How to cut glass with a glass cutter at home

How to properly cut glass with a glass cutter at home?

Sooner or later, the household may need to replace the glass on its own. But working with such a fragile material is very traumatic. In this connection, in order to avoid injuries and excessive consumption of material, you should know the basic rules for working with this material and the selected tool.

Cutting ordinary glass is very simple and it will not cause any difficulties for a person. You can cut such glasses with a special glass cutter or even ordinary scissors.

If you have no idea how to properly handle this tool, then you can watch numerous videos on this topic on our website. They will help you cut out the desired shape and provide the necessary information for working with a rather complex and fragile material like glass.

How else can you cut glass

What if you don’t have a glass cutter at hand? There are ways in which glass is cut with a non-standard tool. This operation can be carried out with a soldering iron, angle grinder, nichrome thread and even ordinary scissors! Let’s find out how to properly cut glass with your own hands using each of these methods.

- With a soldering iron. First, make cuts with a file at the beginning and end of the cut line. Then it is necessary to carefully carry out along the entire mowing line with a well-heated soldering iron. Due to the temperature difference on the sides of the surface, the glass will crack, after which it remains only to gently break it off.

- Angle Grinder. This tool is found in almost every home, so it is not surprising that it was also adapted for working with glass. In order to cut off glass with an angle grinder, you need a thin diamond disc. With its help, a thin groove is made along the entire mowing line of the cut, along which a chipping occurs in the future. But when cutting an angle grinder, make sure that the glass does not overheat, and be sure to use coolant. A good tool is required, otherwise the glass will simply shatter from its vibration. It is imperative to protect the respiratory organs and eyes when working with an angle grinder on glass. The smallest glass dust getting into them will not lead to anything good. Therefore, if you cut a sheet of glass with an angle grinder, you need to stock up on glasses and a respirator.

- Using heating and cooling. A thread impregnated with a combustible substance is laid along the mowing line of the cut and set on fire. Immediately after it goes out, the cut line is cooled with water. The glass will crack from a sharp temperature drop. Another option is heating the glass with a nichrome thread through which an electric current passes. In this case, no water is required, the temperature difference between the two surfaces of the sheet is sufficient.

- Scissors. Non-thick glass up to 3 mm is cut with ordinary tailor’s scissors, if this operation is performed by immersing the scissors and glass in a container with hot water. Feels like cutting thick cardboard.

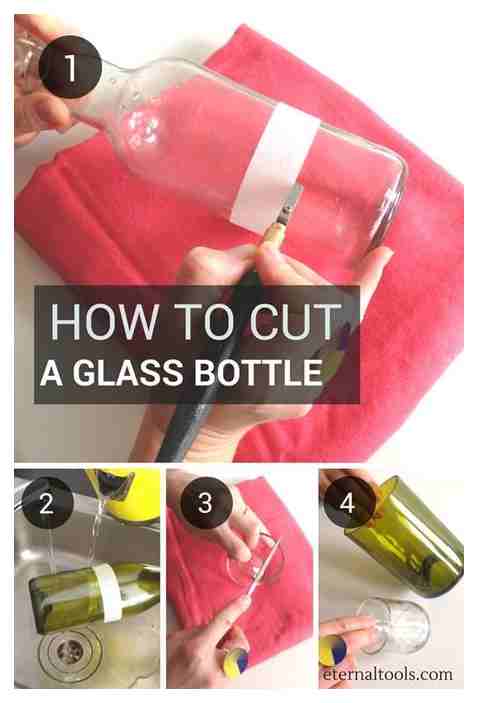

How to Cut Glass Bottles | 3 ways to do it

How to cut glass with a glass cutter: detailed instructions

If you have planned to carry out work on cutting glass, then first of all you should decide which glass cutter is best suited for your case. At the moment there are two types of tools. diamond and roller.

The diamond model is considered to be the leader among the tools of this type. If you are going to use it at home, then the model that has a beveled edge is perfect, which is very convenient for breaking off cut pieces. You can cut glass with such a glass cutter almost ten kilometers of material, with a thickness of up to one centimeter. But at the same time, it should be borne in mind that there are cheap types in which an artificial diamond is installed, which allows you to cut glass with a thickness not exceeding 5 mm.

