How to cut a round hole in wood

How to Cut Perfect Circles (and other Jigsaw Tricks) | Beyond The Basics

Features of working with the tool

The working principle with a circular drill is simple. A hole is drilled with a centering drill, and then the cutters are included in the work. They gradually make a narrow groove, gradually cutting through the material in a circle to the full depth.

The materials used in working with the ballerina are various: wood, fiberboard, chipboard, MDF, drywall, plastic. One common point. the thickness of the part should be no more than 15-20 millimeters. This parameter is limited by the length of the cutters. Usually the manufacturer indicates the maximum drilling depth on the packaging. When trying to drill thicker material, problems with ragged edges may occur.

Runout is typical for single-cut tools. This is caused by the lack of balancing with respect to the longitudinal axis of the drilling. Runout will be felt especially when cutting large diameter holes. Cut holes with a drill at low to medium speeds. When working on a drilling machine, such problems do not arise.

Also, inconvenience during work can be delivered by a laminated or veneered surface. After passing the decorative layer, drilling proceeds without problems.

A feature of the circular drill can be considered the ability to adjust the diameter. The distance between the incisors can be set on a scale on the bar or more precisely using a vernier caliper. This is convenient if you need to make a hole without gaps for a pipe or a round piece.

The spacing of the cutters from the center can be adjusted separately. It is necessary to position the cutting parts as accurately as possible. This will eliminate unnecessary effort during work and extend the life of the tool.

Tool functionality

A high-quality ballerina is made of high-strength steel, which makes it possible to use the device in working with soft and hard wood species.

This tool has an adjustable drilling diameter. This makes it possible to make holes of almost any diameter. The limitation of the drilling range depends on the size of the ballerina. Manufacturers produce fixtures with the following cutter range:

- from 30 to 120 mm;

- from 40 to 200 mm;

- from 40 to 300 mm;

- from 40 to 400 mm.

The maximum drilling diameter is limited by the bar on which the cutters are attached. Minimum. shank thickness.

The drill-ballerina can be used in any places where the use of a jigsaw or a hand router will be inconvenient. For example, this can be assembled and installed furniture, in which you need to drill a neat hole, taking into account the limited space. Another example is an uneven (curved or concave) surface. It is unlikely that it will work out with a jigsaw or a milling cutter. It will be difficult to control the tilt of the tool relative to the surface. A ballerina can easily cope with such a task.

What is a ballerina on wood

Adjustable circular drill “ballerina”. a device that is designed for drilling large round holes. The tool has a simple design. It is a shank with a transverse bar on which movable carriages with cutters are fixed. The rod has a marking, according to which you can set the necessary spread of the incisors relative to the center of the intended hole. A core drill is fixed in the middle of the shank. It serves as a centering element and support for drilling.

In addition to designs with two cutting elements located symmetrically, there are ballerinas with one cutter or even three. In the latter case, they are located on the base in the form of a disc with grooves.

Wood ballerina: adjustable drill or how to make a large hole

Often, when working with wood and materials based on it, it becomes necessary to drill an even round hole. You can use a jigsaw or a router, but such a tool is not always at hand or it is simply inconvenient to do the job with them. A ballerina on a tree can make the task easier.

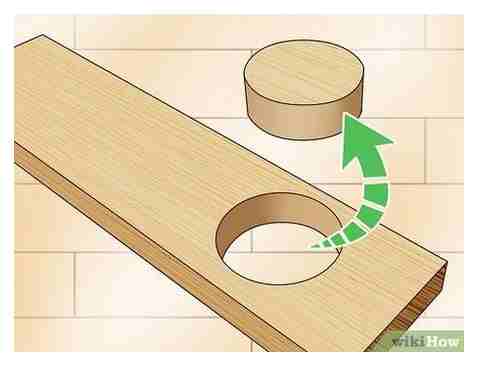

The challenge is to drill a large hole in the wood. Solution. wood crowns.

Greetings to all visitors to my site, where I talk about various types of tools, give advice and recommendations on the choice and operation of this or that tool. Today we will consider a tool with which you can easily drill a large diameter hole in a non-thick tree, most often it is plywood, fiberboard and chipboard.

