How To Cut A Plinth Floor

Components

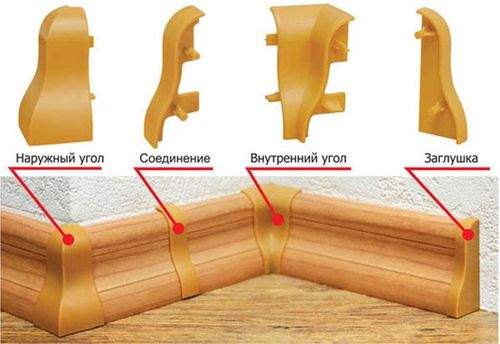

High-quality installation of skirting boards is not possible without the following components:

- External and internal corners, with the help of which the planks are connected in the corners of the room;

- Caps designed to decorate the edges of the skirting board. They come in a set and are left and right;

- Connections. a part with two grooves, which serves for joining and lengthening the strips;

- Fasteners for fixing the skirting board to the wall.

The advantages of plastic skirting boards

Among the varieties of skirting boards, plastic is the most popular for many reasons. Polyvinyl chloride is renowned for its durability and strength.

The lifespan of plastic floor slats reaches 100 years. They are fire and moisture resistant, safe, so they can be installed in any room.

Dimensions and construction of plastic skirting boards

Skirting boards are easy to install, cut with a sharp knife, and their cost is not high.

Compared to wood and plaster planks, plastic planks are flexible. Their color palette is huge, which does not limit the choice of the color of the interior of the room and allows you to fit into the general background as much as possible.

An additional plus is the equipment of some models with a special groove in which the wires are laid.

Determining the amount of material

How much material and accessories to take is a good question. It is impossible to determine by eye, accurate calculations are needed here.

Measure the length of the walls before attaching the PVC skirting board. Add 1.5 and 2 m to this number and divide the resulting amount by 2.5 m (the length of the bar). Rounding the resulting number up, we get the number of planks.

Skirting corners are needed as much as there are outer corners and inner corners in the room.

If the wall is more than 2.5 meters, then connections are needed. One connector is needed for every five meters.

Left and right caps are taken taking into account the number of doors in the room.

Fastening the plastic skirting board at the doorway

How to properly attach a plastic floor skirting board

Installation of a floor plinth is the final touch in finishing works, as it gives the interior a complete, refined look. It is known that the most luxurious renovation will not be presentable if the gaps between the wall and the floor are visible, which the plinth is intended to hide. In addition, it becomes a real lifesaver, able to hide minor defects in the floor finish.

If you are a beginner in finishing work and do not know how to fix plastic skirting boards, do not rush to contact the specialists. There are no difficulties in installing skirting boards with your own hands, and the nuances described below and a detailed overview of installation will allow you to save on the services of a master.

Required tools and materials

How to fix the plinth to the wall? Planks are mounted on screws, using clips or liquid nails. To fix on nails and clips, you will need a drill with different drill sizes, a screwdriver, a tape measure, fasteners, a hacksaw for metal and a vacuum cleaner.

Installation of plastic skirting boards

Having made the correct calculations and armed with the necessary tools, we proceed to the installation. Wooden planks are mounted in the same way as a plastic floor plinth is attached.

Cut off the plinth of the desired size with an ordinary clerical knife

When mounting on a dowel-nails, attach a strip with a dressed corner to one of the corners in the room. It is best to start with the longest wall. Place the corner straight so that there are no distortions during installation.

Mark the mounting location on the wall 5-6 cm from the corner. If the walls are flat, mark them 40 cm apart. If there are gaps, reduce the mounting pitch.

We drill a hole in the wall for a dowel

Now make the holes with a puncher. Keep in mind that the dowel should go 30 mm into the wall, and if the surface is uneven, dowel No. 6 is taken. Remove dust and hammer the dowels into the holes. Attach the skirting board to the wall and transfer the marks made to it. Then drill the holes. The heads of screws or nails must be completely immersed in the bar. To do this, make the notches with a larger drill.

