How To Cut Floor Tiles

Drill with attachment

Facing a bathroom or toilet, you will be faced with the need to make a curly cut in order to lay tiles near plumbing and communications. Therefore, we will consider how to do this at home. Here they use a specific method. a drill with a nozzle. With its help, they make a rounding or even hole.

One of these tools is used as a drill:

- Ballerina. Center-lock attachment and swivel base with cutting element.

- Crown. Round attachments of various diameters with straight or serrated edges and diamond-coated.

- Tubular drill. Smooth, pointed tool of comparatively small diameter made of carbide or diamond-coated.

- Conventional drill. Must be strong and sharp enough.

To trim the cut, use nippers. Work carefully and with concentration to get a normal rounding.

Angle Grinder

It is an alternative for durable floor tiles. The tool allows you to quickly process a large amount of material. Like an electric tile cutter, a diamond blade is used, however, it requires a dry cutting attachment.

Secure the tile to the work surface. Draw the line and use the machine to cut the tiles towards you. Use a face shield to prevent dust from entering the respiratory system and eyes. Due to the increased risk of injury, do not use the tool if you do not have sufficient skills, in addition, there is a risk of spoiling the tile.

Tile cutter

The easiest way is to saw the tiles using this special tool. There are two options: manual and electric. Despite the same name, they differ.

Special tool for tiles

Any kind of tile cutter is like a large glass cutter with a work surface and a lever. The tile is installed at the bottom on the stand, and the handle is retracted to a position closer to you. The roller blade is then positioned at the start of the intended mowing line. With a confident movement, the pressed handle is pulled forward and pressed. Thus, the cutting roller will make a depression in the tile, and then it is split under pressure into even parts exactly along the mowing line.

An electric tool has a different design. It resembles a mini version of a circular saw. The work is done using a diamond blade and water. The material is fixed to the base and then brought to the rotating element. A few seconds. and the tile is cut into the necessary fragments at the right angle. A huge plus. no dust.

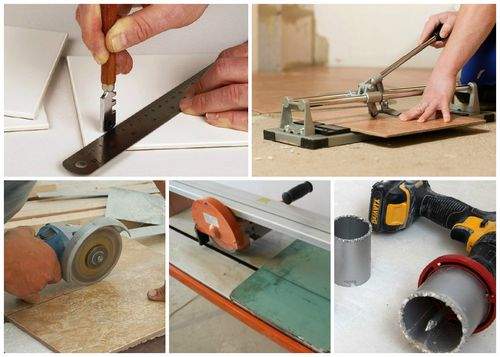

What tools are used

Before you buy a tile for the floor at home, pay attention to its properties in order to choose the best option for both external characteristics and technical indicators.

- Strength. For this parameter, as well as resistance to mechanical stress, floor tiles are selected of a higher class than wall tiles, therefore it will be more difficult to cut.

- Thickness. The floor tiles have more, since a considerable load is expected.

- Structure. It is important that the flooring must not slip. It will play into your hands when cutting the material.

- Relief. It is much more difficult to accurately process a product with bulky details or a complex convex pattern than a simple one with a smooth surface.

Now we will consider how and how to cut tiles directly at home. For this purpose, tools that are completely different in type, design and intended purpose are used.

The following options should be noted:

- Tile cutter;

- Angle Grinder;

- Glass cutter;

- Drill;

- Jigsaw.

Tile processing tools

The principle of their use is different, so we will consider each method in more detail.

Cutting floor tiles at home

When doing cladding work on your own in the bathroom, kitchen or hallway, sooner or later the question arises. what is the floor tile cut at home. There are a huge number of acceptable options from a specialized tool to improvised tools.

Due to the higher strength of the tiles on the floor, it is better to use special devices

Glass cutter

This hand tool is suitable for fragile tiles. The work will require a flat surface and a ruler. First place the tile on a table or directly on the floor, measure the desired distance and attach a ruler. In order not to get lost in the process, it is recommended to pre-outline the area to be treated.

Next, install the glass cutter on the front of the tile and, pressing on it, draw a clear line in one motion. The cutter must go deeper into the structure of the material in order to form a basting to break. Then tap the tiles along this mowing line. Press down with your hand or grab part of the tile with a special holder. The rift must follow the cut line of the mowing line.

The main difference from a mechanical tile cutter is that its wheel leaves a smaller depression, and therefore the risk of performing a poor-quality break is much greater, especially when working with floor tiles.

