How to cut a wooden baseboard without a chisel

How to file a ceiling plinth: methods of cutting corners with a wire cutter, a drawing on the table and markings on the ceiling

Classification of baguettes is carried out by the material of manufacture:

- Gypsum. The oldest representatives of the ceiling plinths. Special matrices were used to cast them. Various mortars have been used as an adhesive mounting compound. Gypsum baguettes are also referred to as “battens”. In modern construction, they are used very rarely because of the high cost and inconvenience of installation. In addition, there are more reliable and inexpensive imitations of gypsum ties.

- Polystyrene (polyurethane). The most common type of ceiling plinth. This type of products is characterized by low price, excellent aesthetic characteristics, easy installation and a wide range of products in terms of external design. The width of polystyrene baguettes varies from 5-250 mm. They can be used in any type of room, complementing the different interior styles.

- Wooden. Expensive and quite bulky baguettes, which are mainly used to decorate wooden houses with the appropriate interior. To install the wooden strips, in addition to glue, often use screws and nails.

- Plastic. A great option for bathrooms and other rooms with high humidity. Installation is carried out on a special moisture-resistant glue or countersunk self-tapping screws.

When installing the above products, you need to know how to cut the ceiling plinth. This does not apply to plastic products, which are equipped with special corner adapters.

What tool is needed?

When installing the ceiling plinth, it must be trimmed to size or in the corners.

To cut the corner of the ceiling plinth, as a rule, the following tools will help:

- Wood saw. Used for work with wood.

- Metal hacksaw. This tool is convenient for cutting plastic, styrofoam and plastic friezes. As a result, you can get a fairly clean joint without burrs. When working with saws, it is convenient to use a plier.

- A box cutter. It can be used to cut foam baguettes without using special tools. The main thing is that the knife should be well sharpened, with a thin and smooth blade. If you act carefully, the cut is smooth, without any dents.

When using the saw, it is important not to apply excessive force, otherwise the skirting will crumple. It is best to practice on a scrap piece of wood first. This will allow for beautiful fragments in the future.

About baseboards and the complexities of cutting corners

Practical element of decor. ceiling plinth or fillet. can be made of:

- Polyvinyl chloride. the most affordable;

- Styrofoam. have a low cost;

- Polyurethane. are much more expensive than the others;

- Polystyrene. slightly more expensive than polystyrene and polyvinylchloride.

A wooden fillet is very popular, giving the interior an austere elegance. To make a corner cut on a wooden baseboard, you should use a hacksaw with frequent fine teeth or a hacksaw for metal.

Advice! If you need a moisture-resistant and durable ceiling plinth, then you should choose polyurethane fillet. It is important to remember that it does not tolerate sharp fluctuations in temperature. quickly deforms, so it is not suitable for use in the interior of the kitchen.

Each of the materials used for the manufacture of baseboards, has its own advantages and disadvantages. For example, polystyrene and polystyrene foam are easy to break, polyvinylchloride has an increased electrostatic.

Regardless of the material from which the skirting board is made, its cutting into corners has its own difficulties, since the walls of the room do not always have exactly 90° corners. Sometimes, especially in older buildings, the walls can have an 88° or 92° angle, so if you cut the skirting at an angle of 45°, at the junction, you will definitely get a gap. To avoid this, use the following method.

Before gluing the skirting board, it is necessary to check whether there is no gap in the corners

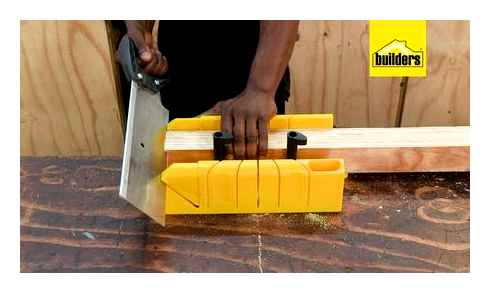

How to cut a skirting board by means of a plier

The plier is a carpentry tool, which is a tray with slots. It allows you to cut the ceiling plinth at the required angle.

If we talk about a professional tool, it has a special swivel mechanism. This allows you to set the required degree of angle. It is most convenient to use a jib, when the angle between the walls is perfectly straight.

How to cut a skirting board by means of a plough

Chisel. a carpentry tool, which is a tray with slots. It allows you to cut the ceiling skirting at the required angle.