Unlike diamond, a roller glass cutter has a working element in the form of a small roller, usually made of carbide materials, usually a tungsten-cobalt alloy, which is capable of cutting material up to 4 mm thick. The advantage of this type of tool is that the roller can easily move on the glass, while not putting much effort to lay the furrow.

The work process is carried out in the following order:

Clean and dry glass is laid on the surface of the working table. The necessary markup is made with a marker. Further, at both ends, small cuts are made along the marked mowing line. Please note that the material used must be in close contact with the surface of the work table.

After that, you need to put a ruler on the glass and draw a line along it with a tool. It is worth holding a diamond glass cutter in your hands in the same way as a regular pencil; when passing along the marked mowing line, only a little effort should be applied. As a result, only a barely noticeable mark remains on the glass, which looks like a scratch. If the instrument is in good working order, then a characteristic crackle-like sound must be present. If the sound is creaking, then this means that its cutting element needs to be sharpened on a special bar for this.

Holding such a tool during operation should be at a slight angle, the correctness of which is determined empirically. Please note that a tool that is in the correct position relative to the glass leaves a colorless thin line.

A roller glass cutter, unlike a diamond one, must be held strictly at right angles to the surface of the glass, while pressing it with the middle and thumb, and pressing it with the index finger. Please note that the roller tool is pressed a little more than the diamond one, and the cut itself should turn out to be white.

In order to get a high-quality and, of course, even cut. remember a few simple rules that must be followed when working with glass using a diamond tool:

- Do not press on the glass while moving the cutter, otherwise the cut will be too deep and the edges will be uneven.

- In no case should you make another cut on the resulting mowing line. Otherwise, the glass may break. The incision should be made as quickly as possible. For example, if we cut a length into a meter, then you need to spend no more than two seconds on it.

- In order for the workpiece to break off quickly and accurately along the mowing line of the cut, you need to lightly tap on the back of the glass. After which you will not need any effort to break it off.

If you are just a novice master, then it is best to practice on small pieces, this will help determine the correct angle of inclination of the instrument, gain experience, reduce losses, and also avoid mistakes in the future.

Preparatory activities

In order for the cut to be of high quality, you must first prepare the material for work. If the glass is new, then just wipe it down. A newspaper is best suited for these purposes, it mainly wipes the surface dry, and also does not leave lint and stains behind.

If the glass was previously in use, then before cutting the material with a glass cutter, it will take a little more time to prepare it. First of all, such a surface will need to be washed well using special glass cleaning products. This is followed by a thorough degreasing process. Alternatively, you can use kerosene. To do this, wipe the glass thoroughly with a cloth soaked in kerosene and wait until it is completely dry.

At the same time, the stage of glass preparation also includes its cutting. There is no doubt that you will be able to achieve the final result without waste, especially if you need to cut a product with an irregular geometric shape. But if you make the calculation as correctly as possible, then you can reduce the amount of waste several times.

Also, make sure that the working surface is sufficiently flat and without slopes, but not too hard, it is advisable to make the working surface of plywood or fiberboard, and cover it with an oilcloth or soft cloth on top.

Safety regulations

Having started a procedure for cutting glass, be sure to keep in mind that working with this material requires compliance with safety rules, which are not recommended to be neglected. Unfinished glass has sharp edges that can easily cut through the skin and cause infection. To avoid cuts, protect your hands with gloves and wear sleeved clothing. Since glass tends to crumble into small, sharp fragments, we strongly recommend cutting with glasses.

The place where the glass is cut must be flat and stable. It is strongly not recommended to perform this operation on the knee, loose stool and other questionable surfaces. Compliance with this rule minimizes the risk of glass falling to the floor, and also makes work more convenient and improves the quality of the cut.

If you have not previously had experience in handling glass, and still do not know how to cut with a glass cutter, we do not recommend neglecting the above recommendations. Perhaps some experienced craftsmen can do this work with their eyes closed on their knees, but for beginners, things usually do not go so smoothly. Due to inexperience, you can make many mistakes: grab a sharp edge, drop the glass on your leg, or pass the cut site and get a splinter in the eye. If you are working with glass for the first time, and have not yet experienced this process, it is best to be fully armed.

Glass selection

One of the key success factors for any job is choosing the right material. This belief also applies to glass, which should be selected based on the task at hand. In the following paragraphs, we will give a couple of recommendations on how to determine the quality of glass and choose the optimal thickness. If you already have the material in stock, you can go to the next heading or directly to the instructions on how to cut glass with a glass cutter.

