How to cut linoleum at home

Choosing a knife for linoleum

- How to cut: types of tools

- Benefits of special knives

- Cutting features

- How to choose the right one?

- Advantages and disadvantages

There is nothing difficult in cutting linoleum. The main thing is to choose the right tool. After all, it is difficult to cut through the face layer with an ordinary knife or scissors due to its density. Therefore, it is recommended to use a special tool.

Benefits of special knives

There are a large number of special tools for cutting linoleum at home. They are divided into several types:

- For cutting synthetic flooring;

- Universal knives with replaceable blades;

- Special, for precise cutting at joints and corners.

- Special knives are required to work with complex contours and corners. Hook and trapezoid knives are often used. These knives are called designer knives.

- Electronic knives are needed for chamfering.

- A special place is occupied by the crescent cutter. It is not only convenient for them to cut corners or seams, but it is also very convenient for them to remove glue from the linoleum surface. The choice of such knives depends on the person’s desire to work and on the level of skill.

How to cut: types of tools

Cutting is done with the following tools:

- Universal construction knife. It has a retractable design with fixation of the cutter in a certain position. Looks like a regular utility knife, but the blade and body are less prone to breakage. Convenient when cutting thin linoleum, but you need to constantly monitor the progress of the knife.

- Roller knife, often called a circular knife. Has one or a pair of blades. Convenient to use when cutting straight line as well as curved line.

- Utility knife. Used for cutting linoleum, carpeting, for cord, leaves the edges smooth. Replaceable steel blade is held by a screw in the handle, preventing it from moving.

- Monthly. Ideal for trimming corners. Also has replaceable blades.

- Cutter with disc. For linoleum, a cutter with a cutting disc is selected. The main advantage is the cutting speed.

Rooms are often both long and wide. In this case, in addition to cutting, linoleum soldering is also necessary. Pieces of material are overlapped with a cut, we go through the seam with a soldering iron and roll the resulting seam with a roller

How to choose the right one?

- Compliance with its purpose;

- Will the coating withstand the load in terms of weight and permeability;

- Compliance with the requirements;

- Room design compatibility.

It is also worth considering which type of linoleum to choose. There is a huge list of materials from which it is made. Natural linoleum is ideal for children’s rooms. It is composed of resin, jute fabric and natural dyes. It has many advantages:

- Resistant to rubbing;

- Does not change color over time;

- Does not burn;

- Easy care.

There are also disadvantages of such a coating, such as high cost, fragility and intolerance to high humidity. The structure of felt linoleum is unique. It consists of 5-7 layers. Each layer is responsible for certain parameters. The main layers are face, protective layer and base. Also, the insulation improves the moisture-repellent qualities of the coating. The total thickness ranges from 2 to 4 mm.

PVC linoleum with a fabric thermal insulation base has certain advantages:

- Such linoleum has low thermal conductivity;

- It is a dielectric;

- Does not rot;

- Easy to install;

- Environmentally friendly.

However, it is sensitive to high temperatures, cracks at low temperatures and is not resistant to chemical cleaning agents.

Such linoleum is divided into commercial, semi-commercial and household. Household. thin and cheap, its service life is 5 years. Commercial is the strongest and thickest material. Suitable for offices. Its service life is 20 years. The middle position is occupied by semi-commercial linoleum, its service life is 7-12 years.

There is also colloxin linoleum. It is baseless, and the main material is nitrocellulose. Its advantages: elastic, shiny and does not support combustion. At the same time, it reacts to any temperature extremes due to the lack of a base.

There is also linoleum. relin. It should not be used in residential areas due to the release of harmful substances over time. Consists of two layers: the first is bitumen-containing, the second layer is a mixture of rubber, pigments and various fillers.

Accordingly, such types as natural, felt, PVC and colloxin can be used in the apartment.

Cutting features

Before cutting out the linoleum, you will need all the cutting tools, rulers, a level, and duct tape. It is also necessary to prepare the surface before laying it:

- If previously there was carpet on the floor, then it must be carefully removed. After that, you need to clean the surface.

- If the floors are wooden, check the condition of the boards. If possible, replace bad boards. Cracks between them can be filled. If the surface cannot be repaired, then it is necessary to lay sheets of plywood or chipboard. It is carefully necessary to deepen the hats of the hardware.

- If you already had linoleum, then if the condition is not entirely bad, it can be used as a base for fresh linoleum. The main thing is to thoroughly degrease the surface.

- The easiest option is to lay linoleum on concrete floors. It must be remembered that all irregularities will be felt through the new material and cause discomfort, both physical and moral.