If we talk about a professional tool, it has a special swivel mechanism. This allows you to set the required degree of angle. It is most convenient to use a plinth cutter when the angle between the walls is perfectly straight.

About baseboards and the complexities of cutting corners

A practical element of the decor. ceiling plinth or fillet. can be made of:

- Polyvinylchloride. the most affordable;

- Styrofoam. have a low cost;

- polyurethane. cost an order of magnitude more expensive than the others;

- polystyrene. slightly more expensive than polystyrene and polyvinylchloride.

A wooden fillet is very popular, giving the interior an austere elegance. To make a corner cut on a wooden baseboard, you should use a fine toothed hacksaw or metal hacksaw.

Tip! If you need a moisture-resistant and durable ceiling plinth, you should choose a polyurethane fillet. It is important to remember that it does not tolerate sharp fluctuations in temperature at all. it quickly deforms, so it is not suitable for use in the interior of the kitchen.

Each of the materials used for the manufacture of baseboards, has its own advantages and disadvantages. For example, polystyrene and polystyrene foam are easy to break, polyvinylchloride has an increased electrostaticity.

Regardless of the material from which the plinth is made, its cutting on the corners has its own difficulties, because the walls of the room do not always have exactly 90° corners. Sometimes, especially in older buildings, the walls can have an angle of 88 ° or 92 °, so if you cut the skirting at an angle of 45 °, at the junction, be sure to get a gap. To avoid this, use the following method.

Before gluing the baseboard, you need to check if there is a gap in the corners

How to trim a baseboard in the corners without a joiner

It seems easy to cope with a wire cutter, but corners are not always 90 degrees. This method will help you solve the problem of trimming the baseboard in the corners quickly and without hassle.

The procedure to properly cut the baseboard in the corners without a ruler:

How to Cut Tacks in the corners Without a Jigsaw

How to cut the ceiling molding in the corners of the first time without a jigsaw

How to cut ceiling plinth corners. Photo 1

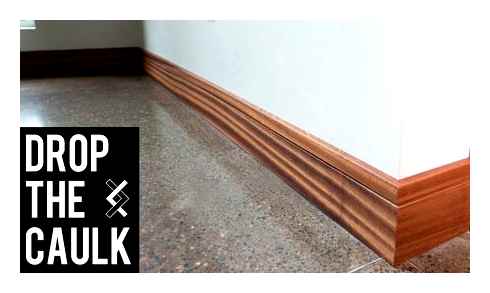

With the problem of cutting outer and inner corners of the ceiling plinth faced, probably, who at least once made repairs independently.

Skirting ceiling, it is also called a tack, used in the repair to hide the uneven boundary between the wall and ceiling, and give the interior completeness.

How to cut the corner of a ceiling plinth without a jigsaw ? About this and talk in our article.

How to cut a skirting board in the corners without a ruler? If you do not have a joiner at home, it is not a failure. Cut out the outer and inner corner of course and without a jigsaw.

Now in the field, the skirting boards are available in various sizes, shapes and colors, with embossed designs and in their absence. The material from which they are made, also different.

For the most part it is: polyurethane, polystyrene foam, polystyrene and polyvinyl chloride. However, in recent years, wooden ceiling plinth has become more popular in repair work

Its neat appearance can add elegance and austerity to the design of the room.

What is the best skirting?

In advance of how to correctly cut corners on the ceiling plinth it is necessary to choose it correctly.

Tip: ceiling plinth will look harmonious if its width is chosen correctly. The higher the walls, the more extensive the baseboard.

The most durable, moisture-resistant and flexible are polyurethane tacks and cut the corner of such a ceiling plinth is not easy.

But such positive properties “overlap” one significant drawback. they do not hold sharp temperature changes, which does not allow their use in many rooms.

For example, in the family kitchen, where there is a gas as it is also called the electric stove, polymer fillets will retain its original appearance of about a week. After that, during the frequent cooking, when the hot air will rise to the ceiling, then fall, they begin to deform, spoiling the whole “picture”.

Baseboards, made of other materials, also have their drawbacks.

For example, products made of PVC have an overrated electrostaticity in the event that, at one time of work on their surface appear dents, to remove them will be unrealistic. At the slightest mechanical effect polystyrene foam and polystyrene ceiling skirting boards break.

How to trim the baguette ceiling plinth without a jigsaw if your corners are not 90°

Failing to trim a baguette into a corner, you’ve messed up a bunch of ceiling plinth! This is the easiest method for you.