The tool is suitable for tiles of standard strength class

Cutting ceramic tiles with a glass cutter

If the amount of work with tiles is small, it is quite possible to do without a special machine for cutting tiles, using a conventional roller glass cutter (diamond). Cutting ceramic tiles with a glass cutter is done in the same way. First, the tiles are soaked in water for 30-40 minutes. After applying the marking with a marker or pencil on the front side, the tiles are laid on a flat board or plywood. The incision is made with strong pressure. just once. Pressing evenly on the tool, roll it in the direction from the far edge of the tile towards you so that a groove appears on the surface of the enamel. To make a break along the formed mowing line, place a nail, match or thin wire under it, and press the tile on both sides at once.

Cutting tiles with a glass cutter

It is quite difficult to carry out a large amount of work with a glass cutter, since the process takes a lot of time and requires concentration. After all, you need to constantly monitor that the incision is in the right place. And of course, you can’t cut thick floor tiles with a glass cutter.

What and how is the easiest way to cut tiles: expert advice

Ceramic tiles are durable and convenient material in many ways. But the installation process requires some preparation, accuracy and patience. In order to tile a working wall or a floor in a kitchen beautifully and with high quality, it is necessary not only to be able to lay, but to know how to cut a tile. When decorating a kitchen apron with tiles, whole tiles are not always stacked. To veneer ledges, window frames, electrical outlets and edge switches, tile cutting or drilling is often necessary.

How to cut ceramic tiles

How to use the tile cutter

The main difference between the tile cutter is the larger wheel, which can be used to cut a greater depth, and the presence of a mechanism that, after the cut, allows you to break the tile. Electric tile cutters, also available on the market, cut the tiles very neatly, the edges are smooth and slightly rounded.

Before cutting the tile, it should be soaked in water for 30-40 minutes, and then mark the part intended for cutting by applying the cutting line with a marker or pencil.

Working with a manual tile cutter

With a tile cutter, you can make an incision at a given desired angle. In this case, the markings are applied using a square with divisions. The cutting line on the tile should be at least one cm from the edge of the tile. Align the mark with the pointer on the cutter when using the tile cutter. The tile is fixed at one level, and the cutting element is moved away from itself. Move the cutter very slowly to the edge of the tile. So you can avoid overheating of the tile, the appearance of cracks and chips on it.

It is very important to break the notched element correctly. Using a tile cutter, apply pressure evenly to avoid breaking or deviating from the markings you applied. If you are using a manual tile cutter, you will not be able to cut strips less than 5 mm wide.

Aligning the edges after cutting tiles

If you get sharp, jagged edges, use wire cutters or pliers to level them. The uneven edge is bite off, and the chips are leveled with a round file. The edges of the tiles are treated with coarse sandpaper.

How to cut ceramic tiles

Wall tiles or glass tiles can be cut with a conventional roller glass cutter. Mark with a marker or pencil before cutting. Tiles designed for flooring are thicker and stronger, so a glass cutter will not be enough.

In such cases, a tile cutter (tile cutter) is used. It differs from a roller glass cutter with a wheel, which is much larger in the tile cutter, so the cutter can puncture the tile to a greater depth. The tile cutter resembles tongs in appearance, with its help you can not only cut, but also break the tile after the cut. The tile breaking mechanism consists of a metal tooth corner on the bottom of the forceps and a special corner on the top.

Electric tile cutting machine

If floor tiles are to be cut, the corner on the top of the pliers should only be made of metal. Therefore, if you decide to purchase a tile cutter, choose a tool not with a plastic, but with a metal corner. The plastic corner tile cutter is only suitable for wall tiles. Most cutters are equipped with a metal ruler with a stop, which is designed for serial cutting. if you need to cut tiles to the same size (for example, for a curb).

Ceramic tiles can also be cut with an angle grinder with a diamond wheel. it is best suited for working with tiles. But this method is the noisiest and most dusty, so you can use an angle grinder only when it is impossible to saw with a tile cutter or other tool.

Angle Grinder

The main advantage of this method is that cutting ceramic tiles with an angle grinder does not require special skills and is available to a non-professional. The principle of operation is very simple: we connect to the network, press the start button and, after the disc picks up the required speed, we cut "from ourselves" according to the markings applied in advance.

It is advisable to cut the ceramic tiles with a tool that has the ability to adjust the speed. It is recommended to work at a speed not exceeding 3.5 thousand rpm. At a higher speed, ceramics begin to crack, and hot shavings and dust fly in all directions at great speed.

The angle grinder is an inexpensive and easy-to-use tool. But it has several significant disadvantages. First, when cutting, a huge amount of dust and debris is generated. Secondly, the edges of the tiles are not very neat. They have to be processed additionally: remove the jagged edges with nippers, process the cut with a file and sandpaper.

