How to cut off a copper tube evenly.

How and how to cut off the pipe

Pipes are the most common type of metal and plastic rental. They are used to transport a wide variety of gases and liquids. In factories, rental is produced by a certain length. To mount them in place in the pipeline, a heating, water supply or sewage system, they must be cut to the desired length. Pipes are cut evenly and with a bevel. To do this, use many methods of cutting and a variety of equipment.

The tools used

I am simple at first glance operation. cutting pipes in practice discovers a lot of nuances and pitfalls. Not so. just cut off the tube evenly:

It is very important to choose a cutting method for each specific case and special equipment. It is divided into individual, domestic and industrial.

For individual use

Used in households, private construction and small business. Deal with small and average diameters (up to 250 mm) used in systems

- Rezaki. They are used to cut off the polymer pipe up to 75 mm. For an even and neat cut, they have a gear mechanism. The workpiece is first clamped by a shelter, which reliably fixes it and does not allow to leave the cutting line.

- Disk cutter. Suitable for ventilation and sewer polymer pipes with a diameter of up to 200 mm. A blade is not a secate type, but in the form of a disk rolling on the surface of the workpiece. The incision is carried out at several revolutions. Not suitable for metal.plastic rolling, since a thin metal liner can mix.

- Guillotine. A flat oblique knife moves in the guides and allows you to smoothly cut off the required length in one pass. Produced both with an electric drive that provides greater performance, and with manual.

- Kryazuvka for metal. A classic locksmith tool allows you to cut off the preparation clamped in a vice. When using it is important to lead the saw smoothly, with constant effort and without distortions. The burrs formed after work with a hacksaw should be cleaned with a file.

- Corner grinder, corner grinder. In everyday life, it is called “corner grinder”. This universal tool on the teeth of any materials and diameters. In order to cut the pipe with a corner grinder, special abrasive cutting discs are used.

- Electric jigsaw. A very popular tool among home masters can cut pipes, but due to the departure of a flexible blade to the side of accuracy you will only have to dream

- Saber saw. The tool has not yet gained widespread among masters. The adjustable emphasis of the saw and its powerful blade allow you to cut off the rental even by weight and close to the wall.

How to cut a pipe evenly

In order for the cut from a general purpose tool to be even, special devices should be used to fix the workpiece. It can be templates, vise or chose. In addition, it is very important to properly mark the future cut and during work to ensure that the fishing line for the trimmer cut does not go to the side.

For industrial use

Such equipment is used in production, where the volumes of work are large or you have to cut large diameter pipes. In order to cut off evenly, use:

- Lathe. Suitable for high.precision cutting of workpieces, removing chamfers, performing ledges, transitions of diameters and other shaped processing. Allows the lathe and cut the thread, both internal and external. The length of the part is limited by the departure of the machine of the machine. Diameter. the fist of the cartridge.

- Ribbon machines. They are used in order to cut off a large diameter pipe without extracting it from a trench or a collector point. Work on deformed products.

- Disk cutting machines. Highly automated installation with a pendulum saw and the mechanism for feeding blanks. It is often included in the production line, used for high.performance rolling of rolling into equal pieces.

- Manual disk installations. Mobile equipment is used to cut off the rental exactly right at the installation site. They are equipped with a multifunctional clamp that allows you to reliably fix products of different diameters and cut them out evenly without damaging the edges. Turning table allows you to cut exactly at an arbitrary angle. The most advanced models are equipped with an orbital welding system. This allows you to not only cut off, but also connect the segments.

Features of execution

Performing the collapse of the tubes made of copper may be required if:

- The cut end of the tube must be given the required configuration;

- The end of the product must be prepared for its connection using a coupling (in this case, using the collapse, they adjust such geometric parameters of the tube as inner diameter, bending angle, etc.);

- It is necessary to prepare the ends of copper tubes for their connection by soldering.

In order to harden the copper pipe using special tools and devices, it is necessary to perform the following actions.

- The end of the tube, the connection of which must be performed, is carefully cleaned.

- A special clutch is put on the cleaned end.