The tool is a hole saw for wood, most often sold in sets in various saw diameters. This is very convenient. you bought one such set and you can drill holes of any large diameters, of course, if the saws that come in the set are of the diameter you need. Photo of such a set:

For home use, a set of Stayer is quite suitable, in terms of price and quality it is optimal, moderately expensive, there are many saws of various diameters in the set. It is worth noting that there are several variations in diameters, there are more complete sets with a large number of crowns, diameters start from the smallest to very large.

The most popular and best-selling set is 19-127 mm, this set contains 12 hole saws for wood of various diameters, it can be said to be universal, since it is almost always possible to choose a crown for the required diameter. However, and. If you take sets with fewer attachments, then, accordingly, it will cost less.

- Versatility. the ability to choose a crown for almost any diameter.

- Convenient case, everything is stored in one place.

- Fast drilling in fibreboard, chipboard, plywood.

- The cut is not clean, unlike the holes drilled with a forstner drill.

- Sometimes it is not possible to find the right diameter, for example, for some spotlights.

- Drilling depth of only 30 mm. Of course, you can drill deeper, but you will have to knock out the tree every time when the crown rests on the tree, because it is not deep.

All in all, a hole saw is the right tool for the home. For example, I recently pulled a 110 mm pipe through a thin partition (double layer of chipboard, between them a block of 50 mm). How to drill 110mm holes in plywood?

There are several options. you can use a jigsaw, using a thin file for a figured cut. It is quite possible to drill a round hole, but a perfect circle still does not work.

But take a set of circular saws, choose the diameter of the crown closest to 110 mm, assemble it and drill a smooth, beautiful hole in a few minutes.

Drill bit

One of the most popular and convenient options for cutting a hole is a special drill bit. It is made in the form of a crown crest and has a rounded shape. With this nozzle, the holes are cut quickly and they are quite even.

drill bit for holes

The attachments come in different diameters, which allows you to cut a hole of the required diameter. If you have already prepared a hole, we can advise you to try yourself in options trading.

Preliminary drawing

Before attempting to draw a curve on a workpiece, design it on a large piece of paper or a piece of corrugated cardboard. Only after a satisfactory result in all positions has been achieved, can you cut out a template from paper and make markings on the workpiece along it.

You can draw circles and fragments of a circle using a cup or plate, simply outlining them with a pencil.

Drill saw

Neither a hand-held nor an electric-hack will help if you need to cut a small hole in the workpiece. less than 10 cm in diameter. The jigsaw can also be useless if the workpiece is large. In this case, the most suitable tool is a drill saw. With its tip, it bites into the tree like a drill and thus makes “starting” holes for further cutting. Outwardly, the saw looks like a round file with the difference that its shaft spirals around the cutting edge.

Drilling saws are available with interchangeable attachments of various diameters, designed for processing both soft and hard wood, as well as a variety of materials from it.

The working body of the drill saw is a metal rod with a cutting edge, like a gimbal, and a cutting edge that goes around the rod in a spiral.

This is what the narrowest of hand hacksaws looks like. Thanks to the fastening unit, the blades in the hacksaw can be changed depending on the nature of the material being processed.

Which fits the template

You can make a circle on the workpiece not only with a compass. Any item of similar shape will do for this purpose. This can be a saucepan, plate, cup, or bowl. However, when taking on work related to the repair of furniture or some piece of furniture, calculate in advance the need for details of rounded contours or with round holes. It may be sufficient to make only minor changes to the design.

Jigsaw

When cutting holes or curves in small workpieces, a jigsaw is sometimes indispensable. Interchangeable blades with teeth of different shapes and locations allow you to work with wood of different densities. However, it should be borne in mind that the cutting depth is limited by the arc of the jigsaw, that is, the saw blade will not be able to move further than 30 cm from the edge of the workpiece.

Very thin, narrow saw blades are easily damaged if the jigsaw is used incorrectly. You need to drive the saw with neat, methodical movements. The main thing is to prevent skewing of the canvas. Otherwise, small and light workpieces will begin to move with the saw, as a result, this can lead to the fact that the blade will burst.

The thinnest jigsaw blade will “master” the narrowest curve, but only in small workpieces, since the blade advance is limited by the jigsaw arc.

Electrohawk

If you need to cut out a round-shaped part and saw through a round hole in the workpiece, then the electric chewer is the most suitable tool. With its help, you will save time and effort, since such a saw has great advantages over a manual one. So, the blade of the electric hacker is narrower, which provides increased maneuverability. Further, it has replaceable blades with various teeth, which allows you to process workpieces of any type, that is, wood, plywood, chipboard (it is no coincidence that the tool is also called a jigsaw).