- Before laying and cutting, linoleum must be rolled out in the room. so it will become smoother and the smell will disappear.

If you buy it in the winter, then you need to try to leave the material on the street as little time as possible. he does not like the cold. Therefore, we bring the roll into heat and leave it first in a rolled state. After letting it lie down for a couple of days, the roll can be unrolled.

After acclimatization, linoleum can be cut out. You need to know and remember:

- It is better to put a plain canvas in the direction of the light. This creates the effect of a “monolithic” finish;

- The canvas must be placed in a pattern, parallel to the outer wall, with strict adherence to the pattern;

- The joint does not have to be in the center of the room. Often two joints are made, but at the edges of the rooms. This does not create a visual division of the room into two parts, and furniture can often hide the joints at the edges of the room;

- Indoor pipes can be a problem. To cut cutouts for pipes, you need to bend the material outward and cut the necessary slots at an angle.

Linoleum covers the entire floor surface. It is advisable to leave 5-10 cm on each side in reserve, then they can be cut. In cold temperatures, linoleum can shrink. Heat waves can cause heat waves. There is no need to throw away the scraps. they can be useful for minor repairs of the canvas.

After you have trimmed it along the wall and trimmed it along the holes, you need to let the linoleum lie on the floor. Only after that it is necessary to start laying it.

Advantages and disadvantages

In general, we can highlight a large number of advantages in laying linoleum:

- Cheapness (the exception is natural, but the price pays off by the service life and service life);

- Service life from 7 to 30 years;

- Ease of laying linoleum, which can be done alone;

- Wear resistance. modern technologies allow even inexpensive material to withstand large and long-term loads;

- Does not support combustion (if it is made in accordance with GOST);

- Prevents feet from sliding on the floor;

- Heat and sound insulation;

- Easy to transport;

- Easy to cut and stack;

- Does not require special conditions and facilitates cleaning the premises;

- Wide range of colors and patterns.

The disadvantages include only those that appear when choosing low-quality linoleum or low-quality laying it on the floor:

- Irregularities, “repetition” of the floor relief;

- If air enters and does not remove, a hump may appear;

- The weak points are the seams. With improper care of them, the service life is reduced by one and a half to two times.

- Linoleum is susceptible to mechanical damage. When heavy objects are found for a long time in the same place, visible dents appear, which are difficult to straighten.

- Elasticity and flexibility are lost over time;

- In some types of linoleum, over time, the release of harmful odors and substances begins, so before laying, be sure to find out everything about the material and its properties.

For information on how to lay linoleum, see the next video.

Introduction to Linocut Printing for Beginners

How to cut linoleum under a baseboard

The technology for trimming the flooring is similar to the previous one, it involves the following actions:

- Lay linoleum in the room.

- Press it firmly to the floor, and stepping back 1 cm from the wall, cut off the excess.

If the coating is cut close to the wall, then in summer at high temperatures a roller will appear near the baseboards, which will be very noticeable.

Features of trimming linoleum

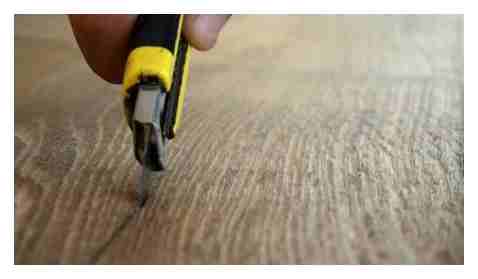

To properly cut linoleum during installation, you need to use a special tool that allows you to make an accurate and clear cut. A regular kitchen knife will not work here. The best option is to use a tool for a specific type of flooring. You should choose a special device taking into account the thickness of the linoleum, density indicators. For these purposes, it is effective to use an office or construction retractable knife, or one that is designed for working with floor coverings.

When cutting linoleum, it is important to follow the technology and use a sharp knife

If you need to cut linoleum at home, then in order to obtain a positive result, you need to follow certain recommendations:

- When cutting the flooring, move gradually, making small cuts. But first you need to make a mark on the inside.

- For work with internal corners, linoleum is cut in a V-shape.

- When laying linoleum with a pattern, the material must be laid face up in order to make the markup without distorting the picture. If mistakes are made when cutting linoleum, then it will no longer be possible to correct them.

For a correct fit, two strips of flooring are superimposed on each other to create an overlap. It is recommended to cut them together. This method is effective, but requires some effort and a sharp knife.

The final trimming of the linoleum should be done with a hook-shaped blade, and the marking should be done with a trapezoidal one. It is necessary to adjust the floor covering to the wall only after the end of the main work with it. To properly cut linoleum on the floor and prevent a gap between it and the wall, you must use a wall marker, a metal ruler.

