How to Cut Drywall at Home Moisture-Proof

Posted by Artyom at 07/31/2019 07/31/2019

Beginners in the construction industry do not know what and how to cut drywall in the best way. After all, any work, whether it be creating a ceiling structure, partition or a complex element of decor, requires knowledge of the rules for cutting gypsum plaster and strict adherence to them in practice. The tool for these purposes is used differently. It all depends on the chosen cutting method. So, how to cut drywall at home, the following recommendations will prompt.

A few words about the structure of drywall

To begin with, a couple of minutes of attention should be paid to the structure of drywall, since this moment will immediately bring clarity to the process of cutting it. And the GKL “device” is very straightforward.

The structural structure of drywall.

The structural structure of the sheet of this material is a three-layer “sandwich”. The outer layers are made of dense cardboard, and the core of the pressed gypsum mixture. The lateral long sides of drywall usually have an edge with corners rounded or converging on the trapezoid and are also protected by cardboard. From the end sides, an edge is not provided.

Cardboard is produced in several types. this is ordinary (GKL) material of gray color, moisture-proof (GKLV) has green shades of the front side, fire-resistant (GKLO) is pink or light violet, and moisture-resistant (GKLVO) is a dark green shade. In addition, an innovative drywall designed for soundproofing walls has appeared on sale today. It is made in blue.

The most common standard sizes of sheets are 2500 × 1200 mm, that is, having an area of 3 m². Other options are available, but they are less common: 2000 × 1200 mm (2.4 m²) and 3000 × 1200 mm (3.6 m²). The thickness of the sheets can be 12.5 mm (for walls), as well as 9.5 mm and 6 mm, which are usually used to create ceiling structures.

The table below shows the main standard sizes of drywall with an indication of the approximate mass of the sheets. This is in order to be able to appreciate. the sheets are very bulky and quite heavy. That is, they should be handled carefully: they may not be able to withstand the fracture load during careless handling. they will break.

Type of drywallSize of sheets (length × width × thickness), mmSheet area, m² Approximate sheet weight, kg

However, no matter which drywall is used for construction or decoration, it is cut equally.

Introducing the Toolbox

The mandatory list of DIY gypsum sawing tools includes three groups of items

1. Devices for applying marking on a GKL sheet. a simple pencil, tape measure, a long ruler.

2. Actually cutting and sawing devices.

- Knife. GVLV can be cut with a clerical knife, as well as with a specialized construction one with a double-sided replaceable blade (suitable for denser materials).

- Hacksaw. It is better if it is a tool for metal processing than wood.

- Jigsaw. Ideal for cutting rounded elements. Least of all, chips on the ends of drywall leave high-quality file for metal with a small tooth.

- Electric drill. Needed for making holes. For gaps of large d, round crowns (which cut the core of the door snap locks) and feather drills will be required.

3. Edging tools:

- peeling planer;

- chamfering planer.

This list clearly shows what home craftsmen cut drywall. Of course, he is far from complete. The arsenal of experienced craftsmen can include professional equipment, for example, a special milling cutter for GVL. However, for those who are working with the material for the first time, this kit is enough. To better understand how to cut drywall, you need to clearly understand the structure of this material.

Basic tools for cutting drywall

To cut drywall sheets to specific sizes, some simple tools are required, a list of which includes the following items:

Tools for cutting and processing drywall edges.

- Electric jigsaw. This tool can be convenient to make long cuts, and in particular it becomes necessary if you want to cut a complex curved shape. As a rule, our jigsaw is included in the instrumental "arsenal" of any private house, since it is difficult to manage without it in the household.

- A special knife for cutting drywall or a regular stationery knife with a removable blade. information about this tool group will be provided below.

- A narrow hacksaw for wood with a small tooth set, or a special hand saw on drywall.

- An electric drill with a set of large feather drills, as well as crowns. for cutting large round holes for wiring communications, sockets for installing electrical outlets and switches.

- Drywall planer or regular wood planer. This tool will be necessary for processing edges when cutting material.

- A needle roller will be required if it is necessary to form an arched opening from a drywall or another curved surface, for example, for a complex multi-tiered ceiling structure.

