How To Cut Porcelain Stoneware Tiles With A Grinder Without Chips

How to cut ceramics with a grinder

Correct cutting of tiles with a grinder at home will not chip. Find out how you can cut off the angle grinder accurately and which disc is suitable for this. Finisher’s advice.

Direct cutting of ceramics with a grinder

On the front side of the ceramic tile, a cutting line is applied with an alcohol marker. The grinder is turned on and given a couple of seconds to set the specified speed.

The optimum rotational speed of a disc with a diameter of 100-125 mm when cutting ceramic tiles is 6-8 thousand rpm. The tile is placed on a flat wooden surface, secured with a clamp through a rubber sheet gasket, or you can simply press it against the board with the sole of your foot (wearing safety shoes!).

Cutting ceramic tiles can be straight and curly

Exactly along the intended mowing line, an incision is made with a depth of 1-5 mm, depending on the material and thickness of the tile. From the edge of the material, they begin to cut slowly, then the grinder is moved faster. So the cut turns out smoother. Once the cut has been made, the tile can be broken by placing a pair of nails underneath it opposite the beginning and end of the cut.

Grinder cutting of large diameter holes

With an alcohol marker on the ceramics, mark the center of the circle and drill a through hole with a diameter of 3-4 mm with a carbide drill exactly along the mark. Then, on both sides of the tile, a contour of a circle of a given diameter is applied. With a grinder with a disc, cuts are made with a depth of 1-2 mm along the contour of the future hole on both sides of the tile, and then through cuts are made inside the contour and small fragments of ceramics are removed from it with nippers. The inner surface of the cut along the perimeter of the hole can be processed with coarse sandpaper or a file until there are no chips.

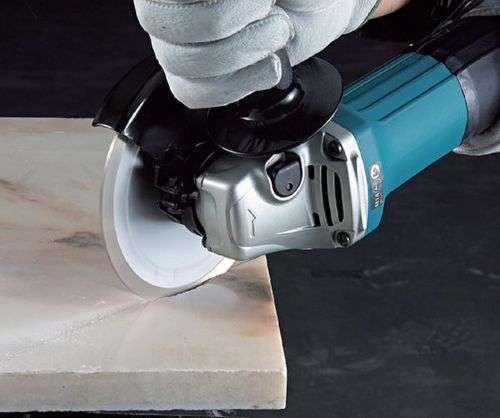

Tile cutting with a grinder is performed using a diamond grinding wheel

Figured tile cutting with a grinder

If it is required to cut an oval shape from a ceramic tile, then short cuts are made with a grinder tangentially to the outer contour of the figure in order to cut off small fragments of ceramic to be removed. At the end of cutting, the surface of the cuts is refined with an abrasive tool until the lines are smooth and there are no chips.

When it is necessary to cut a figured hole in the tile, the material is cut with a grinder exactly along the contour, gradually moving away from it inward and increasing the depth of cut. After cutting through the tile, the edges of the hole are finished with coarse sandpaper.

Stone discs

Stone discs are several times cheaper than dry cutters, but they wear out during operation and must be replaced with new ones. In addition, they are thicker than dry cutters, so the thickness of the mowing line for cutting with a stone nozzle is wider and, accordingly, more dust is generated during operation.

In the process of cutting with a stone nozzle, it is necessary to control the state of its cutting edge. If a chip or burr forms on the edge, the disc must be replaced immediately, since such damage is fraught with destruction of the nozzle and causing injury.

How to cut ceramics with a grinder

One of the tools used to cut ceramic tiles is a grinder. An angle grinder (angle grinder), commonly called a grinder in everyday life.

- Safety rules when working with a grinder

- Discs for cutting ceramics with a grinder

- Stone discs

- Dry cutters

- Segmented dry cutters

- Solid dry cutters

- Direct cutting of ceramics with a grinder

- Grinder cutting of large diameter holes

- Grinder cutting rectangular holes in tiles

- Figured tile cutting with a grinder

- Outcome

The price range of various grinder models makes it available not only to professionals, but also to home craftsmen, so when using angle grinders, you need to know not only the capabilities of this power tool, but also the rules for handling it in order to avoid injury.