Also, despite its simplicity, this tool requires careful handling. In order not to harm yourself while working, you need to know how to cut ceramic tiles correctly. Always hold the tool firmly in your hands to keep the space in front of the saw blade clear. Be sure to use safety glasses, gloves and a respirator.

How to cut floor tiles

Ceramic flooring has a high hardness factor and places higher demands on the tool. When choosing the best way to cut ceramic floor tiles, stop at one of the options discussed below.

How to cut tiles for wall cladding?

Ceramic tiles, which are commonly used for wall decoration, are relatively soft. Therefore, cutting it, in comparison with other types of this finishing material (floor or wall tiles), does not present any particular difficulty.

Glass cutter: regular and oil

If you need to make a quick cut of ceramic tiles in small quantities, then it is most convenient to use a roller glass cutter. It is not difficult to work with this tool. We put the tiles on a hard and flat surface, make markings with a marker. We roll the glass cutter along the intended mowing line, pressing evenly towards you. A visible line should remain on the surface. After that, we break the tiles along the cut mowing line. To do this, put a small object under it. a match or a carnation, and gently press on both sides.

The handle of this tool has a reservoir into which a mixture of kerosene and machine oil is poured. Flowing down a special channel, this mixture enters the roller and greatly facilitates the cutting process.

The advantages of the tool include speed of work, low price and ease of use. At the same time, with a glass cutter it is difficult to cut a large number of tiles in one go.

Manual tile cutter

With a large amount of work, a hand-held tile cutter is a better tool for cutting ceramic tiles. It consists of a base, guide tubes and a cutting element.

Place the tiles inside the device to work. Advance the cutter wheel away from you while trying to keep the pressure even. When finished making the cut, press down on the handle to break the tile.

Cons. the tool is not universal, you cannot cut strips less than 5 millimeters wide on it. The edge of the fracture is sometimes uneven and must be sanded by hand.

Shaped tile cutting

During renovation, it may be necessary to make holes in the tiles for pipes, hoods or sockets. Tiles may also need to be trimmed to fit around a toilet, sink with leg, or door trims. Below we will consider how to cut ceramic tiles in these cases.

We cut ceramic tiles with an electric tile cutter

This tool belongs to the professional category and is quite expensive. With its help, a significant amount of work is easily performed, it cuts any tile quickly, accurately and beautifully. Allows you to cut less than 5 mm wide, make cuts at an angle of 45 degrees, recesses and holes. It is used for curly cutting. The cut has smooth and slightly rounded edges. In some models, the edge of the blade is immersed in water, in others, the surface at the cutting site is only wetted. During operation, all dust settles in the cooling water tank.

The design is very similar to a circular saw. Consists of a platform, a cutting disc fixed on it and an electric motor.

How to properly cut ceramic tiles with an electric tile cutter.

- Water is poured into the container so as to overlap the edge of the cutting wheel by 2-3 cm.

- Include tile cutter.

- Press the ceramic tile against the machine and slowly move it under the disc, focusing on the marked line.

- The blade is moved under the cutting element with a force depending on the strength of the tile. It is not recommended to apply excessive pressure on the knife, this may cause the tile cutter to stop.

- To cut a corner, the tile is gently lifted, unfolded and repeated.

It is necessary to monitor the condition of the cutting edge of the disc, replace it in time. Diamond wheels are commonly used. Also regularly, as it gets dirty, they change the water in the bath.

How to cut ceramic tiles

When working with tiles, the question arises: what is the best way to cut ceramic tiles? The choice of tool is determined by the amount of work and the properties of the tile itself. There are several ways to cut ceramic tiles.

Glass cutter

This is the simplest and cheapest ceramic tile cutting tool. It has a different design:

- Cutting element. small diameter wheel;

- Diamond stylus;

- Roller glass cutter with oil reservoir in the handle. Grease flows down a narrow groove and makes the notch easier.

Glass cutter cutting elements can be replaced as the edge is seamed. How to cut ceramic tiles with a glass cutter? On the front side, a cut line is drawn with a pencil or marker. Holding the ruler on the mowing line, draw the glass cutter towards you from the far edge of the tile. The goal is to draw a uniform depression that reduces the strength of the tile.

Then place the tiles on the edge of a table or other flat surface. The line of the cut should line up with the edge. Holding the edge of the tile on the table with one hand, with the other gently press on the edge that is suspended. The tile should break at the notch. Its edges are sanded with a file for ceramic products.

It is advisable to use a glass cutter for small amounts of work. It allows you to make straight cuts vertically and diagonally. Not suitable for cutting floor tiles, porcelain stoneware tiles and tiles over 5 mm thick. It is problematic to cut a strip less than 20 mm wide with a glass cutter.

