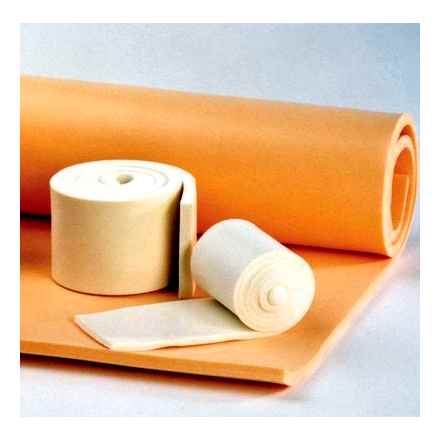

How to cut foam rubber lengthwise

How to cut and how to glue foam rubber at home

On the Internet, the advice is repeatedly found that it is better to cut foam rubber with a heated nichrome wire connected to 12 V or a sharpened soldering iron. At home, you should not do this, because when heated, foam rubber releases harmful cyano-containing substances. These substances, even in small doses, are highly toxic and affect the human respiratory and nervous systems. Therefore, we will not reinvent the wheel and risk our health, because the foam rubber can simply be cut with a sharp knife.

Any construction knife with replaceable blades is suitable for cutting. The main blade must be sharp.

We mark the foam rubber with a marker or felt-tip pen. We put small marks.

We connect the marks with a straight line along a ruler or wooden plank.

It is imperative to put an unnecessary piece of plywood, boards, chipboard or thick cardboard under the place of the cut, so as not to cut the floor. It is better to cut without a ruler. Slowly follow the markings with a precise strong movement. We hold the knife strictly vertically.

If the foam rubber has not cut through to the end, we push the cut part with our fingers and with the second cut we cut the foam rubber to the end.

If we take into account that the foam rubber will be used in a mattress or upholstered furniture, it will be covered with a fabric, then a completely acceptable cut is obtained.

If you get scuffs, the tip of the blade is dull. Break off the tip of the blade or replace it completely.

Curved cuts are made in the same way.

The pattern is used to make markings on the parolone.

Keeping the knife strictly vertical (do not overwhelm)

The cut is not perfect, but quite acceptable.

If necessary, the foam can be glued with glue 88.

The glue is applied evenly over the entire bonded surface.

Withstands 5-10 minutes (see directions for use) and presses strongly.

Foam rubber can be used as an additional mattress. It remains only to sew a cover on it. How to sew a mattress cover can be read here.

How to cut styrofoam

The widespread availability of massive, full-size foam boards has automatically led to a boom in the use of a relatively strong, soft, and at the same time easy-to-work material in the home. In fact, it became possible to manufacture a huge number of all kinds of useful things from a thick foam sheet, you just need to choose a method of how and what to cut the foam in order to prevent deformation, fracture or crumbling of the material.

Communities DIY Blog Styrofoam Cutting.

Hello everyone! Friends, you need to cut dense polystyrene foam (which is used to insulate houses, etc.) with a knife is not an option, you need exactly and in large quantities and at different angles. A good option is to cut with a string with heating, but I can’t imagine how to make such a device, therefore I ask for help and advice in the manufacture of this device.

Demo of Sailrite Blade Foam Saw. Version 2

Cutting polystyrene foam with an angle grinder

Cutting the expanded polystyrene plate can be done with an angle grinder, using a metal disc for this work (you need to choose the thinnest disc).

Such a cutting option is not efficient and comfortable enough, since the work is accompanied by a lot of noise, and after they are completed, a large amount of debris remains.

Thermal apparatus and devices

The use of insulation does not always involve cutting it to the correct geometric dimensions. Sometimes you have to cut out semicircles, holes and other shapes with intricate contours. And here a knife or a hacksaw will no longer help. But to cope with such work will be able to machine for cutting polystyrene, which is quite possible to build with your own hands.

Figured products made of polystyrene and polystyrene foam

The principle of operation of such devices is that an electric voltage is applied to the cutting element, as a result of which it heats up to a certain temperature, which can be controlled by a special device. And given the fusibility of the material, it is easy and quick to cut polystyrene foam with a heated string or wire. And at the same time, stubborn small debris does not form.

How to DIY a Foam Thermal Cutter

If you choose the best way to cut the insulation without the formation of small debris, then, of course, professional equipment will come first. But for home use, the purchase of such a device can be an expensive “pleasure”, so many craftsmen make a machine for cutting foam with their own hands.

Schematic drawing of a thermal cutter for horizontal cutting of foam

How to cut foam like a PRO. Cosplay Tutorial

The main point of the article

How to cut polystyrene. with a mechanical tool. a knife, a file, an electric tool. an angle grinder, a jigsaw, or using devices with a heated cutting element, everyone chooses at his own discretion. Thermal devices eliminate the formation of debris, but are expensive. For home use, it is possible to save money and do it yourself with a thermal foam cutting machine.

How the foam is cut so that it does not crumble

Expanded polystyrene is a versatile material that is used for heat and sound insulation of buildings under shock and noise loads. When carrying out repair work related to thermal insulation or redevelopment, it is necessary to cut out large sheets of insulation. In this regard, the question arises of how to cut the foam so that the line is even.

Consider equipment that is used for cutting foam at home. These include:

- knife

- hacksaw for metal

- wood saw with fine teeth

- angle grinder

- soldering iron

- nichrome wire.

Before you start cutting, you need to mark the workpiece with a simple sharpened pencil. If a hacksaw or jigsaw is used as a cutting tool for Styrofoam, do not make quick movements. This is due to the good thermal insulation properties of the material, when when friction occurs, heat is not removed and it heats up, which complicates the process. Use a soldering iron if you need to quickly cut the workpiece. To do this, flatten its end with a hammer and fix a special part, for the manufacture of which you need to take the metal cap of the fountain pen and the blade. After warming up the device, start cutting the sheets.

Only cut very thin foam with an angle grinder. It is unlikely that it will be possible to achieve a high quality cut, the result will be the same as when working with a jigsaw. In addition, with this method of processing the material, there will be a lot of debris and noise.

To cut the foam, you can use an ordinary knife, which should be sharpened well and preheated. The stationery option is suitable for cutting soft material, it has a sufficiently flexible blade and it is not recommended to use it for processing slabs of significant thickness, since it is difficult to obtain an even vertical cut. The advantages will be a small amount of waste, availability and low cost of the tool. Remember that the thinner the sheet, the smoother the cut will be, the optimal thickness should be no more than 5 cm.

This method can be used if you have an elementary understanding of electrical engineering, for the manufacture of the device you will need to prepare:

The table is placed at an angle (20-60˚), and a wire is pulled across, one end of which is fixed rigidly, and a spring is used to secure the other. The wires of the transformer connected to the electrical network are connected to them. The current is supplied, the workpiece is placed on the table. Sheets are cut by sliding due to their own weight.

You can pass current from the power transformer of the old TV. Another option is to include a variable resistance (rheostat) in the electrical circuit. The strength of the current must be controlled so that there is no strong heating, the result of which will be the melting of the foam and the appearance of sagging along the edges of the mowing line.

The attractive side of this method is the ability to cut fragments both along a straight mowing line and along kinks and convolutions, which makes the process universal

It is important to remember that the wire should not be very hot. It will be enough if it just turns slightly red, otherwise the cut will turn out to be too wide

A strong spring should be selected, this will make it possible to adjust the length.

It is possible to cut the foam slabs with your own hands using simple but effective equipment, such as steel wire with a diameter of 0.5 mm and wooden handles fixed at the ends. Previously, the block needs to be marked on both sides and began to cut quickly. The filament heats up and melts the material, resulting in a hard, smooth and melted surface. To determine the best way to cut expanded polystyrene (polystyrene), it is necessary to evaluate all the advantages and disadvantages of the listed methods and choose a tool based on the features of such cutting.

Types of tools

Mechanical cutting. The most common tools at hand include a knife, jigsaw, saw, and angle grinder.

The main focus when choosing a knife is on its blade. If it is sharp, the cutting process is faster and less waste is generated.

The knife must be preheated before cutting.

The disadvantage of this method is that the use of a knife is possible with a foam thickness of 1. 5 cm.

Stationery knife. The stationery version of the knife is best used for soft material. This knife has thin and flexible blades, so it is not used for cutting thick slabs.

Jigsaw. Jigsaw cutting is used when cutting foam up to 10 cm in thickness. This method does not require much effort.

Hand saw for wood. If the thickness of the foam reaches 40 mm, then it is better to cut it with a hacksaw on wood. The method is quite simple and quick, without the cost of much physical effort.

A saw with fine teeth is better suited. This tool is only used for straight cuts.

“Angle grinder”. The advantages of an angle grinder are that it cuts the foam itself, if you use the thinnest circles.

However, it is not recommended to cut thick material with an angle grinder. You will not get a high-quality result, but there will be a lot of garbage.

In addition, this option is not very good because of the squeal that occurs when the foam interacts with the circle of the machine. Plus, the noise of the instrument’s engine is added to it. Therefore, in the case of cutting a large number of foam boards, you should put on headphones from the very beginning of work. Add to this list the electricity consumption that will need to be paid.

Nichrome wire cutter. The practice of working with foam shows that a high-quality cut is formed when using a tool with a heated wire. The edges are even, smooth, and there are practically no crumbs. The advantages of the method can be added to the high cutting speed and productivity in volumes similar to industrial.