How to cut linoleum exactly

In order to cut linoleum according to the size of the room without any difficulties, and the cut turned out to be even, you need to familiarize yourself with some of the intricacies of this class of flooring. PVC is a fairly durable product, but if there are sharp depressions or small cuts on the edge of the sheet in the direction of the main part, there is a high probability of rapid damage to the material. Therefore, you need to work very carefully, making an even cutting of the canvas.

Considering that PVC linoleum is easy to cut with a well-sharpened tool, all accidental movements should be excluded. Otherwise, it can provoke a deviation from the given direction. It is possible to avoid such troubles by using a template or a long ruler for cutting.

Canvases with uneven edges prevent the seam from being invisible

Since the method of cold chemical welding is used to join two canvases, they must be cut with maximum accuracy. Thanks to this, it will be possible to exclude pronounced seams, which greatly spoil the appearance of the entire floor. Before starting cutting the linoleum sheet, it is imperative to check all measurements, the quality of the sharpness of the cutting element.

The algorithm of work on a section of coverage along the entire length or width provides for the following actions:

- Mark the line on the inside or outside of the canvas, which will serve as a guide for cutting.

- Attach a long ruler to this mowing line.

- Cut off the sheet with a sharp knife.

How to cut linoleum in an apartment: along the walls, under the baseboard, under the pipe and in the corners

The almost widespread use of linoleum in an apartment and a house is explained by ease of maintenance, a large assortment of colors and textures, and an affordable cost. This popular floor covering can also be installed on top of the adhesive mixture and left completely unsecured. One of the advantages of this material is the ability to cover the floor without the involvement of specialists. Cutting linoleum at home is not so difficult, but it is important to know how to do it, which tool is better to use.

How to choose a tool for cutting linoleum

To properly cut linoleum into the corridor or any other room, you need to competently approach the choice of tool. The knife must have:

- Reliable grip. It can be made of metal or wood. The cutting blade must be of high quality and stainless steel.

- Suitable blade thickness. To avoid problems when cutting the flooring, it is recommended to use a cutting blade with a thickness of 0.6-1 mm.

- Ability to withstand severe stress.

For a quick and convenient workflow, you should understand all the variety of tools on the market. There are products for chamfering, for a cord, various scissors, cutters. For the correct selection of a knife, it is necessary to take into account both the structure and thickness of a particular material, its individual characteristics.

How to cut linoleum under the toilet

Instructions for trimming the finish on the floor under the toilet:

- Place the toilet (without cistern) on the floor, only without the cuff and sealant. This is necessary to make the markings on the linoleum. Using a marker, outline the contour of the toilet bowl sole, and then remove it.

- Use a construction knife to cut out linoleum according to the markings. Replace the toilet and secure with fasteners.

What is linoleum cut

There is a huge selection of construction tools for cutting flooring. special knives that have a number of advantages:

- they work equally effectively with linoleum, which is either in a vertical or horizontal position;

- no difficulty in replacing blades;

- the ability to obtain the most even cut;

- high strength characteristics of the blade;

- high-quality blade fixation system;

- there are devices with rubberized pads on the handles (anti-slip).

It is best to cut linoleum at home by using one of the following types of special tools:

- Construction knife. The model is a retractable design, where it is possible to quickly replace the cutting blade. Thanks to the perfect sharpening, working with linoleum is quite easy. In general, the device is very similar to a stationery retractable knife, only more improved and adapted for cutting flooring. It can be classified as universal; it is also used to fit a thin-layer material and a thicker coating. The main thing is to follow the progress of the cutting blade.

- Knife for cutting linoleum. This version of the tool is distinguished by a curved or hook-shaped blade shape. This feature of the cutting element makes it possible to easily cut any floor covering, including linoleum. It is good to use it not only for cutting a straight seam, but also for cutting curly details in corner joints.

- Floor cutter. This special tool is available in different designs on the market. The disc version is excellent for cutting linoleum. Fix the canvas in a frame with a handle. A model with a fixed cutting element is also suitable. Such a conventional cutter is easily capable of making a straight edge along the entire length of the material.

Professional advice

To obtain the desired result when working with roll coating, you must follow the advice from experienced craftsmen:

- It is impossible to start cutting the flooring immediately after purchase. To stabilize its size, the selected material must be kept indoors for at least a couple of weeks. in warm conditions. After unpacking, the roll should be rolled out and cut into canvases in accordance with specific dimensions, but provide for an allowance for shrinkage and adjustment. The rule applies here: the longer the cut, the more allowance is needed. So, if the length of the web will be more than 10 m, then 50-60 mm must be left in reserve, and if the length is less than 10 m, 30-40 mm is enough. If the room is small, where the length is less than 6 m, then the allowance should be up to 20 mm. It is recommended to put all canvases in a pile and give them time for full straightening. 5 days.