- For measuring and marking sheets, you need a simple pencil or marker, tape measure, building angle, meter metal ruler. If there is no ruler, it can be replaced by a flat metal profile used to equip the frame crate. In addition, you must have at hand a construction rule for making long straight cuts “to the ruler”.

Drywall Cutting Knives

Due to the fact that the knife is the main tool for cutting drywall, its characteristics should be considered in more detail.

Nevertheless, the knife remains the main tool of the master when working with drywall

Drywall knives can be divided into three categories. Detailed information about them is presented in this table:

Knife Categories / Tool Features

In principle, drywall can be cut by any of these knife models. However, to decide on the choice of this tool, it is worth considering all the options in more detail.

It should be noted right away that knives with a blade of 9 mm should not even be considered, since they are not suitable for cutting drywall. Such a blade may not withstand pressure and break. Not only will this greatly slow down work. breaking a thin blade is often accompanied by a rather serious injury to the hand.

For cutting drywall, knives with a blade having a width of mm are used.

Appearance of the product Types of knives and cutters and their features

Now, having figured out what designs of knives are most often used for cutting drywall, you can decide on the choice of the main tool for work. This takes into account the scope of the material, the required shapes and sizes of the workpieces, the required level of accuracy. And, of course, the cost of the tool is compared with the scale of the tasks ahead, with the intensity of its use.

Structure and purpose of drywall

Plasterboard sheets are a layer-by-layer combination of two types of materials. gypsum (internal content) and sheets of thick cardboard glued to it on both sides. It is clear that if the cardboard layers are damaged, it is not difficult to cut the rest.

Therefore, in order to be able to quickly cut a sheet of gypsum plaster, it is not enough to find out what is the best way to cut drywall. It is important to know the basic principle of this action: after continuous smooth cutting of drywall is carried out, the second step immediately follows. breaking the sheet.

Sawing drywall, like any solid porous material, is easy. It also lends itself well to drilling.

Functions of the material make it possible to differentiate it into varieties: moisture-proof, fire-resistant, standard, increased strength (for example, a gypsum board or a gyro-board made using KNAUF technology), acoustic drywall, etc.

Despite the large assortment of HA, panels of any of its varieties lend themselves well to dividing into parts by using available material.

How to cut: tool selection

If you are going to cut drywall on a regular basis, or at least often enough, it is recommended to purchase a professional tool once and not to suffer from improvised means in the future. In any other case, you should have clerical. construction, reinforced. or mounting knives. Types of clerical are hardly distinguishable among themselves, but building is stronger. However, in any case, the cut from this knife is such that after it is necessary to eliminate the formed nicks.

Video: How to Cut Drywall at Home Moisture-Proof

For the operation being performed, a hacksaw for metal is quite applicable. its blade is thinner than that of a hacksaw for wood, so it wins in the accuracy of the subsequent result.

Another useful tool is a jigsaw. Its advantage is the lack of the need to think about how to cut drywall, because you just need to lead along the drawn line. To process the edges, additional tools are used, such as a peeling planer, the effect of which can well be reproduced with sandpaper.

When we figured out how to cut drywall, you can go directly to the methods of cutting it, the number of which is also large and varied. Let’s consider some of them.

How to cut with a mounting knife

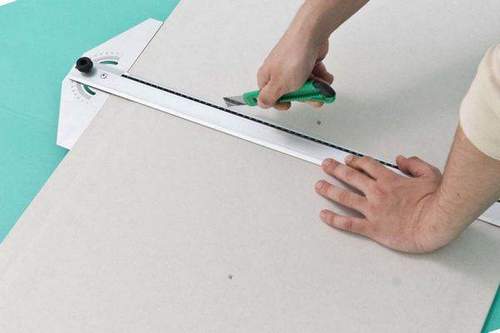

An assembly knife is suitable for cutting drywall into large longitudinal parts. First make the necessary measurements using a tape measure and a pencil, attach a metal ruler to the drawn line and start cutting the material with a point along the edge of this same ruler.

Be careful and take your time so that the cut comes out smooth and accurate and matches the line from the pencil lead.