How To Cut Ceramic Tile Angle Grinder

New wheels are used for dry cutting, diamond dusting or for work on concrete. An angle grinder is best used with variable speed. At a rotation speed above 3.5 thousand rpm, the tile cracks, and the dust content increases significantly.

Floor tiles, porcelain stoneware and wall tiles can be cut with the angle grinder. With a certain skill, you can cut circles of 70 mm in diameter and make curly cuts.

The cut is made from the back of the tile, as small chips may remain on the surface. The canvas is laid on a solid and even surface, mark the line with a marker, draw an angle grinder around it and break off the part that is longer. The cut surface can be trimmed with the same angle grinder.

Other ceramic tile trimmers

What is the best way to cut ceramic tiles if you need non-standard edge shapes? There are various devices for this.

- Nippers. Used to bite off small pieces, corners and semicircles. Leaves behind an uneven edge that must be trimmed with an emery wheel.

- Diamond string. It is fixed in a conventional hacksaw for metal, used for curly cut. It cuts only wall tiles and requires some skill, since jerking chips form on the surface.

- Crowns are used to make round holes in ceramic tiles for sockets and switches.

- Ballerina. With the help of such a drill, holes of various diameters are made. The size is adjusted manually by changing the distance to the cutter. Up to 20 cuts can be made with one nozzle.

How to cut ceramic tiles with a manual tile cutter

The tool allows you to cut strips from 5 mm wide, straight or diagonally.

It can be used to cut durable floor tiles and porcelain stoneware up to 15 mm thick. By design, it is a base, on it are fixed carriage runners with a cutting wheel. It is slightly larger in diameter than in a glass cutter, which allows for a greater notch depth. The minimum size of the wheel is 1.5 cm.It is also removable, it can be replaced after a cycle of work.

On the base of the manual tile cutter there is a strip of hard material, with the help of which, after the cut, the tile is broken. There is a T-shaped piece in front of the roller on the carriage, which exerts pressure on the two halves of the tile.

The tile is placed on the base of the tool, having previously marked the break line, clamped tightly., The clamping corners must be metal in order to cut the floor tiles; plastic is enough for the wall. Pull the handle of the carriage, making an incision on the front surface of the tile.

The incision is made once. After the end of the cut, press the handle and the tile breaks. Edges will also have to be processed if they fall on a corner. If grout is used, then it will hide all defects.

Shaped tile cutting

During renovation, it may be necessary to make holes in the tiles for pipes, hoods or sockets. Tiles may also need to be trimmed to fit around a toilet, sink with leg, or door trims. Below we will consider how to cut ceramic tiles in these cases.

How to cut ceramic tiles, methods and tools for work

When choosing how to cut ceramic tiles, you need to decide on the upcoming volume of work and its type. A tool that can handle wall tiles easily will not work with floor tiles. Radial cutting requires a different tool than simple cutting.

Ballerina

Deciding how to cut a ceramic tile to get a certain hole diameter? Choose a circular ballerina drill for this job. The distance to the cutter is manually adjustable, and you can set any diameter that you need.

To get a neat hole, use a drill stand while working. One ballerina can make up to 20 holes in a tile.

How to cut tiles for wall cladding?

Ceramic tiles, which are commonly used for wall decoration, are relatively soft. Therefore, cutting it, in comparison with other types of this finishing material (floor or wall tiles), does not present any particular difficulty.

Electric tile cutter

If you are looking for a way to cut ceramic tiles quickly and efficiently, then use an electric tile cutter.

An electric ceramic tile cutting machine consists of a motor, a platform on which the cutting element (most often a diamond-coated disc) is fixed and a container with water. In some models, the blade is partially submerged in water, in others, only the cutting area on the tile is wetted. This principle of operation reduces the amount of dust, prevents tiles from cracking and extends the life of the cutting blade.

The electric tile cutter is a versatile tool. It is suitable for cutting ceramic tiles of any hardness; makes straight cuts with smooth edges that do not need additional processing; cuts pieces of tiles less than 5 mm wide. In addition, it can be used to make a cut at an angle of 45 degrees, as well as a hole or recess.

Such an acquisition only makes sense if you plan to use it regularly.

Manual tile cutter

With a large amount of work, a hand-held tile cutter is a better tool for cutting ceramic tiles. It consists of a base, guide tubes and a cutting element.

Place the tiles inside the device to work. Advance the cutter wheel away from you while trying to keep the pressure even. When finished making the cut, press down on the handle to break the tile.

Cons. the tool is not universal, you cannot cut strips less than 5 millimeters wide on it. The edge of the fracture is sometimes uneven and must be sanded by hand.