The grinder is best used with adjustable speed

At home, a small grinder is used, designed to work with discs with a diameter of 100-125 mm and performing many operations. The tool can be equipped with a speed controller.

Segmented dry cutters

This type of grinder attachments is a steel disc with evenly spaced slots directed from the cutting edge to the center and dividing the disc into equal segments. The segmented nozzle can be used to cut porcelain stoneware and natural stone tiles. The slots between the disc segments serve to increase the life of the bit by improving the air cooling of the tool when cutting hard facing material, but increase the formation of chips.

Circular

Some do-it-yourselfers at home decide to cut porcelain stoneware on a circular. As mentioned above, in this case, a special cutting element for porcelain stoneware should be installed on it. The very process of work resembles the process of cutting wood on this equipment. Place the tiles on the work surface and bring them up to the cutting element with both hands.

Jigsaw

If you need to cut in a difficult place, then you can use an electric jigsaw, on which a diamond wire is installed, to help. Thanks to this, work can be carried out with millimeter precision. It is recommended to lightly dampen the porcelain stoneware during the cutting process. This will simplify the cutting process as the resulting dust can clog the cutting thread.

How to make floor curly cutting

When it comes to straight cutting lines, the choice of tools is very large. But what about when you need to cut a rounded line? In this case, the following two cutting methods can be used:

- Hole saw.

- Ballerina.

Material features

Due to its unique properties, porcelain stoneware has become very popular. It is worth highlighting only a few positive aspects, after which all doubts are dispelled regarding its quality:

- Fire resistance;

- Wear resistance;

- Frost resistance;

- Strength;

- Hygiene;

- Durability;

- Antistatic, etc.

The structure of the material has practically no pores. This is what makes it very durable. But not every building material that is usually used for cutting ceramic tiles can be suitable in this case.

Hole saw

This device is equipped with a carbide tip. The use of this equipment has no boundaries regarding porcelain stoneware. It can cut both soft and hard material. However, there is one drawback here. If the surface of the product has glaze, then the cutting process is significantly slowed down. But, on the other hand, you can make a neat round cut. Therefore, if you are not in a hurry, then you can use this technology.

What discs are used for cutting tiles

For cutting ceramics, special discs are required, which can be stone or metal with diamond coating. Stone ones are rarely used, as they are rather thick and quickly grind off, and during work they generate a lot of dust. The cost of stone discs is several times less than metal ones, but experts prefer to work last.

Metal discs can be:

- Solid;

- Segmented.

It is preferable to process ceramics with solid discs. When working with such discs, there is a time limit: they cannot continuously cut for more than 1-1.5 minutes. Then you should let it cool while the grinder is idling.

Segmented for cutting paving stones, porcelain stoneware, natural stone or concrete.

Notched neckline

It is often necessary to cut a round hole in a tile. You can do the job correctly with angle grinders if you have certain skills. To do this, mark a hole on the workpiece and circle the fishing line with a felt-tip pen, mark the center of the circle. They begin to cut at a slight angle, slowly, along the inside of the mowing line, gradually passing along the entire circumference. Then the sectors are cut through, they are taken out in turn, cutting the ceramics if necessary. Finally, the edges are processed with a file, getting an even circle. This processing is called a dry cutter.

When performing shaped processing of a workpiece, it is easiest to make rectangular cuts. In order for the cuts to be smooth, without chips, it is necessary to regularly change the cutting wheel. If you use segmented discs, chips will appear on the cut line.

Cutting paving stones with angle grinder

Having a private house, it becomes necessary to lay paving slabs or paving stones, which must be cut to size. For this, a universal device is also used, which is available in almost every home. An angle grinder.

Paving stone processing has its own characteristics, but basically it is carried out in the same way as cutting porcelain stoneware. The main differences are that the work is done outdoors. Material processing should be carried out on a separate site: the formed dust settles on the laid paving stones and can spoil its appearance. If this happens, you should immediately sweep it off with a stiff brush.

To cut the paving stones, choose a diamond blade for concrete processing. The angle grinder should be held in relation to the workpiece at right angles, and the diamond wheel should be moved exactly along the marking mowing line. It is necessary to cut the tiles to a depth of a little more than half, and then simply break and trim.

How to get rid of dust when cutting tiles

Cutting tiles with a grinder is not very difficult, but it generates a lot of dust. There are tricks that can help reduce dust formation. Specialists use special tile cutters for this, but buying them for a one-time job is impractical due to the high cost. Therefore, when processing parts, the craftsmen act differently. First, a layer of glaze is cut through. It almost does not dust, the main dust appears when a layer of fired clay is processed. Then it remains to gently break the ceramic tile and process the edges with an abrasive material.

A common way to get rid of dust is to moisten the workpiece. For this, water is constantly poured into the working area with a diamond wheel. After each pass of the tool, fill the seam with water or install a special device for supplying water to the working area. This device is attached directly to the protective cover of the grinder. As a result, the workpiece is processed without dust.

Straight cut

It is not difficult to master it, at the same time the cutting line is clean and without chips. When performing the work, the tiles are securely fixed on a flat surface, marked with a pencil or felt-tip pen. The part to be cut should hang freely from the table. The cutting tool is at right angles to the workpiece. Carefully, without jerking, slowly lead the angle grinder along the marked mowing line. The tool should be moved towards you so that the marked line is visible.

Cutting porcelain stoneware

When performing repairs, not only walls are faced. The floors in the bathroom and toilet are covered with porcelain stoneware tiles, an artificial material that replaces granite and marble. Its cost is several times less than natural, but in terms of hardness and abrasion, porcelain stoneware surpasses them. Recently, it has become widespread. It can also be cut with a grinder.

To do this, you need to know the basic methods of processing material at home.

- Choose the right cutting tool. It should say what it is used for: porcelain stoneware, hard ceramics, etc.

- To reduce chips, choose a disc with a continuous cutting edge. The thickness should be minimal.

- Choose a cut-off wheel with a high diamond coating height.

- The grinder must have a speed regulator.

After choosing the tool, they prepare the workplace and begin to cut the porcelain stoneware with a grinder. To do this, you need to perform the following steps.

- Place the material on a flat surface with thin foam or similar material underneath.

- Fix the tiles securely to the surface with clamps.

- To reduce chips, glue masking tape and make markings along which you need to cut off the excess part.

- Prepare a vacuum cleaner to remove dust.

- You need to cut from the front side, moving the grinder away from you.

- It is recommended not to cut along the marked mowing line, but slightly to the side. This is done for the subsequent grinding of the end of the porcelain stoneware to remove irregularities and chips.

Following these simple recommendations, you can cut the floor tiles with your own hands.

How to get rid of dust when cutting porcelain stoneware with a grinder

If the tiles are cut on a table, then, before starting work, a small piece of loose fabric must be pulled under the cutting line or a polypropylene bag must be hung. In this case, most of the dust flies down from the disc, so the amount of work on cleaning the room is reduced several times.

If you cut porcelain stoneware on a substrate directly on the floor, then the best solution would be to use a regular vacuum cleaner. The tip of the hose is attached along the mowing line of the movement of the grinder at a distance of 10-15 cm. It turns out not very convenient, since the pipe has to be rearranged, but the dust is removed quite effectively. Immediately after the end of the work, you need to blow out the grinder and collect part of the dust remaining on the surface of the porcelain stoneware.

Useful Tips

There are all kinds of models of attachments for the grinder on sale, some of them provide connection of the vacuum cleaner nozzle to the protective casing of the tool. At first glance, the thing is quite convenient, but it is better not to use such devices, since the hose greatly interferes with the work and often only worsens the quality of the seam.

In addition, it is necessary to cut porcelain stoneware, be sure to hold the grinder body with two hands, while the left hand should rest on the stand or guide rail, and the right hand is directly moving the tool. This method provides not only partial unloading of the hands, but also allows you to more accurately align the position of the cutting disc in the vertical plane.

