How to cut dust-free tiles

How to cut tiles without dust and sharp corners

Quite often, our desire to lay tiles on our own during repairs is faced with a lack of sufficient experience and special tools. However, don’t waste time borrowing a tile cutter from friends and acquaintances. It will be enough to take advantage of the experience of folk craftsmen and improvised means. Of course, it will not be possible to make cuts of a complex shape, but straight mowing lines will turn out excellently.

One of the most common ways to cut tiles is to use a glass cutter. For these purposes, it is better to stock up on a diamond or oil tool, but if they are not at hand, a regular roller will do. You will also need a flat table, a metal square, a marker, a piece of sandpaper with a grit of 60-80 units and a regular nail 70-100 mm long.

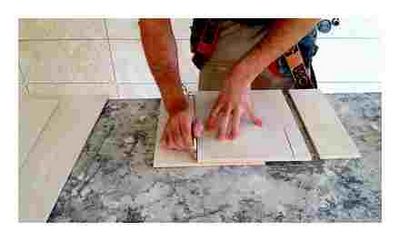

The work begins with measuring the dimensions of the desired piece and applying the markings to the tiles. Then it is laid on a flat table. Contrary to the opinion prevailing among many home craftsmen, the tiles do not need to be soaked in advance. It must be dry.

The metal square is placed on the tile surface and aligned with the marks. Firmly pressing it with your hand to the surface, a glass cutter is carried out along the square. It is not necessary to press hard on the tool, otherwise the tile may burst. If everything is done correctly, then during the work with the glass cutter, a characteristic cutting sound will be heard, and a thin line will form on the tile.

In the next step, the nail is placed on the table and the head is shifted so that it hangs over the edge of the table. A tile is placed on top of the nail, combining the cut line with it. After that, with the palms of both hands, sharply, but not hard, press on the edges of the tile. It will burst strictly along the cut.

However, this is not all. Depending on the quality of the tile, the cut edges may have irregularities or sharp corners. To get rid of them, a sheet of sandpaper is laid on the table and, by attaching the end of the piece cut from the tile to it, the place of the cut is polished until all defects are completely removed. As a rule, such work will take only a couple of minutes.

If a glass cutter is not at hand, then a tap for threading, as well as a drill for concrete or metal, are suitable as a cutter. These tools are made of durable steel that can cut tiles as well as a glass cutter. It will not be so convenient to work, but in emergency situations they will help out. All other operations are carried out as described above.

How to cut dust-free tiles

Ceramic tiles are often used as a cladding material for interior and exterior surfaces. She is not afraid of moisture, the effects of aggressive cleaning agents, practically does not lend itself to mechanical damage and does not need special care. Most often it is used in the process of cladding a bathroom and a work area in the kitchen.

In some cases, it is required to independently cut the ceramic tiles into fragments of the desired size and shape. Equipment such as a tile cutter or an angle grinder comes to the rescue.

However, these works are almost always accompanied by the appearance of a large amount of dust. If this is not critical in the process of carrying out a large-scale renovation, then what to do if the tiles need to be cut in a clean room?

Dust-free tile cutting at home

The likelihood of generating large amounts of debris during work is increased with the use of a powerful electric tool such as an angle grinder. A little trick will allow you to cut the ceramic material and not stain the room in which the work will be carried out. To do this, it is necessary to periodically moisten a piece of material on which the angle grinder will be cut.

You can fill the seam formed after the passage of the electric tool yourself or using a special device. Automatic fluid dispenser attaches to cutting tool guard.

Using a plastic canister

The second simple method of getting rid of dust when working with an angle grinder is to prepare a large plastic canister. This capacity can be preserved after using the primer.

The canister must be turned on its side and one edge must be cut off with a sharp ceramic knife. With this simple action, you can get a sealed open top plastic box.

After the performed manipulations, the ceramic tiles must be laid on the canister walls strictly above the resulting hole. When cutting, almost all the dust will settle on its bottom.

The great advantage of the considered methods is their cost-effectiveness and availability. After all, canisters almost always remain after repair work in a house or apartment, and a special device for supplying water can be purchased at an affordable cost. You don’t need to be a professional builder to apply dust-free tile cutting methods. The main thing is to be neat and not in a hurry.