Before starting the description, we clarify that we are talking about ordinary window panes, which are most common in the construction markets. The first thing you need to pay attention to when buying glass is its end part. The edge of the canvas should have a bluish green tint. Poor quality glasses have greener tones due to their higher iron content. This material is more fragile, but usually costs less.

Tempered glass processing

Often on the forums there is a question: how to cut tempered glass? The answer is simple: tempered glass cannot be cut or drilled. At any attempt to do this, it loses all its properties and simply shatters into small pieces. Tempered glass was used in cars before the triplex technology was invented. In an accident, glass fragments should not have injured passengers. So you shouldn’t even try to cut the tempered glass with any tool.

To understand how to cut glass with your own hands, you just need to take it and try it. The choice of method depends on individual skills and the availability of the necessary tools. But all these options are quite feasible at home.

Glass cutter selection

Any training begins with an introductory part. There are no exceptions in our business. Before getting down to business, you need to familiarize yourself with many equally important aspects. One of them is the choice of a glass cutter. There are 3 main types of these instruments in total:

- Glass cutter with natural diamond cutting tool. This tool is the most popular. It has a tip that is capable of cutting glass up to 10 mm thick. At the same time, the cuts always turn out perfectly smooth and without various defects, of course, if you use it correctly.

- Roller cutting tool. His working tool is made in the form of a roller. Unlike the first option, instead of diamond, a special alloy of hard metals is used, which are often tungsten and cobalt.

- Oil glass cutters are not much different from roller counterparts. To be more precise, there is only one difference. It consists in the fact that during cutting, a special oil lubricant is supplied to the cutting tool. It will not speed up the cutting process, however, this is not the advantage of the tool. Continuous oil supply will extend the life of the roller mechanism.

Returning to the first type, it is worth noting that the tool is not cheap. However, there are also their analogues that cost less. The difference lies in the fact that instead of a real diamond, its artificial analogue is used. It should be noted that in terms of cutting quality it is not much inferior to the original, but it is effective when cutting glass with a thickness of up to 5 mm.

How to cut a circle

We have already figured out how to cut the glass in half. But it is also worth paying attention to one important issue. Namely: how to cut a circle out of glass? In this case, you can use two options:

- Place a round solid template on the glass;

- Use a special compass.

The second option is more reliable and simpler. Therefore, it is recommended to use round templates only if it is not possible to get a compass.

Let’s see what such a compass is. In fact, this is a fairly simple design, which consists of the following components:

- Sucker;

- Glass cutter;

- Tripod.

How to use a compass is intuitive. The suction cup is attached to the glass, and the glass cutter is set on a tripod with the required measurements. After that, an incision is made quickly but smoothly on the glass. Then the contour should be slightly beaten with a hammer. Done.

Preparation of glass and workplace

Prepare the glass before cutting. If new material is used, wiping with a dry cloth is sufficient. But glass, which has already been used in everyday life, should be treated with special detergents, and then degreased with kerosene. you need to dry it thoroughly.

As for the workplace, there are few requirements for its preparation, more precisely, there are none at all. It is enough just to have a flat free table and a container for waste glass.

How to properly cut glass with a glass cutter

Glass cutting can be attributed to jewelry craftsmanship. After all, real experts can make a real masterpiece out of a piece of this material. However, this will require a fairly large amount of experience. At the same time, many cannot simply cut glass in half, since they do not know the very basics of glass cutting.

We are not saying that we will make you a sculptor with a glass cutter instead of a chisel. However, you will learn how to make a glass tabletop and other such things.

Cutting with a diamond glass cutter

The diamond glass cutter is not only reliable but also convenient. The principle of operation is quite easy. The tool is taken by the pen like a pencil. Next, an incision is made along the glass. To avoid messing up, it is recommended to use a ruler or a pre-cut template.

You can also use another trick when marking up. It is suitable if you need to make a straight cut. So, the point is as follows. A straight line is marked on the table with a marker. The glass should also be marked. But there is no need to draw a thick line. It is enough to make notes at the edges of the material, between which the cut will be made. After that, the marks should be set so that the line on the table connects them.

Let’s go back to the cutting process. The essence is clear, but there are some nuances that should be taken into account.

- The diamond glass cutter should be held at an angle. At the beginning of the section, it was said that it looks like a pencil. So you need to “draw” just like with a pencil.

- Do not press hard on the tool, otherwise the cut line will be uneven and full of chips.

- Re-cutting along the mowing line already carried out by the glass cutter is taboo. Don’t ask unnecessary questions, just try to do it right the first time. If the break has already failed, you should move a little and repeat the procedure.

- You need to make the cut quickly. It should take about 2–3 seconds per meter segment.

What to do after the line has been cut? It is necessary to move the glass to the edge of the table so that the unnecessary part of it turns out to be a canopy. Further, one simple procedure should be carried out along the entire mowing line of the cut. From below, with the reverse side of the notch, you need to lightly knock on the glass. If everything is done correctly, the unnecessary part will easily disappear. The main thing. do not forget to substitute a container under it or hold it with your hand.

Cutting with a roller glass cutter

Before figuring out how to cut glass with a roller tool, it should be remembered that it is not as durable as a diamond glass cutter. The roller cuts the first 300 meters properly. After that, you should replace the working part.

Now you can get down to business. The first step is to apply the markings. This can be done in the same way as in the first way, so there is no point in redescribing these methods. The general principle of operation is also the same. However, there are still some differences in the intricacies of the process.

- Unlike a diamond glass cutter, which must be held at an angle, in this case the tool must be positioned perpendicular to the plane of the glass.

- Press more firmly on the roller glass cutter, otherwise the glass will not be cut.

Next, we do everything the same as in the previous section.

Cutting with oil glass cutter

For this cutting method, it was not necessary to create a separate section in the article. After all, the method is no different from the above, only the roller is lubricated with oil, thanks to which the cutting process is facilitated, and the service life of the working part is increased.

ordinary scissors

Cutting glass with scissors like paper is not a fairy tale, but a completely ordinary reality. For this purpose, you will need the scissors themselves (sewing machines are best for this) and a tank of water (preferably hot). It is necessary to apply markings on the glass in advance, and then, elementary physics is included in the work: the scissors create a microcrack, and the capillary effect completes the process. Of course, the result obtained will differ from that achieved with a glass cutter, but if necessary, this method can greatly help out.

What means of protection to use when working

Safety precautions are the most important thing that must be observed when working with any tools, including manual glass cutters. over, you need to prepare for work in advance, because you can get injured when transporting material. For protection when working with glass, you must use the following means:

- Safety glasses. when breaking the glass into two parts, small particles can get into the eyes, so the first thing we do is protect our eyesight

- Glazier’s gloves are special gloves that have a thick coating that prevents the occurrence of cuts on the skin of the hands.

- Special jumpsuit. protects the body from damage in case the glass breaks and the fragments fly to the side

- Boots. there are cases when, after cutting the glass, part of the material broke off and fell to the floor, hitting a person’s leg. Lack of protective ammunition leads to serious injury and damage

- Headphones. If you often have to work with glass, you will also need special ear protectors. After all, listening for a long time to the creak of glass that occurs due to the sliding of metal is a rather unpleasant phenomenon.

Only after putting on protective ammunition, you can start cutting glass. How this is done, and what the main points are important to observe, you need to consider in detail.

How to work with a glass cutter or instructions for its use

The question of how to use a glass cutter is not just a question for beginners. This is because glass is one of the most hazardous materials and can cause serious injury if misused. To eliminate the occurrence of injuries, and at the same time cut the glass of the required size, the following instructions should be observed:

- The material must be free from contamination. The presence of dirt is unacceptable, as it affects the quality of work, as well as the service life of the cutting part of the tool. The surface of the material should also not be wet, because moisture contributes to the sliding of the cutting edge, as well as the appearance of corrosion processes

- Preparing a paper plan for cutting the glass surface

- For cutting, you will need to use a ruler or a prepared template. over, the ruler should not slide over the surface, otherwise it will lead to distortions.

- Having applied a ruler exactly to the previously measured and marked points, you should start cutting. To do this, one hand presses the ruler, and the second draws the line with a glass cutter (the tool must be held like a ballpoint pen, only at an angle of 90 degrees). The pass is made without pressure (depending on the type of tool), which allows an invisible scratch to be made on the surface. Strong pressure is not needed if diamond tools are used. If a roller-type glass cutter is used, then you will need to ensure a strong and uniform clamping of the tool to the surface.

- If the line was not drawn correctly, do not try to line it up. To correct the mistake, you should turn the glass over and draw a new line.

- Glass break. do not try to make a very deep groove in the surface of the material, as the principle of glass cutting is to indicate the break point. On the reverse side of the material, light tapping is carried out using a mandrel. This tapping is needed to create a crack along the cut line. Having laid the sheet on the edge of the table exactly along the drawn mowing line, it is necessary to break it with sharp pressure down

After that, the cut off part of the material is ready for use. The end part at the fracture will have a roughness, which, if necessary, can be removed with a special sharpening nozzle clamped in a drill chuck or an angle grinder.

How to Cut Glass. Quick, Easy, & Safe

Open the glass

Also, the cutting of glass and the preparation of containers for collecting waste are also included in the preparatory work. There should be two containers, that is, for collecting small waste and for collecting larger ones, which may be useful in the future for something.

It is best to start cutting glass with a simple window glass, and then move on to more complex options.

Selection of rollers and lubricants

There are many types of rollers for different applications and different types of glass. For oil glass cutters, rollers are used made of the same material as for conventional ones. tungsten carbide or tungsten-cobalt alloy; hardened stainless steel products are somewhat less common. It is impossible to give an unambiguous answer regarding the quality of the cut of each material: all alloys are definitely harder than glass, and the assessment of the convenience of working with them is mostly subjective.

The roller diameter is matched exactly to the thickness of the cut sheet. If the roller is smaller, there may be problems with breaking, the larger one will leave an ugly chipped edge. For cutting with a curved contour or if the glass has an uneven surface, very small rollers are used, but in this case the markings should be very carefully tapped.

The rollers may also differ in sharpening angle. Glass with a thickness of up to 4–6 mm is perfectly cut by a roller with an edge of 135 °, this is the minimum value. The thicker the glass, the more obtuse the sharpening angle is used, in some models the angles reach 160 °.

There are also nuances with lubrication. For the safety of a high-quality tool, it must be filled with a special water-based composition. The oil has a certain consistency, due to which its minimum consumption is ensured, and is easily washed off with water. In the absence, you can use petroleum jelly: the consumption will be slightly higher, but there are no problems with cleaning.

Safety engineering

Glass cutting is a rather traumatic process. There are three main risk factors:

- microscopic glass dust that irritates mucous membranes;

- small needle-shaped shards that can damage the eyes when rebounding;

- sharp edges of workpieces.

Cutting glass, even on a small scale, must be carried out with glasses and cotton gloves. If you plan to work on this front for a long time, then a regular petal respirator will not hurt.

Most injuries result from excessive force being applied to the instrument. The likelihood that the hand with the glass cutter will slip off from excessive stress is quite high, this can not only lead to serious cuts, but also guaranteed to ruin the material.

And, of course, the traditional source of injury is human inattention. There is nothing worse than a glass splinter, so do not feel the quality of cut edges before sanding them, and do not cut the glass on a canopy or on your knees. Keep your work area tidy, especially on the floor, prefer closed clothing and do not place sheets of glass at too steep an angle.

Winning drill

Having a victorious drill with a non-worn tip can really help out when you need to cut glass without a glass cutter. The advantage of the method is that no other tools are required to work. A flat large table is cleaned of crumbs and other debris. A soft cloth, such as woolen cloth, is laid on top. Then they put the glass, apply a guide ruler and cut off the desired part with one movement of the drill towards itself. Make sure that the sharpest side of the tip is touching the material with the cutting tool. Compared to a glass cutter, you need to press harder on the drill. Finally, the edge of the sheet is hung so that the groove created on the surface runs parallel to the table top at a distance of 3-5 mm. The master, holding the glass with one hand, breaks off the cut part with the other with a sharp downward movement. If he lacks strength, then from below he taps with a hammer along the mowing line of the cut, after which he repeats the attempt.

When cutting corrugated glass, the rough side turns towards the table and the craftsman works with the smooth one. Also applies to mirrors and glass with a pattern.

Preparing glass for cutting

A lot depends on this stage, and the preparation process itself depends on what kind of glass you decide to use for cutting. New glass, bought specifically for this purpose, can be simply wiped off, and it is best to use an old newspaper for this (this will avoid streaks and settling of small villi). With used material, you will have to work with much more effort. First, it must be thoroughly rinsed using a special glass cleaner. Secondly, degrease with a cloth soaked in, for example, kerosene and finally dry indoors to avoid dust getting on the surface.

In addition, the preparation of the glass implies its cutting. As you know, you are unlikely to be able to achieve a completely waste-free production when working with glass, especially if you are planning to get a product of not quite the correct geometric shape. However, accurate calculation will reduce possible waste to a minimum. At this stage, a more rational solution would be to align the longer side of the glass with the longer side of the workpiece. Please note that the resulting scraps should not be thrown away, they can be used in the future to create new products.

What tools to use?

Many of us are accustomed to believe that glass can only be cut correctly and efficiently with a glass cutter. But what if you need to cut off a piece of glass urgently, but this tool was not at hand? There is another unusual, but no less effective way that helped our great-grandfathers get out of this situation. Such a tool is the usual scissors available from any owner. Let’s consider each method in detail.

We cut glass at home: with a glass cutter and simple scissors

Glass products at all times enjoyed great popularity: frescoes, stained glass windows, dishes and many other things created from scraps of this material have always amazed people with their grace and smooth lines. Looking at this splendor, it seems that to create it, you need to be a real professional with vast experience in working with glass and a lot of necessary tools, and a simple “mortal” will never master this complex science. In fact, not everything is as sad as it seems at first glance, and everyone can get knowledge of how to cut glass at home.

glass cutter

The technology for cutting glass with a glass cutter is quite simple. To do this, you must comply with certain conditions and choose the right glass cutter. Today, the choice of this tool is wide enough that allows you to turn work into pleasure.

- A time-tested diamond glass cutter that remains a leader in its field to this day. For home use, glass cutters with a beveled cutting edge are suitable. Such a tool is designed for cutting glass up to ten kilometers and is suitable for any thickness of the material used. From time to time, such a glass cutter needs to be sharpened on a special bar.

- Roller. Following from the name, the cutting part of such a glass cutter is made in the form of a roller made of durable cobalt-tungsten alloy. The number of rollers can be from one to six.

- Oil. Such a tool works on the principle of a roller glass cutter, with the difference that a reservoir with oil is built into its handle, which is automatically fed to the roller. Suitable for cutting thick glass.

For information on how to choose a good glass cutter, see

So, having dealt with the glass cutter, place the glass on a flat surface. Mark the glass and get to work. You can use a ruler to make the task easier. It should be borne in mind that the line must be carried out the first time, otherwise a second attempt will lead to cracking of the surface. It is necessary to cut glass with a glass cutter using equal efforts along the entire length of the mowing line.

ordinary scissors

Cutting glass with scissors like paper is not a fairy tale, but a completely ordinary reality. For this purpose, you will need the scissors themselves (sewing machines are best for this) and a tank of water (preferably hot). It is necessary to apply markings on the glass in advance, and then, elementary physics is included in the work: the scissors create a microcrack, and the capillary effect completes the process. Of course, the result obtained will differ from that achieved with a glass cutter, but if necessary, this method can greatly help out.

Types of glass and features of work

Cutting ordinary glass is almost straightforward. Not only glass cutters, but also ordinary tailor’s scissors do an excellent job with this task. But what to do for those who set themselves the task of obtaining a glass product with a more complex configuration. To do this, you should familiarize yourself with the properties of some glasses.

- Tempered glass products. In fact, it is impossible to cut tempered glass at home. it loses its properties. If you want to purchase an item with elements of this material, you should think about cutting it in the early stages. In addition, work with it must be carried out by professionals, since the hardening process of the resulting product can only be carried out under certain conditions.

- Corrugated glass. This patterned glass is especially popular for glazing doors or creating decorative interior elements. Unlike tempered glass, such glass is quite capable of cutting independently. Working with it differs little from working with ordinary glass, the only difference is that the cut is made from the smooth side. A roller glass cutter is best for this.

- Acrylic or organic glass is a transparent plastic based on synthetic resins. No special tools are required to cut it. At home, a metal saw, a cutter, and other tools used for edge processing do an excellent job with this task. In addition, with glass, the thickness of which does not exceed 2 mm., An ordinary stationery knife does an excellent job.

In any case, it is worth remembering that working with any glass must be accompanied by the observance of certain precautions. The presence of thick gloves and goggles are the main conditions for exercising your own safety. It will not be superfluous to take care of the arrangement of the workplace. Since working with glass implies the presence of fragments, cover the work surface with any material that you will not mind getting rid of. Feeling safe will allow you to achieve the best results.