To cut a section inside the workpiece, a hole is first drilled for a hand saw. But if you have an electric hobbyist, then this is not necessary. The tool is brought to the workpiece with a slight forward tilt and turned on in this position. The saw will cut the hole by itself. Just do not put too much pressure on the body. this can lead to breakage of the saw blade.

Drill

You can also cut a large hole with a drill. To do this, it is necessary to mark the contour of the hole to be drilled in advance. Next, drill through holes along the contour prepared in advance with a small drill. Next, with a jigsaw or a very sharp knife, we cut off the holes, thereby connecting the holes. Then you can smooth out the circle using sandpaper of various grain sizes.

Mark drop-down parts

It may happen that the holes that you drilled for inserting a narrow blade of a hand or electric hack will be in useful areas.To avoid such errors, you should mark all the falling parts of the workpiece with hatching.

What is a ballerina on wood

Adjustable circular drill “ballerina”. a device that is designed for drilling large round holes. The tool has a simple design. It is a shank with a transverse bar on which movable carriages with cutters are fixed. The rod has a marking, according to which you can set the necessary spread of the incisors relative to the center of the intended hole. A core drill is fixed in the middle of the shank. It serves as a centering element and support for drilling.

In addition to designs with two cutting elements located symmetrically, there are ballerinas with one cutter or even three. In the latter case, they are located on the base in the form of a disc with grooves.

Wood bit (core drill)

Crown-type tools are used to drill large holes (19 to 127 mm) in planks, plywood and lining. For example, such a crown can be used to make round blanks, or wide holes for installing spotlights not only in wood, but also in PVC lining, polycarbonate and drywall. Sold in sets of different diameters and with removable bases.

Communities ›Construction (and everything connected with it)› Blog ›How to drill a hole of 150. 154 mm in a wooden wall

Soon I will be installing a gas convector and to install it in the wall of the teraska it will be necessary to drill a hole 150-154 mm in diameter. Now I’m thinking about what?

Milling drill for wood (milling cutter)

The drill differs from all other types by the presence of cutting edges along the entire length of the drill, which helps to first drill a hole, and then bore it to the desired size. Drills of this type are most often used when it is required to perform complex processing of wooden parts.

How to Cut Perfect Holes: 4 Methods

Drill types

When buying an electric drill, the set, as a rule, comes with a basic set of universal drills. To perform some types of processing, this set is not enough, therefore there are drills designed for a specific job and achieving the desired result.

Drills for wood

Any repair, especially major, or construction work involves working with wood and its processing, which requires not only high-quality, but also the right tool. One of the simplest woodworking processes is drilling.

Making holes in glass

There is an ancient, but something now forgotten method of making holes in glass. The space on the glass, where the hole should be, is properly cleaned of dirt and grease with gasoline, acetone or alcohol. Next, moist fine sand is poured onto the washed place and a funnel is made in the sand to the glass with a sharpened stick of the required diameter. Molten solder (lead or tin is acceptable) is poured into the form prepared in this way in the sand. After 1-2 minutes, the sand should be discarded and the solder cone removed. A smooth through hole appears in the glass.

Drilling a large hole in glass

The drill is made from a piece of aluminum, duralumin or copper tube 40-60 mm long. From the first end, a wood cork is hammered into it to a depth of 20-25 millimeters, and at the other end, the teeth are cut out with a triangular file. A small screw 4-5 mm thick is screwed into the cork so that its smooth part protrudes 10-15 mm. The head is sawed off. They are glued to the glass on both sides along a paper washer with a hole equal to the diameter to be drilled. The glass is placed on a piece of rubber. A little abrasive powder is poured onto the drilling space. Then insert the end of the screw protruding from the cork into a hand drill, lubricate the teeth with turpentine and then start drilling. When the tube goes deep into the glass by at least 1/3 of its thickness, turn the glass over and finish drilling on the second side.

