How To Cut Styrofoam By Thickness

How to cut styrofoam

Foam grade OPBS-35, which is commercially available, has good thermal insulation properties.

When using it, it is convenient to cut it in thickness into two plates of 49.5 mm each; three. 32.5 mm each; on four and five plates of 24 and 19 mm, respectively. This is not difficult to do with a simple device that every beekeeper can make (Fig. 1).

As a cutting tool, you need to take a nichrome thread 7 1 m long from an electric stove or iron. Attach a weight 8 weighing 1-3 kg to the lower end. The size of the load should be selected practically, the thread does not have to sag and break off with an accidental jerk or at the end of cutting. It must be fastened through insulator 3, attached to the pin. The insulator can be porcelain rollers or porcelain parts of an electric kettle plug. For the manufacture of a vertical support platform, chipboard or plywood sheet with a thickness of 7-10 mm is taken. If they make it in the form of a lattice, then they take four bars, place them in parallel and under their ends on both sides they knock on a bar.

In relation to this site, set the distance

6 B) with heating thread (fig. 2).

An autotransformer (Fig. 3), as well as an electric stove and an iron (Fig. 4) connected in series, cannot be used. Our low-voltage electrical networks (380/220 V) are most often made according to the “Star with a solidly grounded zero”.

Therefore, if you accidentally touch whining or conductive paths, a person will inevitably be energized.

During work, you need to make sure that the thread does not get too hot, since part of the foam burns out and the surface of the resulting plates becomes wavy. You need to move the letter smoothly, slowly. At the end of the cut, try to avoid jerks, as the load pulls the thread and you can break it.

The dimensions of the device should be such that when cutting the plate in height, it can freely pass between the lower and upper guide boards with a margin of 5-7 cm. The length of the vertical support platform and the lower support board should be one and a half times longer than the foam. For high-quality filling of frame products with foam (chipboard hive, two-layer plywood nomadic booth, etc.) I recommend transferring the dimensions to the sheet, easily tapping it with your hand “in place” into the edges of the frame bars. On the weak marks formed from the edges of the bars, the letter is cut with a knife along the rail, getting the desired shape and size.

Nichrome wire

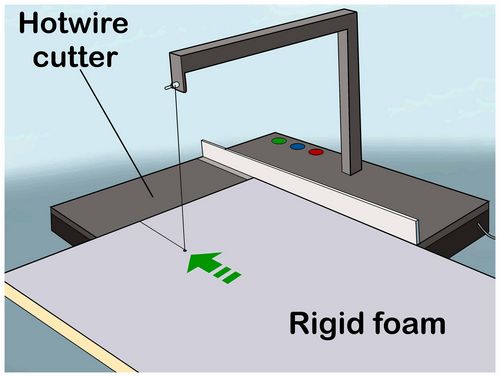

As noted earlier, cutting is best done with temperature. Facade styrofoam is NOT an exception. Russian people have always been distinguished by their ingenuity, which helped to come up with equipment for manual cutting. Required:

- Desktop;

- Transformer that converts 220 to 12 or 24V;

- Nichrome wire;

- Adjustable rheostat;

- Wires.

The wire for cutting the foam is fixed across the table with a gap for the required size. Wires, rheostat, transformer are connected. When heated, the wire will easily make a high-quality cut. The material should be fed without much pressure, and the heating temperature of the wire is also important. Too high can cause sagging.

Designers also use such a tool in their work. The wire allows you to make a number of curly cuts.

Applications

For the most part, this material is used as insulation. over, it is used for external and internal work. With the help of polystyrene, many designers create interesting compositions; it is also used for the production of ceiling tiles, baseboards, cornices, stucco moldings and others. This area of application is associated with several main advantages of the material:

- Environmental friendliness;

- A light weight;

- Low price.

All these areas are directly related to the question: “What is the foam cut?”.

You can take a regular office tool. And execute the cut. In this case, the process will be accompanied by a creak, a large amount of debris, the edges may crumble. This option is suitable for light trimming and thin sheets. In this case, you will need to frequently replace the blade.