We screw the screws into the dowels

Now you can nail the skirting board to the wall. Close them with matching caps. You can glue the plugs to hold them more securely.

The strips are already fitted to the desired size. It is better to cut them with a sharp knife or a hacksaw, so they will not crack. Keep sharp corners while doing this. Also, when cutting the extreme strips, keep in mind that the plugs will take 3-5 mm. If using connectors, install them before attaching.

How to cut the skirting board correctly. Miter box for cutting corners

When installing skirting boards, it is important to arrange the corners correctly. It is they who often spoil the overall picture. How to make a corner on the plinth. external and internal, how and with what to cut. We will discuss all this further.

Types of corners in rooms

When installing skirting boards, you need to arrange the corners in some way. By their appearance, the corners are external (which protrude forward) and internal (for example, corners in a room). In rooms with normal geometry, the corners are straight, i.E. 90 °. When joining two pieces of plinth strip in a corner, they are cut so that each has an angle of 45 °.

To arrange the outer and inner corner, the skirting board must be cut

But how to make an angle on the plinth so that it is exactly forty-five degrees? For this, a special carpentry tool is used. a miter box.

Miter box for skirting boards

A carpenter’s miter box is a device for cutting at a certain angle. It is used with a hacksaw. In principle, you can make a miter box yourself by collecting a guide from the boards and making cuts in the walls. There are various models on sale ranging from 15 to several hundred dollars. They differ in capabilities, materials, although all are called "miter box". Professional models are made on the basis of a good hacksaw, have a scale that allows you to set the saw as it should. With such a tool, it is not a problem to set any desired cutting angle in order to correctly cut the skirting board for a perfect fit.

Professional carpentry miter box. a tool with a wide range

The simplest miter box is a plastic U-shaped profile, in the walls of which slots are formed. These slots are used as a hacksaw guide. They do not allow the web to deflect. In any case, there are two cuts. straight and 45 degrees. Some may have a couple more options.

How to cut a plinth at 45 degrees? One way is to use a miter box

Sometimes a hacksaw is included, sometimes not. Usually the ones included are not very good. Any hacksaw can be used, picking up a blade for the material that is planned to be cut. It is important that the blade moves freely in the slots.

How and what to cut a plastic skirting board

All of the above applies to MDF and wood skirting boards. Cutting them with an ordinary hacksaw is not a problem. It is advisable to take a blade for metal, since it has a smaller tooth and the saw cut is smoother, you will have to work less with sandpaper. With plastic, the situation is different. when you try to cut a piece, some thin-walled skirting boards crumble and break.

Cutting plastic is not very convenient because of the thin walls

To cut normal quality plastic skirting boards you can use:

- Hacksaw for metal.

- Angle grinder (angle grinder) with diamond disc.

- A revolving miter saw. Before cutting, accelerate the disc and only then start cutting.

- Electric jigsaw and file with a fine tooth. Here you have to try. select the speed and file.

- Sharp knife.

- Scissors for metal. In any case, it is not difficult to make straight cuts with them.

Only personal experience will help you decide how it is more convenient for you to cut a plastic floor plinth. If you have a miter saw, try using it. It is not a problem to try an angle grinder with a diamond disc a couple of times. If all this doesn’t work well, try a hacksaw, jigsaw, or knife. There are, of course, special scissors for plastic, but they are too expensive to buy for a single use.

Accessories for the design of corners and joints of PVC skirting boards

In plastic skirting boards, you can design corners and joints using special fittings. There are external and internal corners, plugs and connectors. In principle, they allow you to assemble the desired configuration. Each manufacturer makes its own fittings. for its own profile, colors. But the principle of their use is the same.

How to shape the corners of a plastic skirting board

The first rule is that all cuts are made straight. Strictly perpendicular. The marks in the corners are set at a distance of 1-1.5 mm from the corner. The fact is that the rigidity hardware has its own jumpers. For them, it is necessary to retreat a couple of millimeters, but no more. Otherwise, a gap will appear or skirting boards will pop out of these corners.