How to make holes in glass yourself

There is an ancient, but something now forgotten method of making holes in glass. The space on the glass, where the hole should be, is properly cleaned of dirt and grease with gasoline, acetone or alcohol. Next, moist fine sand is poured onto the washed place and a funnel is made in the sand to the glass with a sharpened stick of the required diameter. Molten solder (lead or tin is acceptable) is poured into the form prepared in this way in the sand. After 1-2 minutes, the sand should be discarded and the solder cone removed. A smooth through hole appears in the glass.

Drilling a hole in the glass

A hole in the glass can be drilled with a carbide drill. The secret to the success of this operation. in the liquid with which the glass is wetted. It is prepared from aluminum alum dissolved in acetic acid, or from a one-to-one mixture of camphor or turpentine. A plasticine roller is built around the drilling space. Liquid is poured into the resulting bath. Glass during processing must lie on soft matter.

Once again on how to drill a hole in glass

How to drill a hole in glass in 10-15 moments. To do this, you will need to sharpen a thin file like a chisel and attach it to a hand drill chuck. Do not forget to let the file cool down only at the moment of drilling, even occasionally sharpening it.

Cutting round glasses

We offer the possibility of cutting rounded glasses. A roller from the glass cutter is attached to one jaw of the caliper. Another sponge rests on the glass through a rubber washer. The roller is rolled a couple of times in a circle, then 3-4 tangents are drawn with a standard glass cutter, which facilitate chipping of the glass along the boundaries of the cuts. Sharpened edges are cleaned with a file or emery under running water.

Another way to make a hole in glass

Another method for making a hole in glass.

For work, a drill made of hard metal plasticine for the production of a small bath, a combination of equal shares of camphor and turpentine, as well as a piece of dense rubber.

With the help of what to make holes in drywall for lamps. the issue has been resolved

Drywall has proven itself as a versatile finishing material. Due to its excellent performance and comparative ease of use, it can be used to solve a wide range of tasks. However, there are some peculiarities of handling it. For example, when you need to cut a round hole in drywall, certain difficulties can arise. How to properly carry out the necessary actions, and will be discussed further.

There are many options for creating a hole in drywall, but this process must be approached very carefully.

Tile drill

Another option for making holes in drywall for fixtures is to use a special tile drill. Despite the fact that such use of nozzles of this type can be considered inappropriate, there are no difficulties in performing the task. The nozzle lends itself to adjustment within a certain range, so that its purchase can be considered a universal solution.

Options for solving the problem

So, if there is a need to make a technological or decorative hole in a drywall sheet, then it should be taken into account that the problem can be solved in several ways. The choice of option should be made based on the specific conditions and the availability of tools.

Special drill bit

One of the most convenient ways to make a hole in drywall is with a hole saw.

Hacksaw blade

An even simpler solution would be to use a hacksaw blade for metal. Here, approximately the same actions will be repeated as when working with a jigsaw. In terms of its availability, this option can be considered the most acceptable in most cases. It is important to note that care should be taken when working with the blade, as it is possible to get injured when sawing. To avoid this, you can take the simplest precautions, for example, wrap one side of the canvas with electrical tape in several layers or put a heat shrink tube over it. If unnecessary, such an improvised handle can be removed.

Jigsaw

If you need to drill a hole of a large diameter or purchase a special drill is not possible, then you can use a simple jigsaw. To do this, markup is performed in the right place. After that, you need to make a through hole on the marked mowing line with an ordinary drill, the diameter of which will be slightly larger than the width of the jigsaw blade. Next, using the resulting hole as a starting point, a circular cut is made. The inner edges of the resulting hole, if necessary, can be sanded.

Other ways

If for some reason the above methods are impossible to apply, the problem can be solved in another way. So, for example, according to the marking, a number of holes are drilled with an ordinary drill. They must be performed at a distance of several millimeters from each other. Then, with a light blow of the hammer handle, the inner part is knocked out, and the remaining irregularities are removed using coarse sandpaper.

Alternatively, you can use a simple clerical knife. For a reference point, you can take a round object of a suitable diameter, such as a saucer or bottle. Several passes are made around the improvised template with a knife, as a result of which a fairly neat hole is obtained.

Thus, it is obvious that there are a lot of options for how to make a hole in drywall for a lamp, so every home craftsman can choose the most suitable method for himself.

How to cut a hole in a tree

Greetings to all visitors to my site, where I talk about various types of tools, give advice and recommendations on the choice and operation of this or that tool. Today we will consider a tool with which you can easily drill a large diameter hole in a non-thick tree, most often it is plywood, fiberboard and chipboard.