The core is cracked with a light tapping, then the plate is turned over, and the drywall is again cut in the broken place. At the end, the material should be processed with a planer so that the edge becomes smooth.

How to saw with a hacksaw

It is worth noting that most often a hacksaw is used to cut rectangular openings. In this case, you need to draw drywall on the reverse side. Drill a hole in a corner of the drawing with a diameter so large that the hacksaw blade can safely enter there. You can also make holes on all sides. After the operation is completed, the edge, as in the previous case, is processed with a planer or file, depending on the size of the hole made. Important: it is desirable for the tool blade to be perpendicular to the plane of the drywall sheet. In this case, the edges come out more evenly.

Jigsaw cutting

Jigsaw is the tool that will help save time and energy. Applying it, it is possible to saw and cut not only straight lines, but also smooth, curved lines and various shapes. If you use it, put the GCR sheet on two stools so that the shape of the desired cutout drawn before this line passes in the distance between the surfaces of the stools. Act smoothly and leisurely, cut strictly along the intended line. The jigsaw has another significant advantage: with it, the processing of the edges obtained is minimized, because it is held perpendicular to the surface of the sheet, which is the key to such a result. This is facilitated by the special sole installed in it. The disadvantages include the fact that you still have to spend money on it, but this tool is worth it. Also, when working with it, a lot of dust rises, you should take care of eye protection and respiratory protection in advance.

General rules for cutting drywall

The gypsum microparticles inside the cardboard cover are light and volatile. Breaking out from under the paper during cutting, the mineral suspension rushes into the air, getting into the eyes, settling in the respiratory tract. Therefore, it is advisable to put on a protective mask.

It is recommended to lay a plastic film on the floor under the cut sheet by sprinkling it slightly with water from the spray gun. Moisture will help the gypsum particles flying on top to swell, get heavier and sink onto polyethylene. At the end of the work, it will remain to collapse and throw it away. Particularly thrifty wash the film in the bathroom, dry and reuse.

If gypsum dust settles directly on the floor, washing the powder will be problematic. There will remain divorces. If there is a porous coating on the floor such as opaque porcelain tile, gypsum particles will clog into it.

A solution of warm water with sunflower oil at the rate of half a glass of product per 10 liters becomes salvage. After the floors are already wiped with vinegar.

For glossy surfaces, the method is not suitable. There it is better to do with a solution of potassium permanganate. It is added to warm water until it becomes light pink.

We cut drywall with an installation knife

The mounting knife has interchangeable blades. There are blades for cutting different materials, the protrusion of the metal part beyond the limits of the handle is regulated. There are the same stationery models, but they are low-power for working with drywall.

You can even cut drywall with an office knife

There is an assembly knife from several hundred rubles. The tool is good when decided how to cut drywall at home in a straight line. Curly lines with a mounting knife are obtained anyhow. Proceed:

- We draw drywall according to previously made marks.

- We attach a steel profile for drywall or a metal ruler to one side of the marking. They will not allow the knife to go sideways during cutting.

- We put the blade to the edge of the marking and drive along it with a pressure of about 3 kilograms.

The knife should not go through the sheet. Properly cut drywall. This is to lead the blade with a recess of about half a centimeter. The rest will break along the line when you bend the panel with your hands.

The cut should appear at the top. For bending, drywall will need to be supported. You can simply put the sheet on the floor, or you can put it on chairs or the edge of the table.

Some useful tips from experienced craftsmen

In conclusion, I would like to give some tips that will help to cope with the task, without having made irreparable errors.

- Do not cut drywall "angle grinder", as there will be not only a lot of noise, but also a cloud of gypsum dust, which will add problems with cleaning the room. And there is no sense whatsoever in such an approach, to be honest.

- If it is necessary to use a hammer when cutting material, you can use only a rubber mallet, since drywall can be seriously damaged with a metal tool. And, of course, carefully measure the strength of the strikes.

- So that along the cut line at the edges of the sheet there are less chipping, it is recommended to keep the hacksaw or knife at a right angle. the lower the inclination of the blade, the larger the tattered cardboard.