This is the result of the assembly

I must say that not everyone likes the look of plastic corners. You can make a corner on a PVC skirting board in the same way as described for wood or MDF. The only difficulty is that you have to be careful with plastic. it breaks down from excessive efforts. There is one trick. before cutting the plastic skirting board, add a little polyurethane foam on the back side and wait for the polymerization to begin. It will be tougher, easier to cut, less deformation. If the foam subsequently interferes, it is not a problem to remove it, but to cut it is, indeed, easier.

First joint in the room

Cut the first plinth as close to the edge as possible. Carpenters have their own jargon and they say "cut" the corner. It does not matter what you call it, it is important that in the miter box we set the bar so as to make a cut at the very beginning. For the cutting line, we push the bar a short distance, for a start, you can 1-2 cm. Cutting a smaller piece is more difficult, so save the savings "for later" when at least some skill appears.

In the miter box, place the plinth at the far wall "facing" you. This makes it easier to check if you are cutting / sawing correctly.

Then you need to make a corner on the plinth like this:

- We put the plinth in the miter box, press it against the wall opposite to us. We expose it in the mounting position. how it will stand against the wall.

- Insert the hacksaw into the required slots (see the picture below).

- Move the bar so that it goes slightly beyond the cut line.

- Cut off.

- We take the second piece of plinth, repeat the same operations, but change the position of the saw on the miter box to the opposite. We insert the bar on the other side. Be careful here, otherwise you will have to redo it several times, since the connection will not work.

How to properly cut a floor plinth in a miter box: for external and internal joint

We got two pieces cut for joining in the inner corner. To make the joint perfect, we try on the details in place. Most likely there are some flaws. We take sandpaper with medium grain, remove everything that interferes with docking. Then, with small grain, we achieve a tight joint without cracks and gaps.

How to saw down the corner of the plinth at the right distance

The second and all other corners of the skirting boards must be made at a certain distance. If the next corner is again inner and the distance to it is less than the length of the bar, use the same fragment on which there is already a cut. We measure the distance with a tape measure. strictly from corner to corner. Then this distance is laid on the bar using the same tape measure. We combine the beginning of the measuring tape with the ledge, measure the required distance, make a mark with a pencil. She will be the starting point for the cut.

You need to know at what distance to cut

Plinth with a mark is placed in the miter box, the desired direction of the cut is chosen. The dash can be combined with a hacksaw blade or with a slot in the miter box. As it is convenient for anyone. Cut off. This segment must be "tried on" in place. If both corners rest against opposite walls or the gap is only 1 mm, everything is fine. You can cut a second strip from a new piece to design a joint. And again we remove the flaws with sandpaper.

If the length of the wall is longer than the length of the plinth plank, take a new plank. We will cut the second corner on it. It is important not to be mistaken in which direction to cut. Having installed both strips along the wall, mark the joint on one of them, make a straight cut. There are also slots for a straight cut in the miter box. So there won’t be any problems.

How to connect two skirting boards in a straight line

But the joint in a straight line does not always look perfect, and during operation it often diverges, forming a visible gap. If you wish, you can cut off at an angle (any) two planks.

To do this, first cut off the edge of one plank at an angle, mark the second joint. The mark is placed on the side of the plinth that is pressed against the wall. At this mark, we saw off another section, without changing the position of the saw relative to the miter box, but inserting the bar on the other side. The joint is oblique. It is more accurate. The difference is especially visible on wooden skirting boards and MDF. Cut, again, to bring "to mind" with sandpaper.

Cutting the plinth for internal corners

Despite the fact that rooms most often look like a regular rectangle, the corners in them are not equal to 90 degrees. Such a corner is the dream of any builder and repairman. If you are still lucky and have a classically correct angle, then to cut the skirting board, you need to do the following:

-

We place a wooden or plastic sheet in a miter box;

We find on the side panel a furrow and a mark of 45 degrees;

Focusing on it, we begin to saw the baseboard with a hacksaw;

When cutting the skirting board, remember which side it is on. When working with wood, a special putty will help to obtain the ideal angle.

