How to cut foam evenly by thickness

How to carefully cut and glue furniture foam at home

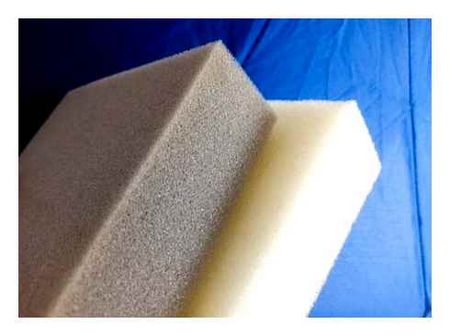

Foam is a universal material. It is used in many large industries and crafts. Characterized by its porous structure, elasticity, softness and attractive cost. When working with furniture foam, craftsmen at home, especially those who have not used it before, have two questions: how to carefully cut and firmly glue the parts of this material with each other. The secrets of how to do it correctly, quickly and reliably shared by the masters of the company “Vinyl Tex”.

To cut smoothly and without scuffing furniture foam for a sofa, chair, tachty or armchair, stock up:

Tips for Cutting Foam on a CNC or CNC Machine

- With a sharp knife: with a box cutter or linoleum cutter;

- Marker or felt tip pen;

- with thick cardboard, plywood or a piece of board under the base;

- With a wooden rail or a usual ruler, a template (for curved cuts).

- Choose a place for laying the sheet of foam and put a thick cardboard or a piece of board under the material so as not to spoil the base (floor, countertop) when cutting;

- Use a marker pen or marker pen to make marks on the foam and connect them with a ruler or ruler. To cut under the radius, use a template or template;

- Take the knife and holding it vertically, firmly, confidently draw the marking. Do not use a ruler when cutting, as it will press the weight of your hand on the foam, crumple it, and the cut will end up uneven;

- if the foam is not cut through to the end, spread the “treated” area with your fingers and with the second cut finish the work. If scoring occurs, break the blade of the utility knife, or replace it.

With what and how to glue the foam rubber

To work with foam rubber suitable contact adhesives on a butadiene styrene, polyurethane, neoprene basis. The most popular and budget-friendly are: BF-6, Glue 88, Rapid-100. They are safe for health (do not emit toxins), easy to use, and securely bind the foam parts together.

- Coat the edges of the prepared parts with glue, using a roller, brush or spray gun. Economical option. gun, consumption of the composition of about 70 gr./cm.sq.;

- wait for the time specified in the instructions;

- Connect details, firmly press or press down until a reliable, even, elastic joint is formed.

Company “Vinil Tex”: furniture foam furniture for the sofa and other upholstered furniture, as well as upholstery, accessories retail, wholesale and delivery to all regions of Russia.

How to cut the foam

Hello all, just recently I faced the problem of how and how to cut the foam evenly, and at home. During all my hobby in carpentry I have never worked with foam rubber, which is understandable, I usually work with wood.

So how to cut the foam rubber? And what do you need for that? The first thing that came to my mind than to cut a thick foam rubber is some expensive machine, which is just not realistic to buy, because I once cut foam, but a long time ago, and it did not work out well.

At work, in a nearby shop are engaged in upholstered furniture, and then at lunchtime I met a guy on the street who does it. During the conversation I found out that in order to cut the polyurethane foam, they use a regular knife and they don’t have any expensive equipment. We got to talking, and he told me how to cut the foam rubber neatly at home.

To cut the foam, you will need the following

- A sharp knife, preferably a box cutter or linoleum cutter

- A highlighter or marker with a fine tip

- Cardboard or something else under the base

- A good ruler

So, how to cut evenly foam rubber, first of all, using a marker, make a scythe line cut on the foam. If it is a straight line, it is better to use a ruler, if you have to cut it under the radius, it is better to use some kind of template, template or other device to draw exactly the radius.

Next, in order to cut the foam plywood, you will need to prepare the base. As a base, many advise to use plywood or particle board. I would not advise you to do this because when you cut the foam rubber with the knife the tip of the knife will blunt on the plywood. So for a base to cut thick foam at home, I suggest using cardboard. By the way, I forgot to tell you what the base is for, the base serves to protect the floor or other base on which you are going to cut the foam rubber, and as you know to protect the tip of the knife.

And the last point how to cut the foam, is the process of cutting. Use a very sharp knife for this. Your kitchen knife will obviously not fit here, as its blade is thicker. Then than to cut evenly foam rubber at home, I advise you to use a utility knife, or a construction knife, such as those that cut linoleum. It is very important that the blade and the tip were sharp, otherwise you will not be able to cut evenly foam rubber.

Well and then proceed to work, hold the knife flat on the mowing line, preferably without using the stop, because the stop will press on the foam rubber, thereby creating a load in it, and the knife will not cut well. If in doubt of your abilities, it is better to train on another piece of foam rubber so as not to spoil the workpiece.

And in general, foam rubber is usually cut in order to cover them upholstered furniture. So it is perfectly flat can not be done, and it will not be 100% flat to cut it all. On top of the foam will still be a cloth, which will smooth out all the irregularities and uncertainties of the cut.

Here I am, this article may be useful to those who have thought about how to cut foam rubber at home with his hands. I would be glad to hear from you, tell me what you think about it, and if you have experience, share it.

How to cut foam rubber at home: expert advice

Foam rubber is a great thing. Soft, comfortable and harmless. Most often it is used to make mattresses and padding for upholstered furniture. It comes in different degrees of hardness and thickness. But no matter what its elasticity and thickness, it should be cut only with a knife. About how to cut foam rubber with a knife, and why it is necessary to do it only with this tool, you will learn from this article.

So, how to cut foam rubber polystyrene at home, so that the edges were as flat as possible and close to those obtained in the production cut? To do this, you will need to prepare the following tools and supplies:

- The actual foam rubber that we are going to cut.

- Lining under the foam rubber that we will be cutting. Of course if we spread it on the linoleum or on the apartment floor it will be the end of those materials, because they will all be scratched by the knife. The best way to use a sheet of plywood with cardboard on it as a pad so the knife tip does not blunt on the solid plywood. Cardboard can be used by unzipping any cardboard box of suitable size.

- It is desirable to have a knife from the category of construction. They are also called linoleum cutting knives. It has a complete set of removable blades, which in the case of bluntness can be replaced. It is better to use a brand-name European, not Chinese knife, as the steel in the “Chinese” is of low quality, and such a blade will blunt after the very first wire.

The work must be carried out in accordance with a certain sequence. Following it will ensure a perfect cut of the foam material. The stages of work are as follows:

- First you need to lay the plywood sheets and put cardboard on them (you can take an ordinary cardboard box and disassemble it).

- A foam pad is placed on top. Make sure that the fishing line of the intended cut falls exactly on the lining material.

- Then you need to take the ruler and the necessary dimensions to draw a line, which will be used to cut foam rubber.

- After that you need to take the blade. It is necessary to make sure that the length of the blade is enough for the entire thickness of the foam rubber blank. There is no difference in the thickness of the material. The main thing after the first cut is to try to insert the knife into the original cutting line, to make a complete cut, a little while gripping the edges of the product to be cut on both sides with your free hand. In this case the cut will be almost perfect.

There is also no need to hold the knife strictly vertically when cutting the foam material. This is not the right advice. In the process of cutting it should try to position it tilted toward you. The plane of the blade should be vertical to the ground. It is not necessary to bend it sideways (in this case the cut edge will look trapezoidal).

If after the first cut, the foam is not cut all the way through, there is nothing wrong with it. In such a situation it is necessary to extend the edges of the cut, insert the knife and make another even cut. If in the process of cutting you feel that the blade began to make hooks when wiring, it will indicate that it is blunted foam material is not cut, but torn, making a burr strip. It is recommended to change it after 5-6 passes, without waiting for that moment. CNC curved cutting foam and cutting foam rubber of any thickness is carried out in specialized companies.

Features of further gluing of foam rubber

If cutting foam at home is not successful, and the edges are crooked or the cut is not made correctly, you can try to glue the workpiece before further use. I did it as follows:

- I needed glue of butadiene styrene polyurethane nonpropylene base. I chose the Rapid-100.

- Lubricated the edges of the prepared parts with this glue, to save money I used a gun, as the maximum consumption was 70 g/cm2.

- Took the time until the glue takes the desired shape (for each model of composition there is an individual spacing of gluing in the instructions on the package).

- Then glued the parts together, making sure each edge is evenly pressed, you can use a press, as one can not perform fixing very convenient.

Here’s a quick tutorial. But, I advise you to try the first time to properly cut the thickness of the foam rubber at home, because the stage of gluing will still require some skill.

This video describes the simple process of cutting foam material into pieces at home