How to cut dust-free tiles

In some cases, it is required to independently cut the ceramic tiles into fragments of the desired size and shape. Equipment such as a tile cutter or an angle grinder comes to the rescue.

However, these works are almost always accompanied by the appearance of a large amount of dust. If this is not critical in the process of carrying out a large-scale renovation, then what to do if the tiles need to be cut in a clean room?

Dust-free tile cutting at home

The likelihood of generating large amounts of debris during work is increased with the use of a powerful electric tool such as an angle grinder. A little trick will allow you to cut the ceramic material and not stain the room in which the work will be carried out. To do this, it is necessary to periodically moisten a piece of material on which the angle grinder will be cut.

You can fill the seam formed after the passage of the electric tool yourself or using a special device. Automatic fluid dispenser attaches to cutting tool guard.

Using a plastic canister

The second simple method of getting rid of dust when working with an angle grinder is to prepare a large plastic canister. This capacity can be preserved after using the primer.

The canister must be turned on its side and one edge must be cut off with a sharp ceramic knife. With this simple action, you can get a sealed open top plastic box.

After the performed manipulations, the ceramic tiles must be laid on the canister walls strictly above the resulting hole. When cutting, almost all the dust will settle on its bottom.

The great advantage of the considered methods is their cost-effectiveness and availability. After all, canisters almost always remain after repair work in a house or apartment, and a special device for supplying water can be purchased at an affordable cost. You don’t need to be a professional builder to apply dust-free tile cutting methods. The main thing is to be neat and not in a hurry.

Round holes

To cut round holes in ceramics or porcelain stoneware, you must use specially designed crowns. They are equipped with diamond segments or a coating for drilling. The diameter of the hole can be any with the use of such devices, ranging from 30 to 80 mm.

If you need to drill more for the installation of electrical or plumbing components, then it is better to use a ballerina drill. It is a drill on a bracket in the center and two cutters, with regulation of their position relative to the center. Also for these purposes, a hole saw and diamond bits are used. The principle is the same.

A few tips on forgotten technologies

Are you going to lay the tiles yourself? Please note that the process is very laborious and will require a certain experience from the contractor. Beginners should be given some practical advice: if you use an angle grinder to cut tiles without a tile cutter, then do not make sudden movements, because the diamond wheel will damage the part that should remain fine.

Also, follow the safety precautions, always use personal protective equipment against dust for the respiratory system and eyes. Shrapnel can damage the cornea very quickly and easily, and clog the airways with dust.

Using a hole saw

A common way to get round holes for sockets, switches, junction boxes or plumbing fixtures. It is a diamond bit with a centering drill. Has thicker walls, and the cutting edge has diamond or carbide cutting segments.

The use of spray crowns is also practiced. Hole diameter can be up to 80mm.

Figured breaking

Figured breaking in ceramics is not easy. To do this, you must first make many cuts with a small step from the end to the figured cut. The smaller it is, the more accurate the bend will be on the ceramic. The cuts are made just short of the main mowing line. Then, with the help of forceps, each segment is carefully broken out and unnecessary ceramics are removed with small bites.

Glass cutter or any pointed tool

This is the oldest and most effective method that is still used to cut glass. With an experienced craftsman and a well-sharpened tool, the butt end turns out to be smooth without bevels and twists. The glass cutter does not essentially cut, but cuts, creating cracks in the upper layers of the tile.

Cutting ceramic tile dust free without a vacuum

After the strip has been drawn, the tiles must be laid on a hard surface along the cut and pressed on the edge with a sharp movement. If the facing coating is hard enough, then the chip turns out to be even, but if the ceramics are loose, then the irregularities will have to be removed with a file.

Alternative tools and their features

Consider the most popular ways to cut ceramic or porcelain tiles with acceptable quality. These include:

How to Cut Tile Without Dust.- by Home Repair Tutor

- angle grinder with large disc. There are several types of these tools that can be used to cut ceramics. To do this, buy the appropriate diamond blade. There are several of their varieties on sale, depending on the grain size and cleanliness of the cut.

- Jigsaw. This is a convenient and very practical tool with which you can make a clean cut, but for this, purchase a special tile file. Its advantages lie in its versatility, that is, you can make curved cuts with a large radius.

- Manual type glass cutter. Suitable for cutting smooth glazed tiles.

