How to cut off plywood with a jigsaw. Professional secrets

How to cut off the chipboard with a jigsaw

When sawing a laminated chipboard, a jigsaw has to face the following problems:

To solve these problems, there are the following methods.

So that the cut line turns out to be flat to use bimetallic saws. They saw better and, therefore, the likelihood that the file will lead to the side decreases. It is also recommended to use a file with dedicated teeth (T144DF), then the cut it turns out as smooth as possible. The same saw will provide a strictly perpendicular surface of the end of the end due to its thickness.

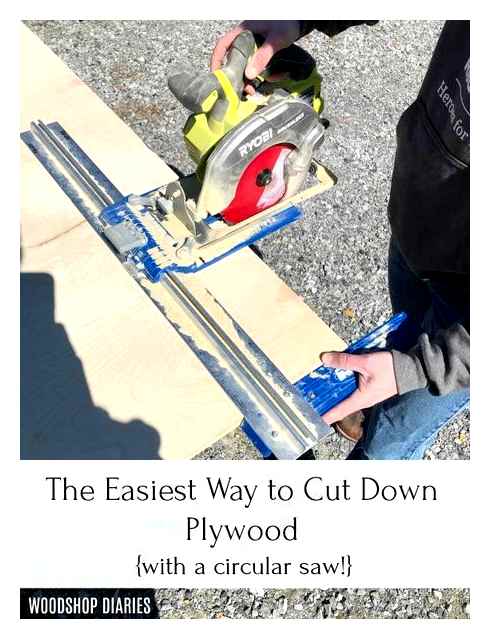

To get a perfectly even cut, you can use a clampin to be attached to the cut part a metal corner parallel to the line drank at a certain distance from it. For various models of jigsaws, this distance can be different, for example, for the jigsaw Makita 4329 It is 37 mm

The disadvantage of this file is too large the size of the teeth, as a result of which many chips are formed. In order to avoid this, you can use a special anti.Skid liner and/or glue on the chipboard along the line of cut a handwriter from the upper side (and preferably both). Thus, you can achieve almost the perfect quality of the saw. If you are professionally engaged in the manufacture of furniture, then this method is certainly not suitable (insufficient quality and small productivity), but for home manufacturing furniture it will fit quite.

You can also use a file T318BF. It is specifically designed to saw chipboard and provides clean cut, almost without chips. But unlike T144DF She is not so fat and her teeth are not so diluted as a result of which it is likely that it will take the file and drank uneven.

Home »Tools for working in the country.

Safety precautions during work

In general, an electrician in its structural features is safer than Ushm and disk saws. The real danger when working with a jigsaw is to get a hand or another part of the body to a working file. This is most likely under the workpiece, where the end of the file invisible on top comes out.

We recommend that you read more about the choice and design of the electrician in this article.

You can not cut small blanks, holding them with your hand near the file. The workpiece should be recorded by any means: clamps, visas, self.Tapping screws, clamps, etc.D.

- A bummer of a file with a rebound of a sharp piece aside in an unpredictable direction. It happens extremely rarely. Often, the saw just breaks into two parts, one of which remains in the workpiece, the second in the rod. If the part is bounced off, then with a slight force, since the speed of the canvas is low, from 500 to a maximum of 3200-3500 tactes up and down per min. This is much less than 12,000 rpm in the Ushm disk and up to 5000-6000 about \ min in a manual circular. At the same time, the peel of the jigsaw has only reciprocating movements, but not rotation. So, there is no centrifugal force, which is formed only during rotation and throws away the released particles to the side.

- Sawdust. Often the operator leans to the file to control the coincidence of the cutting line of the cut and the position of the canvas. At the same time, the air flow from the electric motor cooling fan or a random draft can bring sawdust into the eyes. To protect against this, on the corps of electrician, there are leaning transparent protective covers. Sometimes they interfere with the review and throw them back. Then you should work in protective glasses or at least not lean too close to the working area.

Wood sawdust caught in the eyes. And metal, sawdust from adhesive resins of sheet material, plastic, can damage the eyes. Therefore, it is not worth neglecting a protective casing or glasses.

In the photo operator with glasses, at a safe distance.

Salah Satu Trik Memotong Plywood agar lurus dengan Mesin Jigsaw

The rules of electrical safety for jigsaws are the same as for any electrical appliances.

- You can not use bare wires;

- The contact of the fork and sockets should be dense, without sparking and heating;

- When working, the outer outlet should not be underfoot;

- The possibility of wire falling under a working file should be excluded.

From the point of view of fire safety, an electrician is also safer than other cutting tools. Does not form a stream of sparks, as during the operation of a monkey (Ushm) and open flame, as when cutting gas/electric welding in cutting mode.

Preparation of the tool

First of all, the file suitable for the material is selected. You can not use strongly worn, bent files with broken and erased teeth. If they saw it, then slowly, with an overload of the engine, with great departure to the side.

We also recommend reading a useful article about the choice of files for an electrician.

The screws of fastening of the file should be tightened tightly, but not excessively so as not to disrupt the thread or the slots of the head.

Before the cut of business material, it is advisable to make a trial saw out on an unnecessary workpiece. Wherein:

- The behavior of an electrician is determined, the quality and speed of the cut, the presence of chips;

- Adjustment selects the optimal frequency of tactes of the canvas (electric motor revolutions).;

- On the wood, a pendulum course (rocking) with an assessment is turned on, as the jigsaw saws, better or worse. On metal, laminate, brittle plastics and solid materials, the pendulum course does not include.

After adjustment and trial cuts, they begin to cut business material, already knowing the possibilities of the jigsaw, speed and quality of sawing.

Preparation of the workplace

It is more convenient to saw with an electrician, placing a workpiece on the desktop. (Except when you have to saw on the floor). In any case, the workpiece is located so that the saw is guaranteed not to touch the floor, the edges of the desktop and other extraneous items.

The sawing line should be as close as possible to the support (table cover, workbench, paved on the floor of bars, etc.D.). If you drank too far from the support, the workpiece will jump, vibrate, which is incompatible with a normal even cut and can lead to a breakdown of the canvas.

It is also risky to dispose of the line from the edge of the support too closely, since the saw can hook support. Optimal-5-7 cm for thick unsuccessful materials, 2-3 cm for fiberboard, thin plywood, etc.D.

Before starting the saw, you need to look under the workpiece and make sure that there are no extraneous objects under the cutting line, and that the canvas will not hook the edge of the workbench.

The workpiece should be fixed by any means (clamp, clamps, screws, stops, etc.D.) You can not hold it with one hand, as it is unreliable and limits the operator in movements, distracts from the main operation. The saw.

In the photo. The workpiece is correctly fixed.

With a long cut, it is necessary to provide for how the wire will stretch. Is it enough for the end. Or in the middle you will have to turn off the jigsaw and throw, for example, an extension cord with a fork on a sheet of material.

What materials can be cut

With this tool, you can saw all the materials for which files are produced. Its purpose, as a rule, is indicated on the canvas in one English word.

The easiest way to cut the jigsaw is perfectly smooth | DIY carpentry

It is not enough just draw a line to cut directly with a jigsaw. Often, a knot can get caught, and the tool takes away from the markings. In this publication, I want to bring to your attention the simplest, but, nevertheless, the most effective method to perfectly cut a jigsaw.

And so, our task: to make a perfectly flat jigsaw. Someone can say that together with the tool, the line of emphasis is most often supplied, such as this:

But this method has two disadvantages, first of all, the emphasis is limited, and secondly, this emphasis implies that the side in which we abut it perfectly even. And if this is not, for example, the edge of the plywood, from which I have to cut off the piece far from even

Let’s make markings. I measured 100 mm on both sides, and then drew the line on which I will cut off.

Next, it is necessary to measure the distance from the edge of the lobe platform to the file. To do this, I use a caliper. I got 35 mm.

Most importantly, we need an emphasis. It can be a profile pipe, an even bar, a rule, and so on, the main thing is that it would be the right length and even.

We have this emphasis on the previously extinct distance (remember 35 mm from the beginning of the jigsaw platform and to the file). Distance the location of the stop must be measured from both edges.

We will fix the emphasis on both sides.

And now we just press the lobby platform to the stop and cut. If everything is done correctly, then cutting the jigsaw will be exactly along the line.

Well, the result, as you can see, the cut side turned out to be perfectly even.

I will be grateful if you visit my site Loftstyle.Site, I will be very glad to guests and criticism. If you were interested and useful for an article, then be sure, we just definitely like and subscribe. Do not forget about YouTube channel, Everything is interesting there too. Send all sentences, wishes and criticism to [email protected] or in a comment under publication or through a feedback on the site!

A little about safety precautions

Protect yourself from injury when working with a jigsaw The following rules will help:

- Carefully study the instrumentation instructions before starting it, check its serviceability and the presence of all components;

- Abandon the use of unsuitable saw paintings;

- Manual jigsaws cannot be kept beyond the frame, for this a special handle is provided;

- In the power tool, the integrity of the insulation is necessarily checked, its cutting part should be limited by special devices;

- When working, it is necessary to use protective means. Shields, glasses, respirator, gloves that will protect from fine dust, chips;

- At the workplace, they must provide good ventilation for the removal of dust and varnish varnishes;

- The thread is carried out slowly, holding the distance between the hand and the blade;

- All electric heaters should be located no closer than 5 m to the workplace;

- At the end of all work, the electrician is disconnected from the network.

Using adhesive tapes

By the same principle, you can protect the back of the trimmed material. On the cutting line, you should stick a tape that protects against tearing large fragments. Pashing surfaces is one of the few ways to ensure the purity of curly cutting with an electrician. Unfortunately, the painting tape is not suitable for this in view of its low strength.

The highest quality slice can be obtained when pasting the part of aluminum or reinforced fiberglass tape-fiber. It should be such a width to cover 15–20 mm on each side of the cut line. The density of the sticker is also important: the tape must be well crushed by a dry rag tampon and exclude the formation of folds by any means.

It is worth avoiding tapes with very tenacious glue. In the process of tearing, they can captivate small fibers and fragments of a laminated surface, dissected by microcracks, which are formed during cutting. Also, pay attention to how easily traces of glue are removed and whether adhesion of glue is enough for working with rough materials like unsolved plywood or OSP.

How to adjust the jigsaw to saw evenly

To flatterly saw off the board with a jigsaw, it is necessary to choose the right canvas for work and configure the power tool. The algorithm looks like this:

- For a specific material, choose a blade of the desired width, length and thickness. With regular use of the tool, it is better to have a whole set of various files at hand, otherwise it will not work to perform slices exactly.

- The canvas is installed on the jigsaw, after which the working move is tuned in the tool. If you saw it at high speed, include a pendulum mode. For pure cut, this function is better not to use.

- For work, prepare a strong and stable surface. To cut a jigsaw evenly, you need to take care of the absence of height drops on a workbench.

- The material is applied with a black marker or an ordinary pencil, which will subsequently easily erase.

- The workpiece is firmly fixed on the workbench and proceed to work.

Before the start of sawing, you need to check that the material is not backlash from side to side.

How to cut evenly with an electrician: features and rules

Electrician is a power saw, which is an indispensable thing in each house. Using this tool, you can saw metal structures, wooden objects, plastic and tiles. Unlike a standard saw using a jigsaw, you can cut The most intricate figures. Circles, triangles, stars, in general, almost everything that can be imagined. However, with such extensive possibilities, the problem often arises in the flat walk of the jigsaw so that the resulting lines correspond to the planned. How to cut evenly with an electrician? We will help you figure it out.

The process of sawing

In order to get to work, it is necessary to carry out preliminary measures and prepare:

- Gloves;

- Protective glasses;

- Machine oil;

- The material that we will process;

- Clamps guiding roulette;

- Construction pencil;

- The lobby itself.

The saw process is carried out as follows:

- Strengthening the source material. In our example, the source material will be a tree. The prepared sample of wood and guide, the role of which the ordinary flat rail can play, should fit between two clamps. The sample is put on some elevation so that the jigsaw could not rest in the process of the saw. After that, using a roulette, it is necessary to accurately measure the desired width of the product that should turn out and draw a cut line with a pencil. Then lay the guide to the desired distance from the line and fix it with a clamp. The lobby with the guide is also fixed with a file set by a file in the direction of the marked line. You need to fix it well, but do not overdo it. The same is done on the other side.

- Cut. Turn on the jigsaw and start the work. The correct use of the device does not imply a superpower press on it, which can provoke Rapid heating of the product and breakdown. It is also not worth using the same file for a long time, since it is blunting very quickly. If a very solid tree is selected as the starting material, then you can pre.Lubricate the surface with machine oil. It will be easier to slide with a file, the cut will become smoother, and the jigsaw will last longer.

Some features of the process

Initially, you need to choose Correct file For a jigsaw. A variety of files allows you to dwell on the option that will correspond to both the material of the original workpiece and the final necessary result.

In general, the jigsaw can be with the pendulum and with the usual move. In the second option, for an even saw, the canvas must be moved clearly vertically, cutting the material upwards up. Due to the high speed created, the canvas wears out more slowly.

When working with a pendulum course tool, the principle, in fact, is the same, only preferred material for processing. Soft wood or plastic, difficulties can occur with steel.

In order to make a straight cut, it is necessary to choose a wide canvas, it is better if the jigsaw has a “smooth start” function, which will avoid sharp movement at the initial stage. If it is necessary to cut a round hole, first you need to drill the original version, inside of which the necessary file is inserted. The cut itself is carried out by marking. If the source option cannot be cut out, then it is required Smeasant method of sawing. To do this, the jigsaw leans at an angle to contact with the material, this allows you to make a through hole, and then make the necessary marking.

CUTTING 1/2 PLYWOOD SHEET USING PROMAN JIGSAW

The cut is allowed along the edge of the workpiece, but you must definitely verify its original evenness, without this, the electrician saws crookedly. If the edge is uneven, then only the correct marking can fix it.

When working with wooden sheets of small thickness, there is a risk of chips. To prevent this, the sheet should be placed down the front side.

The names speak for themselves. In the first case, the panels are installed vertically, the beam installed on the guides plays the role of the bracket. The possibility of turning it to a right angle allows you to saw off the material in any plane. The horizontal version involves the presence of a table for sawing, the mechanism itself and the carriage that provides the movement of the file along.

The rules of the even saw

Thus, in order to correctly and evenly make the cut, it is necessary to adhere to the following rules:

When You Only Have a Jigsaw to Make a Straight Cut

- Carefully choose a file suitable for your source material.

- Prepare all the necessary auxiliary objects.

- Carefully fix the workpiece.

- Take into account the correct location of the workpiece so that you do not have to correct flaws. In some cases the canvas is located the front part down.

- Work out the device control technique using professionals or through a training video.

- Carefully observe safety precautions.

In fact, the processing of products with a jigsaw is not such a difficult task, which can be possible for any novice carpenter. Even if an even and neat sawnut is not possible immediately, you should not despair: you need to soberly evaluate what nuances you have not paid attention to. And do not ignore the advice of professionals who can speed up the process of mastering art, how to cut an electrician, and open some secrets. Try and improve!

How to make an ideal cut using an electrician

You can cut wood, laminate, metal, stone with a tool. Before sawing the jigsaw evenly, you need to choose the right file.

The choice of cutting canvas

Better to buy files of trusted manufacturers.

- Standard. The teeth have the same size in them. They are directed in one direction and are at the same distance.

- With a missed teeth. Working with such a file that shows less and warms up, goes quickly.

- With double teeth. The cut is high.Quality, but the speed of the cut is low.

- Reverse. Part of the teeth is directed upward. They can cut plywood, chipboard, chipboard without chips.

Fastening of the material

To understand how to cut a jigsaw evenly, you need to know some nuances. In a home carpentry workshop, they are highlighted for work table with a flat countertop and strong legs. The board on the surface is attached with a clamp, slightly fixed on both sides. The edge of the material that hangs, it is desirable to tighten, attaching the load. So when cut on the canvas, pressure will not be exerted.

Why can a jigsaw cut crookedly

Many are interested in how to sprinkle evenly with a jigsaw, because sometimes the cut is obtained crooked. This happens if:

Errors when working with a jigsaw

If the carpentry did not bring an acceptable result, it is worth considering how correctly the sawing procedure was carried out and whether all the conditions were met.

Among the main errors arising in the course of work with the jigsaw, it is worth highlighting:

- Lack of experience in working with the device. In this case, only practice can help.

- Insufficiently reliable fixation of the material. When trying to cut the workpiece, the sheet begins to move off, which causes a crooked section.

- Too fast.

- The use of homemade devices. If you cut the material with such a tool, it will be difficult for the master to achieve a good result.

- The use of a large weight unit. Against the background of a significant mass, the tool starts to the side during carpentry work.

Curved sections can occur in cases where the master uses a faulty tool.

Starting to sawing any material, it is important to familiarize yourself with information on how to configure an electrician for a flat saw. This will make it possible to make a workpiece with correct geometric outlines and an attractive appearance. So that thin sheets do not deform during work, you can use the substrate. Using life hacks in working with a jigsaw, you can learn to professionally handle the tool.

How to make a flat drink by an electrician

A jigsaw is a tool for sawing parts. With it, you can perform curved cuts of plywood sheets, wooden/metal objects and plastic. Using the tool, the master will be able to cut products in the form of a star, triangles, circles, etc. D. Below you can familiarize yourself with the methods of working with this power tool, understand how to make cuts without chips on different materials and find out how to cut a jigsaw evenly.

Method 1: Using painting tape

On the surface of the workpiece (plywood or chipboard), glue the strip of painting tape. After that, we make a cut with an electrician.

Such a simple way will allow you to reduce chips and lifts in the process of cutting many times. You can see the result at the photo below.

How to cut the chipboard or chipboard with a jigsaw

To clean the chipboard with a jigsaw, it is necessary to adhere to a clear algorithm. It looks as follows:

- The workpiece is tightly fixed on the desktop. During the cutting process, the sheet should not twitch and play, otherwise it will not be possible to perform the cut exactly.

- Marking is applied to the surface of the material. If the lines should be drawn on the front side, it is better to use not a marker, but a pencil, the traces of which can then be erased.

- The selected nozzle is inserted into an electrician, preference is given to completely new and high.Quality canvases from well.Known brands. If you cut the workpiece to be completely, the old and cheap equipment should be avoided.

- The speed in the tool is set maximum. The angle of inclination of the files does not change. The pendulum mechanism must be turned off. It simplifies a quick cut, but most often it does not allow DRP to cut evenly and with high accuracy.

- The jigsaw is installed clearly according to the applied markup and tightly pressed to the material, and then included in the work.

- Slowly and carefully lead the canvas along a pencil or marker line, if possible using backlight and laser pointer.

If the chipboard is cut without chips and defects, then even when using a reverse nozzle, it is better to place the material with the front side.

When cutting a chipboard by an electrolobian, it is recommended to use a special anti.Skid liner. It is a small part with a cut, which is installed in special guides on the sole of the tool. Ideal results allows you to achieve an insert, the hole in which exactly corresponds to the thickness of the canvas. The part can be supplied with a tool in the amount of several pieces, it is usually proposed to make an opening on its own.

The chips from the cut line must be removed in a timely manner, otherwise it will not work to cut the chipboard exactly

The components of the electrolobian

The correct use of this tool also depends on the knowledge of the owner in the field of the composition of the electric lobe. Since in 1944, Bosch released into the world its first copy of this multifunctional device, its component has undergone many changes, but its main design remained unchanged. So, the electrician has the following components:

WALL CUTOUTS for a 6FT CAMPERVAN BED! | Fiat Ducato | UK Self-Build Campervan Conversion

- The gearbox (its case should be made exclusively from metal, since the eraser case questions the strength of the tool, since it worsens the heat transfer);

- The sole (the best version of the sole material is cast metal, because some electrolobsics have a plastic plastic plastic, which completely affects the quality of work);

- The engine housing (an electrician is considered good if this part is made of the highest quality, strong material, because it is here that the engine is located);

- Lever.

How to saw off the workpiece at an angle of 45 degrees

Typically, various guide tires are used for these purposes. But you can not complicate anything and use the ruler.

We apply it to the workpiece, fix it with clamps, and then we saw off the workpiece without unnecessary body movements. It turns out exactly, neatly and exactly under 45 degrees.

If you need to cut off the edge of the workpiece at the angle, then this is also easy to do.

Unscrew the screw under the support sole and tilt the sole to the desired degree. Then, in the same way, we saw off the workpiece in the ruler.

Artistic sawing a jigsaw: drawing, stencil and work

Let’s get acquainted with the devices

Lobzik. Tools that are designed for work on different contours. The blade is equipped with a teeth, small enough to make a cut of working material, practically without forming burrs and chips.

Manual

The “founder” of the genus, of course, is a manual jigsaw. Everything is ingenious-simple: a metal U-shaped arc, and a working blade, which is fixed by clamps, is stretched between the endings. They hold the files during operation, with them they also regulate its tension. The handle for convenient work is on one side of the frame. The clamps of the instrument can turn, thereby creating a different plane for the work, providing opportunities for carving along the faner with a lobby of increased complexity.

- With creativity, using a manual device, it is necessary to observe maximum accuracy: the design is quite fragile, and with intense pressure, the blade is sometimes torn and it must be replaced. Each novice master should stock up on additional working files.

- When working with a jigsaw, it is convenient to use auxiliary plank: it protects the table and solves problems in the convenient location of the workpiece from the plywood.

Electrics

This device works with electricity. Represents the case where the mechanism is placed, the control handle is also located there. The sawing element is located in the lower part of the device. The blade is protected, and this allows you to cut the contour very smoothly, without deviations. Professional equipment models have many nozzles that greatly facilitate the process of work, for example, aligning the edge of the material. Electric blades can also have teeth that differ in shape and size. They should be selected in accordance with the material for the file so that there are no damage to the plywood sheets during operation.

- Household jigsaws are electric for non.Production purposes, usually of small power (from 350 to 500 watts). For beginners, this is the most common of the options when you only learn to cut crafts and figures from plywood (usually small thickness). It is quite safe to work such a device, especially when it is equipped with protection.

- Professional electrician is intended for industrial purposes, has a capacity of more than 700 watts, high speed and accuracy of cutting. He can cut sheets with a thickness of more than 10 cm, aluminum, thin steel.

Milling mill

Sometimes this device is used for thread. It is a type of manual special tool, with the assistance of which in domestic conditions, you can perform different types of work on wood and faner. However, to work with it requires a certain skill; But the masters deftly managed with these equipment can create real highly artistic masterpieces of folk art.

Cooking a stencil

Drawings for creative work are of different sizes, depending on the scale of the manufactured products. For example, for the schemes of a shelf or a fragment of furniture, for a voluminous toy, you should take a sheet of the A1 dubman format, the wallpaper roll remaining after repairing, and for small figures (such as souvenirs) we take office paper (A4 or A3 format).

We apply the contours of the future object to the surface of the paper with a marker or pencil, adhering to the specified size. The templates are presented in the public domain in a wide spectrum, select the appropriate one (for beginners, as a rule, not too complicated). And you can come up with your own options for cutting a jigsaw and then transfer to a paper base.

Then we carry out the transfer of images to the surface of the working material (plywood, boards). To do this, cut out a figure of paper, apply to the faner and carefully circle the contour with a pencil. The lines must be accurate and even. If necessary, we correct it, erased with an eraser.

The contours are applied “with the rear” of the material, so that in the finished form there is no noticeable drawing of the drawing. The internal areas can also be shaved so as not to cut an extra piece, thereby indicating the inviolable fragment.