How to cut porcelain stoneware at home

Tile cutter tongs

Tile cutting tongs are the cheapest (200-400 rubles), and they are only suitable for small volumes of work with thin ceramic tiles at home.

After notching, press down on the tile with a cracking pliers

- Make markings taking into account all gaps and seams (-5 mm).

- Attach a metal ruler to the mowing line and run the cutter along the line once. The pressure should be moderate to form a visible streak. Lead him from the far end to you.

- Place the tongs with their feet along the mowing line of the crowbar near the edge. The sponges should be on top of the glaze and the straight part on the bottom. the line of the break should run right in the middle between the edges of the upper lip.

- Press gently on the handles to break off the tiles. At the same time, do not raise it high, otherwise after falling it will break.

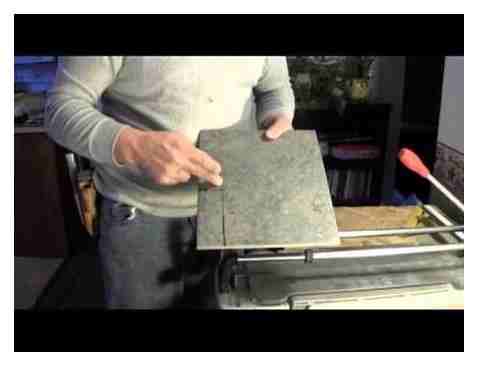

Cutting tiles with a manual tile cutter

How a manual tile cutter works

- The tile is inserted into the tile cutter, and the markings on it are aligned with a special label.

- The handle is lowered and held away from you. It must be driven at the same speed and even pressure so that the roller cuts the glaze to the same depth. It will be enough to run the roller once. If you drive several times, the breakage may turn out to be of poor quality.

- Next to the roller there are special paws that lower and break the tiles into 2 parts, after a sharp push on the lever. At the same time, all tile cutters have a metal tubercle on their platform, and soft pads along the edges. When you press on the edges of the tile with your paws, maximum stress will be created at the notch, if correctly aligned with the backing, and it will evenly break off.

It is difficult to explain this in words, so it is easier to watch a video that shows how to cut tiles correctly with a tile cutter:

High-quality tile cutters allow you to cut even tiles with a thickness of 10 mm without problems. It doesn’t matter at what angle you cut it: at least 45 degrees, at least 30.

Electric tile cutter

If you have a large amount of work, then the fastest and highest quality cut comes from an electric tile cutter. They use a diamond wheel and supply water to the cutting site to cool and remove dust. The cheapest types of amateur class can be found on sale for 3-4 thousand rubles.

How to cut tiles without a tile cutter

If you only need to cut a few tiles, it doesn’t have to be spent on a tile cutter. You can use the tools at hand:

- Glass cutter.

- Drill. It should preferably be with a victorious tip, as it will scratch the tile better.

- Nail.

- Construction knife.

Attach a metal ruler to the notch and draw once with a glass cutter or drill. A deep scratch should remain on the enamel. If you use a knife, but will need to carry out several times.

Place the tile with the cut at the corner and press down on its edges with a sharp motion. The cut will not turn out perfectly even, unlike the tile cutter, but you will not have to spend extra money either.

To make cutting ceramic tiles easier, many craftsmen soak them in water for about 1 hour.

We make a drink at 45 degrees

Ceramic pencil skirting is best for protecting the sharp outer corners of tiles

If you are using a professional electric tile cutter, the tilting platform there makes it easy to make a 45-degree angle on the tile bevel, but not everyone has such a tool. It is easy to make such an angle on your own using the same angle grinder “by eye”. The disc is guided along the line of the cut, with the disc tilted slightly inward.

Undercut tiles at 45 degrees

How to choose the right disc by tile

For cutting, metal discs are used with diamond plating along its edges. But they are different: for concrete, brick, stone. Tiled discs do not have any holes, the soldering on them is uniform and smooth. Discs for concrete have slots on the solder, and will chip when vibrated. If you cut ceramic tiles with them, then these chips can fly into the face.

How to cut porcelain stoneware

It is believed that porcelain stoneware is the hardest material from which floor tiles are made. You can trim it in the same way as a regular tile.