Power tool

How to cut styrofoam at home with a power tool?

- Electric jigsaw. The process seems to be partially automated, the speed of work will increase. But the quality of the cuts will be low. Again there will be creaking, garbage. At the same time, one must understand: slabs with a thickness of more than 80 mm are unlikely to be cut with such a tool.

- Angle Grinder. It will also speed up the slicing process. But at the same time the rubbish will scatter in all directions, and even there is a strong noise from the operation of the instrument. If, nevertheless, an angle grinder for cutting is chosen, then it is better to purchase a diamond wheel with a minimum thickness, this will help to raise the quality of the cut.

Separately, it is worth considering a tool such as a soldering iron.

Hacksaw for metal

This type of tool will allow you to cut sheets of any width, but the productivity will be low. Rubbish and creaking will also accompany the entire process. The edges will crumble. This method is suitable for a small number of cuts. Work should be done on a table. The cut-off part is moved from the support structure so that you can work with a hacksaw.

Thermal cutting with a knife

For this method, you need to think about heating the tool. Open flames or heating equipment can be used. The knife itself must be well sharpened. You need to stock up on a guide straight bar for cutting. It is best to do the work outdoors. This will prevent the accumulation of harmful odors that negatively affect health.

What is Styrofoam?

Full name of the material. Expanded polystyrene. This type of insulation belongs to foamed (cellular) plastic gas-filled masses. If you look at this material, you can see many small balls fastened together. Therefore, during normal cutting, a large amount of fine debris is formed, and the cut itself turns out to be uneven. What is styrofoam cut with? The question is interesting and relevant.

There are two main options for density:

- Soft. Such layers have a porous structure. When cutting, they crumble strongly, break.

- Solid. This material is easy to process. Minimally crumbles, the cuts are smoother.

Worth Note that the first option is cheaper than the second.

Shaped cutting of foam

Often, designers use expanded polystyrene to create any decors.

Facade styrofoam

This material can be produced in several variations:

- Pressed;

- Suspension, uncompressed;

- Self-extinguishing non-compressed suspension;

- Extruded polystyrene foam.

The thickness of panels for facade insulation ranges from 70 to 150 mm. You need to understand that such work is accompanied by a large number of cuts. Therefore, the previously listed methods of cutting foam will not be very relevant.

How is styrofoam cut at home? Foam cutting wire. Facade styrofoam

Polyfoam is a heat-insulating material widely used in individual construction. It is sold in canvases, so it is often required to cut the desired length. Anyone who has come across such materials understands that it is difficult to do it with high quality with ordinary tools. How to cut styrofoam at home? Consider further.

Special knife. How to cut styrofoam so as not to crumble

Polyfoam or expanded polystyrene refers to a versatile material that is used for insulation and sound insulation in building structures. Its structure is based on foamed plastic. This explains why the foam crumbles quite often when cutting.

When processing the material, it is necessary to decide how it needs to be cut, so that the cut line is even, and the crumbs are as small as possible.

Nichrome wire cutting

To use this tool, you will need to additionally assemble the device. It will include not only a nichrome thread, but also a 12 or 24 volt transformer. In advance, you must also take a piece of a small pipe and a table. The string tension will be organized by the spring. Nichrome is a material that is part of any hair dryer. The apparatus must function in such a way that the filament is heated and the foam can melt. Thanks to this, it is possible to obtain various complex shapes from the material.

In order for the device to start functioning, a wooden block is fixed on the table. You must first make a hole in it and install a piece of pipe. Next, you need to fix the nichrome wire on it with the introduction of a spring. It will only heat up after being connected to the transformer. A piece of foam should be brought to it and given the required size.

Electric Angle Grinder Cutting

Styrofoam is a pliable material that can be cut with any sharp object. Some people use an angle grinder for this purpose. In this case, the choice should be stopped on the thinnest disk.

This cutting option is simple and comfortable. However, in the process of work, a lot of noise will be created, and after its completion, a large amount of garbage will appear.

Tool types

Mechanical cutting. The most common tools at hand include a knife, jigsaw, saw and angle grinder.

The main focus when choosing a knife is on its blade. If it is sharp, the cutting process is faster and less waste is generated.

The knife must be preheated before cutting.

The disadvantage of this method is that the use of a knife is possible with a foam thickness of 1. 5 cm.

Disadvantages to use:

Stationery knife. The stationery knife is best used for soft material. This knife has thin and flexible blades, so it is NOT used for cutting thick slabs.

Electric jigsaw. Trimming with a jigsaw is used when cutting foam up to 10 cm in thickness. This method does not require much effort.

Hand saw for wood. If the thickness of the foam reaches 40 mm, then it is better to cut it with a hacksaw on wood. The method is quite simple and fast, without much physical effort.

A saw with fine teeth is better suited. This tool is only used for straight cuts.

“Angle Grinder”. The advantages of an angle grinder are that it cuts the foam itself, if you use the thinnest circles.

However, it is not recommended to cut thick material with the angle grinder. You will NOT get a quality result, but there will be a lot of garbage.

In addition, this option is not very good because of the squeal that occurs when the foam interacts with the circle of the car. Plus the noise of the instrument’s engine is added to it. Therefore, in the case of cutting a large number of foam boards, you should wear headphones from the very beginning of work. Add to this list also the electricity consumption, which you will need to pay.

Nichrome wire cutter. The practice of working with foam shows that a high-quality cut is formed when using a tool with a heated wire. The edges are even, smooth, and there are practically no crumbs. The advantages of the method can be added High cutting speed and productivity in a volume similar to industrial.

DIY styrofoam cutting device

Polyfoam cannot be cut not only with nichrome thread, but also with metal plates. As a basis, you should take a conventional soldering iron with a power of 60 watts. It will need to be reconstructed. instead of the sting, place a knife plate. Hot melt synthetics are also used as the main material.

The wooden leg must be additionally equipped with supporting legs. Previously, a gap should be made in the board and a knife should be placed in it. Additionally, the device should be equipped with a stand with brackets. A protective screen plays an important role, which in the future will protect a person from burns.

During cutting, the thermal knife must be positioned at an angle to the surface. The blade is also sharpened from both sides at once. You should first hone your skills on unnecessary trimming of the material. In this case, a smooth and beautiful surface is guaranteed.

Shaped cutting of foam

Polyfoam is quite one of the most demanded finishing products. Various figures cut from such material are especially popular. Volumetric foam compositions are used as architectural decoration, to create advertising elements, various design structures for interior decoration.

Figured cutting is carried out using laser installations and special CNC machines. Each device has its own advantages and features of use:

- Laser cutting. The processing of foam by means of radiation allows the creation of 2D and 3D shapes of various shapes. This method of cutting provides the smallest cut thickness, contributing to increased detail of products. The whole process on laser CNC equipment is fully automated. Therefore, in the process of cutting the material, defects and errors are excluded.

- String processing. The formation of bulky products occurs with the help of thermal effect of strings made of nickel-chromium. This method of cutting the foam ensures the accuracy of the cuts according to the given sketches. The cost of stringing cellular material is much cheaper than laser cutting. All actions on the machines are controlled by a special computer program.

With the help of modern 3D equipment for cutting foam plastic, you can make figures of varying complexity in a short time.

1 Cutting foam

So, polystyrene foam, like any other material, needs to be processed before use. Initially, it is supplied in conventional boards with a certain thickness. However, the shape of the plates is not always enough to use them wherever necessary.

Often the slab has to be cut into pieces, trimmed, cleaned up. Sometimes it becomes necessary to cut the decorative part at the edge of the slab or make a certain angle.

There are actually a lot of options. But the question remains one. How to cut the foam? It would seem, why still invent any additional units, buy a special cutter for foam plastic if it cannot be cut, you can even break it with your own hands. And that’s literally.

Here we must turn to the features of the expanded polystyrene itself and. The foam itself consists of small polystyrene balls.

The initial raw material in it is a polymer that is mixed with a foam filler and air. In total, a rather pliable and very light construction is obtained, which is easy to cut or break by hand.

Just breaking the foam is not the best solution. Kink line will never be accurate. Styrofoam balls will bend it, making the final structure unsuitable for precision work.

However, we still note that it is very easy to break or cut the foam. That is, cutting foam at home is quite real. Another question is how to do this accurately and with minimal material destruction. This is where a foam cutter or any homemade apparatus will come in handy.

Typical construction remains in the distant past. Today, each owner strives to make his home functional and individual. At the same time, attention is paid not only to design. Sound insulation, heat preservation and proper ventilation are also important. A lot of work can be done with foam. However, manufacturers pack the material into large sheets. That is why it is important to choose a reliable and comfortable tool for cutting them.

Than the foam is cut so that it does not crumble

Expanded polystyrene is a versatile material, which is used for heat and sound insulation of buildings under shock and noise loads. When carrying out repair work related to thermal insulation or redevelopment, it is necessary to cut out large sheets of insulation. In this regard, the question arises of how to cut the foam so that the fishing line turns out to be even.

Consider equipment that is used for cutting foam at home. These include:

- Knife

- Hacksaw for metal

- Wood saw with fine teeth

- Angle Grinder

- Soldering iron

- Nichrome wire.

Before you start cutting, you need to mark out the workpiece with a simple sharpened pencil. If a hacksaw or jigsaw is used as a cutting tool for Styrofoam, do not make quick movements. This is due to the good thermal insulating properties of the material, when when friction occurs, heat is not removed and it heats up, which complicates the process. Use a soldering iron if you need to quickly cut the workpiece. To do this, flatten the end with a hammer and fix a special part, for the manufacture of which you need to take the metal cap of the fountain pen and the blade. After warming up the device, start cutting the sheets.

With an angle grinder, the foam is only cut very thin. It is unlikely that it will be possible to achieve a high quality cut, the result will be the same as when working with a jigsaw. In addition, with this method of processing the material, there will be a lot of debris and noise.

Choosing the right knife

To cut the foam, you can use an ordinary knife, which you need to sharpen well and preheat. The stationery option is suitable for cutting soft material, it has a sufficiently flexible blade and it is not recommended to use it for processing slabs of significant thickness, since it is difficult to obtain an even vertical cut. The advantages will be a small amount of waste, availability and low cost of the tool. Remember that the thinner the sheet, the smoother the cut will be, the optimal thickness should be no more pain than 5 cm.

The most optimal cutting method

This method can be used if you have an elementary understanding of electrical engineering, for the manufacture of the device you will need to prepare:

- Wire

- Transformer

- Spring.

The table is placed at an angle (20-60˚), and a wire is stretched across, one end of which is fixed rigidly, and a spring is used to secure the other. The wires of the transformer connected to the electrical network are connected to them. The current is supplied, the workpiece is placed on the table. Sheets are cut by sliding under their own weight.

You can pass current from the power transformer of the old TV. Another option is to include a variable resistance (rheostat) in the electrical circuit. The current strength must be controlled so that there is no strong heating, which will result in fused foam and the appearance of sagging along the edges of the mowing line.

The attractive side of this method is the ability to cut fragments both along a straight mowing line and along kinks and convolutions, which makes the process universal

It is important to remember that the wire does not have to be very hot. It will be enough if it just turns slightly red, otherwise the cut will turn out to be too wide

A strong spring should be selected, this will make it possible to adjust the length.

Features of working with large leaves

It is possible to cut the foam slabs with your own hands with the introduction of simple but effective equipment, such as steel wire with a diameter of 0.5 mm and wooden handles fixed at the ends. The pre-block requires scattering on both sides and start quickly getting dusty. The filament heats up and melts the material, resulting in a hard, smooth and melted crust. To determine the best way to cut expanded polystyrene (polystyrene), it is necessary to evaluate all the advantages and disadvantages of the listed methods and choose a tool, based on the features of such cutting.