- Drilling holes with a drill. This is a convenient way, but to get a high-quality end face after cutting, you need to go through the place with additional grinding tools, for example, a file and sandpaper.

To make round holes in ceramics, a hole saw, a crown, a ballerina drill are used. Radius bends with small twists are selected manually using pliers or pliers.

Angle grinder angle grinder

Let’s take a look at how to cut tiles without a tile cutter using an angle grinder. This will require:

- Machine with a diamond wheel of appropriate grit.

- Smooth, stable surface to get the job done.

- Ruler or pre-drawn line on the back of the tile.

- Substrate under the tile so that it does not wobble or slip during the cut.

- It is advisable to connect a vacuum cleaner, because a lot of dust will be generated during operation.

After the tile is stable, you can start cutting. You should start from the near edge and lead the stone in such a way that it runs over the front covering. So chips will form only from the bottom, and the top will remain smooth. It is convenient to make incisions in the same way.

How to cut tiles without a tile cutter: a selection of simple ways

Professional tools for high-quality finishes are always very expensive, but what to do if you need to lay the tiles, and buy because of a couple of square meters. m equipment no money, no desire? Then the question arises, how to cut ceramic or porcelain tiles without using a tile cutter due to its absence? You should immediately warn you, you can complete this task, but in order for the cut to be even and with minimal chips, strictly follow the technology.

Safety engineering

- Work must be carried out with goggles and a respirator.

- The area around the workplace must be free to avoid the possibility of injury from the saw blade.

- It is advisable to work with a partner who, using a vacuum cleaner, will remove construction dust.

Cutting tiles with a glass cutter

A direct cut of a tile with a glass cutter is quite simple to make, but you will have to tinker with curly cutting.

The operation is performed as follows:

- first, outline the fishing line with a felt-tip pen or pencil, along which the cut will be made;

- with one hand they hold the tile, and with the other they confidently hold the glass cutter along the intended mowing line, while the tool is directed “towards you”; the glass cutter must be kept strictly at right angles;

- the cut tiles are placed on a wooden glazing bead and hit with the palm. the tile breaks exactly along the cut line of the cut.

Important! Working with a glass cutter requires skill, which is acquired with experience. Therefore, in this way, you can cut a couple of tiles. To handle more tiles, more advanced fixtures should be used.

Electric tile cutter

This tool, equipped with a diamond blade, is the most ideal device for cutting any kind of tile. At the same time, using the circular saw of the tile cutter, ideally even cuts are obtained, the edges of which are slightly smoothed and rounded.

Electric tile cutting machine copes with any amount of work, no matter how large they are. The design of the perfect tool is capable of providing a high level of safety to the person working with it.

Important! Stone tiles covered with carbide chips must not be processed with an electric tile cutter. Since this causes the destruction of the diamond saw from interaction with this coating material.

The marked tiles are laid on the working platform of the tile cutter and slowly advanced under the diamond saw blade. At the same time, they try to hold the tile tightly, pressing it to the platform with both hands.

How to cut tiles

Manufacturers offer to use a different tool for cutting tiles, which can be selected depending on the volume and characteristics of the material chosen for the manufacture of tiles. The tile is cut:

- roller glass cutter;

- electric tile cutter;

- manual tile cutter;

- tile nippers;

- angle grinder (“angle grinder”).

Let’s dwell in more detail on the features of the application of each of the above tools.

Using the “angle grinder

A diamond disc mounted on an angle grinder allows you to quickly cut the tiles according to the markings made. With this universal tool, both straight and curved tiles can be cut. The advantage of an angle grinder over an electric tile cutter is its mobility. But it loses in terms of the quality of the cut obtained, after which the edges of the tile need additional processing (grinding).

Manual tile cutter

The manual tile cutter allows you to take tiles that are less than 6 mm thick. It is an affordable tool that allows you to quickly cut fragments of tiles according to measurements taken. Such a tile cutter is convenient for those amateur craftsmen who perform cladding work with their own hands. Professionals use an electric tile cutter, which we will talk about a little later.

Important! The denser the structure of the tile, the easier it is to cut a narrow strip from it.