Trimming Technology

With the use of a wire cutter

Instructions for corner fitting baseboards and fillets depends on what configuration the joint will have. As a rule, when performing repairs parts are connected perpendicularly, so in this section we will consider in more detail is such a variant.

As mentioned above, the easiest way to cut corners is with the jigsaw.

Cutting direction when forming an inside corner

- We bring the part to the place of installation, and then we measure the necessary length of the piece.

- Place the frame on a stable and even surface. The workbench is the best for this purpose, because it would not be so convenient to saw on the floor.

- Lay the bar in the chair in the position in which it will be placed on the wall. Press the product to the wall of the tray so that the flat parts are adjacent to the inner surfaces of the jigsaw.

- Use your left hand to hold the workpiece so as not to dislodge it.

- Insert the saw blade into the slot at the right angle (the correct orientation for inside and outside corners is shown in the diagrams and photos). Carefully saw off the detail, avoiding unnecessary pressure on the tool.

Cut to form an outside corner

Tip! Baseboards with thin walls can crack under pressure. To avoid this, we put a wooden staple or any other bar of suitable size under it and saw them together.

- Now proceed to cut the second corner. The other part of the skirting board is placed symmetrically to the first one in the jig and the same way we press it to the tray.

- Carry out trimming, setting the hacksaw in the appropriate slot.

After that, it is desirable to check how closely adhere to each other trimmed corners, and only then proceed to glue them.

Connect the fragments should only be after a preliminary adjustment

Without the joiner

The price of such a device as a plinth and molding mitre is relatively small, but at the right time it simply may not be at hand. Of course, in this situation, the labor intensity of the task will increase, but it is still possible to cope this way.

Marking scheme

The first method is suitable for ceiling moldings and involves the use of marking on the ceiling:

- Cut the two parts to be joined at 90.

- Put one panel on the fastening point, press it firmly, level it and set the end against a perpendicular wall.

- Using a pencil, draw a trimmer line outlining the contour of the panel.

- Remove the panel, put a symmetrical detail and repeat the operations.

- Now we have the point of intersection of the two lines on the ceiling. Attach the parts one by one to the base and make a mark opposite this point.

- Having laid the baseboard on the workbench, connect the mark to the corner and trim along this line.

- As in the previous case, check the quality of the joint skirting boards.

Sequence of operations

You can use templates for the skirting boards:

- We take two strips of thick paper or cardboard, whose width corresponds to the width of the baseboard.

- We apply them to the place of installation of the product, noting how the connecting line for the trimmer should pass.

- According to the marks, cut out templates, which we then lay on the skirting board and use as a sample for trimming.

Tip! Use one pair of templates to join several corners only if you are sure that they are perfectly perpendicular. Otherwise the gaps will be quite large, and laborious fitting is required.

Using the markings on the cardboard

Complex configurations

Sometimes it is necessary to join not perpendicular baseboards, but parts located at a different angle.

In this case, the task is seriously complicated:

- Cut out two blanks with a good margin by length.

- Apply one workpiece to the mounting area and mark the lines corresponding to the location of its edges at the top and bottom.

- Repeat for the second piece.

- At the intersections of the lines determine the place where the joint will be located.

- Before you cut a corner on the baseboard, we put it against the wall and transfer the marks directly onto the material.

- Connect the marks with a line along which we make a neat kerf.

- Let’s try on if we have correctly adjusted the parts, first by weight and then on the base. If necessary, either remove some of the material from one edge, or (if the discrepancy is too great) repeat the trim, measuring all measurements more carefully.

Angles larger than 90

Proceed in the same way when you want to assemble a curved surface of several segments, but the lines of the joints of parts will naturally be more.

Outside connection types

Oddly enough, but while the overall identity of the work with the inner joints, the outer ones cause more problems. The joining of the elements is carried out in exactly the same way as in the case of internal connections. The only difference will be the position of the sawn slat when sawing. it is necessary to consider that the sawn blanks should be joined together projecting outward, instead of connecting inward. The rest is the same. a wire, a saw, and the trimming of the cut.

Using decorative corners

We mean the special corner adapters, which are usually supplied with polyurethane and polystyrene friezes. Decorative corners are glued in the corner, and baguettes adjoin to them on both sides. Trimming in this case is either not required, or conducted with a simple office knife.