If you are unlucky and your angles do not have 90 degrees, then you need to do the following steps:

-

We make small markings on the floor. Use a pencil or a washable marker for this. On one and the other side of the corner, it is necessary to draw the future border of the skirting board. In the corner, you will get a kind of rhombus. Its diagonal is the cutting line.

Attaching the plinth to the resulting rhombus, we mark its diagonal.

Draw a straight line from the resulting mark to the corner of the plinth. This is your cut line. Focusing on it, sawing is done with a hacksaw.

Some experts recommend making the cut at a low magnification. This will allow you to manually adjust the skirting board to the corner as accurately and tightly as possible.

At the end, it is necessary to insert a plug into the resulting joint to form a neat inner corner of the baseboard for the floor. If this is a tree, then the joint should be treated with putty and prepared for further painting.

Cutting skirting boards at non-standard angles

Modern design solutions in interior decoration often consist in the use of original forms. In this case, it is quite difficult to carry out the installation of a floor plinth in non-standard corners. After all, they are often both internal and external at the same time. Sometimes the corners are completely rounded. That is why the above docking methods are not suitable.

If you are dealing with a round corner, then you need to cut the skirting board into 4-5 pieces. Using the connection plugs, carefully lay out the entire corner in small pieces. Do not forget to fix them with glue or putty. This way, you will have a neat rounded corner.

If you have an inside-outside corner in the room, then you should take the following steps:

-

On one side, we apply a plinth and draw its border on the floor.

Now we apply the second half and make two marks: one is the intersection with the drawn border, the second is with the wall.

We connect the resulting points and make a cut.

If you use wooden skirting boards to finish non-standard corners, then instead of plugs you will have to use putty. After hardening, the resulting surface must be carefully sanded with sandpaper. And the principle of how to cut corners for a wooden plinth remains the same.

Forming outer corners on skirting boards

If you have a classic outer angle of 90 degrees, then the process of its formation is the same as the inner one. When cutting, you must remember which plinth you have on which side. After receiving the joint, it is necessary to close the ends with a special plug. If during the cutting process there are small flaws, they can be easily corrected with mastic, and then closed with a plug.

If you have non-standard angles, then cutting the skirting board comes down to the following steps:

-

We apply the canvas to one wall.

Using a pencil, mark its inner and outer borders.

We do the same with another skirting board.

As with the inside corner, we get a rhombus just outside. Its diagonal will serve as the cutting edge.

Using a file and a miter box, we cut.

We carefully clean the resulting ends and install the plinth.

Your outer corner of the plinth on the floor is ready, and you can finally fix the product around the perimeter of the room using self-tapping screws or special glue.

How to cut the corners of a skirting board

The acquired plinth must be cut according to the perimeter of the room. To make this process faster and easier, you can draw a diagram of it on a sheet of paper, marking all the outer and inner corners.

The main types of floor skirting boards

To date, skirting boards made of the following materials are used for interior decoration. wood, plastic, MDF.

Wooden skirting boards are a traditional type of finishing product. In old houses, only such were laid on the floor. Wooden skirting boards have a raised surface on the outside and special grooves for mounting wires and cables inside them. They are fixed with self-tapping screws, less often nails. It is allowed to use a sealant to fix them on the floor. If self-tapping screws are used for fastening, then dowels are pre-installed in the walls.

Among the advantages of wooden skirting boards are durability, environmental friendliness, safety for humans and animals, the possibility of reuse.

However, their use does not always hide the wiring. In addition, after installing a wooden skirting board, it must be additionally putty and varnished, paint, stain. In addition, wood is an expensive material, and therefore products from it will be distinguished by a high cost. And before cutting the skirting boards to the floor, you will need to prepare special equipment.

Plastic skirting boards are simple and convenient products for finishing flooring. In them, everything is most often thought out to the smallest detail: the design of the outer and inner corners, pockets for laying cables and wires, end caps, special fasteners for fixing on the wall and floor.

Plastic skirting boards are characterized by quick installation, a variety of colors, no need for putty and painting after installation, the presence of additional elements for sealing joints. This finish goes well with any flooring material: parquet, carpet, tiles, laminate, linoleum. Whatever coating you have, you can easily match a plastic skirting board to it.

However, plastic is a fragile material, and with a strong impact, chips and holes can appear on its surface. This will require a complete replacement of the entire whip of the product, as a minimum. Despite this drawback, modern builders prefer plastic skirting boards due to the large number of its advantages.

MDF skirting boards are environmentally friendly and attractive products. On their front side, paper impregnated with dyes is glued. over, the process is carried out at high temperature and under pressure. This excludes peeling of the decorative coating during operation.

A melamine coating is applied on top of the paper. It protects skirting boards from moisture and stubborn dirt. Even when exposed to direct sunlight, the product will not lose its appearance for many years. Also, the advantages of MDF skirting boards include quick installation, easy maintenance, cost-effectiveness, a wide palette of shades.

Before joining the floor plinth in the corners, remember that MDF is highly fragile. In the process of mounting and cutting such a product, extreme accuracy is important.

Plastic or MDF, from which skirting boards are made, are lightweight materials that have a large number of colors. That is why it is quite easy to choose a product for any interior decoration and design solution. Most often, when choosing a color for skirting boards, they are repelled by the shade of the floor covering.

How to join the floor plinth in the corners

Articles:

- Main varieties

- Installation tools

- How to cut the corners of a skirting board

Docking the floor plinth in the corners is a responsible process, which is important to carry out with high quality, since precisely defined, precise corners delight the eye and give the floor covering a complete look. To connect products and get a neat joint, you need to know the technology for cutting them and the existing methods of fixing. Before cutting the plinth, read the instructions and recommendations below.

Special fastenings. staples

The advantages of this method are that no obvious traces of fasteners are visible, the plinth is easily dismantled and re-installed. Although the latter circumstance, advertised by the manufacturer, in practice may not give an ideal implementation. Very often, the skirting board removed from the fastening cannot be ideally re-installed. Especially when it comes to metal mounts. The disadvantages include the fact that during installation, fasteners require the ideal condition of wall and floor surfaces.

Using self-tapping screws

This method is reliable and cheap. Before attaching the skirting board, you do not need to prepare the contact surfaces. Disadvantages of this method: the plinth looks a little rough, and when installing, more time is spent.

Installation of plastic skirting boards: a comparative overview of 3 fastening options

As you know, during the repair and arrangement of any room, insignificant details do not exist. over, sometimes seemingly minor interior elements actually play a key role in creating the perfect picture. Here’s what you think: what is more important than the floor or skirting board, which is installed last? If you think about it sensibly, then it is impossible to give preference. everything should be harmonious. As part of this article, let’s take a look at what it is like to install plastic skirting boards. Why exactly them? Yes, because they are currently clear sales leaders.

What tools and consumables will be needed?

Naturally, you need to have a well-equipped set of tools in the house. it will come in handy in many situations. But if we take specifically the installation of this floor element, then at least you must imagine in advance what will be required during its installation:

- Rotary hammer or hammer drill (drilling concrete walls).

- Screwdriver or conventional drill (drilling wood materials or drywall).

- Trimming machine (angle grinder) or hacksaw (will significantly reduce the time required for trimming parts).

- A set of attachments for a screwdriver or screwdriver.

- Roulette.

Even before buying, you need to calculate not only the number of skirting boards, but also take care of how to fix it correctly. Depending on the mounting option, you may need:

- Clips for fastening;

- Self-tapping screws;

- Glue or liquid nails;

- Dowels.

- Connecting profile.

- End cap (left).

- End cap (right).

- Outside corner.

- Inner corner.

Comparison of fastening methods

Fastening plastic skirting boards can be done in several ways:

- On special mounts;

- On glue;

- Simply screwed on with self-tapping screws.

Glue mount

The main advantage is the visually attractive appearance of the skirting board. Installation in this case is very simple: grease the material of the required length with glue and press it against the wall. Naturally, before installing corners, couplings and plugs. Disadvantages: in fact, it is impossible to dismantle without loss of appearance, and in most cases the deformation is critical. High demands on surface quality.