- With the help of a special tool or device, the end of the tube is collapsed until the angle of its expansion is 45 °.

- After the end of the procedure, the end of the product is extracted from the device. Then you can immediately proceed to the connection.

If you have never performed such a technological operation before and are going to carry out with your own hands for the first time, then you should cut off the pipe with some length of length (2–2.5 cm), which will allow you to collapse it again in case of failure, cutting off the defective area.

Rimer. devices for stripping the ends of copper tubes

If you turn the pipe from copper in order to perform its connection by soldering, then the sequence of actions for the implementation of such a procedure will look as follows.

- The surface of the end of the tube, which must be destroyed, is thoroughly cleaned (for this it is best to use a special brush).

- Using a special device, the end of the copper tube expands to such an extent that it is possible to insert the end of another tube into it and at the same time withstand a gap of 0.124 mm between the connected elements. Naturally, for this it is necessary to use a measuring tool.

- A flux necessary to ensure the formation of a reliable and hermetic compound is applied to the inner surface of the pipe section that is already broken off, a uniform layer is applied.

- In the broken part to a depth equal to the diameter of the pipe, the end of the second compound element is inserted.

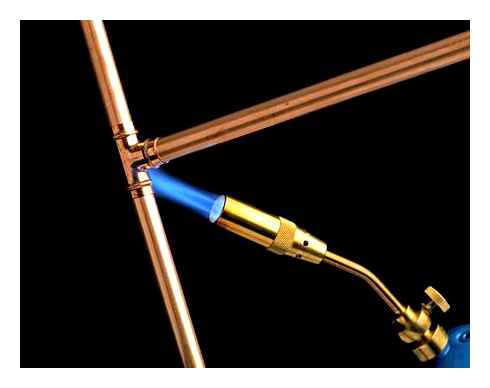

- With the help of a gas burner, an electric soldering iron or a soldering lamp, the place of the future connection warms up until the moment when the solder begins to melt.

- With molten solder, all the gaps between the edges of the connected copper pipes are filled, as a result of which a reliable and sealed connection is formed.

After the connection of two copper tubes is formed, they must be put on a horizontal surface and let them completely cool. Only after the connection place has completely cooled down, the resulting design can be operated.

Tools and devices

In order to collapse with your own hands, the tubes made of copper use special devices. Such devices can have both manual and electric drive. They are used to install air conditioning, water supply and heating systems. Tools equipped with an electric drive often combine several functions: with their help you can not only destroy a copper tube, but also bend it at the required angle.

Any device with which the tubes made of copper is carried out works according to the principle of plastic deformation, therefore it is very important that it copes with this process as carefully as possible, without violating the uniformity of the structure of the material, maintaining the uniformity of the thickness of the products, as well as the smoothness of their internal surfaces.

The scheme of the correct collapse and examples of the incorrectly performed operation

To efficiently carry out the collapse of copper tubes (even if you carry it out with your own hands for the first time), you can use one of the following devices.

This is a cone.shaped blank made of a stronger metal alloy than copper. The advantages of such a device are low price and ease of use. Meanwhile, its use may be accompanied by ruptures of the walls of the copper product, which gives low quality collapse.

This simplest device can be destroyed by one pipe, but there is no need to talk about any quality of work

The main working body of this device is a solid alloy roller, which, rolling along the edge of the copper tube, gives the latter the required configuration. The use of a mechanical collapse allows you to perform uniform deformation of the processed section of the tube, to form the same thickness at its end with the high quality of their inner surface.

A hand tool is able to provide high quality collapse and good speed

Such a device with a whole set of interchangeable nozzles, possessing all the advantages of a mechanical tool, allows the collapse of copper tubes with higher performance and less labor costs. Perhaps the only drawback of the electric collapse is its fairly high price.

The battery of this collapse is enough for about 100 operations

Such a manual device operating on the principle of a lever mechanism allows you to collapse the end of the tube in one movement. Possessing the simplicity of the design, such a device has a number of significant disadvantages, the most significant of which is the inability to control the thickness of the walls of the processed product. Thus, the use of an expander, which is most often chosen by those who perform a collapse with their own hands, do not guarantee to obtain a qualitative result.

Method 2 chop metal with a chisel and hammer

Another primitive and unprofitable way. However, it is quite applicable in order to cut off (cut off) a small metal bar or wire in diameter.

This method is suitable for small volumes of work, with small sections of the metal pipe, corner, iron strips, screw stilettos, etc.P.

Theoretically, you can manually saw off an iron pin five to seven centimeters with a diameter or a corner of fifty to fifty and half a centimeter thick. True, this will take more than one hour of time, will require many efforts and excerpts.

If there is no hacksaw for metal, then a simple file will sometimes help, but rather not to cut off, but to cut the metal (for example, not a weed bar for subsequent bending).

Method 4 Cut an electric jigsaw with a metal file.

The jigsaw can be used for cutting, including curly, thin (up to one or two millimeters with thickness) metal sheets, as well as small parts, rods, pipes, etc.P.

The cutting speed is small, but a fairly high accuracy is achieved. When cutting more or less thick sheets of iron, it is recommended to grease the file and grease the cut surface itself with solidol.

How to cut and bend copper pipes

Copper pipes are good that they are not difficult and easy to bend and cut. The bending of copper pipes is a process that needs a certain ability and the presence of skills, because copper is a very soft material that you need to handle carefully. To date, in practice, several reliable methods of cutting and bending copper pipes are distinguished.

Manual pipe and its features

Due to the manual pipe bend, you can carefully bend the pipe directly at the site of installation or repair, or fixed on the workbench. During the use of a pipeline, the risk of crushing, flattening and breaking minimum. Using a hand.pipe for copper pipes, you can abandon auxiliary docking elements. With it, copper pipes can bend in accordance with the desired size and shape.

Using a spring pipe, any deformation of the walls of the pipe is excluded, and therefore the correct bend of the pipe is obtained by a given angle. A spring pipe for copper pipes is used as follows:

A pipeline, as an ideal option for cutting pipes

A pipeline for copper pipes will allow you to save a significant amount of time on cutting pipes. In addition, a pipeline can be used to clean the pipes and before the preparatory installation operations.

Using the pipeline, you can get a perfectly even cut without much effort, avoiding the deformation of the pipe, regardless of its diameter.

Copper pipe processing with cutter

Cutting copper pipes occurs using a special cutter. a pipeline or pipe.cutting scissors, perpendicular to the longitudinal axis of the pipe.

Using a cutter for copper pipes, you need to be careful, since the internal edge of the cut of the pipe is acute.

Set for cutting/rallying copper/aluminum tubes

Good afternoon! I was offered a set for cutting/rallying copper/aluminum tubes for a review, and since I own an old car with a hydraulic suspension in which all the carts are made of copper tubes (before that I read on the documents, about how the owners of car with a hydraulic suspension independently change the rotten tubes) I agreed accordingly. I’ll say right away that before that I had never rolled the tubes.

Any device with which the tubes made of copper is carried out works according to the principle of plastic deformation, therefore it is very important that it copes with this process as carefully as possible, without violating the uniformity of the structure of the material, maintaining the uniformity of the thickness of the products, as well as the smoothness of their internal surfaces. The scheme of the correct collapse and examples of the incorrectly performed operation:

Distinguish between several main options for the funnel. European standards (in the center). In shape resembles a wheel bus, widely used in most cars produced at the factories of the Eurasian continent. It turns out the strongest version of the connection from the above, but is considered a one.time. With skillful production, you can use up to three times. The usual simple funnel obtained by the bending of the walls of the end of the tube with a special tool for shaving brake tubes. Funnel obtained by double addition of the pipe of the tube or simple funnel. It is considered the standard in American cars. Receive this type of collapse of the brake tube from the fungus, besieging its upper part using conical mandrel.

One of the main conditions for rollering is the height of the tube release (in articles and videos, few people talk about the height, and this is one of the main conditions of high.quality rolling):

Never Need A Coupling Again! How to Swage Copper Pipe!

Equipment:

First, try to cut the tube: the cutter at first glance looks high quality, has a spare disc and is able to cut tubes with a diameter of 4mm. up to 28mm.:

We adjust the knife to the tube and begin to rotate the tool around the tube, gradually squeezing with a slight effort: after pruning, it is necessary to remove the binding, for this there is the necessary tip on the pipeline:

To begin with, we will try to make a single funnel: pinch the tube in the shape so that its release corresponds to the height indicated in the table, in my case it is from 0.5 to 0.8 mm.

Result: in general, for the first time it’s not bad, there are notches from the shape on the tube, I tried to put the paper, the result remained almost the same:

Next, we will make a European standard fungus, for this we will need a mandrel of the corresponding diameter: this is the best result, all the same, experience is needed.

Double funnel: with this type of rolling is much easier than with the previous one, the result is corresponded:

After two hours, something began to turn out, these are the best results: the end of the end is perfectly even:

Initially, I thought that the roller pipe is an easy lesson, but it turned out to be a practical one needed to harden the phone that I did not have. I and Valtsevka took off the whole evening and spent a meter of a copper tube and after that it only began to turn out more or less (the European standard fungus was also on the sample and did not work out). Do your own pluses include the fact that you will treat work responsibly and seriously and will be sure of the quality of the work done. There is no need to pay someone for work, often an unreasonable price. Of the minuses, it is worth noting that copper tubes do not often fail and your tool may need only once. DIY repairs according to the instructions or to entrust specialists to decide each person individually. I decided for myself that I would better turn to a proven master.

If you have questions, contact me, I will try to answer them. Thank you all for your attention! If you liked the review, do not forget to click “I liked the review”!) For all good!

Product for writing a review is provided with a store. The review is published in accordance with P.18 Rules of the site.

Methods of cutting metal pipes at an angle

Sprinkle the pipe or cut it into pieces in several ways. Of the available tools, the angular grinder copes with this task. But the biggest problem is the need to correctly mark the cutting lines. They can be different, most often you have to withstand either a right angle relative to the axis of the pipe, or 45 degrees. Techniques are somewhat changed depending on which products need to be cut:

pipes for laying the water supply, gas and for wiring heating;

profile products for assembling the gates, visors, other metal structures;

Large diameter pipes. as a rule, it is rarely necessary at home, where the widest clearance only in the sewage system;

Pipes made of steel, cast iron, thin.walled from non.ferrous metals and soft alloys.

Both problems are solved quite simply even without using a special pattern of the angle of the pipe.

Cut the pipe at an angle of 90 degrees

To mark the cut [water and gas pipes] at right angles, you can use a sheet of paper of the standard A4 format, wide isolation or construction tape. If you wrap a fairly wide material around the pipe so that its edges are definitely coincided with the imposition, you get the perfect fishing line for a cutting trimmer. If the tape or the tape is tightly glued to the metal, you can go right along the edge.

It is important to be able to properly use the grinder, keep it with a certain effort and follow the safety rules. The described technique is the simplest, it is suitable for cutting a large diameter pipe.

Pipe expander for copper tubes of refrigerator equipment

Recently, I am slowly learning to repair refrigerators, and surround the appropriate tools. About one of these specific tools, a trumpeter for soldering the tubes of the same diameter, and it will be discussed. UPD. The day after writing the review, I realized that the tips were bent. I don’t recommend buying. First I’ll demonstrate the final photo so that it is clear why everything is done. Here are three aduls in a copper refrigerator: if you already understand this photo that you do not need this, then you can not read the review:-).

So. Trubkiders are of two types. I used to use about such a set for a rolling (photo from the Internet): it includes a clamp and a screw plunger or a cone, which is screwed into the tube, something like this: accordingly, if a cone is used, then a tube is turned off for a collapse for air conditioning. If the cylindrical plunger, then the tip of the tube expands into a wider tube, into which you can insert a piece of another, not expanded, tube, and sealed hermetically tightly. It would seem that everything is simple and convenient-but in practice it turns out that, firstly, it is not always possible to clamp the pipe, and, secondly, some tubes are not suitable for a standard set of diameters of plunger-it turns out that the plunger expands the tube too much, And an unexplored tube dangles in it. To solve these two problems, the hero of the current review was acquired.

The trumpeter came in a sealed blister. On the back of the blister there is an instruction in the pictures. In general, “insert, press, crank, remove”.

We take out a brigade tool. We look at the painted pens, on which the paint immediately peeled off in places. We put on the pens of 30mm heat.assembly pipe. We sit down. We look at the structure, it is simple. The tool consists of two halves. Each half. a number of semi.cylinders one on the other, and a pen. Когда ручки не сжаты, два полуцилиндра сложены в цилиндр, который вставляется в трубку. If the handles are compressed, then the semi.cylinders diverge, and the tube around them stretches.

Now we cut copper tubes for the sample, 1/4 “, 3/8”, 1/2 “. And we expand the tubes. A misfortune happened with a half.inch tube: I inserted an extensor into the phone and immediately squeezed the handles until it stops. And the tube broke: then I was more accurate: I pressed a little on the pens, let go, turned the expander of degrees for thirty, pressed it again, let go again, turned it. and so on, until it turned out that an unexplored piece climbed into the extended tip of the tube. So I expanded the tubes by 3/8 “and 1/2”, but with the most necessary for household refrigerators 1/4 “the problem came out: the inner diameter of the tube. 4 mm. It would seem that everything is fine, the seller promised that the tool works from 4 mm. But, in fact, the diameter of the thinnest part of the expander is 4.5 mm! It does not fit! Okay. We take the supra.films, and slowly and slowly plunge 4.5 mm up to 4 mm. True, after that it turns out that, even with maximum compression of the handles, the diameter of the resulting extension is barely enough to install an unexplored tube. Well, at least something. As a result, I collected all three pairs of tubes. And he seized them with a silver solder. so we finally reached the final photograph, which I placed at the beginning of the review.

Summing up. a tool for your money is not bad. But, unfortunately, it requires a file in the literal sense to work with the most common tube diameter in everyday life. However, if the tubes are slightly more thin.walled, then without refinement it will take.

UPD. Only the day after writing the review, I realized why 1/4 “the tube did not expand to the desired size. It turns out that the ends of the expander not only stretch the tube, but also bend themselves. As a result, it is completely impossible to use them on 1/4 of the tube. With thicker tubes, everything is fine, but if you need to expand 1/4 “tubes most common in refrigerators, then I don’t recommend buying.

Pipe cutter for copper pipes

Quite often, in the process of laying water systems, installing air conditioning systems and in other work, it is necessary to cut a copper pipe several times. It is undesirable to use a hacksaw for this purpose, since metal particles can get into the pipes, thin copper walls can be deformed, it will be difficult to ensure the perpendicularity of the cut, and the burr will definitely remain on the pipe cut. And this work will be long, uncomfortable and tiring. Just for this purpose is a pipeline for copper pipes. It allows you to perfectly cut the copper pipe perfectly in a very short time, providing even edges around the entire perimeter of the circle. Copper is soft and supple metal, and copper pipes can easily be deformed with rough exposure. Therefore, to purchase a pipeline for copper pipes, the price of which depends on many factors, it is necessary for working with copper.

All tools designed for cutting pipes can be divided into several categories, depending on the type of drive:

- Manual. All actions are performed by the master using physical efforts.

- Electric. An electric motor comes to the aid of the master.

- Hydraulic. Work is carried out by creating pressure in the cylinder.

- Pneumatic. Uses the force of the spring.

Hand pipeline for copper pipes of Ridgid

It should be said that for cutting copper pipes, a manual tool is quite enough, although the use of battery models significantly accelerates the work. Automation of the cutting process is necessary for work on an industrial scale and for cutting large diameter pipes.

The pipeline is manual

This device is easy to work and does not require the qualifications of the master who uses it. A pipe cutter of the handle and the clamping mechanism with rollers consists. A copper pipe is inserted between two rollers. supporting and cutting. After that, the adjusting screw is twisted until. A pipeline must be done several revolutions around the pipe. Then the adjusting screw is twisted again, and the tool is again turning around the pipe. Such work is performed until the pipe section is completely circumcised.

At this time, a steel cutting video smoothly cuts copper, as a result of which cut walls are smooth and even. Some models built a special knife that automatically removes the chamfer from the end of the pipe. Also, a cutter for copper pipes can have a gran show in a set, which is removed by hand, after the end of the trim. A spare knife that can easily be replaced if the installed cutting video is dulls is also a useful addition.

Telescopic manual pipelines allow you to cut pipes of various diameters by changing the distance between the rollers. There are also mini-pipe designed to work in constrained conditions. For example, when the pipe is located close to the wall. They have smaller dimensions.

In the video, you can familiarize yourself with the Rothenberger pipeline with the built.in grarifice shower.

And another video with a battery pipeline.

The following factors affect the cost of the tool for copper pipes:

Using a metal for cutting metal

The electric jigsaw is most often used for cutting slab materials of the OSP, plywood and for figure cutting on wood. And although it is written in the technical characteristics that the tool can cut metal, novice masters have questions: which metal can be cut with a jigsaw, what thickness, at what speed and supply of the pendulum stroke and which file to use for this?

I have a regular electric jigsaw. The tool was lying idle. Once I decided to cut a sheet of stainless steel with a thickness of 5 mm. I tried the files for the metal of several manufacturers. It’s not easy to saw, but the cut is very neat. True, at the end of the work there was not enough patience and cut the metal with a “corner grinder”.

Big Muzzy also tried to saw a lace of a regular “black” metal with a thickness of 2-3 mm. The tool cuts, as in clockwork, and having adopted, you can even make figured cuts.

ITPB also sawed a jig. It takes about 1 minute to cut the workpiece. The revolutions are smaller, the passage of the pendulum was not used or put on the first step. Oil was supplied to the cutting place, t.to. without butter, the saw quickly fails.

I cut a metal sheet with a thickness of 4 mm. The cut and the back of the cut was lubricated with fat, everything worked out.

I sawed two steel plates with a thickness with a thickness of more than 1 cm. It took about 25 minutes 1 saw on a cutter 25 cm long. He cut with “smokers” on the first presentation, set the turnover into the third and fourth division of the revolutionary regulator. The oil was added into the cut zone. Still cut metal 9 mm thick. Sawed with a file on aluminum, at the smallest speed. That’s what happened.

Musicman3 shares the experience of metal cut with a thickness of 0.5 cm and 1300 mm long. He set the speed on the number 5 of the available 6. The pendulum is 1. Cut without the use of water and oil. Taking into account breaks to work, it took about half an hour, and one saw was used up. According to Musicman3, it is easier and safer to saw a jigsaw than a corner grinder, and the cut is better than.

Summing up: buying an expensive specialized tool for metalworking is not always justified if it is needed for one.time work. After all, then he will be lying around most of his time in the workshop or, at best, use 1-2 times a year. Therefore: Before you purchase any tool, you need to think and weigh everything “for” and “against”. Often cut the metal, cut off the pipe from the right angle and even turn the parts with the help of the simplest household power tools or budgetary forces. The main thing is to know how to do this, but for this you need to study the topics on Forumhouse.

There is a section on the portal where users are divided by the experience of metalworking and the secrets of choosing a metal.cutting tool. The material on the features of manual arc welding inverter is also useful.

Copper tire

Copper tire is a type of conductive product, which is characterized by high electrical conductivity, as well as resistance to corrosion. This type of conductor is used as a binder in modern power plants, electrical engineering and energy supply and automation systems at various facilities.

Externally, a copper tire is a strip of rectangular metal metal, although various types of this conductor are produced for various operating and installation conditions.

Copper conductors of this type are significant due to their unique properties:

The use of tire trunks significantly saves time when designing equipment, and also reduces the time to introduce powerful systems into operation. In the manufacture of modern electrical equipment, its components and electrical parts, many manufacturers give their preference to copper tires, and not their analogues. Features of production

As the main material for the manufacture of conductors of this type, pure copper is used 99.9%. Less than 0.5% of the workpieces make up various kinds of additives. The presence of these additives significantly affects the quality of the manufactured products, so the composition of the metal is carefully monitored. In the manufacture of products, manufacturers use different copper brands, among which are the most popular: are:

The brand of copper is determined by GOST chosen for products. The most common raw materials are copper of the brands M1 and M2, but at the same time a copper tire from different brands will have differences in characteristics. For the formation of semi.finished products, the technology of cold rolling of hot pressing copper is used.

The typical dimensions of the products are determined by the selected GOST. For different operating conditions, blanks of different types of plasticity are made:

A separate type of conductor is an oxygeneric (SMTV) made of copper alloy without oxides. This type of copper tires is characterized by higher strength when exposed to high temperatures, therefore, even with significant heating, such a conductor practically does not lose its qualities. Due to too high prices, such products are not popular.

Among other things, copper tires can be of various forms, which allows them to be used purely on certain objects. Now there are the following types of conductors:

The finished products can be delivered in the form of stripes, or bays if the tires of small thickness. The manufacturer of copper tires sets the warranty period of storage of products from the moment of its production. Thus, the shelf life for SMT, SMTV. 6 months, SHMM. 12 months. The warranty is valid in the absence of violations during transportation during storage of conductors. Features of copper tires

Most of the features of copper tires are due to the qualities of the material from which they are made. For example, copper is not subject to corrosion in conditions of minimum humidity, but contact corrosion may begin when interacting with aluminum or zinc. Another interesting property of the copper tire is that it can oxidize in the air, but its conductivity does not change, since the film also conducts current, although it is somewhat worse. Copper tires are resistant to bending and twisting, which allows you to create highways of the necessary shape and at the same time save place and materials. Now it is worth moving on to the main advantages:

Impurities and their influence on the quality of the conductor of the copper brand and its types differ not only in production technology, but also by the number of impurities in the metal. Different types of analyzes are used to determine the composition of the material, which allows you to identify up to 22 different impurities in 99.9% of copper. Different impurities can both improve and worsen some qualities of the conductor, so you need to know their exact number. Certain impurities negatively affect the quality of copper, for example, lead, zinc, as well as a number of other light.melting impurities. These elements complicate the welding and soldering process when connecting copper tires, since fragile zones are formed due to their presence at the junction. This significantly reduces the life of the conductor and exposes the entire danger system.

Negatively affect the electrical conductivity of phosphorus, iron, antimony, arsenic, tin. In general, their share, usually does not exceed 0.06%, so the effect is insignificant.

Harmful impurities include oxygen, which in a small amount is contained in the metal. Its amount in the workpieces does not exceed 0.08% of the mass of the product. Under normal operating conditions, this does not affect its quality in any way. However, with prolonged exposure to high temperatures, the copper tire becomes more fragile. If the systems or equipment is operated in the condition of high temperatures, it is recommended to purchase an oxygen.free copper tire. Obzlosvodny copper is more expensive and mainly produced only to order, but at the same time provides stable operation when exposed to high temperatures.

M0NWK. How to straighten microbore copper tube / pipe

Of the useful impurities, silver should be mentioned, its fractions of 0.05% are enough to increase the creep of copper without negative consequences for the beneficial qualities of the material. When heated, copper with the addition of silver holds the shape better, in addition, its recrystallization temperature rises.

A change in the number of impurities by at least one percent can lead to loss or, conversely, to improve the electrical conductivity of copper by 3%. Its manufacturing technology is strongly affected by the quality of the conductor, and GOST taken to create products, which is why copper of one brand, but from different manufacturers can have significant differences in the characteristics.

The use of copper tires at modern enterprises is a rather expensive pleasure, many enterprises are ready for such costs for the stable operation of power supply systems and electrical devices. Due to high throughput and high dynamic stability, the copper tire exceeds the aluminum analogue therefore in most cases, it will be the best choice.

Using high.quality copper tires, you can create simple, reliable, durable, economical in terms of consumption of system electricity and device.