The tool is a hole saw for wood, most often sold in sets in various saw diameters. This is very convenient. you bought one such set and you can drill holes of any large diameters, of course, if the saws that come in the set are of the diameter you need. Photo of such a set:

For home use, a set of Stayer is quite suitable, in terms of price and quality it is optimal, moderately expensive, there are many saws of various diameters in the set. It is worth noting that there are several variations in diameters, there are more complete sets with a large number of crowns, diameters start from the smallest to very large.

The most popular and best-selling set is 19-127 mm, this set contains 12 hole saws for wood of various diameters, it can be said to be universal, since it is almost always possible to choose a crown for the required diameter. However, and. If you take sets with fewer attachments, then, accordingly, it will cost less.

So, let’s look at the pros and cons of such a tool.

- Versatility. the ability to choose a crown for almost any diameter.

- Convenient case, everything is stored in one place.

- Fast drilling in fibreboard, chipboard, plywood.

- The cut is not clean, unlike the holes drilled with a forstner drill.

- Sometimes it is not possible to find the right diameter, for example, for some spotlights.

- Drilling depth of only 30 mm. Of course, you can drill deeper, but you will have to knock out the tree every time when the crown rests on the tree, because it is not deep.

All in all, a hole saw is the right tool for the home. For example, I recently pulled a 110 mm pipe through a thin partition (double layer of chipboard, between them a block of 50 mm). How to drill 110mm holes in plywood?

There are several options. you can use a jigsaw, using a thin file for a figured cut. It is quite possible to drill a round hole, but a perfect circle still does not work.

But take a set of circular saws, choose the diameter of the crown closest to 110 mm, assemble it and drill a smooth, beautiful hole in a few minutes.

I hope there will be a flange on the exhaust pipe? I would drill around the circumference, but it is better to use a machine tool so that it does not walk along the axes

and then well, probably foam or tow

Yeah, this tip digs in 5 centimeters. that’s not counting broken files and the pleasure of pulling out jammed debris. A 20 cm piece of wood against the wobbling end. strength.

And the remaining, excuse me, 16 centimeters by hand? :)))

It’s wiser to think about the power of the drill first. which will carry such nonsense.

And it is even wiser to call your husband for an hour with a proper mandula.

In the general store in the electrical department, a brass bushing with an external thread is bought for the installation of an electric cartridge.

costs five kopecks, but a brilliant nichrome conductor comes out of it.

Will leave, as to his home. And what? shook.

if you jerk off to a dozen at once. well, call the boy with the stray, he needs concrete, that firewood. pay and the hole will be as you want.

But if you really want to have sex. twist drill 10, they are long and their noses are reasonable.

Why screw. it is faster in great thickness.

A compass, a pencil and a mother and a bit of geometry. draw with a compass one circle 120 and the second 110 with the same center. Reduce the compass to “5 mm” and, having set the starting point on a small circle, put marks at the intersections with the circle. Mark the puncture points with a pencil. The nose of the drill will go there.

Having finished these laces, take a drill, put a drill there and screw in a circle.

If everything is done correctly, it remains to knock down the cloves. Well, here you can already use a cone and a firm hand to bring.

Something like this I performed a round hole in marble. Only it was only 10 mm but out of pieces.

There is such a thing, what is it called something. Crown or something. In general, a drill bit. They are sometimes sold as a whole set of several thin blades of different diameters and a piece that is inserted into the drill chuck and holds the blade. There is also a drill for centering.

Practice shows that this is the thing that breaks down. reliable solid steel powerful cutters.

You can cut a round hole in a piece of wood in different ways. The lightest and simplest. using a variety of drills (conventional, feather, spiral, Forstner) and crowns (split and solid, conventional and bimetallic):

There are also so-called “ballerinas”:

You can also, after having previously plotted the desired size, cut the hole with a jigsaw (especially important for large sizes exceeding the diameter of the available crowns), best of all electric, since manual is demanding on the size of the part.

If there is no special tool at hand, then you can build a “ballerina” from a bar and two nails:

But such a hole will be less tidy and will take a lot of time and effort.

I am generally silent about a file for wood (rasp). they can, of course, expand the existing hole and trim the edges, but this no longer applies to the question “How to cut a round hole in the board?”