How to cut hot glass with a grinder. How to cut off the potato glass in simple words about a complex process

How to cut glass with a grinder

Glass glass, thanks to a special hardening technology, becomes several times stronger than usual, although its degree of processing is significantly reduced. But if you listen to the advice of experts and comply with certain rules, you can avoid the appearance of defects when cutting this material. Therefore, before cutting the glass with a grinder, you need to familiarize yourself with the nuances.

Experts advise before cutting glass at home by a grinder, be sure to study safety requirements and certainly take them into account. Near the workplace there should not be combustible materials, flammable liquids and gases.

It is necessary to remove everything that may be damaged from getting on it:

It is forbidden to cut glass of the Ushm near the Windows if there is no other way out. Cover objects with a dense wet rag. It is impossible for children to be nearby during work. If you have to cut the material in a room with high humidity, the tool is connected to electricity through Protective shutdown device. This will prevent the current blow.

When cutting glass, a grinder must adhere to safety rules

Types of glasses

Before considering how to cut the glass, it is necessary to determine what types of it are, because further actions will depend on this. For example, cutting ordinary material should not cause almost any difficulties. It can be carried out both using glass cutter and with scissors. But cutting hardened glass at home is not recommended, because it will lose all its properties. It is best to cut it before hardening, and then entrust this process to professionals.

The corrugated glass is most often used for glazing doors or to create interesting interior elements. As well as ordinary material, it can be cut at home with the only difference that the incision must be done on the smooth side. It’s good if the roller glass cutter is at hand for processing such glass. You can cope with organic material without glass cutter, using a cutter, ordinary saw or other tools for cutting. With a glass, the thickness of which is no more than 2 millimeters to cope with a perfectly and stationery knife.

Preparatory work

First of all, before the harsh it is necessary to take care of your own safety, protecting the face and hands from fragments. After that, you need to prepare the material with your own hands. It’s enough to wipe the new glass, using a crumpled newspaper for this, for example, for this. With old material you need to work a little longer. First, it must be thoroughly washed with clean water, and also treated with a means of washing glasses, then degrease, for example, with alcohol or gasoline and dry well (see. Video).

Wheak cutter will help us

The method of cutting the material using glass cutter is quite simple. The main thing is to choose the right tool. For example, you can choose a diamond device, such as, for example, in a photo, which has been the most popular for a long time, or glass cutter with a slightly beveled cutting edge. The latter can cut the material up to 10 kilometers, after which it must be sharpened in a special bar. The roller instrument can consist of 1-6 rollers that are made of cobalt-wolframa alloy. Oil windshields work almost in the same way as the roller, with the only difference being that its holder is built.In a tank with butter, which allows you to cut even rough material.

So, after choosing the tool, the glass is placed on a flat horizontal surface. It makes a corresponding markup on it, to create which you can use the usual ruler. After that, making the same efforts along the entire necessary length, a flat line is made (see. Video). This must be done the first time, since repeated manipulations will lead to cracking of the material.

Without glass cutter. And this happens.

You can cut the material with your own hands and using ordinary scissors. To do this, prepare the scissors themselves, as well as a vessel with hot water. Marking on the surface is done in advance. Further, the spicy side of the scissors is carried out according to the marking, creating a small crack, after which the glass is simply broken with his hands. Of course, this method of cutting will not be as ideal as the previous one, but can help out in an unforeseen situation.

Wood. The material is extremely grateful. Strong enough to be durable, hard enough to hold even a very thin shape, enough.

Cerambitus is a very specific weapon of near.Battle, which became suddenly popular thanks to the game Call of Duty: Black Ops, as well as numerous.

Is it possible to cut glass after hardening it?

Despite the opinions of some “specialists”, you can really cut glass after hardening. However, in order for the work to be successful, you need to carefully prepare for its implementation. To break the glass, it is just very hit hard. But in order to give it the desired shape, you will need to make much more effort and spend a lot of time.

In connection with the features of production technology, zones are formed on glass, which are commonly called internal areas of voltage. In the process of heating and with further cooling, these areas are redistributed. As a result, the layers inside become similar to a liquid body with a certain viscosity. The outer layers, on the contrary, become more solid and durable. If you apply spotlights on the ends of the glass, there is a re.Distribution of voltages. In connection with the appearance of microcracks, the structure is violated. In order not to violate the integrity of the sheet, you need to handle it extremely carefully.

How to Cut Glass. The Basics | Delphi Glass

Cut the glass

This principle can be observed in cases of an accident: the glass of the machine literally scatter from the blow with a sharp object. The film helps to make car glass safer. Tempered glass gains all its characteristics when hardening. According to the technology, first the material is cut into the necessary parts, they make holes, and only after that they start hardening. Many experts advise not to further process the material further. Nevertheless, if there is a need to cut the already hardened material, then this can be done by adhering to certain recommendations.

Advantages of hardened glass

After the hardening procedure is performed, glass takes on new qualities. It is worth noting the increase in the strength characteristics of the material. Compression strength increases almost ten times. Bending strength is 132 MPa.

The exceptional heat resistance of the material is expressed in the ability to easily maintain its initial qualitative characteristics with a sharp change in the temperature of the outdoor air in the range from 350 to, minus 180 degrees Celsius.

Preparation of glass and cutting tools

The preparation process will depend on which product you will use for cutting. If the product is new, then it is enough to wipe it, using the old newspaper for this.

With the glass that has already been used, you have to tinker:

- It must be cleaned well. For this, a special cleaner for glasses is used.

- It must be degreased. For this, kerosene is used.

- It must be dried in a closed room.

In addition, it is necessary to prepare cutting for cutting. When working with such material, it is impossible to avoid non.Waste production. Especially if you plan to cut out a figure of irregular shape. To minimize waste, it is necessary to make a workpiece and cut a figure on it. The resulting scraps do not need to be thrown away, They can be useful to create other products.

For cutting, you need to use special tools:

- Diamond glass cutter. Used at home, glass cutter with a beveled blade. It withstands up to 10 km of incisions. Such glass cutter often needs to be sharpened.

- Roller glass cutter. It is an element in which from 1 to 6 videos made of durable cobalt-wolframa alloy fit.

- Oil glass cutter. The structure is similar to a roller tool, differs with a capacity with oil. From the container, liquid is supplied to the surface. The tool is ideal for working with thick glass.

- Tool for cutting circles and ovals.

You can also cut the double.Glazed window using scissors.

The above methods have the right to life and give out a good result with skillful handling of glass. Perhaps without experience in glass work, getting an even chip the first time does not work. Before proceeding with the processing of the main material, we recommend that you first fill your hand on unnecessary fragments. If you want to get high.Quality cut without prolonged practice, it will be better to purchase roller or oil Windows. Article from the heading rating

Hand.Handed manual instruments and crafts

Save this page in your social. Network and return to it at any time.

How to cut hardened glass

Wikihow works on the principle of wiki, which means that many of our articles are written by several authors. When creating this article on its editing and improvement, authors-volunteers worked.

Number of views of this article: 22 254.

The process of cutting hardened glass is actually impossible. Tempered glass is, in fact, safe glass, and if you try to cut it off, you will break the hardened glass into many small fragments. Despite the fact that it is impossible to learn how to cut hardened glass, you can learn how to anneal hardened glass so that it can be cut, and then re.Temper it.

Find out what annealing process is. This is the process of uniform heating of hardened glass in order to remove the voltages that arose in it during the hardening process. These voltage concentrators are the reason that hardened glass cannot be cut.

- Effetre glasses (tti), Bullseye, and Lauscha need to soak at 504 degrees Celsius. Borosilicate glass. At 566 degrees Celsius, the hardened glass of Satake is better to soak at 477 degrees Celsius. Small beads requires soaking for only 20 minutes, large beads require an hour-long exposure, and for large press-parties it may be required for 12 hours. Very large glasses weighing 45 kg or more may require hardening months.

Slowly cool the glass to a temperature below the temperature of the deformation ( = 1014.5 PUAZ). This must be done slowly enough so that additional stresses do not appear. For Satake glass, the cooling temperature of 399 degrees Celsius, and for other glasses. 427 degrees Celsius. Cool the glass in the furnace until its temperature becomes room.

Wearing protective glasses, prepare and cut an excessive glass. Draw a cut line using the square, and hold the square along this line. With the help of glass cutter, cut the glass into this lines by pressing medium force by making a scratch along it. Do not draw a glass cutter along the line more than once.

Put a wooden rod with a diameter of 0.6 mm directly under the cut line and attach a sharp and fast pressure force on both sides of the rod. Glass is broken into two exactly cut off a piece.

Pull the edges of the newly cut glass with a grinding cauldron. This will harden it and make it safer and appeal.

If desired, re.Harden the glass. It is better to entrust repeated hardening to professionals, since this is a complex chemical process.

How to cut hardened glass with your own hands correctly?

After all the lines are drawn, you need to carefully tap on them with the handle of the tool on the back of the glass, and then strongly press on the edges and break the sheet.

FOE| zoom h1 recorder |short film background sound recording

How to cut glass with a diamond glass cutter?

Such glass cutter cuts thanks to special diamond edges. It is more convenient and durable, but it is more expensive than the roller. Most often, the tool is used for cutting thick glass. Up to 10 mm inclusive. Beginner should choose a model with a beveled edge. The technology of cutting is generally similar to the described above, only the pressure on the glass during cutting should be slightly stronger.

Is it possible to cut red glass with glass cutter?

“I Cut Off My Own Arm To Save My Life” | Pleasure and Pain with Michael Mosley. BBC

Ground or hardened glass. The material is durable, but fragile. Therefore, it will not work to cut it with an ordinary glass cutter. It will definitely crumble. To do this, you need a special machine with a diamond circle, which is supplied to a special cooling composition.

How you can cut glass except glass cutter?

If there is a situation when it is necessary to cut a glass sheet of a certain size, and there was no glass cutter at hand, then other tools can be used. For example, ordinary large tailor scissors will cope with this task perfectly. You still need a container with hot water. Glass should be prepared, marking it, then draw lines with scissors and pour water into them. Then break the glass, pressing to the edges. Of course, the cuts in this case can turn out to be uneven, so they need to be cleaned with sandpaper or file. Thick glass and plexiglass can be cut with a saw grinder. In addition, an acrylic sheet can be cut with a hacksaw with small sharply sharpened teeth.

After the tile is placed, a logical question arises, how to choose a grout for seams so that the tile and grout look harmonious. It is about what to pay attention to when choosing a grout and will be discussed in our article.

How to tighten plastic Windows so as not to muzzle?

Plastic Windows are widespread today everywhere. But during the operation of double.Glazed Windows, their adjustment may be required. You can perform it with your own hands using a minimum set of tools.

How to install a plastic corner on a bath?

To protect the walls of the bathroom from excessive humidity and mold will help a simple device. A plastic corner. You can mount it with your own hands, guided by the advice of experts.

How to make gold in World of Tanks?

In order to earn gold in World of Tanks, you do not need to replenish the balance, cleaning your wallet to a penny. To date, there are many ways in which you can easily fill your account with Gold.

It is impossible to cut hardened glass in the usual sense. After hardening, the material changes its properties. Kallen glass is more known to an ordinary consumer called “safe”. Its cutting in the traditional sense will lead to the fact that the material will simply collapse on many small fragments. However, despite the existing restrictions, with a great desire, such material is quite successfully cutting. The work boils down to the fact that the glass is first anneal, and after that it is cut. Then, if desired, the glass can be repaired again to make it very durable and safe again.

The difference between hardened glass and usual.

Do not throw away the old glasses! Make an unrealistically steep home.Made one of them worth a million!

Subscribe to Igor’s channel. Https: // goo.GL/F9VLWww the leather bed. Https: // YouTu.Be/D9VTT9ZPLWU Igor’s website-https: // Stelaga-house.RF order this lamp I have. Https: // vk.COM/Germanleo or video about creative hours here. Https: // goo.GL/ZSULZ2 Place your home.Made here on the wall. Https: // vk.Com/Turboulitron Add Friends. Https: // vk.COM/Germanleo Order advertising: https: // goo.GL/9RBNIC ——- tools.

Running glass cutting at home

Glass is considered one of the most common materials. To increase its strength, hardening technology is used. After such a procedure, the degree of processing of the material is significantly reduced. When considering whether it is possible to cut hot glass, we note that only with the use of special technologies can the appearance of a defect be avoided. Today, cutting of hot glass can be carried out at home, for which a variety of tools are used.

Turned glass cutting instructions

The high strength and hardness of the surface determines that during cutting, quite serious problems can occur. When considering how to cut off the hot glass, attention should be paid to the points below:

- Preparation of the workpiece is carried out by annealing. This technology involves uniform surface heating. Due to this, the voltage is eliminated, which is formed inside the material at the time of its hardening. Due to such a voltage, it becomes much more difficult to achieve the required size.

- The annealing process provides for water heating to a certain temperature, after which the workpiece is lowered into it. It is worth considering whether the car glass or decorative use should be at different temperatures, it all depends on the brand of the material.

- Redeeping glass exposure time in water can vary significantly. In some cases it takes about an hour, the most difficult execution options are withstanding for a month.

- After reaching the required temperature, the product is slowly cooled. The work is carried out slowly, due to this, the likelihood of even the smallest defects is excluded.

- As soon as the surface temperature has decreased, you can put on glasses and cut it when using glass cutter. Similarly, you can cut the glass for the phone.

- Before cutting, marking should be carried out. Even and accurate lines are achieved when using a square and other measuring devices.

- Press on the material with average force, since high load can lead to serious defects. The cut is carried out quickly, it is not recommended to make a line re.Trying to make a line because such actions can lead to the appearance of a split and cracks.

- At the time of cutting, you should be careful, since the cut line will not work re.Making. After receiving the required line, a rod is placed under it, the product is divided into two parts with a sharp push.

With careful work, you can get a quality cut. You can finish the end surface with a grinding stone.

When considering the question of how to cut fisted glass at home, you need to pay attention to the choice of a more suitable tool. The following glass cutters were distributed:

- Diamonds today are used extremely often. Due to the use of durable and solid material, the tool can last for a long period. From time to time, it is necessary to sharpen the cutting edge when using a special sharpener stone.

- Roller. Cutting hardened glass at home is often carried out when using such a tool, since it is ideal for the work under consideration. There may be 6 videos that are often made from cobalt and tungsten. Due to the combination of a large number of rollers from durable and wear.Resistant material, the task of cutting is significantly simplified.

- Oil is similar to the option with rollers, but at the same time the design has a special oil storage container. When performing work, lubricants are added to the cutting zone, due to which the cutting process is greatly simplified. That is why such a version of execution is used more often than others.

Before direct work, you need to check the degree of sharpening of the cutting edge. When using a worn tool, the processing quality is significantly reduced, there is a chance that the cut line created will have an insufficient depth.

How to cut hardened glass at home. How to cut paved glass

Glass products have been very popular at all times: frescoes, dishes and many other things created from scraps of this material have always struck people with their grace and smoothness of lines. Looking at this splendor, it seems that in order to create it you need to be a real professional who has vast experience with glass and a lot of necessary tools, and for a simple “mortal” do not master this complex science. In fact, not everything is as sad as it seems at first glance, and everyone can get knowledge of how to cut glass at home.

The most ordinary sheet is called the hardened glass (the manufacturing temperature and the hardening temperature during the production of ordinary glass coincide and are approximately 660 O C), which is cooled very quickly, using blowing (cold air) on both sides of the finished sheet. Hardening (process) is due to very fast cooling. The glass hardened in this way has high mechanical strength, resistance to high temperatures and increased safety (in case of destruction, the glass breaks up into a large number of small and non.Resistant pieces that will cause special harm to a person).

Tempered glass is used as a showcase.

The inhabitants of the former USSR are familiar with such glass. It was called “Stalinist”. This is due to the fact that with such cooling, in the crystal lattice of such glass, the residual compression voltage appears. Due to its three positive qualities, such glasses are widely used in the construction sector, in the production of dishes, they are used as Windows of supermarkets, in various social institutions (schools, universities, hospitals, etc.D.), in the manufacture of cars and other machines.

The main drawback of such material is its vulnerability with mechanical shots to the ends. Even with a weak blow to the sheet edge, the glass is broken into a bunch of small fragments, and the whole sheet becomes unusable. However, even such a drawback found its application in everyday life. It is used if you need to create the effect of “broken glass” (in the design of furniture or dishes).

Most often you can find tables or cabinets with “broken glass”.

This effect is achieved through the use of 3 sheets at once: the upper. Whole, the middle. Broken, lower. Whole.

Manufacturers of such leaf glasses do not recommend (and some even prohibit) cut such glass at home, since there is a high probability of leaf damage. And how then there is a cutting of hardened glass in domestic conditions?

Selection of quality cutting material

To get a high.Quality glass product for inserting into the frame, it is recommended to be painstakingly prepared. Glass cutting will be more successful if you select high.Quality material.

One of the signs of high.Quality glass is the greenish or blue colore of the ends. At the glass production stage, technological incorrectness is allowed. In the course sheets with stripes are obtained for them. Such sheets do not need to use such sheets for inserting into the window. They noticely distort the images. No need to take glass plates with scratches.

As for the glass thickness for cutting, it should depend on the size of the frame. With a height and width of the least 600 mm, a sheet is enough with a width of 4.5 mm. On the contrary, the height or width exceeds this value, the glass sheet is approximately 4 mm wide.

When performing glazing in home A piece of glass should be cut off so that it is 3-5 mm less than the size of the frame created for its insertion. With the smallest skew, it is already impossible to stick glass into the frame.

Cutting hardened glass

As not required cut hardened glass.

In this video, I decided to try to process the edge as an experiment Glass With the help of Bulgarians.

Before cutting, it is necessary to prepare the glass properly. If it is new, wipe the plate with a damp cloth, then with a dry newspaper. With a dry fabric, it is not recommended. It can leave a pile particle on the surface, which can prevent the tool for cutting.

If the glass that has already been in use is selected, you need to know: it looks much worse and requires more thorough preparation. It is necessary to rinse the surfaces, adding special detergents. Then everything needs to be dried and degreased using kerosene or turpentine for wiping. When the glass sheet dries, it is necessary to exclude dust on it.

Work tools

Before starting cutting glass, you should decide on which tool to do this. Most often cut glass sheets using a special tool. Glass cutter. It is ideal for small in volume of working tasks. But there are many other tools with which you can in home adjust the glass.

For example, many home masters can successfully. Such a tool is in the arsenal of almost every owner of the house. But it must be borne in mind that for cutting glasses you can use a grinder only when you need to make a small section in length. The use of the ruler is extremely difficult.

To cut off the part, you will need to install a thin diamond disk on it. Cutting at low speeds. So it is possible to reduce the risks of premature cracking of the glass sheet and obtaining glass dust in large quantities.

- A disk of suitable thickness on the tool is installed.

- The saw area is slightly moisturized. It is better to simply pour water with water.

- With the help of a disk on the glass, a thin furrow is carried out.

- Then a chip is performed on this furrow.

So, to the question, is it possible for a grinder cut glass, the answer can be given positive. But at the same time it is necessary to monitor in working hours Behind various trifles. In particular, glass overheating should not be allowed. For this you can stock up with liquid for cooling.

How to cut fisted glass

All trustworthy experts claim that cutting of hot glass is impossible. Nevertheless, three ways are known on how to cut hot glass, without resorting to supernatural forces.

One. Hydroabraseic cutting of hot glass. The method consists in feeding under huge pressure (up to 4 thousand. Atm.) water into a special chamber, where water is mixed with abrasive powder, and then through a very thin nozzle (0.2-0.4 mm with a diameter), fired on the processed surface. The water speed reaches 1000 m/s (3 sound speeds). Will cut steel armor, not like glass.

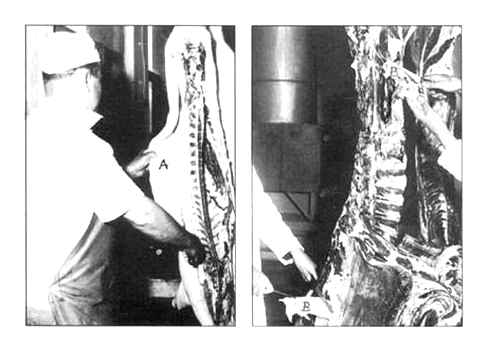

Froken glass cutting with volcanite circle

Cutting with an abrasive circle. The glass is attached on a movable table, and something like a grinder with an abrasive circle (for example, from a volcanite) of small thickness is lowered on top of it. It is believed that with a low supply of the table relative to the circle and intensive watering of the cutting zone lubricating and chipping liquid, the process can lead to success.

Cutting with vacation. Under the “vacation” (or “anneal”) in this case is understood not a trip to the south, but the heating of the glass to the temperature at which the hardening effect will be removed.

That is, the glass will return to its usual state, after which it can be processed and, if necessary, harden again.

Cutting Holes Through Glass Experiment

Perhaps theoretically this operation is feasible, but the most primitive calculations suggest that it is cheaper to buy again (see. Article “Where to buy feline glass?») Ordinary glass, cut it into pieces of the desired shape, drill the necessary holes, and then harden.

If you are interested in the place and methods of using hot glass for the house, read about this at: http: // oknanagoda.COM/STEKLO/OSTEKLENIE-STEKlo/STEKLOPAKETI/KALENOE-STEKLO-Dlya-Doma.HTML

How, where and why glass is used with spraying. You will also find on our website.

Clocking concrete without dust

At a construction site and during home repairs, you often have to cut concrete with a grinder. You can’t do without this very dusty procedure, especially during the installation of hidden wiring. To do the work, the tool is equipped with continuous or segmented Diamond discs

Various diameters. In this case, the size of the circles depends on both the used power tool and on the necessary streaming depth.

In order to cut a non.Reinforced concrete block of small size without dust or make a strobe, do this:

- On a working surface with a construction pencil or marker, marking lines are applied;

- The marked area with a nearby zone using a spray gun or a brush (even rags) is moistened with water, which is then periodically watered with a cut groove;

- They saw concrete, regularly taking out the disk and cooling it with water.

To saw concrete without dust, some masters use a special Homemade casing

, which is practically sealed. Dust of dust is provided by a vacuum cleaner connected for this purpose.

Carry out cutting bricks, glass, concrete, wood, plywood and other materials considered, using individual protection means

Glasses, respirator or mask, headphones. Shoes with shoes should also be suitable.

The operated corner grinding machine must be good. It should be used for sawing high.Quality cut circles, without defects. Disks and the power tool itself before performing work needs to be inspected. You need to cut the sawing by accepting a convenient, stable body position.

During work, it is forbidden to use narcotic or alcoholic drugs. Overall well.Being should also be normal. The grinder should be constantly controlled, because you can get a very serious injury. At the same time, the more powerful the device is, the more careful, neat, and more carefully, you need to handle it.