Sometimes simple floor tiles are more difficult to cut than porcelain stoneware. There is a hardened tile, on which, after cutting with a tile cutter, the notch on the glaze is almost invisible. And even a diamond disc does not take it on an angle grinder. the notch turns out to be torn, like after a tractor. In such cases, you need to use an angle grinder, and file a groove 2-3 mm from the back side to mark the place of the fracture.

4 ways to cut porcelain stoneware: tile cutter, angle grinder, waterjet

Many people dislike trimming tiles. This lesson is quite difficult for a beginner. If you have never encountered it, practice first on a clay tile. It is much softer and more pliable than porcelain stoneware. The tools are the same, and by stuffing your hand on ordinary ceramics, you can more confidently handle the artificial stone. Cutting porcelain stoneware involves the use of mechanical and electrical “helpers”.

How to Cut Porcelain Tile Around the Toilet Flange

Fast navigation through the article

Electric cutter

An electrical apparatus is devoid of the disadvantages of a mechanical one. Thanks to him, they achieve a very high-quality cut. It allows you to work with dense and thick porcelain stoneware without compromising on quality. In addition, he is able to cut thin pieces of ceramics; in the case of a mechanical tool, even if there is a new roller and lubricated skids, there is no guarantee of a positive result.

An electric tile cutter is not as fast as a manual tile cutter, but that hardly matters where impeccable quality is needed. The only drawback is the relative high cost. However, the price is comparable to a quality imported mechanical tool.

What is an electric cutter?

- Table or mill.

- Guide.

- Cutting element (diamond wheel).

- Electrical engine.

- Water system.

Cutting with a diamond wheel is accompanied by a large amount of dust, therefore the device has a hydraulic system that cools the cutting element and prevents active spraying of the ceramic. The models differ in the water supply scheme. In one case, it is a reservoir with a liquid, in which part of the circle is constantly immersed, in the other, wetting is carried out by running water. The fluid must be changed periodically to avoid the accumulation of waste contaminating the diamond element. The latter should also be washed regularly, otherwise cutting particles become clogged.

Electric water cooled tile cutter.

Undercutting at an angle of 45 degrees on an electric machine.

Angle Grinder

An angle grinder is the tool that will help out in the absence of any other cutting tool. Further about the advantages and disadvantages of the angle grinder.

The angle grinder can be trimmed to any shape and size, and the angle can be sanded at 45 degrees. For work, you need a special diamond disc for tiles: smooth and without holes.

- Availability. there is an angle grinder in almost every home, it is enough to purchase a diamond wheel.

- Possibility of curly cutting. The portability of the tool allows you to cut almost any shape. skill would be enough.

- Many people have a certain skill of working with an angle grinder, this provides a quick mastery of the trimming process.

- Noise and dust. Working with an angle grinder is accompanied by “audio” and a lot of dust.

- An angle grinder is a dangerous tool. Careless movement and negligence in safety can easily lead to injuries.

- Poor quality cut. Depending on the quality of the angle grinder, the degree of chips and microcracks in the tile is different, but there are always flaws. Finishing the cut by grinding partly solves the problem, but it is better to use an angle grinder for working with tiles, which, from an aesthetic point of view, are not of great importance. the cut points should be hidden.

Safe working techniques with an angle grinder:

http://www.youtube.com/watch?v=fvqotukmgEo

Having outlined the cutting line, cut a couple of millimeters from it. the diamond wheel “eats” part of the ceramics. Set the circle in accordance with the direction of movement of the mechanism; there is an arrow on the cutting element. In the process, try to drive the car back and forth less, this will reduce the number of chips. This advice does not work when cutting thin pieces of porcelain stoneware, here the desire to cut in one pass will turn into a scrap of a slab.

Approach responsibly when choosing a diamond wheel, buy high-quality consumables. Otherwise, it is fraught with the destruction of the element, which at high speed leads to injury. Give preference to circles without ventilation (gaps), ceramics do not like them.

Video about choosing a diamond wheel for trimming porcelain stoneware:

http://www.youtube.com/watch?v=5Bn8ab9DkRI

A blunt “diamond” can be brought into working condition with a brick. Walk over it 2-3 times with a cutting element, this will rid the circle of accumulated dirt.