Handle the manual tile cutter as follows:

- marking is made on the surface of the tile with a felt-tip pen;

- the tile is laid on the base of the tool in such a way that the wheel coincides with the marking;

- skip the wheel along the mowing line of the marking once, controlling the handle of the glass cutter;

- with the help of “wings” the tile is fixed on both sides of the cut for even division into two parts;

- with a light movement of the hand, hit the handle, while getting the desired fragment for laying out the cut row.

Important! If after several hits the tile remains intact, then you should not waste time on this “tough nut” by taking another tile.

Safety engineering

- When working with a power tool, use protective goggles to protect the eyes from small fragments of tiles.

- The manufacturer recommends to monitor the water level in the pan and responsible for cooling the cutting blade.

- Periodically, the water in the sump should be changed, as it heats up and becomes clogged with tile chips.

How to cut tiles with wire cutters

Nippers are indispensable when cutting holes for water pipes, platbands in tiles. hoods, fireboxes and other structural obstacles. Better fracture is done with a pair of wire cutters equipped with two carbide clamps. The upper clamp cuts through the glazed surface of the tile, while the curved lower clamp holds the tile from below. Before work, a contour is applied with a felt-tip pen, along which it is necessary to make a cut. Rather, in this case, the tool does not cut, but bites off fragments of the tile until a groove of the desired size is obtained.

Important! Do not try to “bite off” large pieces of tiles at once, otherwise the edge will turn out to be completely sloppy. In any case, the resulting cut needs processing, which is carried out with a file or special sandpaper.

Bluetooth music streaming device

Alarm and automatic lighting from the RCWL-0516 sensor

DIY pvc pipe lamp with RGB backlight and Bluetooth speaker

A simple dust-free tile cutter of a conventional angle grinder from a simple plastic bucket.

Hello everyone, I found an interesting device in the vastness of the network that will help you cut dust-free tiles when performing repair work.

Making this device is simple and affordable for everyone.

rezka-plitki-bez-pili.mp4 [5.13 Mb] (Downloads: 1393).mp4

How to cut a tile without dust with an ordinary angle grinder.

The procedure for making the device

For the manufacture of the device, an ordinary plastic bucket from under construction mixtures will be used.

At the bottom of the bucket, drill a hole for the diameter of the hose from the vacuum cleaner with a small allowance.

The hose nipple is inserted into the slot and glued with glue or sealant.

The hose itself, on the back side, we connect to the vacuum cleaner.

Marking the required dimensions on the tile for cutting.

We take an angle grinder with a special ceramic disc.

And smoothly start to wind up.

We are slowly moving the angle grinder further.

Dust generated during cutting falls down the bucket, and from there is sucked in by a vacuum cleaner.

Here is such a simple and useful device.

Nonsense, dust will still fly in the direction of the disc ejection.

Cut the tiles along the short part of the angle grinder, and the long part with a tile cutter and the dust will be several times less.

It’s true…. The way is delusional, and indeed not a way at all. Indeed, it is better to cut along the short side, and then scratch and break off with a tile cutter or glass cutter.

And in general. The name “angle grinder” enrages. angle grinder is a citizen angle grinder. What is shown in the photo is at least a Chinese woman, if you do not consider the country. the birthplace of the brand.

This disgusting abomination came from the 70s, when we, wild, began to supply an angle grinder within the CMEA with a hand-held power tool. For drills, pistols and other things, we had speech equivalents, but for grinding machines (lo and behold) we did not. And we, as aborigines, christened this mechanism according to the country of origin. In fact, all over the world this machine is called “flex”. Name it at any international construction site. and they will understand you. Since this is consistent with the company that first began to produce such machines, and to this day is considered the legislator of standards in this area.

Tools

There are many ways to cut tiles. For this, special tools are used. For instance:

- tile cutters;

- nippers;

- glass cutters;

- drills with appropriate attachments;

- Angle Grinder.

Each option has its own characteristics, advantages and disadvantages.

For example, the tile cutter is a very popular tool used for this purpose. It can be performed in three variations:

- electric;

- manual;

- tile cutter tongs.

The first option is more suitable for the conditions of mass work. This means that the volumes must be large. Such a device is capable of even the most durable materials from which tiles can be made.

In the process of cutting the material, water is supplied, which makes it possible to get smoother edges, not to heat the material and not to spread dust. The only drawback of such a device is its high price. over, one-time work is not for him. Better to rent an electric tile cutter.

As a result, the hand model is a fairly popular model. But in this case, everything will have to be done by hand. An alternative is the tongs cutter. The tool is designed for thin metals. In this case, there is another drawback. subsequent processing of the ends is required. grinding. And this is not always good.

A glass cutter, a drill, as well as wire cutters, can also be used to cut tiles. In the first case, there is a limited thickness of products. As a result, the tiles may not cut through. The drill together with the nippers allows you to get a good cut.

Next, consider the application of the angle grinder in more detail.

How to cut tiles with an angle grinder: no chips or dust

Tiling is almost impossible without cut rows. As a rule, they are located along the edges. Very often, the need for cutting tiles appears at doorways, in the places where pipes are located, and so on. where neat laying is required. And for these purposes a special tool should be used. The correct choice of the device will allow you to get high-quality pieces, and therefore, to make the styling at a high level.

Training

If an angle grinder is used for cutting, it is recommended to check the tool for damage and function before the procedure. Need to insert a disc to work on cement or metal. There is certainly a difference between them, but not significant.

How to cut without dust

It is necessary to inspect the tool itself, otherwise some flaws can ensure poor-quality work.

Do not forget about personal protective equipment. This means that you should also put on a hat on your head, protective gloves on your hands, and clothes on your body to protect your eyes. glasses. The latter is perhaps the most important. After all, dust, small fragments can get into the eyes with a very fast rotation of the disc. This can be a dangerous injury. Therefore, you should think about your own safety first.

Instructions on how to cut

angle grinder is the popular name for an angle grinder. Not everyone knows that people began to call this tool that way since the 70s. It was at this time that the first samples began to arrive in the Union. And they were called “Eltos-angle grinder”.

In general, an angle grinder is a multifunctional tool. It is capable of processing materials thanks to the diamond wheel. The unit allows you to perform not only straight, but also figured cuts.

Recommendation: It is not necessary to cut the tiles to the full thickness. If you make a line-cut, then the product will break very pliable.

Of course, when compared to the results of a tile cutter, an angle grinder has more fragmented edges. At the same time, preparatory manipulations are not needed to carry out the process.

The disadvantage is that you cannot do without dust and chips. The only thing is that they can be compensated for by the protective casing of the tool itself, personal protective equipment, as well as the use of a special disk. For example, a good cut quality, practically no chips can be provided by a disc designed for metal processing. This is largely possible due to the reinforced relatively smooth surface.

Tiles are easy to cut with wet cutting attachments. This will allow you to get the absence of chips, as well as a flat and smooth cutting surface. In this case, the nozzle must be new, and the cut itself must be made from the back of the tile.

Chips and dust are inevitable?

You can put it this way. Indeed, everyone can perform certain manipulations to reduce such negative phenomena.

In addition, you can watch video and photo materials about this. After all, a lot depends not only on the tool itself, attachments to it, but also on the cutting technique. This aspect also affects the presence of chips and dust.

Be that as it may, but it is important to devote enough time to this moment. And then the result will please you with the high quality of work.

Sawing paving stones with an angle grinder

Having a private house, it becomes necessary to lay paving slabs or paving stones, which must be cut to size. For this, they also use a universal device that is available in almost every home. an angle grinder.

Paving stone processing has its own characteristics, but basically it is carried out in the same way as cutting porcelain stoneware. The main differences are that the work is done outdoors. Material processing should be carried out on a separate site: the resulting dust settles on the laid paving stones and can spoil its appearance. If this happens, you should immediately sweep it off with a stiff brush.

To cut the paving stones, choose a diamond blade for concrete processing. The angle grinder should be held at right angles to the workpiece and the diamond wheel should be moved exactly along the mowing line. It is necessary to cut the tiles to a depth of a little more than half, and then just break and trim.

Cutting porcelain stoneware

When performing repairs, not only walls are faced. Ceramic granite tiles are laid on the floors in the bathroom and toilet. an artificial material that replaces granite and marble. Its cost is several times less than natural, but in terms of hardness and abrasion parameters, porcelain stoneware surpasses them. Recently, it has become widespread. It can also be cut with an angle grinder.

To do this, you need to know the basic methods of processing material at home.

- Choose the right cutting tool. It should be written on what it is used for: porcelain stoneware, hard ceramics, etc.

- To reduce chips, choose a disc with a continuous cutting edge. The thickness should be minimal.

- Choosing a cut-off wheel with a high diamond coating height.

- the angle grinder must have a speed controller.

After choosing the tool, prepare the workplace and begin to cut the porcelain stoneware with an angle grinder. To do this, you need to perform the following steps.

- Place material on a flat surface with thin foam or similar material underneath.

- Fix the tiles securely to the surface with clamps.

- To reduce chips, glue masking tape and make markings along which it is necessary to cut off the excess part.

- Prepare the vacuum cleaner to remove dust.

- You need to cut from the front side, moving the grinder away from you.

- It is recommended not to cut along the marked mowing line, but slightly to the side. This is done for the subsequent grinding of the end face of the porcelain stoneware to remove irregularities and chips.

Following these simple recommendations, you can cut the floor tiles with your own hands.

What discs are used for cutting tiles

For cutting ceramics, special discs are required, which can be stone or metal with diamond coating. Stone ones are rarely used, since they are quite thick and quickly grind off, and during work they generate a lot of dust. The cost of stone discs is several times less than metal ones, but experts prefer to work last.

Metal discs can be:

- solid;

- segmented.

It is preferable to process ceramics with solid discs. When working with such discs, there is a time limit: they cannot continuously cut for more than 1-1.5 minutes. Then let it cool down while the angle grinder is idling.

Segmented for cutting paving stones, porcelain stoneware, natural stone or concrete.

The segments are designed for better cooling of the tool during operation.

Straight cut

It is not difficult to master it, at the same time the cutting line is clean and without chips. When performing the work, the tiles are securely fixed on a flat surface, marked with a pencil or felt-tip pen. The part to be cut should hang freely from the table. The cutting tool is at right angles to the workpiece. Carefully, without jerking, drive the angle grinder slowly along the marked mowing line. The tool should be moved towards you so that the marked line is visible.

Tile and Porcelain Tile Cutting Angle Grinder

Every master who is engaged in wall cladding with ceramic tiles knows that it is impossible to lay them without cutting. This is true both for wall cladding and for laying porcelain stoneware on the floor. But not everyone knows that a regular angle grinder (angle grinder) can be used for trimming. Let’s consider how to perform this operation correctly and without chips.

Notched neckline

It is often necessary to cut a round hole in a tile. You can do the job correctly with an angle grinder if you have certain skills. To do this, mark a hole on the workpiece and circle the fishing line with a felt-tip pen, mark the center of the circle. They begin to cut at a slight angle, slowly, along the inside of the mowing line, gradually passing along the entire circumference. Then they cut through the sectors, take them out one by one, trimming the ceramics if necessary. Finally, the edges are processed with a file, getting an even circle. Such processing is called a dry cutter.

Such holes, as a rule, are cut for sewers or ventilation.

When performing shaped processing of a workpiece, it is easiest to make rectangular cuts. In order for the cuts to be smooth, without chips, it is necessary to regularly change the cutting wheel. If you use segmented discs, then chips will appear on the cut line of the mowing line.

Angle 45 0

Docking is often necessary, which means cutting the material at an angle of forty-five degrees. This angle can only be obtained with a large workout. But you can use this technique: first, cut the workpiece in a straight line, and then gently process the edge at the desired angle with a disc, sandpaper or sharpening stone.

How to get rid of dust when cutting tiles

Tile cutting with an angle grinder is not very difficult, but it generates a lot of dust. There are techniques that can help reduce dust formation. Specialists use special tile cutters for this, but buying them for one-time work is impractical due to the high cost. Therefore, when processing parts, the craftsmen act differently. First, a layer of glaze is cut through. it almost does not produce dust, the main dust appears when a layer of fired clay is processed. Then it remains to gently break the ceramic tile and process the edges with an abrasive material.

A common way to get rid of dust is to moisten the workpiece. For this, water is constantly poured into the working area with a diamond wheel. After each pass of the tool, fill the seam with water or install a special device for supplying water to the working area. This device attaches directly to the protective cover of the angle grinder. As a result, the workpiece is processed without dust.

Electric cutter

The more powerful, the more hardy and filigree the cut. An 800 watt motor is a good option. The diamond disc cuts like clockwork, only the crumbs fly.

Dust-free (but noisy), you can cut many pieces of the desired size without spoiling a single one. You don’t have to make any special efforts, and the exhaust is effective.

- Most models have an angular scale ranging from 0 to 45 ° on a solid surface.

- The device is stable as it is equipped with anti-slip feet.

- For precise control of the cut at an angle, a parallel stop with a scale of 45 ° / 45 degrees is provided.

- The built-in water tank is of great service. Water cools the saw blade in a timely manner.

At home, a glass cutter will help out

When you need it quickly, a glass cutter is indispensable. It is nowhere easier to work with him at home: he marked it → jerked at a right angle towards himself → slowly broke the tile, placing a glazing bead or a nail under it. Well, or over the knee, if it’s long.

Angle Grinder

Networked or rechargeable, small or large. it doesn’t matter. The angle grinder is more likely to do rough work because jagged edges remain on the mowing line. But you can get used to working clean, if the cut is successfully masked when laying.

This is a tool for all occasions: suitable for shaped and straight cutting, you can make a hole in the tiles of the desired diameter. The main thing is to choose a suitable cutting wheel diameter. Diamond coated. tougher and cuts slightly deeper than carbide. It is better to nail the product with a clamp to the tabletop or fix it in a vice, placing plywood under the bottom so as not to spoil the table.

3 steps to properly cut ceramic tiles that often chip.

- Mark the tiles along the entire length on the front and back sides.

- Make a surface cut up to 3 mm in one pass from the outside, then from the underside.

- Repeat until you reach your goal.

There will be a lot of dust, noise and flying debris. Therefore, do not neglect glasses, headphones and a respirator, otherwise it is more expensive for yourself.

Porcelain stoneware: how and how to cut it better

Strong as a rock. It is not surprising: porcelain stoneware is a composite material that has taken the best properties of natural stone and ceramics. It does not crumble, does not absorb water or even scratches. Working with it in the same way as with tiles will not work, but you can adapt.

A mechanical or electric cutter and an angle grinder will help out. The procedure is standard: put the part on the bed → outline the cutting line → and act depending on the tool:

- to cut with a machine tile cutter, press on the carriage, moving it away from you → release the handle → break the tiles along the mowing line;

- the electric tool simplifies the work: we start the unit at low speed → gradually increase the speed and do not confuse it: on the unit with an upper cutter, we lay the tiles facing up; with the lower disc. down;

- The angle grinder is even easier: we put a metal corner on top of the tile and fix it with clamps. for an accurate cut. We start the grinder → direct it “away from ourselves” → grind the butt end. Or we simplify: we make a cut, not a cut, then break the tile with a sharp movement.

Professional tool

They say about this: “Iron and jelly cuts.” If the volume of work is hoo, it is pointless to suffer with a glass cutter. It will become dull after a dozen tiles. Better to make it easier for yourself with tools specifically designed for cutting. They will be discussed below.

Round holes: how to make tiles

Drill and feather drills help! And it is better to take for work on concrete. those with victorious tips.

- The former have sharp tips that are harder than the glaze, so they do not slide off the surface.

- The latter can deepen holes with a diameter of 3-12 mm.

First you need to make a mark on the tile. Attach a dowel to it and chop it off with a hammer. it will be easier to fix the drill in the mark. Then, at low speeds, make a hole or screw in self-tapping screws with self-drilling tips.

If you need a hole for a socket on an already tiled wall, it is better to use castellated ones with a centering drill, and you will not find it. It’s easier to work with such. Nakernil contours, set the drill and. to the point. Deepened. drilled with a crown.

It is worse if it is not centered. Then you have to circle and drill at a low start. You will have to grind the grooves along the contour, then bring the work to the end. Just do not be zealous: the crown heats up quickly, it must be periodically cooled in water so as not to burn out.

And if you are impatient to cut when laying, there are many options. See in the table:

Jigsaw

The jigsaw will not take floor tiles, it is too thick. But wall tiles are a nice thing. Especially if you pre-hold the tiles in water for a couple of hours. Then no dust, no chips, and a minute of business:

- you need to fix the tiles in the grooves,

- mark line notch,

- turn on medium speed on the jigsaw and make through cuts along the contour.