How to cut a pipe at an angle of 90 degrees

How to cut a cast iron pipe

If the pipe is made of cast iron, you have to use some knowledge to cut it evenly. The thing is that this material is characterized by high fragility, which means that before you cut such a pipe you must determine the algorithm of actions.

- We mark out similarly to steel pipes.

- Place a wooden block as a support at the place where the saw is made.

- Then it is necessary to make a cut of a few millimeters around the circumference.

- After that, a chisel is inserted into the groove and it is necessary to make a sharp and strong blow with a hammer.

As a result, it will split along the mowing line, forming a fairly even cut that can be further trimmed if necessary.

View steel pipe cutter on AliExpress →

How to make a 45º cut on a profile pipe

Some “experts” argue that with a square cross section, which has a profile pipe, you can make a marking for the cut at 45 ° with a regular tape measure. HouseChief editorial board does not advise the reader of such a method, unless it is planned to spoil the material. The fact is that it is very difficult to perform such work perfectly when measuring with a tape measure. And here a school ruler in the form of an equilateral triangle will be very helpful.

An excellent tool not only for school, but also for work with metal

To begin, a straight line is drawn on one of the edges, perpendicular to the side of the pipe. Next, the product is rotated, and an oblique marking is applied to the adjacent edge, running from the edge of the first strip at an angle of 45º. Nothing needs to be measured here, everything is already done by the manufacturer of the triangular ruler. After that, the profile pipe is again turned and drawn perpendicularly. Now all that’s left is to connect the beginning and end of the mowing line on the fourth edge diagonally. All, you can safely work with an angle grinder. such cuts will perfectly join in a right angle of 90º. For easy work you can glue a masking tape along the edge of the strip. It will add clarity and make it easier to cut directly on the mowing line.

For the convenience of marking, if you have time, you can weld such a template

Using a water basin

What to do if we are dealing with a pipe of small diameter, and we need to cut the pipe at an angle somewhere near the edge? A deep container full of water will help. Before starting the work it is necessary to calculate the angle of inclination and make a mark on the vessel. Then we just have to carefully lower the edge of the tube into the water and bend it to the mark on the tank. We take out the pipe, mark the line of contact with the water, and boldly cut on the marking. This method is good for marking a large number of pipes. Ready template from a container of water will accelerate the process of our work.

Twisting the tube

This method is used when working with products with small diameters. Requires no additional attachments. A pencil or marker will come in handy. To use the method, you need to:

- Position the workpiece along the wall;

- One end to rest against the corner;

- Put the marker or pencil to the place of the cut;

- With the other hand, rotate the product to obtain an even circle.

This method can quickly draw the cut line.

Trimming pipes at right angles

The technique of cutting at a right angle is quite simple. You just need to fix the metal part, draw the markings on the cut line, and directly cut the workpiece. The end of the cut off part of the pipe must be over the support.

To make the mark for the cut, a wide or narrow scotch tape, marker or a simple pencil will do. You just need to wrap around the product, mark the place of the cut, and make an even cut. When you wind it, both ends of the tape have to fit together exactly

How to cut a pipe evenly with an angle grinder without marking, by eye. Locksmith tricks

If you are a beginner in welding or metalwork, or just love and know how to work with metal, then our channel is just for you!

I’ll show you an interesting way to cut a round pipe with an angle grinder. It’s an old locksmith’s trick, you can saw off a pipe without marking, by eye and fairly even.

First, see how to make a normal, precise marking for cutting a round tube at 90 degrees.

We take a flexible strip of metal or a piece of paper. We wrap the entire circumference of the pipe and mark the end of the tape or paper with a pencil or marker. That’s it, now we take the tool and carefully lead by this marking.

It’s pretty accurate. But if you don’t make these marks, is it possible to saw straight? At first glance it seems that you can not do it just by hand, it will still be crooked. No, there’s a trick, look.

Here we have a piece of galvanized pipe with an outside diameter of 48 mm. We’re going to face this pipe. As I said, we will not make any markings, why do we need all this trouble?! But in a simple way we saw off by eye.

When we bring an angle grinder with a rotating disc and touch the pipe with it, you get a picture like this.

We’re going to have a bunch of sparks coming out of the disc. And here on this stream of sparks we also correct the angle grinder, or rather the disk relative to the pipe that it was perpendicular. So you’re sawing at right angles to the pipe.

The sheaf of sparks won’t be exactly a thin line, it will change its thickness depending on the position of the plunge disc in the metal. But we can always visually see the center, the middle.

This stream of sparks, its middle, we need to put it at right angles to the pipe. Yes, you can’t do it to within a degree, but all the same, if you are attentive and careful, it’s not hard to keep this approximate right angle.

We make a cut in the pipe, we go a little bit deeper, then we twist the pipe a little bit towards ourselves. And from this kerf on the pipe we start to move the disk further. Also oriented so that the flow of the spark is at a right angle. And so around the circle we have to saw off quite accurately. Look at these pictures of the circular kerf.

We got a pretty straight cut all the way around, check it out.

It’s all worked out quite accurately. You can see it in the photo. We take an angle and check the whole circumference. There are small deviations, but they are no more than 1-1.5 mm. That’s an error we get even with the marking.

The method is simple, but very working and useful. It is certainly interesting and unexpected for beginners, I want to see it in a video-format, as it happened, and especially the cutting by the angle grinder. This video is on the channel, uploaded a week ago. Go to the channel itself and see.

Another frequently asked question is how to evenly cut a pipe with an angle grinder along. Here the algorithm of action will be about the same as in the cross-cutting

It is important to pay attention to the marking. You could, for example, use painter’s thread, as is usual for marking walls. Make sure the pipe is firmly supported in the process

The sawing process itself must be done carefully and slowly, because when sawing long elements there is a high probability of the cutting disc slipping off the mowing line of the marking

Make sure the pipe is firmly secured in this manner. The sawing process itself should be done carefully and slowly, because when sawing long elements there is a high probability of the cutting disc slipping off the marking line.

Cutting pipes at an angle: advantages and disadvantages of different methods

In the course of installation and plumbing work it is often necessary to cut blanks at a certain angle. Changing the direction of the cut line is necessary for further jointing and welding with other pipes of the same configuration, or for the installation of shut-off and control valves.

It is worth bearing in mind that the accuracy of the cut at the right angle is necessary to obtain high-density connections of rolled metal. To do this you need to have the necessary tools, quality pipe cutter and possess the appropriate experience in the processing of pipes.

BRILLIANT Idea For PIPE 90 degree Joint WITHOUT CUTOFF MACHINE

In this article we will consider methods of cutting pipes at different angles.

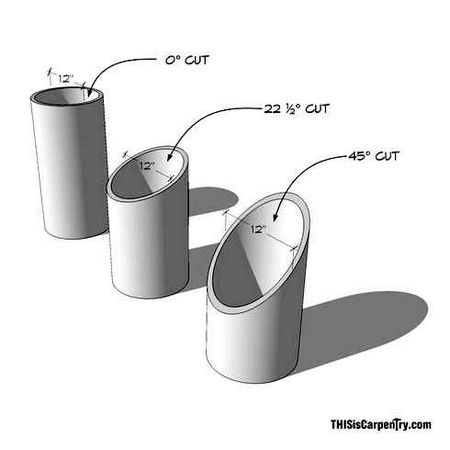

Methods of marking pipes at an angle of 45 degrees

Cutting pipe blanks at an angle of 45 ° is most in demand for the installation of heating mains, sewerage networks, gas pipelines. For this purpose they use pipes of ferrous metals and stainless steel of cylindrical cross-section, of small and medium diameter. 20-500 mm.

One of the main tasks when cutting pipes at an angle of 45 degrees is the accuracy of the angle measurement and flatness of the cut pipe, so that when joining the joined elements coincided with the accuracy of the millimeter. This is especially true for thin-wall pipes: if there is the slightest cutting error the walls of the pipes being joined will not fit together in the required configuration. That is why great attention must be paid to cutting accuracy.

- Fold a square piece diagonally with the opposite corners aligned. The length of the diagonal of the template must be equal to the circumference of the workpiece.

- The folded sheet is wrapped around the pipe. It is important to make sure that the side of the template closest to the end face of the workpiece is perfectly perpendicular to the central axis.

- The dotted line is marked in the place of the future cut.

- The next step is cutting the pipe.

Marking square and rectangular pipe

To make a template for marking a profile pipe it is advisable to use a similar workpiece with a larger cross-section. Markings on the workpiece are made once, using an engineering ruler or protractor. A profile is inserted into the cavity of the prepared template, marked and then cut.

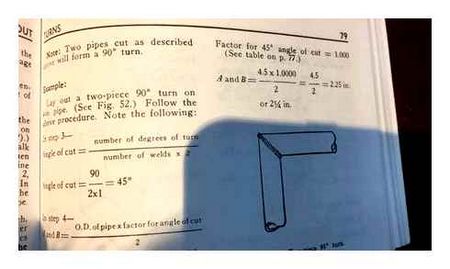

90 degree marking of pipes

It is easy enough to make a 90 degree angle marking of a pipe. If necessary a sheet of paper can be used: it is rolled around the pipe, fastened and marked. It is important to ensure that the edges of the sheet coincide around the circumference, then the cut will be even.

How to cut a profile pipe at an angle of 90 degrees?

For cutting pipe with a square or rectangular cross section it is preferable to use a triangle. Using this tool we mark each side of the profile in turn with a marker. After drawing the dotted line the cut of the pipe is made.

Marking pipes at other angles

To cut pipes at an angle of other values, you will need templates with the corresponding values. The template can be prepared using Excel or other computer programs by entering the pipe diameter, desired angle, etc in the appropriate window.д.

The calculation programs can calculate the cutting of any pipe diameter and angle. But more often this method is used to create a template for cutting pipes of small and medium diameter. Programmable cutting machines are preferred for cutting large-diameter and large-volume pipes.

How to cut the pipe using the “collar” method?

Often when installing water supply systems pipe billets are required that have a triangular cut at the end. This pipe configuration is required to join another pipe of circular cross-section at right angles.

- Measure the circumference of the pipe.

- You cut the pipe at an angle of 90 degrees.

- At the end of the tube mark equidistant points, which are relative to each other at angles of 90 and 180 degrees.

- The calculations are performed: the diameter of the pipe divided by three.

- From two diametrically located points postpone the received size and mark points.

- These points are connected with other smooth arcs.

- After cutting, the pipe cutting tool separates the semicircular segments, which are ready for subsequent welding work.

How many times to measure and how to cut the pipe evenly

When you have all the necessary tools at your disposal, you do not think about how difficult it is to perform certain routine operations correctly. For example, do you know how to cut a pipe evenly with an angle grinder?? It was with this request came to me from a neighbor in the garage, who, unlike me, is accustomed to do little with his own hands.

It turns out that after the dismantling of the plumbing in the apartment there was a lot of unnecessary pipe, out of which his wife decided to make a greenhouse in the cottage. I don’t know why he needed to cut the parts exactly straight, but I gave him all the necessary recommendations.

And at the same time I thought that other people who do not have in their arsenal of professional pipe cutters, will need the instruction, which describes how to cut the pipe under 90 degrees. That is why I have prepared the material, which I now present to your attention.