How to make a narrow crop:

http://www.youtube.com/watch?v=uCTfHEy2j7g

Mechanical tile cutter

It is the most popular exclusively tiled tool. There are many variations, but a porcelain tile cutter should be relatively powerful and durable. It consists of a bed, rail guides, a cutting roller and tabs for breaking tiles. The machine (bearing or cylinder) with two guides has become widespread.

Manual tile cutter device.

To cut porcelain stoneware:

- Mark the boundaries of the cut.

- Place the plate on the tool bed so that one mark corresponds to the center of the bed and the other to the cutting roller.

- Swipe the roller evenly from one mark to another.

- Press your paws gently into the cut.

Cheap tile cutters chipped due to roller play and poor pressure.

We are talking about “standard”, popular, tile cutters with a relatively low cost. An expensive tool, especially a monorail, is free from this drawback. But for homework, for obvious reasons, it is not suitable.

The hand tool is good for quickly cutting a large number of slabs, the cut of which will later be hidden. In this he is much better than an electric apparatus. Considering that it comes with a template that helps you not to be distracted by marking the ceramics when trimming identical pieces, this is the best solution for volumetric and clean work.

The video shows how easy it is to cut porcelain stoneware with a hand-held tile cutter:

http://www.youtube.com/watch?v=GTC9H3T_bLs

Waterjet cutting

How does a waterjet machine work?

- Choosing a water-cooled electric tile cutter

- 3 ways to cut tiles at home

- Manual tile cutter: choosing a quality model and using

Glass cutter

It is not necessary to spend money on a special tool, a regular glass cutter will do. But in large-scale repairs, it is unlikely to help, a small amount of material is another matter. Of course, the cutting roller must have a diamond element, otherwise the efficiency of the glass cutter will be questionable.

Answering the question of how to cut a tile with a glass cutter, we can safely say. the same as glass! However, there are some nuances:

- Before starting the procedure, the plate is immersed in water for 30 minutes to soften the structure;

- Then it is necessary to make a markup based on the dimensions of the working surface;

- Then it is laid on a smooth and flat surface and the cut is made along the marks with one strong movement;

- As a result, you need to put a wooden block under the formed fishing line and press on both sides of the material.

If you are going to use a glass cutter to cut tiles or porcelain stoneware tiles, buy more material, you cannot do without cracks and chips!

Electric tile or wet cutter

This device is capable of adjusting the size of the heavy-duty structure tiles. By design, it is a conventional machine with an electric drive. In other words, if you need to exert effort to work with the manual option, everything is automated in an electrically driven machine.

An electric cutter at home is rarely used due to too high prices. It is not strange, because nothing better than this mechanism has yet been created. The installation is capable of processing huge volumes of material for finishing walls and floors for any size with excellent final quality (complete absence of chips, roughness and cracks), which allows it to be actively used for commercial purposes.

If the goals set do not imply enrichment, but only require the completion of the repair, then you need to follow a few simple steps yourself:

- Fill the tray with water.

- Install the tiles in the seat.

- Smoothly skip the tiles under the disc.

With intensive use of the equipment, it is necessary to periodically change the water in the sump, as well as clean off plaque from the disc. These actions will help you get the most out of your wet cutter.

Angle Grinder

This type of tool is one of the most affordable options for adjusting tiles to the required dimensions. With the help of an angle grinder, you can cut ceiling, wall, floor and even mosaic tiles, both tiled and porcelain stoneware. In addition, it is indispensable in a situation where it is necessary to make a figured cut.

The best cutting result is shown by thin diamond-coated discs, they are also dry cutters. If the beauty of the cut doesn’t matter, a regular disc will do. There is no point in explaining how to cut a tile with an angle grinder correctly, since there is no particular difference from metal or concrete processing in this process.

In operation, this is a rather traumatic tool, the dust from which will also make it difficult to work without a respirator, glasses and other protective attributes.

Tile cutter

This mechanism has proven itself perfectly when processing tiles. Similar results can be achieved in the case of porcelain stoneware, having previously familiarized yourself with the design of the installation. It consists of a base (platform) and several guides along which the carriage moves, and with it the cutting mechanism located below. There is a handle on top that allows you to cut the material mechanically. Thanks to a fairly accurate final cut without chips, this type of tile cutter is the main tool of many construction specialists.

Better than a manual tile cutter, only an electrical modification can cut off, we will talk about it later. Everyone can use the manual option, because by and large, you need to correctly perform 4 steps:

- Mark the future cut line on the tile.

