured to the workpiece with clamps or fastening screws. For self-made fasteners in the side surface of the U-shaped plate of the template drill a hole and weld at this point from the outside of the captive nut, into which a bolt is screwed. To secure the template, place it on the part to be trimmed and screw in a bolt, pressing the template surface to the workpiece, then make the cut with an angle grinder with a disc for metal, slightly touching the guide edge.

Other alternatives

A good option for template making is to use a short piece of larger diameter pipe for marking, with the guide edge pre-cut at the desired angles. When marking, the part is put on the pipe to be cut, and then its surface is marked with a marker or a scribe. The second way rigid fixation of the template on the workpiece with wedges or clamps with further cutting with a disk on metal with light pressing to the side surface of the template part.

In order not to cut a metal pipe or sheet iron by eye, some craftsmen at home use homemade fasteners to the angle grinder, rigidly securing it to a vertically mounted spindle. When moving the tool from top to bottom a stable even cut occurs in the workpiece below the disc, if the machine bed is fitted with metal slides, then any desired angle of cut can be achieved when holding the workpiece against them.

Cutting a large diameter sectional tube

Metal profile of large diameter has thick walls and heavy weight, if for cutting thin-walled parts (wall thickness up to 2 mm.) you could use thin discs about 1 mm in size., then for cutting thick-walled metal take 2 mm. disc wheels. Accordingly, it is more convenient to cut thick walls with a disc of large diameter using a powerful large-sized construction angle grinder household devices do not have enough power to quickly perform the work, and their small discs quickly wear out.

When carrying out the work, the following rules apply:

new trick to cut 90 degree angle round pipe the welder never told before #pipecutting

- When heavy pipes are cut, they should be placed on flat ground or low supports so that when the last pipe section is cut it should not change its position or be lowered downwards to prevent the cutting tool from compressing its walls.

- If the surface is flat, each edge is completely cut, turning the part; if the support is uneven the last lintels are not cut a bit, allowing the workpiece to separate under its own weight, then the protruding area is ground.

- When working with angle grinders to cut heavy metal parts, a protective hood must be worn, the risk of the disc splitting into separate elements is too high.

Many people work with the wrong direction of rotation on themselves that results in constantly teasing the sharp edge of the metal, the tool is harder to hold in a fixed position, and the cutting wheel is worn out faster. Furthermore, the reverse direction of rotation of the cutting wheel is dangerous from a safety point of view.

Using a water tank

What to do if we are dealing with a pipe of small diameter, and we need to cut the pipe at an angle somewhere near the edge? A deep reservoir filled with water will come to the rescue. Before starting work, you must calculate the angle of inclination and make a mark on the vessel. Next, we just have to carefully lower the edge of the tube into the water and bend it to the mark on the tank. We take out the pipe, mark the line of contact with the water, and boldly cut according to the marking. This method is good for marking a large number of pipes. A ready template from a container of water will speed up our work.