- You need to start working with linoleum after laying it on the floor, where the walls are marked on the spot. To press the material to the floor, you should use a provil or a building ruler. First, they make a puncture and a small incision with a sharp tool, and then they lead the knife along a ruler along the entire perimeter of the room. A V-neck is made in the corner. To work with pipes, columns, a bay window, it is imperative to make patterns; for convenience, you can cut it out on a newspaper, and then attach it and make it out of cardboard. In order not to spoil the floor covering in difficult areas, it is necessary to cut the cut in small sections, according to the template.

- If the floor covering is used with a pattern, then first lay it face up and try it on. After laying the material parallel to the wall, it is pressed, you can use a heavy object, cut it off. In the place where the canvas ends, apply the following (overlap), pay special attention to the selection of the pattern. The canvases collected in two layers are carefully cut through without haste. If the room is very large, then the selection of the pattern occurs along the border. Here it is necessary to cut off the abutting elements using a ruler and a sharp tool, controlling the accuracy of the coincidence of the picture.

How to properly and quickly cut linoleum at home, you can look at

Features of the

There is a wide variety of construction tools on the modern market, including special knives for linoleum.

These products are characterized by the following features:

- well suited for work with material that is located vertically or horizontally;

- it is possible to change the blades;

- the cuts are as smooth as possible;

- blades are durable;

- reliable blade mounting system;

- some models are equipped with rubberized grips that prevent the hand from slipping.

Such a versatile and functional tool greatly facilitates the work with trimming linoleum, performing the function of an irreplaceable assistant during repairs. A high-quality linoleum knife will help even the most inexperienced master decorate the floor not just with a practical coating, but with a complete and unique composition that will delight others for many years.

The world market offers a wide range of knives for linoleum, each of which is high-quality and functional in its own way. There are several types of these products, such as:

- Construction. Such models do not have a fixed blade width, therefore they are most often used for cutting not only linoleum, but also wallpaper. The blade is perfectly sharpened, which contributes to maximum comfort in the working process. It is made in the form of separate fragments that can be broken off in order to preserve the performance of the item.

- With a removable blade. The blade is 25mm wide and 6mm thick. Such a blade has a long service life without losing its original qualities. This model is completely unsuitable for curly cuts.

- Special. They have a specially selected blade shape for complete and accurate trimming of linoleum. Such instances are great for making both straight and curly lines.

The following types are also often used:

- Stationery with replaceable blades designed exclusively for thin material.

- Monthly, used for almost all types of linoleum, including felt-based.

- Cutters made for thick base linoleum.

- Electronic, battery operated, the principle of which does not differ from other types.

A certain version of the knife is chosen taking into account all the features of linoleum, because each model of the product has an individual purpose. Therefore, in the process of choosing a knife, it is necessary to take into account the peculiarities of the coating structure and its thickness.

Which knife to choose?

So that working with linoleum does not turn into a complex and lengthy process, it is necessary to choose the right knife for one or another type of this floor material.

A quality cutting knife should have the following characteristics:

- strong handle made of metal or wood, with a blade made of high quality and stainless steel;

- the product should be comfortable, while the thickness of the blade can be from 0.6 mm to 1 mm;

- the ability of the pruner to withstand heavy loads is one of the most important features.

It is necessary to be able to correctly navigate among the entire offered range of products. There are knives for chamfering, for a cord, as well as special cutters and scissors. To choose the most suitable type of knife, it is recommended to take into account the individual characteristics of linoleum, because it largely depends on how high-quality the entire working process will be.

On the floor

The base in the form of linoleum is perfect for any carpet, but it depends only on the quality of its laying, how smooth and beautiful it will look on the floor.

There are some nuances of working with linoleum on the floor, the essence of which is as follows:

- The roll is laid in such a way that one edge fits snugly against the wall, and the other unfolds on it.

- The cover should be flattened to create a clear cut line. Alternatively, for accuracy, a level is used with which the coating is pressed against the wall, leaving a small gap for the knife blade to pass.

These points are very important in the process of working with linoleum. A properly organized initial stage of laying will create all the conditions for further actions. To do this, you need to choose a durable knife with a sharp blade and show maximum professionalism.

Up the wall

When carrying out a work process with linoleum in a vertical position, it is necessary to take into account the fact that the walls often have obvious irregularities.

Following a few simple rules, you can easily make any cut:

- To make it look neat, you should use a special cutter with a durable blade.

- The maximum allowable gap can be no more than 1 cm, so that in the future there will be no problems with the installation of skirting boards.

Observing these simple rules, you can quickly and easily lay linoleum, which will become a real decoration for the room. A good knife with a sharp blade and a comfortable handle is of the utmost importance in this process. After all, it is on its quality that largely depends on how smooth and neat the joints of the material and the result as a whole will be as a result.

The better to cut?

For the correct laying of linoleum, it is imperative to use special knives. As you know, there are a large number of options for linoleum knives, so you need to know about the purpose of each category of these tools. All models have individual characteristics that you need to know so that the cuts have a neat and presentable look.

Everyone is familiar with a clerical knife. It is often used at home to cut paper or wallpaper, but few people know that it is also used to cut thin linoleum. But this option can only be used for straight cuts due to the relatively soft blade.

The construction knife is considered one of the best options. It can be safely used even after direct laying of linoleum. The retractable blade function facilitates quick and easy removal of excess material. This type of blade is thicker than a clerical blade, and the process of working with it is carried out as quickly and conveniently as possible. Such a knife is used most often, since it is able to cut linoleum of almost any thickness.

The universal version does an excellent job with straight cuts, but it is not recommended for curly work. If the product has high quality indicators, then the mowing line will also be smooth and neat.

Linoleum knives

- Features of the

- Views

- The better to cut?

- Which knife to choose?

- How to prune properly?

- On the floor

- Up the wall

- Helpful hints

During the interior decoration of the premises, special attention is paid to the floor. To make it look beautiful and practical, many people prefer to lay linoleum. Correctly chosen material design, as well as special knives for linoleum, contribute to high-quality styling and impeccable appearance. The choice of such tools is quite diverse, so it is possible to purchase the most suitable copy.

How to trim properly?

To properly trim linoleum, you need to follow certain rules that will help you achieve an excellent result.

They are as follows:

- Preparing linoleum for work. After purchasing the material, the roll should be left unfolded for 24 hours. The temperature in the apartment must be at least 10 degrees so that the product does not deform. The width of standard rolls is in the range of 150. 400 cm, therefore, when buying, it is recommended to choose an option with a width of the room and an additional margin of 8 cm.

- To carry out the laying of linoleum, you will need tools such as: a ruler or square, a pencil, a spatula with notches and a knife.

- Cutting off each side is done with an allowance of 6-7 cm, which will allow you to adjust or trim the pattern if necessary. In addition, shrinkage is inherent in linoleum, and this must be taken into account.

- After leveling, the covering is laid on the floor and needs to be adjusted. In the case of a perfectly flat room without the presence of elements that require additional cuts, the material does not need to be adjusted, but you can immediately proceed to the final trimming.

- To simplify the adjustment of angles at 45 degrees, it is recommended to use a special square ruler, which allows you to create the most accurate and even cutting of the material.

- If the drawing is complex or in the form of an ornament, then linoleum is allowed to be cut only from the front side.

- It is necessary to start the work process from the window.

- The joints should be practically invisible, then the whole canvas will look like a single composition.

In addition to following the step-by-step instructions, you need to be able to make the correct cut. It is this detail that can affect the quality of the work as a whole and affect the final result.

How to cut linoleum at home, the rules for using knives and the subtleties of cutting

Linoleum is one of those materials that, having appeared on the construction market and occupying their niche in it, keep it, without giving up their positions for decades. In addition to the ease of maintenance, the choice of colors and textures, it also differs in an affordable price. Good performance makes it possible to lay this coating even in problem areas: bathroom, kitchen and corridor. You can do this yourself, without the help of professionals. The only thing that remains to be done is to find how to cut the material so that the joining seams are smooth.

Varieties of knives for cutting linoleum

Already during preparation, you may be faced with the question of how to cut linoleum, since the knives used at home quickly become blunt and do not allow you to make an even cut.

If you have a furrier’s or tailor’s knife, you can use it to process linoleum. Such knives have a strong rigid blade, so they will not be difficult to cut thin and soft building material. The main thing is that the knife is sharpened with high quality.

In other cases, you need to purchase a special cutting tool. The easiest to use for a person inexperienced in construction work are 3 types of knives.

- The retractable construction knife is visually similar to an ordinary stationery for cutting paper, only larger and equipped with a strong steel blade. Suitable for indoor repairs where you don’t have to make many curly cuts. It is convenient for them to cut the covering near the wall and in the corners.

Construction knife for cutting

- A multi-purpose cutter is the most popular tool, but it takes some dexterity and skill to work with. They are comfortable with straight cuts. Well suited for cutting linoleum that is already fixed to the surface, for example, when you want to cut the cover on the cellar lid. The blades are strong, made of hardened steel, do not bend. In fact, this tool is similar to a tailor’s knife and therefore can subsequently be used for household needs.

Utility knife

- The circular knife, despite its high price, is ideal for those with zero skill in construction work. Using it, you don’t have to think about how to cut out a complex shape.

The advantages of the circular cutter:

- you can cut any linoleum;

- the mobility of the rotating cutter makes straight cuts and complex shapes easy;

- the coating material is always cut evenly;

- there is the possibility of cutting linoleum directly into rolls, which is convenient when making a coating from fragments;

- equipped with a lid on the side where the cutters can be removed.

Disc view of the knife

Special construction cutters are sold with other cutting attachments. You can get acquainted with the principle of their work and how to cut the material correctly during the installation process.

The best coverage for any room

Having decided to lay linoleum in the room, keep in mind that laying this coating, despite its apparent simplicity, requires proper preparation. First of all, you need to correctly choose the material itself.

- If this coating is intended for a hallway or kitchen, it is recommended to take linoleum with an increased degree of wear resistance and not too bright.

- For the bathroom, a foam-based coating is a suitable solution.

- In the living room, it is allowed to lay linoleum of any color and pattern. The main thing is that its background is combined with the rest of the interior of the room.

- A children’s room is a place where even recklessly bright and contrasting colors are appropriate. The more unexpected color bursts, the better the child’s emotional state. You can even connect 2-3 pieces of linoleum by combining them with a single design idea. over, they are necessarily cut from material of the same thickness.

- It is required to create a cozy atmosphere in the bedroom, therefore it is recommended to use soft and light shades.

You can choose any drawing on linoleum, depending on the taste inclinations of the owner of the room. But it should be borne in mind that a large pattern on the floor of a cramped room will make it even smaller in visual perception.

Linoleum is a versatile floor covering material, which is presented today in a wide range

Preparation before laying linoleum

Before you start laying linoleum, the roll, without unwinding, is kept for 2-3 days in the room for acclimatization.

This time is enough to prepare the foundation.

- The plane on which the coating is laid must be flat.

- Remove all skirting boards.

- All the cracks in the floor are carefully putty and rubbed.

- The bumps are removed by knocking down with a hammer, and then the floor surface is leveled with a solution.

- If the subfloor is wooden, it is carefully inspected for protruding nail heads and screws.

- If in the rough field there are large gaps in the basement that cannot be repaired, sheets of chipboard or plywood are laid on it. This will make it possible to increase the service life of linoleum and, at the same time, it will become an additional bridge on the way of cold entering the room.

After completing the preparation of the floor, they begin to work with the coating itself. To do this, the roll is rolled out on the floor in the room in the position in which it will subsequently be laid, and left for another 2 days so that it straightens out. This is done to stabilize the material.

How the material is cut

Cutting linoleum with and without a pattern

The prepared material that has passed the stabilization procedure is leveled to the level of the room and markings are made on it.

Further work is carried out in the following order:

- linoleum is tightly pressed against the wall and a line is drawn on it along which cutting will take place;

- press the building material to the floor and make a small puncture with a notch with a cutter;

- a bar is applied to the drawn mowing line and carefully begin to cut, instead of a bar, a level will also fit;

- perform an incision to the end of the drawn line;

- near the ledge, cut out a small corner in the linoleum and carefully lay it.

In rooms with a large number of protrusions, it is better to use professional cutters, which will make it possible to make correct cuts without spoiling the material.

Specialized knife for cutting linoleum

If the material is patterned, then be sure to consider the size of the rapport:

- before cutting the canvases, fold them and align the junction of the pattern;

- if the canvases are applied to one another along the length of the canvas, find the connection points of the pattern and mark them;

- when joining two canvases, cut off the excess material so that later the patterns can be joined.

To lay linoleum requires desire, a little patience and a tool that can be used to make even cuts. Everything else is easy.

An experienced master tells how to properly lay the material and how to cut it:

How to properly cut linoleum when laying. the choice of tools and technology of work

Hello, Alexander. Recently I bought linoleum for laying in the hallway. The room has a complex shape, so you will have to cut a lot. Tell us in detail what is the best way to cut linoleum at home? What tool is required for this and how to use it correctly.

Hello. There is nothing difficult in cutting linoleum. The main thing is to choose the right tool, since it is very difficult to cut a dense canvas even with a well-sharpened knife or stationery.

Linoleum cutting tool

The construction knife is a versatile tool for cutting roll coverings

Cutting PVC or natural linoleum can be done using the following tool:

- Construction knife. has a retractable design, the ability to change and rigidly fix the cutting blade. In fact, this is an adapted and improved version of the stationery retractable knife, adapted for construction needs. Suitable for cutting both thin-layer and thicker roll coverings, but when working, you should carefully monitor the path of the blade.

- A knife for cutting linoleum. has a curved or hook-shaped cutting element. Allows you to quickly and quality cut through linoleum, carpets and any other soft floor coverings. Suitable for cutting a straight seam, and curly elements in corner joints.

- Floor Cutter. Available in various variations. For linoleum, a design is used with a disc cutting element fixed in a special frame with a handle. A conventional fixed blade cutter can also be used. Allows you to quickly and efficiently cut a flat edge along the entire length of the blade.

Additionally, you can mark such a tool as a “beveler”. It is used when laying natural linoleum when it is necessary to cut off the “broken” edge. In the case of PVC coating, it allows you to cut off the “fringed” edge if gross mistakes were made during cutting.

When choosing a working tool, one should take into account the type of coverage that is planned for laying. Household linoleum has a low density and thickness. An ordinary construction knife is enough to cut it.

expensive semi-commercial or natural linoleum is best cut with a specialized knife. This will cut through the dense sheeting and get a smooth cut.

The appearance of the tool can be seen in the photo above. for an entry-level branded product. It is better for a master finisher to purchase better equipment.

Among the manufacturers are the products of Truper, Suntool and Romus. For DIY work, knives from Biber, Jettools, Fit are quite suitable.

how to lino-printing/lino cut tutorial /linocut for beginners

How to cut linoleum at home

How to cut roll coverings correctly

Highlights when cutting linoleum during installation

To carry out work on cutting linoleum canvas, in addition to the purchased knife, you will need to prepare a square, a long ruler and a tape measure. To create a template, you need plain paper or thick cardboard.

When working, try not to rush and take all measurements several times. You need to cut with confident movements, applying effort. If necessary, you can draw up a diagram of the location of the canvases, and only after that start cutting them according to the calculated parameters.

DIY linoleum cutting technology will consist of the following:

- Before cutting the linoleum, it should be kept indoors for 7-14 days at room temperature. For a more precise date, refer to the instructions or paper insert supplied with the coating.

- Next, the roll is cut according to the length of the room, taking into account the allowance. For a canvas with a length of 5-6 m. 20 mm overlap, less than 10 m. 40-50 mm, over 10-12 m. 50-70 mm. This is necessary for a stock of material for trimming and natural shrinkage.

- The cut canvases should be left for 3-5 days until they are completely straightened. If “waves” remain on the surface, then you should not try to eliminate them using third-party methods. High-quality roll coating will straighten naturally.

- Then the cut pieces are laid out along the length of the room. If there are protruding communications and other decorative elements in the room, then you will need to prepare a paper template. After that, according to the template, the pattern is transferred to linoleum and cut off in the right places.

- If the room has the correct shape, then the linoleum is pushed up against the wall with an overlap and cut off at the junction.

- For joining the canvases with a pattern, the first canvas is laid out on the floor surface. The second canvas is superimposed over the first until the joining edge forms a continuation of the pattern. Next, the edge is pressed with a long ruler and cut through both pieces.

Upon completion of the cutting, the linoleum must be shifted by one half of the room and the work surface must be removed from dust, debris and abrasive particles. After that you can start fixing and docking.

Docking two or more canvases

Cold welding is used to join two or more canvases.

Fixing linoleum to the floor can be done in several ways. Glue applied over the entire floor surface is the most reliable solution. Double-sided adhesive tape is used for rooms where fixing rigidity does not matter or linoleum is a temporary floor covering.

The adhesive mass is prepared for work according to the instructions on the package. A spatula is used for application. First, linoleum is fixed against the wall for a large width of the canvas (60-70%). The adhesive is applied to a clean surface in undulating movements without excess.

After that, the web is carefully lowered and rolled with a heavy roller. If there is no roller, then it can be replaced with a regular building level wrapped in a soft cloth. The surface must be carefully smoothed over the entire area.

Do the same with the second half of the room. To join the canvases, you will need to glue the tape along the entire length and remove the protective coating. After that, an adhesive mass is applied to the remaining part. After gluing, the seam should be carefully rolled.

If you plan to weld the seam, then it is necessary to cut a groove for the filling. Before welding, it is necessary to thoroughly warm up the hair dryer for several minutes, put on the nozzle and insert the cord.

Above you can watch a video on how to properly cut linoleum when laying flooring in an apartment. Pay attention to the sequence of actions when laying multiple canvases.

How to cut linoleum?

The main types of cutting tools successfully used in cutting linoleum are of three types: retractable construction knife, flooring knife and linoleum cutting knife. Sometimes, in the absence of the above tools, a clerical knife can be used, provided that a stock of replaceable blades is used.

However, such a knife can only be suitable for cutting thin linoleum. The cutting angle with such a knife should be kept the same. Otherwise, there is a high probability that the knife will “lead” to the side, and, instead of a straight edge of linoleum, you are guaranteed to get a “fringe” effect along the edge of the cut material.

The choice of tool for cutting linoleum very much depends on the thickness, density of the coating and the complexity of the shape that must be given to the various parts of the material that is used.

A retractable construction knife is better suited for cutting thick types of linoleum, as it has a stronger structure than a clerical one. Although the design principle of this knife is the same, however, the thickness of the blade and the guiding elements are made taking into account the greater load on the cutting surface.

Such a knife will be able to qualitatively cut linoleum of any thickness. The tool itself can be used for other functional tasks when repairing your apartment, but it will not always allow you to accurately cut the coating for parts of the material that are installed end-to-end. Uneven seams can be conspicuous.

The flooring knife is a very durable and easy-to-use tool that allows you to cut any type of flooring used for flooring. However, its technical design will allow high-quality cutting of material only in a straight line.

The linoleum cutting knife is a specialized tool with a fixed curved blade designed for cutting linoleum of any available density. If it is on sale, then it is better to opt for it. It is a knife equipped with a front-loading retractable blade and several working positions.

How to cut linoleum

If you decide to start making changes in your apartment, starting them from the kitchen, then you will definitely need to change or lay linoleum. The modern quality of materials allows you to use linoleum in the corridor or hall.

Having made the necessary measurements, you will be faced with the task of cutting the material correctly. The appearance of the final work on the improvement of the floor of your premises will depend on the quality and accuracy of cutting.

Most often, linoleum sellers offer you to purchase a special knife when purchasing material. Those who have not encountered the features of cutting this finishing material mistakenly assume that this operation can be performed using improvised tools, the list of which includes knives (kitchen, pen, stationery), scissors (gardening, tailors), etc.

Of course, for such operations, there are specialized tools, the use of which guarantees you high quality joints between parts of linoleum prepared for flooring.

The cutting technique of linoleum itself also affects the quality of the connection of its individual parts. The easiest and most common way to cut the material in the same way, in order to eliminate gaps in the joints, is to overlap the edge of one piece of linoleum while cutting. Cut both pieces of material at the same time, then you can avoid gaps with a width of 1 mm or more.

The inaccuracy of the joints between the parts of the linoleum will lead to the accumulation of dirt in the crevices, which will lead to rapid wear and the violation of the integrity of the entire coating. This cutting technique requires increased attention to the quality of the cutting surface, since any mistake made during this process will damage both pieces of material, and, as a result, increased labor or financial costs.

How to properly cut linoleum?

When cutting linoleum, we will need other tools: a square, rulers of different lengths, a spatula with teeth. The procedure for cutting and laying linoleum:

To level the coating, linoleum must be rolled out and left to level for a while.

It is necessary to cut material blanks taking into account the allowances for cutting and shrinkage of the coating (from 2x to 6 cm, depending on the length of the material).

After cutting the linoleum into ready-made pieces, they must be left for 4-5 days in the form of a stack of sheets, for full straightening.

After straightening, it is necessary to place the pieces of linoleum on the floor and where it is necessary to fit, cutting off small pieces of the coating in the places where the protrusions, pipes and other communications are located, pre-marking on thick paper, which will be used when cutting the coating as a template.

You can adjust the dimensions of the covering directly on the floor if there are no additional protrusions in the room and the room has the correct shape.

Cut linoleum at the base of the corners should be “V-shaped”, pressing it to the floor with a ruler or corner, cut along the ruler.

When using linoleum with a complex visible pattern, perform face-up cutting operations to evaluate the quality of the joint pattern of the applied coating.

Linoleum should be cut along a long line, starting from one side of the wall.

After cutting the first piece, secure the edge of the cut material with any heavy object. Mark a seam line over the finished piece. Place the next piece on the finished piece, cut both along the intended mowing line, butt the new piece back to back.

High-quality raw material, the right tool, precise cutting of the coating, butt-to-end linoleum installation and a good fit when the material shrinks will bring you maximum satisfaction with the work performed, and the room will sparkle with new colors. The new coating of your floor also depends not only on the tool you choose, but also on the patience when cutting linoleum.