How to cut a pipe at an angle of 45

How to cut a profile pipe

Profile pipes are widely used in the home. The material is used for the construction of greenhouse complexes, benches, tables and other garden furniture, sheds, swings and other small architectural forms. For this reason it is important to know how to properly perform cutting of profile pipe at an angle of 45 degrees, 90 ° and so on, as well as along the.

How to properly cut pipes of different metal

Accurate cutting and trimming of pipes depends not only on a competently made marking. The material is also important. metal of different thickness and hardness is cut with different efforts and side effects. To properly cut a cast iron pipe, it should not be sawed all the way through. Cast iron. a fragile metal, so usually make a few notches, and then a specialist chisels a piece of it with one precise blow.

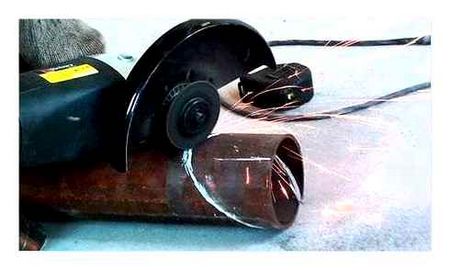

To work with thin-wall pipes it is necessary to very accurately align the position of the angle grinder. In this case, the master must correctly pick up [discs for cutting metal with an angle grinder]. In industrial settings, special pipe cutters, gas cutters and welding machines can be used to perform the same tasks.

IMPORTANT: Seamless stainless steel pipe

Safety when cutting a gas pipe

When working with gas pipes connected to the mains, it is important to observe safety precautions. First shut off the gas tap, then make sure there is nothing in the pipe. To do this, it is enough to open the burners of the stove and light the gas. when it runs out, the flame will go out.

How to cut the pipe at an angle of 45 degrees

When carrying out work on the installation of gas or water mains, it is often necessary to change the direction of the mowing line, and the pipeline is cut and then welded at the desired angle. Most often the direction is changed to 90 degrees, and the question arises. how to cut the pipe at a 45 degree angle to accurately connect the joints when welding.

To cope with the problem with 45 or 90 degree angles of the cut edges is possible with the appropriate knowledge and techniques that will save not only time but also materials during the work. At other angles of turn it is impossible to solve the problem with a ruler and a sheet of paper. you will have to call a computer technician for help.

Cutting pipes at an angle: the pros and cons of different ways

Pipes are a widespread construction material. They are used in the installation of various systems. A common case in the installation process is a situation where the pipes must be joined at an angle. However, it is not quite usual to see the technology of such works.

To create a similar connection configuration, pipe cutting at an angle is required. Let’s see how such operations are performed and what cutting methods are available.

Techniques for cutting pipes at an angle

Considering the methods of work. cutting straight or at an angle. it is necessary to take into account the different material of the products to be processed. So, hoses made of polypropylene or thin copper are easier and easier to cut than thick-walled steel pipes.

Plastic products of small diameters can be cut at the right angle using special scissors. You can control the angle with an ordinary protractor.

In the process of working with these installation elements it is very often necessary to cut pipes. A popular tool for such cases is the so-called angle grinder. This tool is used to cut straight and at an angle

The most common installation requirement is cutting water or other pipes at a 45º angle. Let’s find out what tools can be used for cutting at this and other angles.

A paper template for a pipe

To perform a relatively precise cut you can use a simple technique, where an ordinary sheet of paper acts as a kind of template.

For example, A4 size printer paper is good for making a template. Preliminarily mark the sheet under the square using a ruler.

The size of the diagonal of the square must be equal to the length of the circumference of the tube to be cut. The unnecessary parts of the sheet are cut off.

The simplest way to get a scythe line marking on the pipe to make a cut at an angle of 45 degrees. An ordinary sheet of paper is used, which is superimposed on the pipe body in the area of the cut

- Fold the sheet diagonally, aligning the opposite corners.

- Turn the resulting triangle so that the line of the hypotenuse is perpendicular to the axis of the pipe.

- In this position wrap the paper around the pipe surface, aligning together the extreme points of the hypotenuse.

- Mark the cut marker on the mowing line of any of the triangle’s cathetuses with a marker.

- To cut the pipe according to the intended mowing line.

It is convenient to use this method to mark and cut the pipe at an angle of 45º in the diameter range from 32 to 63 mm. For more convenience of marking it is recommended to take a thick, but soft paper. You can also use paronite and similar materials.

Cutting Angle Calculation Programs

The technology of cutting by templates allows to get different angles of cut.

But to form a template for angles other than 45º, you will already need to perform mathematical calculations and according to the calculated data to cut a template from paper or similar materials.

How to cut a pipe evenly angular grinder at 45 and 90 degrees | Methods of cutting

In working with construction or plumbing tasks, you need to know how to evenly cut the pipe with an angle grinder. In this article we will consider quick and easy ways to cut the pipe with an angle grinder to obtain the perfect result.

Cut the pipe at an angle of 45 and 90 degrees

If you need to cut the pipe at an angle of 45 degrees, which is often required when laying water pipes, heating pipes.

Often steel, cast iron pipes are used, which have a cylindrical shape. Rectangular or profile pipes are used in installation works.

However, you should properly cut the pipe with an angle grinder, so that it can then be easily connected. Therefore, you should carefully mark the pipe.

Some masters try to mark the place of the cut with a tape measure, but we warn you that the result will most likely be negative. And for a positive result, consider the following recommendation of professionals.

Round Pipe Cutting idea // 45 Degree Angle Cutting

Take a sheet of paper or cardboard, preferably A4, fold it diagonally and wrap it around the pipe where you plan to make an even cut. The edges of the paper should absolutely coincide with each other. And the side of the paper that is closer to the end of the tube was perpendicular to the axis. After that, mark the cutting line in a circle.

If you need to cut exactly at an angle of 90 degrees, then solve the problem quickly, again using paper or masking tape. Wrap it around the pipe so that the ends coincide. Make a straight mark and saw off.

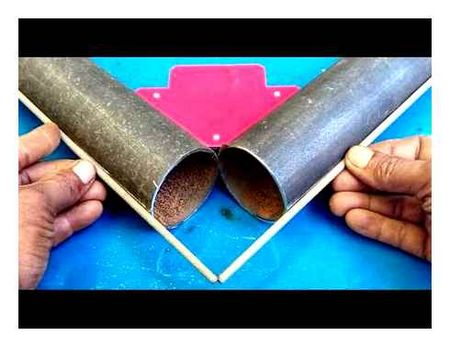

Masters are advised to use an angle piece when cutting a profile pipe. To do this, the angle piece in turn put to the sides, and with smooth movements turn and apply the marks. After the action, fix the pipe and cut. Prepare yourself a template that will be useful in the future and save time. It is better to perform the action with an angle grinder, so the cut will be smoother.

When working with cast iron pipe, keep in mind that it is a fragile material. Therefore, let’s introduce a method by which you will be able to cut such metal without damage.

Before you begin, make marks for the cut, as in the work with steel pipes. Put a wooden block as a support. Pass an angle grinder around the circumference of the pipe, making small cuts. Then take a chisel, insert it into the groove and hit it hard with a hammer. Keep in mind that bakelite-based cutting discs are used to cut cast iron pipes.

If you do not have at hand an angle grinder to cut cast iron pipe sewer or other purposes, use a hacksaw for metal, chisels or special pipe cutters.

Cutting a gas pipe is a dangerous action, so it’s best to trust professionals. But if you are confident in your strength, then for cutting metal take an angle grinder, weld, hacksaw, gas welder.

Method of marking with a container of water instead of a template

This method of marking is suitable for small-diameter pipes, which are planned to cut at a certain angle close to the edge. First prepare a deep container of water. The planned angle of inclination is marked on it. Now you need to carefully immerse the end of the product in the liquid, tilt it to the mark, and then pull it out.

As a result of such actions, a clear line of contact with water will appear on it, it must be highlighted. According to it, the pipe is cut at an angle. This method is best suited for work where multiple markings are required.

Marking and cutting the pipe

The process of marking the cut workpiece itself seems to be a fairly straightforward affair. But it should be noted that allowed rounding in the process of marking by hand will create an irreparable error after cutting, which will lead to inconsistency and formation of defective products. In order to avoid such defects, it is necessary to make a simple tool for clear marking of profile parts. Cutting workpieces at a 450 angle is made much easier. An ordinary piece of n-shaped steel profile, made at an angle of 45 degrees, will be a reliable tool for precise cutting of pipes. The size of the profile for the ruler must be chosen so that it is possible to easily place the cut profile pipe in it.

To make such a tool marking the right angle it is necessary to have the following additional tool:

It is not difficult to make a measuring tool for cutting pipes. To do this, you must cut a 20-30 cm long section from the profile workpiece. By means of an angle gauge on either end of the section, mark an angle of 45 degrees. Next, cut the profile with an angle grinder. The obtained template needs to be tested for accuracy. In case of deviations, treat the measuring tool with a file.

Using such a marking tool, made with your own hands, the process of cutting pipes is much easier, especially with their large volume. For marking it is necessary only to place in the made device to cut a profile tube, to trace by means of a scribe the correct corner. In the process of marking the length of the products is controlled. Next, the pipe should be cut cleanly along the lines of the markings, using an angle grinder. It is worth noting that first the pipe is notched diagonally on both sides, then the straight lines marked with mowing line are cut. Such templates for trimming pipes at an angle of 45 degrees will save enough time and money.

Inserting a profile in the center of a right angle

To the inner side of the resulting angle we place the end of the short pipe section vertically and draw a straight line as if continuing the line of contact of the two identical sections of the pipe.

We measure the distance from the outer point of contact of the ends of the two equal lengths to the end of the short piece. We set aside this distance along the sides of the short piece and draw a fishing line through them, and connect the ends with the middle of the end.

According to the obtained slanting lines we cut off the outer side fragments and put the broken line of the short section in contact with the line of the inner corner of the two slanting elements.

Profile pipe can be cut in a similar way, but it is easier to use an angle grinder. The device is applied in turn to each side, for which the element to be cut will need to be rotated, and a marking is made. Next, the pipe must be fixed in place and the work can begin.

Any suitable tool can be used for sawing. If you have a lot of pipes to cut, it is advisable to make full-fledged templates from scraps. In this case the measuring and marking work only has to be done once.

Cutting asbestos cement pipes with an angle grinder

The most common way is to cut asbestos-cement pipes with an angle grinder (aka angle grinder, angle grinder; something like Bosch GWS 850 CE Professional or Makita GA5030K).

In this case, there are 2 types of work, depending on the equipment used:

- angle grinder with a stone disk. You’ll need two people to cut it with this method. One of them must cut the pipe with the angle grinder, and the other one must use a very thin stream of water to the place of cutting. That way the dust from the cutting is not dispersed around the room, but runs down as dirt.

- An angle grinder with a diamond wheel. Here you will need a respirator, construction goggles and other protective equipment. To reduce the amount of dust that gets on a person when cutting, you should do this process in an open space with the leeward side, so that all the dust flies away. If you’re cutting a pipe in the winter, you can lay it flat on the snow to keep particles of material down.