Regardless of which disc and how to cut porcelain stoneware, after the completion of work, the edge must be rubbed with hand or tape emery. In this case, you just need to slightly align the lower edge of the porcelain stoneware and in no case touch the upper front edge with an abrasive, otherwise chips will appear, and the quality of the seam will noticeably deteriorate.

How to cut correctly with a high-raised grinder

Most beginners and DIYers prefer to cut porcelain stoneware with a tool with a very large angle of inclination relative to the plane of the tile. The angle can be 45-60 degrees.

The tool can only be lifted high if there is a supporting surface on the cover

In this case, the grinder has to be held with both hands and at the same time perform small oscillatory movements with the cutting disc. It is as if the porcelain stoneware had to be cut with a hand saw. This is not very convenient, but the method really improves the quality of the cut and prevents the formation of chips.

On the one hand, with such a movement of the grinder, it is easier to control the cutting line, on the other hand, the tool is in an unstable position relative to the markings, which negatively affects the quality of the straightness of the seam.

Cutting porcelain stoneware with a grinder: how to saw off without chips

Anyone who has had a chance to cut faience, ceramics, porcelain stoneware with a cutting disc knows very well that the problem is not to cut. Such an operation is not particularly difficult. The problem is to learn how to cut porcelain stoneware with a grinder without chips. At the same time, control the process at any stage, otherwise the expensive material will go to scrap.

It is best to cut porcelain stoneware using a guide bar as a support for the grinder body

What disc to cut porcelain stoneware grinder

Sawing of porcelain stoneware tiles can be performed in two ways, it all depends on the thickness of the material and on how complex the seam is to be cut. Since porcelain stoneware is still not granite, but just an artificial imitation of it, two types of discs can be used for cutting:

- Vulcanite discs based on synthetic superhard ceramics. With such a circle, you can cut thin grooves, corners, trim the edges. In order to cut expanded clay with a grinder over a length of more than 10 cm, they are not suitable, but they are quite suitable for small jobs;

- Diamond cutting wheels. With this tool, you can cut seams of unlimited length. The only drawback of a diamond is the rapid grinding of the cutting edge, which will need to be repaired and cleaned periodically.

The optimum circle diameter for a grinder is 115 mm, in this case the tool is easier to control by holding the body with both hands. A larger diameter blade will require a more powerful tool, such as a circular saw.

Diamond cutting wheels themselves are quite an expensive and capricious tool, so they try to do most of the work with vulcanite discs, only the most delicate operations, such as trimming and adjusting the plane, are performed with diamond powder.

In addition, discs for cutting porcelain stoneware with a grinder must have a solid edge without a notch or turtle profile. Such a tool cuts well natural granite, rubble stone, but at the slightest attempt to cut porcelain stoneware tiles along the cutting line of the cut, a huge number of enamel chips appear on the front surface.

If there is no specific preference for a well-known brand of cutting disc manufacturer, then it is best to buy discs from leading hand tool manufacturers. Simply put. You bought a grinder made by Makita, buy cutting discs with accessories produced by the same company.

How to cut porcelain stoneware with a grinder without chips

There are two ways to cut porcelain stoneware tiles. The first is to mark a 1-2 mm deep line on the mowing line in a circle, and then split the granite into two halves as it is done on a tile cutter. The method is quite risky, it requires a good eye and accurate dosing of effort. The advantages include an order of magnitude higher cutting performance. The disadvantages include the unpredictability of the result and a large percentage of defects.

The second method is the classic cutting of porcelain stoneware to the full thickness of the tile. It turns out a lot of dust, the process takes a long time, but as a result, we get a very high-quality and fairly even cut.

In any case, when using a grinder, the seam is uneven. Visually, the line looks perfectly straight, but as soon as the cut plates are turned over and applied to the factory edge or metal ruler, all the irregularities will immediately become visible. An example of cutting porcelain stoneware with a grinder without chips is given on: