How to Cut Laminate at Home

Considering how to saw the laminate, it should be noted that the laminated coating is recommended to be laid according to the same technology as brickwork, that is, in a breakdown. Only in this case will the finished floor look natural and very attractive. The only drawback of such a stacking scheme is that it involves cutting the material in each row.

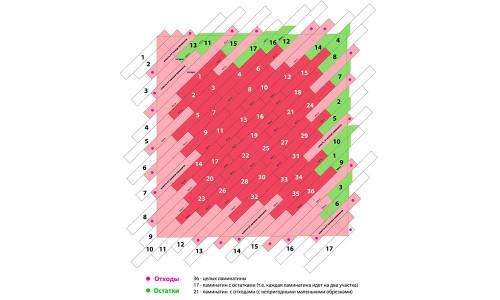

Laying scheme of the laminate.

Laminate cutting is a very important task, the appearance of the floor covering will depend on the correctness of its performance. Therefore, such work must be approached with all seriousness, having first figured out how and how to saw the laminate.

Laminate Construction

To choose the right tool for cutting laminated panels, you first need to figure out what they consist of. Laminate is a finishing material having a layered structure, which consists of chipboard or fiberboard and special paper impregnated with melamine resins. In the process of its manufacture, all layers are glued together by pressing under high (high pressure laminate. HDL) or low (low pressure laminate DLP) pressure.

The device of the laminate board.

Thanks to this production technology, the material has the following advantages:

- strength;

- moisture resistance;

- environmental friendliness;

- resistance to aggressive substances;

- long service life.

Structurally, laminated panels consist of the following layers:

- Bottom layer. It is made of plastic or tarred paper. Protects the material from moisture coming out of the subfloor. Some brands of laminate flooring are additionally equipped with a soundproof layer. Such panels are recommended to be installed in apartments located on the upper floors in order to muffle noise from neighbors from below.

- Base. It is made from fiberboard or particleboard. The strength and moisture resistance of the material depends on the quality and thickness of this layer. The butt part of the laminate, called the lock, crashes into the base.

- Decorative layer. Thanks to him, a unique panel pattern is created with imitation of natural stone, tile, wood, etc.

- Protective layer. It consists of acrylic and melamine resins that protect the material from wiping, shock and other mechanical influences.

Laminate Cutting Tool

You can cut the laminate with the simplest metal saw.

Processing of laminated panels should be done so that the cutting line is even, without chips, burrs and other defects.

For cutting this material, you can use both mechanical and electrical, including narrowly targeted, tools, namely:

- a hand saw for wood or metal;

- jigsaw;

- circular saw;

- special cutter.

Video: How to Cut Laminate at Home

Consider each option in more detail.

Laminate cutting with a hand saw

The cheapest tool that allows you to cut the laminate is a conventional hacksaw, which is available in the arsenal of each owner. Unlike chipboards, laminated panels lend themselves well to similar processing. the fishing line in this case will not be ideal, since the hacksaw teeth leave small chips after themselves. However, this is not critical, because small damages at the end can be hidden by a floor plinth mounted around the perimeter of the finishing base.

To obtain an acceptable result, it is necessary to use a tool with small teeth, for which a metal saw is suitable. With its help, you can get a better cut, but you will have to cut much longer than a hacksaw on a tree. Therefore, working with a hand saw is relevant only for small volumes of building material.

Before cutting the laminate with a hacksaw, it is placed on a hard and even surface with its face up, after which it is cut with smooth movements. In the process of work, it is not worth putting pressure on the saw, as this will only worsen the quality of the cut.

Using a jigsaw

Working with a jigsaw will save a lot of time and effort.

The most effective tool to quickly and efficiently saw through a laminate is a jigsaw. It is very convenient to use, so even a novice master can handle it. In addition, it is characterized by an acceptable cost, which is why its great popularity is due. Sawing with a jigsaw is performed at high speeds, which results in a clean and even cut line.

The quality of the work performed, to a greater extent, is affected not by the tool itself, but by its cutting part. If speed is not the first priority, that is, for a short period of time it is necessary to process a lot of material, then a saw with large teeth should be installed in the jigsaw. The larger the teeth, the faster the laminate will cut.

At the same time, with an increase in cutting speed, its quality decreases. This should also be taken into account. For fast cutting of panels it is recommended to use a saw marked T101D or 344D. To obtain a clean cut, a cutting blade marked T101B is used, equipped with small teeth.

To cut the laminate with a jigsaw, you need to install a saw with reverse teeth, since in this case the likelihood of chips and other mechanical defects is reduced.

It should be noted that with a jigsaw you can create not only straight lines, but also curly cuts. First you need to prepare a template from a cardboard box of the appropriate form. Then the template rests on the front side of the panels and is outlined with a simple pencil. After that, the cut is made according to the obtained curve.

Other laminate cutting tools

To cut the laminate with a circular saw, a disk with small teeth is taken.

In the absence of a jigsaw, it is possible to cut a laminated board using a circular saw and a disk with small teeth. The cutting technology is no different from the previous version, however, in this case, achieving an even cut line will be somewhat more difficult. To simplify the task, you can use not a circular saw, but a stationary circular. However, due to the high cost, not everyone can afford such a tool.

Answering the question of how to saw laminate flooring, it should be noted that in the modern construction market it is possible to purchase highly specialized equipment designed specifically for processing laminated boards. Such a tool is a laminate cutter. Outwardly, it resembles a clerical guillotine for cutting paper. The cutter consists of a horizontal platform on which the material rests, and a sharp blade, driven by a lever.

This tool does not produce noise during operation, does not emit dust and does not chip. It should be noted that only longitudinal sections can be made with the cutter. For transverse cuts, you need to use one of the tools described above.

Laminate can be cut using various tools, both mechanical and electrical. The choice of this or that option will depend on your financial capabilities and the amount of work ahead. If it is necessary to saw a large number of laminated panels, then the best option is a jigsaw or a circular machine. For several cuts, an ordinary metal saw will suffice.