Joining in straight areas

The most difficult areas when decorating the ceiling perimeter frieze considered corners. After passing the first corner, usually begin to move immediately in both directions, dokleivaya sail by sail. If the frieze at a straight dock all fits, there are no problems: both edges trimmed with a wire cutter at an angle of 90 degrees, they are connected with mounting glue. The main thing. to maximize the invisibility of the joint.

A small difficulty arises when the installation work is approaching the next corner, and it is necessary to cut the frieze to length. This should be done with a certain allowance for undercutting the corner. the skilled masters recommend to leave a reserve not less than 10-15 sm, taking into account possible errors at registration (sometimes from the first time it does not turn out). After the corner of the frieze is trimmed and checked, the bar is attached dry on the area remaining from the corner with a straight cut in the direction of the nearest baguette. Having marked the necessary length with a simple pencil, cut off the excess at an angle of 90 degrees, and spend gluing the fabricated and fitted piece.

Prefabricated corner elements

In order not to engage in trimming ceiling plinths yourself, you can use ready-made solutions. In any construction store you can find factory-made products, already made at a certain angle. Such a corner element allows you to connect the edges of the plinth, just cut at a right angle. Corner pieces allow you not only to connect the bar in the corner of the ceiling, but also to hide the imperfections of the cut on the edges of the parts.

Unfortunately, such a method is not relevant in all situations. The sizes of corners, manufactured at the factory, are adjusted to certain standards. but the skirting boards themselves do not always meet the standards. Of course, such parts can be combined, but the result will not look aesthetically pleasing. If corners of a suitable size are not available on sale, it will still be necessary to deal with the trimming of baseboards on their own.

Trimming by means of a chisel

To give the skirting board the necessary angle, a special tool is used. the plinth. Structurally, this tool is a tray made of wood, metal or plastic. There are vertical slots in certain parts of the plinth, which allow you to cut various parts at an angle of 45 or 90 degrees.

It is possible to meet on sale and more complex devices in which, in addition to the angles already described, there is a possibility of a 60-degree cut. There is also a professional power tiller equipped with a swivel mechanism. This tool differs from the simplified tool in that it has the ability to fix the cutting blade at any angle. You need to know how to properly glue the ceiling plinth in the corners so that everything looks nice.

Other methods of cutting corners

When the contacting planes of the walls of the room form a right angle, the best solution will be the use of a pencil saw. In other cases, you can use other methods of how to saw the ceiling plinth under the corner, for example, by marking this product on the ceiling. This technology allows you to take into account all the deviations relating to the size of the angle, as well as the unevenness of the walls.

- First of all, two workpieces are cut according to a straight vertical line.

- Then one of the slats is applied to the surface, with its end against a perpendicular wall. Similarly proceed with the second part of the skirting board.

- Their contours are outlined on the ceiling plane with a pencil. The point of intersection is the mark against which cut the tack, forming a corner in it.

- Then reapply each of the slats and mark the cut trimmer line on them, which will connect its two edges.

- The skirting board is cut according to the planned lines, then both parts of it are joined and placed at the place of installation.

If of all the ways, how to saw the corners of the ceiling plinth, selected this, it is important to take into account a few nuances:

- It is better to use it for internal corners;

- Do not proceed to attach the boards one by one, without having made a preliminary docking of the two parts and not checked their mutual position. The gaps left between the slats must be shpaklevat.

Types of ceiling decorative skirting

Before you start installing fillets, they must be purchased, and for this you should have information about the range of this product.

Skirting boards are made of different materials, namely:

To have an idea of each type of decorative ceiling elements and choose the right product, you must have at least their brief characteristics:

- Baseboards made of polyvinyl chloride, have a good price, but this material has the ability to accumulate static electricity.

- Polyurethane molding is characterized by high quality, durability, moisture resistance and elasticity. Its main disadvantage is insufficient resistance to sharp temperature fluctuations and for this reason polyurethane products should not be installed in rooms with high humidity.

- Wooden ties are exposed to high temperatures, moisture and have a lot of weight.

- Baseboards made of polystyrene are characterized by moisture resistance, good quality and attractive appearance, but break under mechanical stress.

In addition, the baseboards differ in other parameters. in width, length, relief and shape. Their use in rooms of different sizes depends on these characteristics.

For example, wide products look harmoniously in high rooms. There are nuances in how to cut a wide ceiling plinths. The fact that these profiles dock at an angle of 90 degrees. For an accurate cut use a wire cutter. But when the corners of the room deviate from the standards, the work is done manually.