- Place the material on the platform so that the mark aligns with the cutter wheel.

- Next, holding the plate with your hand, take the handle and, applying a slight effort, move the carriage from one side of the guides to the other, thus making a cut.

- To break, you need to apply force to the handle.

Experts do not recommend using a manual tile cutter for processing mosaic tiles and in cases where the material thickness exceeds 15 mm. However, even in the permissible range, you can make a mistake with the selection of the desired installation, because the dimensions of the tile cutter can be different. So, ceiling and wall tiles are cut with a tile cutter up to 40 cm long, floor tiles. with larger models.

Curly cutting

You can figuratively cut off porcelain stoneware tiles at home with just a few tools, a jigsaw is one of them. Using diamond wire as a cutting element, it can cope with a wide variety of sections, including complex cutting around. They can effectively process wall, ceiling and even dense floor tiles, but it is better to refuse to process the mosaic, otherwise you can damage your own limbs. To properly cut a figure in this way, you need to abundantly moisten the material as it dries and promptly clean the surface of debris.

How to cut porcelain stoneware tiles at home

Before starting to decorate the walls, floor or ceiling with porcelain stoneware tiles, each owner should be well prepared, both theoretically and practically. A person who has come across how to cut porcelain stoneware tiles at home will confirm that the main pitfall of the process is cutting the material to specific sizes, especially in the case of a stronger floor. Of course, it is likely that in some cases the dimensions of the full row will correspond to the length of the wall, but even with such layouts, one should not forget about the corners, heating mains and other built-in elements. Here, you will definitely have to think about how to cut a tile with a tile cutter into a smaller surface area without splitting it at the same time.

In the arsenal of any owner, you can find a wide variety of tools that will allow you to process floor, ceiling and wall tiles, which means that success is guaranteed. But in order to achieve it, the availability of equipment alone is not enough, you need to know how to use a tile cutter or any other unit at home.

Cutting tools

Choosing a tool in order to cut even the most common mosaic tiles, you will have to “break your head”. Judge for yourself, every second knows how to cut ceramic tiles, and only a few will answer the same question regarding more durable materials. In addition, it is unlikely that it will be possible to achieve success without certain skills, so it is better to practice well.

Absolutely all tools that can cut porcelain tiles are divided into two types:

- Mechanical. installations that allow you to make a manual cut.

- Electric. automatic devices.

It is possible to carefully perform the procedure with both options, but, as already mentioned, a certain skill will be required. Let’s consider each tool separately. As for the cut of small mosaic tiles, special nippers will come in handy.

Complex shaped cutting of porcelain stoneware

Very often it is necessary to cut curly sections in porcelain stoneware tiles. For example, for curved steps, holes in tiles for columns or pipes. How to do it?

What way to choose to cut the porcelain stoneware tiles figuratively:

- Hole saw;

- Ballerina;

- Angle Grinder.

What is the advice of a specialist in these cases? Hole saw. perfectly copes with the task when it is necessary to make round holes in porcelain stoneware. But alas, it works slowly but neatly. The ballerina also copes with the task of sawing round holes in the tiles, but she does it very carelessly, the edges remain uneven and often have to be refined by hand, and trimming is inevitable. an angle grinder is the best option for curved cuts.

When cutting tiles, the cutter should go a little further than the mowing line of the cut by 2-3 mm towards the chips.

Thus, it is possible to correct the unevenness of the cut with a grinder. It is necessary to work with a grinder “from oneself”. All tile ends must be sanded with a grinder or sandpaper. Next comes the final processing of the tile cuts. it is necessary to finish with a grinder, using flexible grinding wheels with a grain size of 0-100.

How to make a simple Jig to cut 45 degree tile edges. Резка плитки под 45

How to properly cut porcelain stoneware tiles at home

Porcelain stoneware is an excellent finishing material that combines the best qualities of ceramics and natural stone. The material is stronger than granite, wear-resistant and resistant to aggressive environments. The tiles are produced by the industry, various.

Types of porcelain stoneware:

- Technical porcelain stoneware;

- Glazed;

- Matte;

- Polished;

- Structured or patterned porcelain stoneware;

- Lapped;

- Aged;

- Slim. Slim.

You can cut any shapes and configurations from porcelain stoneware tiles at home. Porcelain stoneware tiles are often used in the design of the floor, steps of stairs, porches, walls and plinths of the house. Although the material is very hard, it often leaves unclean chips in place of the cut. Types of cutting porcelain stoneware tiles at home. using an angle grinder with a diamond disc (diamond), tile cutter, glass cutter, jigsaw, waterjet cutting (only industrial cutting on professional equipment).

An angle grinder with a diamond wheel is often the only option for cutting porcelain tiles. But when working with this famous tool, there are some nuances. The fact is that when tiles are cut, this work is associated with the release of a huge amount of harmful dust, an unpleasant burning smell and wild noise. Therefore, when working with an angle grinder, you must protect your eyes with protective goggles, and also wear a respirator.

When cutting tiles, you need to know that the diamond wheel must be kept straight without moving and clearly follow the mowing line, which is held on the back of the tile.

It is necessary to work with the disc carefully, drive the disc along the mowing line, retreating behind the cut line 2-3 mm from the mowing line towards the chips. It is also necessary to press the tool firmly and guide it along the mowing line calmly, with great pressure. If you make a cut in this way, then the cut will be neat, without chips. There is also one more piece of advice when working with porcelain stoneware. The ceramic granite tile must be rigidly fixed, clamped with clamps and screwed to a fixed surface, for example, to a table. The fact is that this must be done according to safety precautions. after all, when cutting, you must press hard on the tool.

Simple cutting of porcelain stoneware with a tile cutter

It is necessary to find out what kind of tile cutters are. The types of tile cutters are manual and electric (this is a stationary machine). Basically, the principle of operation of an electric and manual tile cutter is almost the same. But they differ in price.

An electric tile cutter has more convenience and quality in cutting tiles, compared to a manual tile cutter, but an electric tile cutter has a rather high price, no one leases it, and it has a high energy consumption. But the quality is of course excellent. During work, there is practically no dust from the tile, since when cutting, water is supplied to the wheel and cools it.

Cutting porcelain stoneware: 8 kinds of material

How and how to cut porcelain stoneware floor tiles

It is best to cut your porcelain stoneware floor tiles using an angle grinder with a diamond wheel. But at the same time it is necessary to use personal protective equipment against dust and noise.

Personal protective equipment when working with an angle grinder:

- Protective gloves;

- Glasses;

- Headphones;

- Respirator.

Experts give a few tips for beginners when working with an angle grinder, if you need to cut porcelain stoneware floor tiles, because these tiles are thick. Place foam plastic under the tiles on a firm, flat surface. To reduce the number of chips, in the place of the cut on the tile on the front side, it is necessary to stick masking tape and apply the cut thread with a pencil on top of the tape.

Tiles need to be cut only on the front side.

With a large tile thickness, to control the accuracy of the cut, it is necessary to use a metal building angle, it is attached with clamps to the tile, on the front side, and thus it is possible to correctly cut the tile.

The better to cut porcelain stoneware

Sizes of ceramic granite tiles (cm):

- 30×30;

- 45×45;

- 60×60

- 120×360.

The last size of the porcelain stoneware tile belongs to the so-called thin porcelain stoneware, which is most often used in the renovation of residential premises. It is especially beautiful when decorating the walls and plinths of the facades of private houses. There is another way to cut porcelain stoneware tiles, but with small amounts of work, it is working with a glass cutter.

Granite processing at home

It is clear that cutting porcelain stoneware tiles is quite difficult. And more often than not, beginners should seek professional advice. They have special tools and experience.

Professional advice

Oddly enough, but the greatest number of problems arise not even with the drive or the tool used to process porcelain stoneware, but directly with the diamond disc. The main complaint about the diamond is the rapid loss of cutting ability. As a result, with an increase in feed and force, the edge of the wheel heats up and begins to lose diamond powder. If you try to cut at home in this mode for at least 10-20 seconds, then nothing will remain of an expensive disc.

In this case, before each cut, the edge is cleaned and restored; at home, this can be done on an ordinary red brick by performing several small cuts. This removes soft material adhering to the diamond strip.

Experienced craftsmen, before cutting porcelain stoneware tiles, soak the material in water for 10-15 minutes. Artificial granite absorbs moisture very poorly, but a small amount of water still remains on the edge of the slab. As a result, the first time the cutting edge touches the surface, a beautiful, chip-free entry hole is guaranteed.

How to cut porcelain stoneware tiles with a tile cutter

A tabletop or floor device for cutting all types of tiles is a small frame with rails installed at the top and a carriage with a carbide head. The carriage is driven by a lever or electric drive. Simple and convenient mechanism at home.

At home, the tile cutter turns out to be the most affordable tool for cutting porcelain stoneware.

Before cutting the porcelain stoneware, the tiles are laid on the frame and fixed with plastic or metal stops. This is to ensure that the material does not shift during the notching process. Next, we bring the head to the edge of the tile until it touches and push the lever away from you, the carriage with a diamond or carbide tip evenly passes over the surface of the tile, leaving a deep scratch behind.

It remains only to break the porcelain stoneware into two parts with a slight but sharp movement. One of the ways to cut porcelain stoneware with a manual tile cutter is shown on

- It is very easy and comfortable to cut porcelain stoneware at home, you can master the cutting technique even with minimal experience and qualifications;

- A minimum amount of dust is formed, which is very valuable at home, especially if you plan to lay porcelain stoneware tiles on a small area of the floor or wall.

An electric tile cutter resembles a circular saw for processing and sawing wood in its structure. In order to cut porcelain stoneware, you just need to set the size of the cut strip, after which you can cut in unlimited quantities.

Home compact electric tile cutter

The disadvantages of the device include the fact that only material of a certain shape and size can be cut, for example, it is very difficult to cut a thin strip of porcelain stoneware or make an incision of a non-standard, curved shape.

A thin strip of porcelain stoneware is easier to cut with an angle grinder

How to cut porcelain stoneware tiles at home

In terms of technology, there are two main ways to cut porcelain stoneware. To do this, you can use various tools and devices, but, regardless of the number and type of technical equipment, porcelain stoneware is still cut in two ways:

- Mechanical sawing of a porcelain stoneware array. In this case, the cutting line is sampled with an abrasive tool;

- Injection method. A deep scratch is cut on the surface of the porcelain stoneware along the future mowing line of separation. Further, a bending or shear force must be applied to the porcelain stoneware, and the tile splits exactly according to the markings.

At home, you can use both methods, depending on the tool available, the amount of work and the thickness of the material. In addition, the complexity of the cut line configuration must be taken into account. For example, if you want to cut a tile that is large enough in size at home, which simply does not fit into a tile cutter, then you will need to look for a diamond cut-off wheel and an angle grinder. For cutting at home, this is one of the most reliable ways.

Having laid the tiles on a sheet of drywall, you can cut the porcelain stoneware angle grinder along almost any path, it is only important to take your time and evenly press the edge of the disc against the surface of the porcelain stoneware. Otherwise, you can easily overheat the tile at the cut point, which will lead to the formation of a pinch.

How to cut porcelain stoneware with a circular saw

Porcelain stoneware tiles can be cut and cut without any problems with a more powerful cutting tool, such as a hand-held circular saw. Engine speed and power allow you to cut almost everything at home, from wood to metal profiles.

- First, a standard carbide-tipped saw blade must be replaced with a diamond disc;

- Secondly, a bandage ring is placed under the disk mounting, thanks to which it is possible to damp vibrations and uncontrolled bending of a thin and flexible diamond wheel.

Alteration of the saw for porcelain stoneware

The process of sawing material is not much different from working on an electric tile cutter, the only difference is that the engine power is noticeably higher. Therefore, you need to carefully control the supply of the diamond wheel with minimal effort, otherwise the porcelain stoneware quickly overheats and cracks.

If you need to cut large quantities of porcelain stoneware, then there is no better option than an electric machine.

This method of sawing porcelain stoneware is considered the most productive, but at home it is used for short-term cutting of a small amount of material. You can work only in the yard, in the garage, in the shed, but in no case inside the dwelling. The amount of dust that is generated when cutting even a small amount of material is about an order of magnitude higher than all other cutting methods. The only indisputable advantage of this option is that with the help of a circular and a diamond wheel, you can cut porcelain stoneware at 45 degrees.

Water cutting of porcelain stoneware

The most efficient and at the same time accurate method of sawing very hard natural and artificial granites is considered to be the waterjet system. It allows you to cut out entire designs and 3D images. The system is powerful enough to cut porcelain stoneware up to 200 mm thick. At home, such equipment is not used for obvious reasons.

Cutting using water can be done on a hydromechanical machine. The use of water or water emulsion can significantly reduce the heating temperature of the tool and the porcelain stoneware itself. The result is less wear and better surface quality. The emulsion is applied to the edge of the wheel, but not to the surface of the ceramic.

The diamond wheel, mounted on the rotor of the motor, is fed along the guides of the machine along the surface of the porcelain stoneware, the coolant is supplied from a special reservoir directly to the cutting zone. This method is considered the most harmless, since almost all dust is washed off with water and removed from the surface of porcelain stoneware. It is clear that you can cut the material in this way if you can find a separate room at home, for example, in a garage or in a barn.

Such machines have very high characteristics and cutting speed, therefore, if you plan to cut porcelain stoneware of complex shapes and sizes at home, then using a hydromechanical machine will be the best option.

Cutting porcelain stoneware tiles at home

Anyone who prefers to make repairs or do small jobs with their own hands must have had to cut porcelain stoneware at home. In the first trials, cutting of porcelain stoneware tiles is more difficult than in the case of cutting tiles. It turns out a lot of scrap, but in general, the process itself is not much different from working with high-quality ceramic tiles.

The line of the cut should be marked with an allowance for finishing

Where to cut porcelain stoneware tiles

Oddly enough, but it is the smallest ceramic dust that forms when cutting artificial ceramic granite that turns into the main problem. At home, it is most convenient to cut the material directly at the place of its laying.

If you plan to cut tiles with a tile cutter, then you can cut out porcelain stoneware in any suitable place for this. The amount of shavings and dust in this case is insignificant, but the performance at home is relatively small.

For curly cutting or cutting sufficiently thick slabs of porcelain stoneware, you will have to use an angle grinder or machine. You will have to work at home either in the courtyard of the house, or you will have to sacrifice a bathroom or a toilet.

Features of cutting porcelain stoneware

It should be noted that cutting a very dense and hard porcelain stoneware slab is sometimes even easier at home than in the case of ceramic tiles. Those who don’t believe can try to cut overheated ceramics made on old Soviet or Chinese equipment at home. In comparison, cutting porcelain tiles does not look so problematic.

It is quite possible to cut porcelain stoneware without chips, although some masters argue that it is impossible to achieve this in principle. If this were really the case, then most of the walls and steps tiled with porcelain tiles would be with wide seams, curves and unattractive.

It’s not even about the hardness of porcelain stoneware. The technology for the manufacture of artificial granite is such that as a result of pressing and deep firing, material is obtained practically without internal stresses, and this is the guarantee of high quality mowing line sawing.

In order to accurately and accurately cut porcelain stoneware at home, only two conditions must be met:

- Choose the right cutting mode, ensure constant and uniform pressure with the cutting tool on the line of the cut of porcelain stoneware;

- Choose the right tool for your specific cutting conditions.

It is clear that at home the possibilities of cutting the material are significantly limited, but even in an apartment it is quite possible to cut porcelain stoneware without a tile cutter, although initially the amount of dust generated when working with electric machines is frightening.

Electric tile cutter

Owners of electric machines can tell you how to cut porcelain stoneware tiles at home. With this equipment, you can get higher accuracy and speed than with a mechanical counterpart or an angle grinder. The design of the device is simple. The tool consists of two parts. This is a work table and an electric drive. For all its simplicity, there are a huge number of modifications of this equipment. So, porcelain stoneware was chosen as the finish. What makes cutting faster, easier? Of course, with an electric tile cutter.

On sale you can find mechanisms with a fixed type of drive, as well as with a movable cutting tool. The first group of devices requires manual feeding of material under the cutting edge. This will require maximum concentration and some experience. The second group is safer and more accurate cutting of porcelain stoneware. The better to cut at home, everyone decides for himself. But it must be borne in mind that the process is very dusty. In the case of electric tile cutters, it settles in a container of water.

Benefits of electric tile cutters

The main advantage is the ease and speed of work. Quite large volumes of tiles can be processed in a short time. Also, there is no need for additional processing of the edges. The cut is as smooth and clean as possible. The disc is equipped with a special turning mechanism. You can fix the position at any angle to the table. This allows you to get cuts at different angles.

An experienced specialist is able to make even curved cutouts of any shape using electric tile cutters. There are special porcelain stoneware floor tiles for sale. What and how to cut it? Answer. only with electric tile cutters. In other ways, you can only spoil expensive material.

Also, the advantages of this equipment and the method of cutting porcelain stoneware include the ability to adjust the feed of the cutting element in different areas. So, at the beginning and at the end, the feed should be done slowly, while in the middle it can be accelerated. With the help of this equipment, effective cutting of porcelain stoneware is performed. Flawless cutting technologies don’t even need to be used here.

Even with a little experience, the cut will turn out perfectly smooth without any chips.

Waterjet cutting of porcelain stoneware

This technology is used only at production sites. In addition, specialized equipment is involved here. Tiles of simple shapes can be cut as you like. But to get a complex profile, elements of various panels, complex shapes and compositions is possible only in this way. Waterjet technology involves water and a special powder. The mixture is fed into the nozzle of the system under high pressure. Cutting is done with a fine jet. This guarantees the highest accuracy. This method is used for the production of artistic compositions based on porcelain stoneware. The cutting process itself is done quickly enough.

Methods for cutting ceramic granite

Often such tiles are extremely durable, which means that high demands are placed on its processing. The process of cutting ceramic granite is quite complicated and requires special skills and tools.

Despite the popularity and widespread prevalence, there are not so many cutting methods. The methods differ according to the instrument used. Cutting with mechanical tile cutters is possible. You can also use an ordinary and familiar angle grinder. There is also a method using an electric tile cutter. Artistic cutting is carried out using waterjet technology.

All methods can be divided into two groups, which are carried out independently or in an industrial environment. The first three options can be done at home. But to work with the waterjet method, production machines will be required. The process is quite noisy and requires a lot of water and electricity. Therefore, we will consider how to cut porcelain stoneware tiles at home.

Material characteristics

It combines the characteristics of ceramics and the properties of natural stone. This finishing material is obtained by powder pressing. It is a mixture of sand, clay, kaolin. The resulting powder is pre-fired in ovens. Modern technologies allow to produce tiles of any color. Special coloring oxides are added to the powder. You can also get any texture. Today, glazed, matte, polished, structured and other types are sold.

Among the properties of the material, high strength can be distinguished. It is much stronger than its counterparts. Also, the tile has high wear and frost resistance. Porcelain stoneware is fireproof and has an aesthetic appearance. The tile is durable, environmentally friendly. High strength is due to the almost complete absence of pores in the structure. Also, the material cannot be scratched, it cannot be painted. That is why many are wondering how to cut porcelain stoneware tiles at home.

How and how to cut porcelain stoneware tiles at home: description, technologies, methods and recommendations

If specialists in architecture in their work were guided only by the standards of manufacturers of building and finishing materials, then cities and houses would be approximately the same. These are standard cubic buildings, somewhat reminiscent of anthills. Fortunately, architects have a good sense of style and keep up with the times. Artistic taste is based on rational calculation. Of course, this gives builders and interior decorators some difficulties. This is work with porcelain stoneware, wood, fitting plastic and metal elements, as well as other work.

Specifically, porcelain stoneware is a fairly modern material and there are questions about working with it. For example, not every master knows how to cut porcelain stoneware tiles at home. But laying tiles necessarily involves cutting. Below we will consider the most effective methods that are available at home without a special tool.

Working with an angle grinder

With this tool, you can cut anything you want. And our material is no exception. If we cut porcelain stoneware tiles at home, then a special diamond-coated wheel should be purchased.

The cutting process will be dry. In order not to spoil the cutting line, as well as not to damage the tile surface, the outline of the future cut is preliminarily outlined with chalk, a marker or a pencil. Next, the tile must be fixed to a stable surface. The disc is installed in the direction of travel and a lot of effort is required in the process. Before starting to cut, it is recommended to step back a little from the mowing line of the markings. Move the tool smoothly and slow down at the edges. Among the disadvantages of using an angle grinder for these purposes, there is a high level of risk of chips. And this is marriage. This is true when working with glazed tiles.

What is it?

Classic porcelain stoneware is a beautiful rectangular tile with or without a pattern.