- All main cuts are made before attaching the material to the crate, because if the cut is unsuccessful, you will have to replace the sheet with a new one, and the damaged one can be used for inserts. The exception is windows and openings. it is better to cut out from the place of installation, after fixing to the frame.

- It is not recommended to cut complex patterns with thin partitions in drywall, for example, openwork nets, since the material is quite fragile.

- If a whole sheet is cut, then most often this process is performed on the floor. After the cut is made, a timber is placed along its line under the drywall. Then you need to click on both parts of the canvas, which easily breaks along the cut line.

From the information presented above, a logical conclusion is drawn that there is nothing particularly complicated in the process of cutting drywall sheets. And anyone who does not have any experience in building an amateur can easily cope with this work. If you have any doubts, you can try your hand at a small piece of material and see how simple it is if you follow the technological recommendations and wield a quality tool.

Video: How to quickly and efficiently cut drywall

The nuances of cutting drywall depending on its type

Drywall sheets are specialized, for example, waterproof. Paper on these is impregnated with polymers. They close the pores in the cardboard, making it resistant to moisture and reliable protection for compressed gypsum powder inside.

However, even the waterproof gypsum board edge is not protected. Accordingly, the workplace should not be wet. Once in gypsum, water will cause it to swell, and the geometry of the building sheet will change.

Arched Drywall

Separately, there is an arched drywall. It is as thin as possible, only 6.5 millimeters in thickness. It would seem that such a sheet is easier to cut than a centimeter. However, fiberglass is laid inside the arched panel.

It reinforces drywall and gives the flexibility necessary to deform a sheet intended for curved doorways, ceilings.

Due to the fiberglass inside, the arched material is cut harder than a simple drywall. It is better to use a power tool. An assembly knife or a hand file "go" hard.

Edge processing

A slice is treated with a peeling plane, since the edges never come out smooth and neat enough. this is a property of any tool, the experience and skills of the performer play a smaller role here. You can also chamfer with a regular knife, but it will take more time and require professional skills.

In conclusion, it should be noted that cutting drywall is one of the most common operations in the list of those that can easily be done independently at home, without the help of a specialist. It is enough just to approach any work with the mind and patience and carefully familiarize yourself with the sequence of the task, based on its features. Then the result will be appropriate.

Video: how to cut (cut) drywall do it yourself at home

We cut a profile for drywall

Since work with the hero of the article has begun, the question is also relevant, how to cut a profile for drywall. It is used to create a frame for paper-mineral sheets.

They are attached to the profile on self-tapping screws. Accordingly, drywall closes the profile base. You can not focus on the accuracy of cutting steel bars. Their ugliness will hide the sheets.

You can cut the profile with scissors for metal

For cutting a profile for drywall use 3 tools:

-Scissors for metal. They are good for cutting sheet steel. It is inconvenient to work with U-shaped profiles for gypsum sheets, but it is profitable. A manual version of a tool resembling nippers costs from 200 rubles. Also, the inconvenience of working with scissors smooth out their independence from the power supply and noiselessness.

-Jigsaw. Cuts neatly and quickly. It is convenient to work with the tool only with a rigid fixation of the profile. It is made of thin steel. If such a person “walks” under the jigsaw blade, the cut will be uneven.

-Miniature angle grinder. In working with an angle grinder, the profile is placed on a bend. In other words, the cut-off part should hang over the air and bend under its own weight down as it is cut. The rest of the profile rests on a chair, table.

The convenience of handling a power tool is overshadowed by the noise emanating from it. However, you can wear headphones. Of the mandatory protective equipment, glasses are worth mentioning.

Cut the profile of a small angle grinder

Chips can fly off from the steel being machined. She can get into her eyes, damaging them. Such pieces of metal are called dross; they are extracted at emergency rooms.

The danger of cutting a profile with an electric tool is not only the damage to human health, but also the decoration of the apartment. Flakes of steel flies hot.

Stay away from wallpaper, plastic panels. Of course, they cannot ignite from the shavings, but point darkening-burns, sometimes remain.

Number of blocks: 18 | Total number of characters: 31258

Number of donors used: 5

Information for each donor: