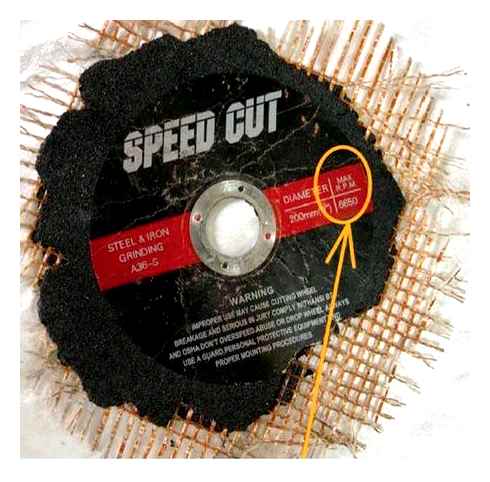

How to cut off a grinder correctly. The diameter of the circle must match the permissible grinder

How to cut a grinder correctly

Modern Bulgarian is a universal tool designed to perform different works. With its help, you can cut various materials: metal, wood, plywood, natural stone, foam block, slag block, paving and tile, brick, laminate, concrete, ordinary and organic glass. At the same time, sheets, blocks, pipes are cut, strokes make. Also, the corner grinding machine is grinding and polishing surfaces. When performing work, it is important to know how to cut a grinder correctly. Not only the quality of the result depends on this, but also to a large extent personal safety. When working with different materials, it is necessary to use only circles intended specifically for them.

To cut a tree, plywood or laminate with a corner grinding machine, the corresponding discs are used. They are designed on purpose To work at high speeds. But the best.Suitable circles on sale are quite rare.

Cutting wood

Special Wood disk has side teeth that increase the size of the cut. In any case, it is necessary to cut wood carefully. The thickness of the boards should not exceed 4 cm.

Zoom H1 | Best 2021 mic and recorder? Worth it? Bonus track of Ligaya by Eraserheads (sample cover)

Cutting wood with a grinder is a very unsafe activity, during which you can easily get an injury. At the same time, it is strictly forbidden to use circles from the circular saw, because they are designed to work at a speed that does not exceed 3,000 rpm. If jamming occurs, then such circles may collapse. This is due to the fact that they make them from solid, but relatively fragile steel. Also, do not use nozzles with large teeth, because the probability increases that the teeth will hook, and the circle will jam. In this case, the probability of pulling out the power tool from the hands increases repeatedly.

If, despite the increased danger, it is decided to saw boards with a corner grinding machine, then you must adhere to the following recommendations.

- If there is the possibility of adjusting the number of speed revolutions, it is recommended to set the minimum possible number.

- The tool during sawing is required to be kept in one (working) plane, because distortions can easily cause traumatic consequences.

- Blocking button After turning on the power tool, you should not clamp, since if necessary, it is more difficult to turn it off.

- The sawing wood should be dried, not dried (raw) lumber should not be cut.

- With a relatively large length of the boards, it is better to work with a partner.

- It is required to comply with safety regulations.

- The best option is to work with boards with the same thickness.

- The sawn material should not contain extraneous inclusions, for example, nails, screws, bolts, wires.

To best protect the workflow, the Bulgarian must be used Like a circular saw, fixed in a stationary (motionless) position. In this case, the tool is fixed on a bed with guides. During sawing, the working material is served in the same way as on the circular.

Cutting laminate and plywood

To cut the laminate, use metal circles, concrete, intended for cutting ceramic tiles, as well as small.Tooth wood. When working, it is recommended to adhere to the following rules:

- The cut should be performed from the front part of the lamellas so as not to leave chips at the place of the cut;

- Due to the formation of a large amount of dust and the appearance of an unpleasant smell of burning material, you need to work in a well-ventilated room;

- To obtain an even cut, the lamella must be motionless.

To saw plywood, use Wood wheels. The cut is performed according to the previously marked line. At the same time, you should make sure that the circle does not jam the sawed fragment of the sheet before the end.

Sample of a quarter in the board

Using a corner grinding machine, you can choose a quarter in the board, but to perform this operation requires the experience of carrying out work of this kind and good instrument ownership skills. The best option would be to fix the grinder in a stationary, motionless position. Then the work will be done as On the circular machine.

With manual sample of a quarter using a grinder, you should securely fix the wooden workpiece so that there is no progress. This method is suitable mainly only when working with a thick board, because it is quite problematic to control the depth of the cut. In this case, it is easily possible to cut through the wood through thin places.

A quarter is chosen in the board as follows:

- Designed with a pencil or marker of lumber;

- Perform the cut from the ribs (end) of the board, slowly, gently leading the tool on the marked line;

- Cut the lumber in another mark.

You can also choose a quarter by a grinder With a special milling cutter. Homemade nozzles are better not to use for personal safety purposes. The method using the cutter allows you to make grooves in details of a relatively small size.

Both of the considered options with significant volumes of work are not suitable, since the process of sampling a quarter of the angle grinding machine proceeds relatively slowly.

How to cut exactly

For these purposes, you can use construction tape, which is easier to wrap the pipe and fix it. On the edge of the paper or adhesive tape we draw the cutting line. Remove the paper, hear the pipe in a vice and cut the grinder.

In a similar way, you can cut a corner, profile or sheet. Do not only forget that during cutting it is impossible to change the position of the car. Circle skew will lead to jamming or breakdown. Should not be excessively pressed on a circle, especially thin. Deformation will immediately affect the curvature. The machine should be driven into the material, it only needs to be held.

The evenness of the cut depends on the correct selection of the circle. It is difficult to achieve a flat trajectory, cutting off part of the thick.Walled pipe with a thin circle.

How to cut a circle with a grinder

We set the grinder not perpendicular to the sheet, but at an angle. Over, the Bulgarian will be inclined to the center of the circle. At low speed we make a preliminary contour cut. Both the contour and the main cut must be performed with short movements, moving the position of the circle along the contour.

Similarly, you can act by working with other materials. To cut a circle in a tile under the pipe, you need to mark on the back of the tiles. Then take a grinder and make a slot of slots along the chord at a distance of 4-5 mm from one another inside.

Naturally get a cut of an oblique, with an extension to the back side. But this land can be grabbed gradually with pliers and painted. At the end of the operation, the back of the hole is polished. Here you need accuracy, attention and patience.

How to cut a bell without chips tiles and porcelain tiles

The situation with porcelain tiles is a little more complicated. Porcelain tiles are somewhat thicker than ordinary tiles and stronger than it. Manual tile cutter very quickly stupid, without achieving the result. Therefore, you can cut porcelain stoneware around stone.

On the drawn cut line, we make a contour incision. Then another, third. Until the cut thickness of the material is less cut out. We shift the tiles of porcelain tile to the edge of the table and with a sharp but not very strong movement we break.

How to saw without dust

This device is very similar to a medical dropper. In a regular plastic bottle with a volume of 1.5. 2.0 liters, we put a tube from a dropper. We leave only the regulator on it. In the protective casing of the grinder we make a hole in the diameter of this tube. In this hole we insert the other same tube.

We connect these two tubes, pour water into the bottle and open it to the supply to the circle. After the first approximate cut, we adjust the supply of water, which should extinguish all the dust released during cutting.

With such a device, you can process concrete, brick and many other materials that, when destroyed, distinguish a large amount of dust.

How to cut or cut a grinder correctly

Various materials behave differently during processing by a grinder. Some immediately overheat and break, others are deformed, others do not want to succumb to processing at all. All the subtleties of working with a grinder is difficult to know, but practice requires to know at least something.

Cut the tiles of paving, tile, porcelain tile

Tile tiles without chips are better processed by a cutting circle for stone. A line is applied to the tile, along which a contour cut is made. Then the depth gradually increases. Когда прорезанная часть станет больше, плитку кладут на край стола и переламывают по линии. Irregularities and roughness can then work out.

Porcelain tile is well processed around the stone. The cutting technology is no different from the technology of cutting tiles.

Cut the wood with a grinder

The most ordinary disk, to which we have long been accustomed to the circular saw. The main feature of the selection of such a disk is that the calculated speeds of the grinder and disk must match. Only in this case it is possible to cut it smoothly and without combustion of wood.

Such a disc easily cuts wood in any direction, but traditionally prefers to cut across. Not only raw wood is easily cut, but also trees knots. It is convenient to dissolve boards on the bars or planks. For a large volume of such work, the grinder must be fixed in a stationary. Get a complete analogy of the circular saw.

Pressed wood materials of any density are very simple. And, if it is necessary to cut a wooden panel with nails filled, then a disk is produced for such work. He is not afraid to meet with nails. This universal disk is made from tungsten carbide by Bosh. Marking Bosh Carbide Wheel disc. Produced in size 76, 115 and 125 mm.

Bulgarian for brick, concrete, concrete ring

Cutting brick and concrete is performed using special circles for stone. The brick is easily cut, the main thing is to correct it before the sharp and not to use your leg as a clamp.

The concrete plate or concrete is cut practically without problems. But the concrete ring creates some problems. Not concrete itself, but a steel reinforcement invested in it. The circle in the grinder experiences a large load during concrete, and the reinforcement does harm it.

What disk to cut tiles

The tool for the tool is selected for a specific material. Several varieties of discs are suitable for cutting tiles.

Circles made of stone

Cutting element of significant thickness. Due to this, the cut is wide, the amount of dust during work increases. The main disadvantage is the Rapid wear of the consumable. Over, if chips or other defects appear on it during work, the circle is immediately changed. Otherwise, it can collapse by damaging the processed part and causing harm to a person working with him. Stone discs are the cheapest.

Steel circles

Thin equipment with different processing. For solid materials, select steel with diamond spraying. Such a cutting device easily copes with the task, for a long time does not grind. For cutting, three varieties of steel disks are used.

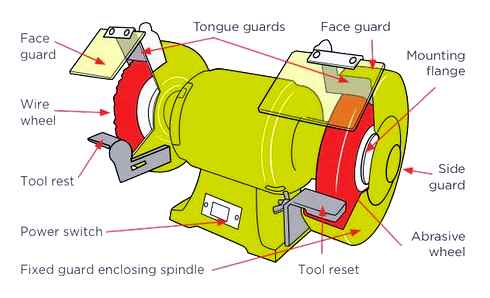

Recommendations when working with a grinder

Recommendations concern primarily the safety of work. It is forbidden to use the device in case of a number of faults:

- Cable and fork damage;

- Failure in the operation of the power buttons and latch;

- Brushes sparkle;

- Lubricant flows from the gearbox;

- The appearance of a characteristic of burning isolation of smoke or smell;

- Too loud knock, vibration or noise;

- The appearance of cracks or a breakdown of a protective shield, body or handle;

- Damage to the nozzle.

In any of these cases, you need to turn off the grinder, remove the fork from the outlet, fix the defects, and after that you can work further.

Successfully cut solid materials. A few simple tips for their processing:

- Cutting thick.Walled parts or blanks is carried out exclusively straight. Rounding is cut out by sectors.

- Working with long corners, profiles or pipes, it is necessary to cut off the hanging edge. The cut between the supports leads to the deflection of the workpiece and the jamming of the disk. You need to try to place the blanks so that they do not have to move during operation.

- After cutting profiled sheets (sheet corners), metal tiles or metal siding (metal.Bending), the edges must be treated with an anti.Corrosion coating.

- Paving and tiles, paving stones, concrete are well cut only by special (diamond) discs on stone. The tile is first cut into a small depth with light pressure, the next passage is already a full cut. In exceptional cases, it is allowed to cut these materials with a disk for the metal. But it is important to understand that it will be enough for only a few tiles or a couple of meters of a concrete wall.

- When cutting gas cylinders, care must be taken. They explode easily, so you need to reliably make sure that gas and condensate are completely removed from the cylinder. In general, it is better not to carry out such work at home.

- Highly waterproof wheels in ceramics are suitable for cutting glass or mirrors.

- Wave and flat slate cut through stone discs without unnecessary effort. Then it is possible to avoid chips and it turns out even cut.

When working with any materials, you must first make an accurate markup, determine the action plan, and only then proceed to cutting.

Bulgarian. An indispensable assistant in the household and at large construction sites. With its help, you can process any solid material by spending a minimum of time and effort. In order to gain initial experience and subsequent successful work, the tool should follow simple security tips. The main thing is to observe safety requirements at all stages of work.

How to saw without dust

Any dust is harmful to human health. During repair or construction, it settles everywhere. Remove it later and for a long and quite difficult. But the main thing is that it cannot be removed from the body. In order to work without dust, you need to make a small and inexpensive device for a grinder.

This device is very similar to a medical dropper. In a regular plastic bottle with a volume of 1.5. 2.0 liters, we put a tube from a dropper. We leave only the regulator on it. In the protective casing of the grinder we make a hole in the diameter of this tube. In this hole we insert the other same tube.

We connect these two tubes, pour water into the bottle and open it to the supply to the circle. After the first approximate cut, we adjust the supply of water, which should extinguish all the dust released during cutting.

With such a device, you can process concrete, brick and many other materials that, when destroyed, distinguish a large amount of dust.

How easy and accurately cut leaf metal with a grinder

Greetings everyone. The Bulgarian today has become one of the most popular tools. Few of the lovers have something to make something with their own hands at least a small grinder for 115 disk. Today I want to tell you about the method of cutting leaf metal grinder, which I have been using it myself for a long time. In this way it turns out quite easily and accurately cut the sheet metal.

This method is quite simple and reliable. I used to marry the line of the future cut with a coated lace, but no matter how carefully I tried, the cut still turned out to be not perfect. After all, we are people, not robots. Then I realized that it turned out well and evenly, it was necessary to conduct a cut along the guide. Began to use profile pipes or corner for this, it became easier and more convenient. But the best view of the guide (in my opinion) is the same sheet metal, namely, its flat factory side.

So I cut sheet metal. I mark the desired size using a tape measure and put the guide side of the sheet on these marks, holding with clamps with a lower sheet. And in this way it will be quite easy to cut. There is no need for unnecessary stresses and constant control of the disk of the grinder, it itself goes along the desired path.

Today I had to cut quite a lot. Not only across the sheet, but also along, using the same technology.

Then we clean the sharp burrs with a small grinder with a 125 grinding disk.

It turns out a pretty high.Quality cut that will never work if you do not use the guide for the disk of the grinder.

The photo shows that by connecting a cut on a sheet and a profile pipe, there is no uneven torn edge, so I recommend this method who did not know yet.

I almost forgot. I used a large grinder with 230 2 mm thick disk. It is also necessary to put a wooden block or professional pipe to the entire length a little away from the cut under the cut sheet so that the disk does not clamp. Do not use narrow guides from sheet metal. Can be crooked or play a little (bend) from the pressure of the disk of the grinder, better than 30 cm wide.

Cutting techniques

Oxygen cutting is used not only for obtaining blank blanks, but also from specialized rolling and pipes.

The cutting of the corner is performed as shown in rice. 83, a. After one shelf is cut through, the cutter is deployed and installed perpendicular to the second shelf.

The procedure for cutting the double.Rotary beam is shown in rice. 83, b. When the cutter approaches the vertical stance of the beam, the cutting speed should be reduced to completely cut off the rack.

When cutting a channel (rice. 83, in) the cutter can be placed both from the side of the inner and outer surface of the channel. Rice. 83. Sublower of a profile rental cutting: a. Corner, b. An I.Beam, c is a channel The preparation of steel of a square section begins to cut from the corner (rice. 84, a). After heating the angle to the ignition temperature, the cutting head is transferred to a vertical position and start cutting. At the end of the cutting, in order to first cut the lower corner, the cutter is tilted to 5. 10 ° to the side opposite to the direction of cutting.

The process of cutting a round blank is understandable from rice. 84, b. When moving the cutter, the distance between the end of the mouthpiece and the surface of the cut workpiece should be maintained by constant. Rice. 84. Techniques for cutting rods of various profiles: a. Square, b. Round, B. Non.Resistant cutting of several rods; 1. 6. Cutting sequence You can increase the performance of rod cutting by using a non.Stop process (rice. 84, in). In places of transition to each subsequent rod, the cutter should be tilted to the side, the reverse direction of cutting.

Pipe cutting has to be performed, especially in installation conditions, in all positions; In this case, the quality of the cutting is different. It is advisable for cutting pipes, mainly of large diameters, use roller stands (rice. 85) with drive or non.Water rollers. Rice. 85. Scheme of the roller stand for cutting pipes: 1. Cutter, 2. Pipe, 3. Support rollers A large role is played by the quality of cutting when preparing the end of the pipe for welding; In these cases, it is necessary to apply markings using a tape made of thin flexible material (tin, cardboard, etc.). The pipe is wrapped with a ribbon and a cutting line is applied along its edge with chalk. For the harvesting of a large number of identical parts, a package cut is used, the essence of which is that several sheets are collected in a bag, clamped along the contour and cut this package for one passage of the cutter. Package cutting is amenable to carbon steels with a carbon content of up to 0.4% and low.Alloy with carbon content to 0.25%. Package cutting modes are given in the table. 21. 21. Package cutting modes Cutting steel of large thickness (more than 300 mm) is performed by special cutters (see. § 54) at a reduced oxygen pressure, at the beginning of cutting the cutting is installed with a small inclination (2. 3 °), as shown in rice. 86. The speed of moving the cutter should be sufficient to warm the lower layers of the metal, otherwise the cutting process may stop. Too high speed can lead to “non.Cut”. After the cutter goes a fairly long way along the upper plane of the metal, the through cutting will begin. At the end of cutting, it is necessary to slightly tilt the cutter to the side, the reverse direction of its movement, in order to first cut the lower part of the workpiece. To increase the length of the heating flame, it is installed with some excess of acetylene. The cutting modes of steel thickness are given in the table. 22.

Cutting techniques

Oxygen cutting is used not only for obtaining blank blanks, but also from specialized rolling and pipes.

The cutting of the corner is performed as shown in rice. 83, a. After one shelf is cut through, the cutter is deployed and installed perpendicular to the second shelf.

The procedure for cutting the double.Rotary beam is shown in rice. 83, b. When the cutter approaches the vertical stance of the beam, the cutting speed should be reduced to completely cut off the rack.

When cutting a channel (rice. 83, in) the cutter can be placed both from the side of the inner and outer surface of the channel. Rice. 83. Sublower of a profile rental cutting: a. Corner, b. An I.Beam, c is a channel The preparation of steel of a square section begins to cut from the corner (rice. 84, a). After heating the angle to the ignition temperature, the cutting head is transferred to a vertical position and start cutting. At the end of the cutting, in order to first cut the lower corner, the cutter is tilted to 5. 10 ° to the side opposite to the direction of cutting.

The process of cutting a round blank is understandable from rice. 84, b. When moving the cutter, the distance between the end of the mouthpiece and the surface of the cut workpiece should be maintained by constant. Rice. 84. Techniques for cutting rods of various profiles: a. Square, b. Round, B. Non.Resistant cutting of several rods; 1. 6. Cutting sequence You can increase the performance of rod cutting by using a non.Stop process (rice. 84, in). In places of transition to each subsequent rod, the cutter should be tilted to the side, the reverse direction of cutting.

Which Metal Grinding Wheel is Best? Let’s find out! Diablo, DeWalt, Makita, Avanti, Norton, Warrior

Pipe cutting has to be performed, especially in installation conditions, in all positions; In this case, the quality of the cutting is different. It is advisable for cutting pipes, mainly of large diameters, use roller stands (rice. 85) with drive or non.Water rollers. Rice. 85. Scheme of the roller stand for cutting pipes: 1. Cutter, 2. Pipe, 3. Support rollers A large role is played by the quality of cutting when preparing the end of the pipe for welding; In these cases, it is necessary to apply markings using a tape made of thin flexible material (tin, cardboard, etc.). The pipe is wrapped with a ribbon and a cutting line is applied along its edge with chalk. For the harvesting of a large number of identical parts, a package cut is used, the essence of which is that several sheets are collected in a bag, clamped along the contour and cut this package for one passage of the cutter. Package cutting is amenable to carbon steels with a carbon content of up to 0.4% and low.Alloy with carbon content to 0.25%. Package cutting modes are given in the table. 21. 21. Package cutting modes Cutting steel of large thickness (more than 300 mm) is performed by special cutters (see. § 54) at a reduced oxygen pressure, at the beginning of cutting the cutting is installed with a small inclination (2. 3 °), as shown in rice. 86. The speed of moving the cutter should be sufficient to warm the lower layers of the metal, otherwise the cutting process may stop. Too high speed can lead to “non.Cut”. After the cutter goes a fairly long way along the upper plane of the metal, the through cutting will begin. At the end of cutting, it is necessary to slightly tilt the cutter to the side, the reverse direction of its movement, in order to first cut the lower part of the workpiece. To increase the length of the heating flame, it is installed with some excess of acetylene. The cutting modes of steel thickness are given in the table. 22.

The better to cut the tiles: a tile.Cutter or a grinder

If you need to cut the tiles on straight lines, then it is better to use a special flat cutter. And the Ushm allows you to make curly cuts. Therefore, when working, both tools should be used.

The grinder helps to make cutting of ceramic tiles if it is necessary to lay it at home. However, this tool is not able to replace the plane cutter with a large amount of work.

Metal cutting technology by grinder

Corner grinding machine (Ushm), or a Bulgarian, as it is customary to call it, an indispensable and universal tool in construction, is designed for cutting and processing solid materials. But this is one of the most dangerous types of equipment, so cutting metal with a grinder and other types of material requires all safety rules.

For proper and clear work, it is necessary to purchase a tool suitable for power and diameter of the cutting abrasive circle and functionality. You need to decide for which work the tool is needed.

For home repairs, masters can cost a low.Power grinder, and for professional construction you will need serious multifunctional equipment.

Low.Power units are connected to a 220 V household outlet, powerful ones are connected to an industrial three.Phase network, with a capacity of 380 V. In low.Power Bulgarians, the disk often jams, when cutting thick metals, this is dangerous because the device can break out of the hands, injure, or break the disk.

Advice to beginners to buy a grinder for a 125 mm disk with a capacity of 0.8–1 thousand. W and the number of spindle revolutions 10 thousand. About./min. This power is enough to cut iron.

Used for cutting metal, stone, glass, as well as with this apparatus, they make a peel, grinding and cleaning. Having fixed it stationary, it is easy to drag incisors, jail knives, etc. D.

When choosing a grinder, you need to pay attention so that it is conveniently lying in the hand. The quality and safety of work also depends on this. If possible, you should choose a model with rubber handles.

How to cut tiles with a grinder without chips and dust?

As for the material from Porcelain tile, then he is rather fragile. Before cutting a porcelain tile, you need to get acquainted with the nuances. To get the perfect result, certain rules must be observed, much depends on the dexterity. During the operation of the Ushm, it is impossible to do without the appearance of chips and dust. In order for them to be as little as possible, experts recommend at the beginning and end of the cut reduce the intensity of rotation. Reducing speed will also reduce the likelihood of cracking tiles.

The ceramic plate is not completely cut, a deep groove is left in it and cut it off along the cut line with hands. If you begin to cut the planned line to the right, then it will be possible to avoid chips. Even if they still appear, they are removed grinding circle.

With inept operation, a grinder next to the final finish of the rooms on the front side of the tiles will definitely fall Owls of abrasive. Sparks leave dark traces. If they are incorrectly deleted, the appearance of the finishing material will suffer significantly. To clean the stains, take fine sandpaper, the cleaning is carried out carefully. It will be possible to get rid of the Okhalin faster chemical drugs.

Wet cutting

In this method, during cutting, the cutting edge of the material is in contact with the liquid. It is lowered into water or treated with a stream.

Wet cutting It is difficult to perform, however, this method has advantages:

Cut metal Multifunctional power tool (multi.Renovator multitul, multi.Cutter).

A new, extensive advertised tool on which various nozzles are put on, in the middle of them there are those that are used for cutting metal.

One of the advanced titles of the instrument is the multi.Renovator multitul. True, other manufacturers (in the middle of which Bosch, Devalt, Makita, etc.) this name is not consumed. By virtue of universality, to expect severe abilities for cutting metals of huge sizes from the renovator is not worth. The best use is for cutting sticking nails, self.Tapping screws and other cutting of small metal metals, especially in inaccessible places.

How to hold a grinder correctly

Many have a Bulgarian, but most people do not know how to use it correctly and how to keep it. This leads not only to marriage in work, but also to severe injuries. Bulgarian is a rather dangerous power tool.

The circle should be installed by the pattern up and clamped by a special nut.

A person with the leading right hand holds the grinder by the handle with his right hand. In this case, the circle should be located on the left side of the machine, and the protective casing should close it on top. The rotation is so that during cutting sparks fly to a worker. If a circle jams a circle and a grinder breaks out of the hands, then it will not go to the cutter, but in the opposite direction.

The left hand holds the car by the handle, which is wrapped in a threaded hole on the case. There are somewhat for special cases of use, but the right position of the handle is only the upper.

This position of the machine requires the use of protective equipment. To protect the eyes and open part of the face, these are protective glasses, and even better. A protective mask. To protect the open parts of the body from sparks and small fragments during cutting, it is necessary to put on a suit made of dense material.

Instructions and recommendations for cutting a grinder

Work with materials is characterized by one proposal: the direction of movement of the tool and rotation of the disk must match.

Safety precautions when working with disinfectants

How to fit an Angle Grinder blade, label up or label down?

Note! It is necessary to in contact with the cut surface at the maximum revolutions of the spindle. Otherwise it may occur.

- The cut line should pass by a working person, and not rest against him. If the disk is shining, the reactive movement of the tool will pass by the operator.

- Cut profiles start from a place with the smallest cross section.

- The protective casing ensures safety only if it is between a person and a circle.

- When cutting the walls, a cable, reinforcement or pipe may fall, which will lead to the opposite impact. Be away from the possible line of displacement.

Features of cutting thin.Walled pipes

Sawing thin.Walled metal rolling has its own characteristics. When cutting these products, there is a large risk of crushing edges at the rolls of cuts. To prevent this, experts recommend filling the pipes from the inside.

A wooden stick of suitable diameter or sand may come as a filler. For a thin.Walled profile, when cutting a grinder, thin cutting discs are selected. Work with such material is carried out much faster.

Features of cutting different materials

Bulgarian is used to process various materials. Starting from the type of product, select suitable nozzles.

Wood

Tree processing requires a number of rules from a specialist.

- The surface of the floor is covered with a film or material from which the dust is easy to assemble.

- Old coating is removed from the product.

- A protective casing is put on a grinder.

- The circle is kept at a slight angle to the processed surface. Back-setting movements, without pressure.

Ceramic tile

For ceramic tiles, a disk with diamond crumbs is used.

- The tile is laid on the table and fixed.

- The first to make an incision of 1.5 millimeters at low speed.

- At the end, the tiles are transferred to the edge of the table and broken along the line.

Metal

The Bulgarian is a suitable tool to cut reinforcement, rounds, pipes, corners and other metal products.

- The disk is chosen based on the type of product.

- Work is carried out with small breaks. It is not recommended to cut continuously for more than 5-7 minutes.

- The blanks are securely fixed.

- To cut the thick profile, use additional cooling of the disk. The cut is carried out straight.

- They do not have strong pressure on the grinder. Excessive effort leads to faults and clip of disk.

- Grinding heads are used to process the edges.

Glass

Glass is prone to the appearance of chips and cracks, so it should be cut with particular caution.

Stone (artificial or natural)

To work with granite, marble, concrete products, brick, a segmental disk with diamond spraying is used. For high.Quality cut of stone, an abrasive in size in the range from 50 to 1600 μm is better suited. According to FEPA from F220 to F16.

Two techniques are used to cut stone. Wet cut and dry. Everyone has its own advantages and disadvantages. With dry cut, the material begins to dust, with wet. Gives more dirt.

Other types of materials

When processing other types of materials, it is recommended to adhere to general safety principles. It is necessary to choose the right nozzle and install the processed part. Only after that they move to cutting or grinding.

Cutting a profiled sheet and metal tiles

Quite often, in practice, one has to face the need to cut a profile sheet or metal tile. These materials are made of steel, which is covered with zinc and polymer protective layers, stained.

Regarding the possibility of applying a grinder for their cutting, different opinions are expressed. The installation instructions say that the profile cannot be sawn with the help of an angle grinding machine. To do this, use other tools. But they need to be acquired, which is not always justified by the volume of upcoming work, and also requires additional financial investments. When there is no tool except Ushm, before cutting a grinder, you should know the possible Negative consequences.

- If you cut a metal tile or corporate grinding machine, then the protective coating in the sawing area and a little near it will be destroyed, and the cut edge will begin to rust.

- The material is removed from the warranty.

- Spreading sparks can ruin not only the appearance of the rest of the sheet (spread the paint), but also damage the polymer coating.

- The edge of the cut can turn out to be torn.

All considered negative consequences can be minimized if you cut the corrugated board or metal tile, observing the following recommendations:

- Do all the work immediately before installation;

- Treat sections with anti.Corrosion compounds;

- Cover the cut edges with a primer and stain;

- Use the disks for the metal of the minimum thickness (up to 1 mm);

- In order for the edges to remain neat, you need to cut quite quickly;

- Gently polish the torn edges.

Before sawing, as usual, they carry out Marking sheets.

If you need to cut a square, then do this:

- Draw it on the surface of the sheet;

- Cut the material along the marked contour by a grinder;

- At the end, every corner is carefully cut out.

Circles or other figures cut out, working in the same scheme.

The use of a grinder for cutting metal tiles and a profiled sheet facilitates the work. It becomes more convenient to perform it, because you can adjust the sheets in size directly on the roof.

Metal cutting with a grinder is a cheap, almost affordable and fairly effective way to cut it. In this case, the corresponding discs without defects should be used for each material. Not only the quality of the result obtained will depend on this, but also its own health. Be sure, cutting the metal, it is required to comply with the safety rules and use personal protective equipment. It should be constantly remembered that when working with an angular grinding machine, any shortcomings and inattention can turn into an injury. Therefore, you need to work with concentration and carefully.