How to cut plywood at home

How and what to cut thick foam rubber at home?

Polyurethane foam is a modern synthetic material. At home, it is quite easy to cut the foam rubber: you just need to outline the line along which the cutting of the canvas will take place, hold it with a knife with a sharp blade and cut the canvas to the end, slightly holding the edges with the other hand.

How to cut the foam rubber if the thickness of the web is 10 mm or more? If you adhere to the rules for cutting foam rubber, then you can achieve an even edge of the material even at home.

How to cut foam rubber correctly?

It is enough to use a sharp knife, you can take a knife with notches, which is used to cut a loaf. Thanks to its shape and length, the edges of the material are smooth. If there is no such knife, then any other well-sharpened knife will do. If you have a construction knife with a retractable blade, then this is also suitable for cutting foam rubber.

The secret of an even edge of the material is to tilt the knife towards yourself during cutting, if you need to make an even line. When curly cutting of foam rubber is required, the angle of inclination should be increased. This will avoid bevels at the edges.

Foam cutting stages

To cut the PPU web, no expensive tools or special conditions are required. To cut the canvas at home, you need to stock up on a sheet of cardboard and plywood, a ruler or curly patterns (if the line is uneven), a marker or construction tape, as well as a sharp knife. The whole process consists of simple steps:

- You need to choose a flat surface where you will cut the foam rubber.

- Place plywood and cardboard on the surface of the floor or table so as not to damage it with a knife when cutting the material.

- Using a ruler with a marker or construction tape, mark the line of the intended cut. Scotch tape is suitable for an even mowing line, and a marker for curly line.

- The ruler can hold the material while cutting the sheet into pieces. Do not put too much pressure on the ruler, as this can lead to deformation of the canvas, and the edge at the cut will turn out to be uneven.

- Two wooden planks can be used when cutting along a straight mowing line. Leave a gap for the cut between the planks. This will fix the sheet.

- Cut the blade with a strong and smooth movement of the knife. If the first time you cannot cut through the thick material, then you must repeat the procedure by inserting the knife exactly into the line of the cut already made. You can first cut to half the thickness, and then continue cutting to the end.

- Curly cutting of thick material with a knife is more difficult, so you need to hold the knife at a large angle towards yourself, and guide the knife more carefully.

How to cut plywood without chipping with a jigsaw?

There are several factors to consider when working with such a layered material. Including this:

- selection of tools with fine teeth and the minimum amount of their setting;

- feeding the cutting blade at low speed and at right angles to the plane of the processed sheet;

- sawing across the veneer grain.

The problem of how to cut plywood without chipping with a jigsaw has been partially solved by the tool manufacturer Bosch. They have a line of special “clean” canvases CleanWood.

- small size of teeth;

- lack of their pronounced focus;

- their minimal wiring.

If it is problematic to purchase CleanWood, then you need to use a blade for cutting metal.

When cutting material with an electric jigsaw, it is not recommended to work by weight, but only on a special workbench table. Otherwise, skew is inevitable and the cutting blade may break.

How to cut plywood without chipping with a hacksaw?

For this, the material must be securely attached to the workbench. It is also recommended to process the place of the future cut along the entire length:

- with PVA glue, using a brush 1–2 cm wide (sawing can be started after it is completely dry);

- with a sharp knife, making two parallel grooves.

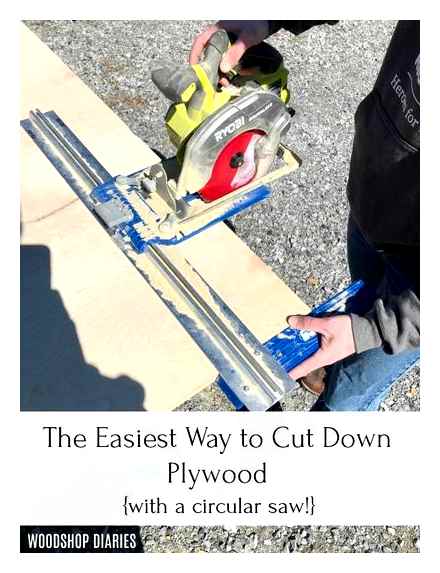

Cutting Large Sheets With A Circular Saw

To speed up the process, PVA can be replaced with a sticker of electrical tape or masking tape.

When choosing the option “two grooves”, they are applied with a sharp knife, under a metal ruler, in three steps. The cut is made between parallel lines to prevent chipping. The load of the hacksaw blade must fall on the plane of the plywood sheet.

How to cut plywood without chips?

Plywood is several layers of wood veneer bonded to one another with an adhesive. If you do not follow the technology of cutting such material, then the teeth of the cutting blade will tear off pieces of the upper layer. Flaws, called chips, are obtained.

You can cut plywood with any of the following tools:

- manual or electric jigsaw;

- circular saw;

- hacksaw.

Each of these tools is recommended for use under certain conditions.

How to cut plywood without chipping with a circular saw?

It is recommended to cut on a flat floor. A sheet of plywood is laid on wooden blocks of equal thickness, placed perpendicular to the cutting line of the cut. Full support from below ensures that no corner of the sheet breaks off at the end of the cut. A metal or wooden guide is installed on top, which is fixedly fixed with clamps.

In order to cut the laminated plywood accurately and without chips, you need:

- Setting the minimum cutting depth. On the opposite side of the sheet, the teeth should protrude 2-3 mm. With this setting of the cutting depth, the blade does not cut, but neatly cuts the wood.

- Choosing the right circular saw. For a gentle cut, select a blade with a minimum size and a large number of teeth (for example, 40).

- Low feed speed of the cutting blade when moving without stopping. In this case, the teeth do not chop, but gently cut the wood without chipping. In order to properly cut the film faced plywood, it is also recommended to set the blade speed to maximum. Disadvantage of the method: the carpenter runs the risk of overheating the canvas.

- Placement of adhesive tape in place of the cut. For this, it is recommended to use masking tape that does not leave marks on the surface of the sheet. At the end of the work, the tape is removed at an angle of 90 ° by moving towards the cut.

If laminated plywood is to be processed, it is recommended to also tape the sole of the circular saw with tape. This avoids scratches on the face of the sheet.

Both an electric jigsaw and a circular saw are suitable for cutting such material. The first option is indispensable in the case of a curly cut path.

To cut thick plywood without chipping with an electric jigsaw, it is recommended to use any of two types of blades:

- clean series CleanWood (Bosch);

- for metal.

A conventional circular saw is also suitable for smooth cutting of plywood. It is enough to install a blade with a fine tooth (for example, 40), adjust the cutting depth within 12-13 mm and lay the sheet on even wooden blocks. Cutting is recommended to be done along the guide, with a low feed rate of the tool and without interruptions.

If the front surface of the sheet is laminated, then the place of the cut is pre-pasted with masking tape.

Anyone who doubts which saw is better to cut plywood, we recommend contacting a specialized company with laser cutting and professional equipment for cutting.

How to cut and process plywood

Quite often the question arises as to what is the best way to process plywood. This can be done using conventional hand or electric woodworking tools. At the same time, we note that it is recommended to use only hard alloy tools in the work. In our century, modern methods can be used for such an operation: cutting with laser beams, hydraulic systems.

Sawing. When sawing, we use a band or circular saw. But such an operation must be performed correctly. First, sawing occurs across the direction of the fibers from the front side, then along. This will help avoid splitting. On the front side of the material, the operation is done with a hand or band saw, on the back side. disk.

Drilling. Excellent holes are obtained with a fairly sharp drill fitted with a front cutter. The operation starts from the front edge. In this case, a backing sheet is used on the back of plywood.

Application of nails. Plywood on walls, ceilings and floors is fastened with threaded nails or special screws, with a hidden head. Perhaps using typical wire nails. We can also use acid-resistant nails for excellent rust protection on the outside of the panel. The length of the nails is defined as 3 panel thicknesses.

The fasteners should be located at a distance of 15-20 cm along the edge, and 25-30 cm in the center. For the floor, the distances can be made wider by 15-20 cm.The structure of the plywood allows you to place fasteners close to the edge, at a distance close to 15 mm.

When mounting plywood, you can use popular fasteners such as glue, nails, staples, screws, rivets and bolts. When choosing a fastener technology, one should be guided by the operating conditions, the required strength and appearance. Installation of panels with a gap of 2 mm is considered correct.

The use of an elastic filler will not be superfluous. When using building heating, ensure adequate ventilation of the structure to be reinforced.

There are many types of plywood board joints: tongue-and-groove, tongue-and-groove and others. Plywood ends can be protected with vertical and horizontal aluminum profiles, which can also be used for outdoor use.

Bonding of uncoated plywood is performed with any glue for wood: PVA, as well as phenol, epoxy resin, and polyurethane, etc. PVA is used for interior work. Phenol and epoxy adhesives. for outdoor use. Epoxy glue is used to attach plywood to metals.

You should not try to glue the laminated plywood surfaces. This connection will be short-lived. Only in the case of stripping to the wood layer, you can carry out a similar operation using epoxy.

Grinding is required to be done with abrasive paper perpendicular to the wood texture, then to obtain a high-quality paintwork, fine-grained paper should be fine-grained along the direction of the wood texture. The sanded surface of the material is the basis for further finishing.

Plywood boards can be cached, laminated, and covered with coloring or impregnating solutions, etc. When choosing a paint or soil mixture, you should remember about the possible appearance of cracks on the facing side. The surface can be laminated or veneered with valuable wood species. Probably stretching the film, wallpapering.

Before proceeding with any finishing of plywood, it should be cured in normal conditions and dried. This procedure must be repeated before each stage of finishing.

The primer is made with elastic compounds of the correct combination, taking into account the reaction to the humidity of the environment.

Painting should be done after priming. There is a wide range of paints and varnishes on the market. So the texture of the wood can be emphasized with transparent compositions, or you can completely hide them. Painting is done with a brush or spray.

Colored plywood is used for finishing both outside the building and inside. But before applying the last coloring layer, the surface should be treated with an antifungal composition, because transparent paints contain a minimum of binders and, as a result, are biologically less resistant.

Plywood thickness. 20 mm Compression mill. 4 mm working mode. 3000mm / mm Frequency.

Work process

Cutting should be started with a soft start, if there is such a function. It is essential to ensure work at low speeds, increasing the torque as needed along the way. Almost everything in a strategy for configuring cut characteristics depends on the hardness of the workpiece itself and its dimensions. How to cut wood with an angle grinder if you need a bevel cut? Sometimes, a crooked cut is not allowed at all. The workpiece is cut only at a right angle, and any inclinations are excluded, since you literally like the skew is not safe. Complex operations of curly wholly unusual cutting are performed as part of post-processing with a different inventory. After work, wait for the disc to stop, turn off the device and unplug the plug. Then the tool is disassembled and cleaned of wood chips with dust.

Not a jigsaw, not a saw

How to cut plywood if there is no power tool at hand that can cope with the task at hand? The answer is simple: you can try to handle it with a regular hand with a saw. In this case, the saw must have good sharpening and small teeth. As for the cutting, it must be carried out at an acute angle to the plane of the plywood. You should not make sudden movements and jerks. Plywood carving is a very responsible business, especially at the end, because a sudden movement can make a large chip and the entire part will be rejected. Since the saw leaves a rough mark, the end faces of the parts must be sanded with sandpaper.

There is also laser cutting of plywood. This technique is a modern way of cutting this wood material. The use of laser cutting allows you to create more complex shapes, including unusual design solutions. Such cutting of plywood is performed only by specialized companies. By the way, it is inexpensive, no matter how many parts are required. Their cost will be almost the same.

Deficiencies in wood processing with an angle grinder

The main argument against using an angle grinder when working with wood is safety. There are certain ergonomic aspects associated with awkward cutting direction, but professionals from such a cutting strategy are often stopped specifically by the risk of injury. Why is it unsafe to cut wood with an angle grinder?

Is it possible to cut plywood with an angle grinder

How can you cut wood with an angle grinder? Pro Secrets How To Do It Right

Wood species is one of the oldest natural materials used in construction, production and household use. Until now, it remains in demand due to its environmental friendliness and affordability. And another significant plus of the tree species is due to mechanical compliance, which is fundamentally according to the theory of processing. For lumber, there is a wide range of cutting tools from a simple hacksaw to a jigsaw. But is it possible to cut wood with an angle grinder? It is a versatile tool for processing solid materials, but due to its combination of wide functionality, ergonomics and productivity, some craftsmen use it when working with soft-bodied workpieces like wood. How does this use of an angle grinder pay off??

Benefits of using curved plywood

Bending the plywood allows you to give it a smooth shape. Therefore, it can be used to decorate arches, furniture and create products with curved shapes. In this case, the products are obtained not only visually beautiful, but also resistant to mechanical damage. The use of bent plywood allows:

- reduce the number of fasteners used;

- minimize the number of corners, which reduces the risk of injury;

- gives the interior a sophisticated, stylish and modern look.

Plywood sheets are the optimal material for furniture and renovation work. Their use in a curved form opens up great design possibilities.

Gluing

A great way to bend plywood. It consists in completely cutting it, and then gluing it. In this case, it is also necessary to leave the workpiece for a day to dry it completely. The advantage of this method is the ability to create clear geometric shapes. However, you cannot get perfect smoothness by gluing.

For this method, it is recommended to use synthetic or protein glue. At the same time, various types of adhesives can be used to glue sheets that will not be used for cladding. During gluing, the material must be strengthened with a channel.

Steaming

The steaming method is popular for changing the shape of plywood not only at home, but also in large industries. In this case, the plywood sheet is softened with steam, after which it is given the required shape. On a production scale, this method can be used for sheets of various thicknesses and sizes. Only small sheets can be bent with steam alone.

Technologically, the steaming process is the supply of steam directly to the sheet. In production, this process is carried out using a special steam installation. At home, you just need to keep the sheet over a container of boiling water for a while. In case of high material density or low steaming efficiency, you can immerse the material in hot water.

Notching

If the plywood has a high density or large size, the home steaming method will be difficult to use. In this case, you can use the scoring method. In those places where it is necessary to bend the sheet, cuts of a certain depth should be made. This indicator depends on the thickness of the sheet, and should be no more than half of this value. If the cuts are too deep, the workpiece may simply break.

The notch width is determined depending on the angle that should be obtained when bending the material. After making the necessary cuts, the sheet should be placed on a pre-made template, and a veneer sheet should be glued onto it. After that, it is recommended to leave the workpiece for at least a day so that it dries completely.

Features of folding large sheets

To bend a large sheet, using the steaming method is quite difficult and ineffective at home. Therefore, it is recommended to make cone-shaped construction cuts. For this work, you can use a milling machine. In this case, the details are recommended to be made to the opposite layer in order to reduce the likelihood of material fracture at the bend point. When bending plywood with a thickness of 4 mm, it is necessary to make cuts of 2 mm.

It is recommended that you make as many cuts as possible to make the bend as smooth as possible. After making the cuts, the sheet must be attached to the template, and then a layer of veneer must be glued to it. Leave for at least a day so that the glue is completely dry.

Basic methods of bending plywood at home

Plywood is one of the most popular and easy-to-use materials. It is used not only in construction and renovation, but also in jobs such as furniture manufacturing. The popularity of the material is due to its flexibility, durability and lightness. For wall or ceiling cladding, flat sheets of a straight spatial shape are used. But when making furniture or to create crafts of various shapes, the sheets will need to be bent. There are various ways to bend plywood using heat, moisture, notching and other methods.

How to break down plywood. A guide to cutting, moving and hauling plywood by yourself.

Material features

Plywood is a multi-layer board type material. For its manufacture, veneer sheets are used, which are laid crosswise and coated with an adhesive based on resins. The strength and durability of the material is ensured by the crosswise arrangement of the veneer. This guarantees additional resistance to mechanical damage.

However, when it becomes necessary to bend the material, its strength becomes a disadvantage. But there are effective ways to bend plywood at home without damaging the material.

Laser cutting

How to cut plywood with a laser and what parameters of the material should be cut with this tool. Plywood can be cut in this way to a thickness of 8-10 mm. This process can vary depending on the type of wood, the type of glue and the processing option. It is better to cut the de-resinated coniferous plywood sheets. Birch plywood is not recommended for cutting, and material with formaldehyde resin is even harder to cut. The upper part of the cut is always dark. The mode and level of cutting quality for all types of plywood are determined by experiment.

The laser cutting process will allow you to make parts without mechanical influence on the sheets. This prevents chips and lint from appearing at the edges. The laser beam has such a small diameter that it will allow you to cut elements with parameters of several millimeters and complex geometric shapes.

The maximum material thickness that a laser can cut depends on the power level of the laser emitters and is usually limited to 15-20 mm.

Important! The cut upon completion of work with the laser is able to change color due to the burning of the material. However, this can be both a positive and a negative result of the work, depending on the desired result and the intended purpose of the parts obtained.

The principle of work requires a level of training. After all, wood is a fairly flammable material, so it must be constantly cooled. To do this, the tool blows up along the cutting part, which is manually adjusted. In this way, you can achieve maximum processing cleanliness without the formation of deposits. At the same time, processing of elements of a technical nature is being performed, which can last longer.

Laser is the best option for those interested in how to cut plywood figuratively.

Hand tool

Who does not know how to cut plywood at home, you should look at the information below. The main tools for cutting plywood are distinguished:

Plywood is considered a fairly dense material, so you have to apply physical force while cutting it with a hacksaw by hand. The device is usually used to divide sheets into equal fragments. The teeth should be small to avoid damage to the structure of the material.

- Elements of different shapes are also created from plywood sheet with band or circular saws. Due to the high speed of rotation of the cutting wheels, it is difficult to get a neatly perfect cut. Therefore, in the work it is advised to use cutting wheels, which are equipped with small teeth, intended for work processes exclusively with wood.

- Any plywood can be easily cut with a jigsaw with a fine saw. To do this, you just need to press the tool against the tile and guide it carefully, without jerking. Upon completion of the cutting process, the edges of the sheets are advised to be processed with sandpaper.

The better to cut plywood and in what quantity. A hand-held jigsaw is considered the ideal tool if you need to make a small number of complex parts. With a certain skill, it can allow you to get neat cuts. The manual method of cutting cannot be called productive, especially since it is very tiring.

- When creating rectilinear forms of cuts, a circular saw with fine-toothed cutting wheels is used. Cutting wheels for chipboard can quickly cope with the task of cutting plywood sheets. In this case, the saw is guided with a small pressure and at a slow speed.

- If you do not have jigsaws and power tools among the available tools, you should try to saw the material with a regular saw manually. The tool should be fine-toothed and well-sharpened. In the process of cutting, the blade is led at an acute angle to the surface of the plywood sheet. Movements should be performed even with great pressure, and without jerking. Careful work should be done especially at the end of cutting, because the slightest wrong movement can lead to the formation of a large chip, thus rejecting an already finished element.

Attention! The saw makes a rough cut, therefore, after this process, the ends of the sheets must be processed with sandpaper.

Saw cutting tips

How to cut plywood without chips will become clear after reading the basic recommendations for the workflow:

- The plywood sheets are cut on the floor with absolute support;

- It is necessary to adjust the cutting depth, which can affect the level of cut quality;

- In the longitudinal direction of the cut, a long straight object is used as a guiding tool;

- Before making a cut, you should check the guide;

- Recommended cutting at high speed, which should not be changed;

- When cutting with a circular saw, the discs must be selected with the largest number of teeth;

- The cross-cut is advised to be done with duct tape.

How to cut plywood. recommendations and instructions

How to cut plywood, despite the fact that its sheets have a minimum size of 12.2×12.2 cm. After all, during construction and repair work, fragments of smaller parameters and various shapes, sometimes even curved, are needed. Cutting this material cannot be avoided, as it has become a necessity in most cases.

Milling

How to cut 10mm thick plywood with a hand router, the following recommendations will suggest:

- The cutter is fastened to the collet.

- The number of engine revolutions suitable for this work process is set.

- The required milling depth is adjusted using the immersion limiter when working with plunge cutters or fixing a specific value of the overhang of the cutter relative to the base. when working with edge cutters).

- Installs a pilot bearing or beveler ring or other equipment to help maintain the desired cutter path.

The following basic safety measures are noted when using a router when cutting plywood sheets:

- The cutter must be fastened and adjusted with the power cord unplugged.

- Operating a hand router requires care and concentration. During milling, you need to clearly stand on your feet and firmly hold the router with your hands. It is not allowed to work in a state of fatigue or absent-mindedness to avoid injury.

- The processing element must be firmly fixed, otherwise it may break loose with the cutter and rush with great force and speed.

- It is necessary to beware of possible impacts when the tool touches the material. To avoid impact, you need to firmly hold the router, firmly pressing it to the base and move it with smooth movements. Clothing should be selected for work without loose parts that might catch on the tool.

- It is better to avoid inhaling the fine dust that occurs during the milling process. It is sucked off with a vacuum cleaner. You can use a respirator.

Thus, it became clear what can be used to cut plywood and basic recommendations with the principles of work when cutting.

Adhesive tapes

To protect the back side of the plywood, tape is glued along the mowing line of the cut. This method helps to prevent large pieces from breaking off, which is especially effective if the decision is made to use a hand or electric jigsaw. However, not all adhesive tape is suitable for this purpose. For example, masking tape in this case will be completely useless due to the small margin of safety.

Before you start sawing, tape-tape with fiberglass or aluminum reinforcement is glued to the surface. The requirements for its width are as follows: on both sides of the mowing line, there should be a margin of 1.5-2.0 cm.It is better to paste by pressing the tape with a dry cloth, avoiding the formation of wrinkles and gluing.

After the saw blade or electric jigsaw has stopped working, remove the tool after disconnecting it from the mains. Then proceed to peel off the tape. In this case, great care should be taken so that with sudden movements not to cause the separation of small fragments of the laminated surface, which inevitably form during cutting. Therefore, it is necessary to abandon the use of materials with a strong adhesive base. When choosing such a tape, one should take into account its adhesive ability and ease of cleaning from a rough surface.

Features of cutting tools

Each plywood cutting tool has its own characteristics when used. Consider the rules for working with plywood with various cutting tools.

Electric jigsaw

Sawing any plywood is best done with an electric jigsaw. When working with this tool, you should use small files, cut the blade, pressing the jigsaw and avoiding jerky movements. At the end of the process, the ends of the material are processed using sandpaper.

You should not buy low-quality tools, because after a 5-meter cut, there is a strong bluntness of the cutting edge, which causes chips. The lack of setting and the opposite sharpening of the adjacent teeth and the small width allow you to make a complex figured cut. But these qualities of fine cut files cause the blades to be brittle.

Finish cutting of plywood can be done using blades for working with metal parts. The size of the teeth of such saws is minimal, which greatly slows down the cutting speed, but allows you to achieve the highest quality. Since the width of the metal files is large, it is possible to carry out a figured cut only with a large bending radius (0.6-0.8 m).

Electric jigsaw cutting

To obtain an even cut, the sequence of actions should be as follows:

- Securely fix the material.

- If possible, cut perpendicular to the grain of the wood, otherwise it will be very difficult to get an even edge.

- In no case should you put pressure on the tool, the cutting speed will not increase from this, but the tool is guaranteed to break.

- The surface of the teeth should be lubricated with oil to facilitate work (when working with heavy wood).

- It is undesirable to use the tool for a long time due to its heating and damage to the engine.

- After use, you need to clean the jigsaw and lubricate it.

Sawing purposes and suitable tools

Depending on the purpose of sawing, we select what can be used to cut plywood most efficiently. Among the tools used for work are the following:

- electric circular saw;

- hand saw;

- electric jigsaw.

Consider the features of using various tools for cutting plywood and in which cases it is more expedient to use this or that device.

Circular Saw

Plywood sheets can be cut into various shapes using a circular or circular saw, but the main purpose of these tools is to create rectangular cuts. It is very difficult to get a neat cut when cutting material because the rotational speed of the discs is very high. In this regard, preference should be given to those cutting wheels that have small teeth and are used for working with wood. When processing plywood, it is good to use cut-off wheels designed for sawing Chipboard.

Advice: when cutting the plywood sheet, make sure that the pressure on the sheet is low, and the rotational speed of the disc is low.

When making furniture or repairing it, you often have to choose how to cut laminated plywood. To get a clean cut, it is necessary to select discs or blades with frequent and fine teeth. The angle of their sharpening, as well as the shape, is of great importance. It is advisable to select discs with a positive sharpening angle and a different shape of the teeth (there is an alternation of trapezoidal and straight teeth). If the disc has negative sharpening angles, then it is necessary to reduce the speed, otherwise the wood will burn.

Important: the larger the diameter of the disc, the wider the cut will be and, accordingly, the number of chips will increase. It is completely impossible to avoid the formation of chips, but it is really possible to reduce their number and size to such an extent that subsequent processing could completely eliminate all roughness.

A relationship has been established between the size of the chip and the saw teeth: small ones leave less damage than large ones. The set of teeth has an impact on the cleanliness of the cut plywood. Best results are obtained with minimal wiring. You can check this parameter using a regular ruler. Sawing a thick sheet with a disc with a minimum set of teeth should not be done, since increased friction will cause it to burn and pinch the disc.

Hand saw

When cutting plywood with a hand saw, physical effort has to be made due to the high density of the material. This tool is used when it is necessary to cut a sheet of plywood into equal pieces.

A manual jigsaw is considered the best tool and allows you to decide in advance how to cut plywood without chips, saving yourself the need to purchase electrical tools. With its help, you can make a small number of elements of complex shapes. Having certain skills in working with a jigsaw, you can make a neat cut, however, due to high labor costs and low productivity, this method cannot be called optimal.

If you don’t have power tools or a simple jigsaw at hand, then you should resort to using a simple hand saw. To cut the sheet conveniently and avoid chipping, the tool blade must have a large number of small and well-sharpened teeth. The angle of inclination of the saw to the plywood sheet must be sharp. It is recommended to avoid jerking and make steady movements with strong pressure.

Tip: The cut of a conventional saw is rough, therefore it is recommended to process the end parts with emery after the end of sawing.

Advice

To cut the plywood sheet correctly, you must use a suitable tool and follow some rules:

- before cutting, it is required to take all measurements and check yourself in order to avoid annoying mistakes;

- during operation, it is necessary to monitor the power cord;

- before using the tool, you need to adjust the cutting depth to an unnecessary value;

- the saw blade must be suitable for cutting plywood;

- the use of the saw should be accompanied by the use of protective gloves and goggles;

- dull saw blades are more dangerous than sharpened ones;

- when cutting plywood, it is necessary to observe safety not to bring your hands to the blade;

- do not start work without power tool skills.