How to cut the board along smoothly. Ways of cut

How to cut the board along the jigsaw

In most cases, the process of direct and curly sawing materials requires the ultimate accuracy of the tool. This statement is most fair for the electric jigsaw. Thin saws used in this device can easily change the cutting angle, which can negatively affect the accuracy of the line. The clarity of the faces of the product and the evenness of the cut line depends on the operator’s skills, the serviceability of the device and the file. Next, we will tell you how to get the planned contour with perfectly clear faces and what to do if the jigsaw takes aside.

The care of a saw canvas from a pre.Intended line may be due to several reasons. The operator may not get experience in handling the tool, the file can be defective, and the rod and a guide video for the jigsaw can seriously play seriously. In order not to guess on the coffee grounds, it is worth starting to start the factors that determine the accuracy and evenness of the cut line in your, individual case.

As it is started, it is better to start with yourself and your approach to sawing. Often, beginner craftsmen rush events and wanting to speed up the cut, add great pressure on the jigsaw. The tool does not have time to evenly bite into the material and create a clear groove for a file, which begins to follow the path of least resistance and makes unpredictable movements. This problem is especially common when working with a thick beam (from 40 mm) and lacquered plywood of Soviet times.

This is one of the reasons why the jigsaw leads to the side. What to do at the same time? The answer is obvious. Add minimal pressure sufficient to send the tool along the line and set the maximum number of revolutions (when working with a tree). The pendulum mode usually does not affect the evenness of the sawing if its design is good.

The quality of the assembly and wear of the tool details can become a good reason for the formation of mowed lines when sawing. There are no claims to devices from the budget segment (up to 2500 rubles), as well as hopes for their conscientious assembly. Another thing is when such fortels begin to perform original, brand tools. Often, the cause of the crooked saw is a guide video, a rod for an electrician or its sole.

Check the reliability of fixing the element, you can elementarily pulling it with your hand. Steppery of a roller or roller by more than 1 mm, determines that this device is not able to produce a perfectly even cut. The larger the backlash of parts, the less accurate line the cut they form. Correct this problem, should be based on circumstances. If the detail itself is worn out, it can be replaced with a similar. It is difficult to fix the breakdown if the mounting unit is worn to the mechanism. Not every modern Kulibin is taken for such repairs, and usually this problem is solved by the purchase of a new tool.

The products of many proven brands, unfortunately, are often falsified, and jelly for an electrician in this regard are very popular. It so happened that poor.Quality and counterfeit products have a fairly short service life that brings many problems to the owner. One of these problems is the cut curve. Initially, an even canvas can bend due to poor.Quality metal, which can be deformed by the divorce of the teeth if it was at all present. In this regard, if your jigsaw saws crookedly, the situation will be able to correct the situation. The process of choosing a high.Quality saw for an electrician, was disclosed by us in a separate topic.

Which affects the accuracy of the cut

To make the cut even, you need to choose an electrical device suitable for the processed material. We list what you need to take into account.

- Equipment capacity. The higher it is, the less effort is applied during cutting. Vibration is reduced, the risk of bending the file and moving it to the sides decreases.

- Speed or speed. For hard metal, for example, steel, they choose low values, for a soft tree. High.

- Peel length. The wider the workpiece, the longer the blade should be. The discrepancy between these dimensions provokes vibration, peak mode of operation of the device. The seam is often broken. Uneven edges and chips are formed, its width increases.

- The thickness of the blade. Determines its rigidity. The thicker the element, the better it retains perpendicularity relative to the workpiece, the cut quality increases, the risk of “leaving” to the side decreases.

- The width of the file. The wider the part, the easier it is to maintain the direction of the saw. Wide plates are used for sawing in a straight line, narrow are used for curved cuts.

- Step of teeth. Selected for the type of material. For example, a step up to 1 mm is intended for metal, within 2-3 mm-for furniture shields, laminate or parquet board, within 3-6 mm-for rough processing of wood.

The material of the blade can be different. This affects its rigidity, strength and severity of the teeth. Release files with different characteristics for working for metal, wood, ceramics, plastic.

How to protect the saw from damage

Any saw (especially its cutting edge) should not in contact with other tools during storage. From such a neighborhood, she can fail.

If the saw does not have a cover, then a simple way will help protect its teeth from damage. In a piece of the hose, a slot of the desired length is made, after which the hose is planted on the saw blade. A hard hose covered from the inside with a cloth is best for this purpose. It holds tightly on the saw canvas even after repeated use.

If the longitudinal sawing is carried out in large volumes, then it is better to purchase a disk saw. Do it with a hand saw. You get. This is the first, and the second: the information that can be gleaned from the texts in the frame is incomprehensible for a beginner, and for a professional it is useless.

How to cut the board along smoothly

Very often, during various works in construction, there is a need for an operation such as sawing wood on boards. In this review, we will tell you how to organize the workflow depending on the conditions and specifics of a particular operation, since sometimes you need to dissolve only one element in length, and sometimes it is necessary to cut a whole log or timber.

What criteria should be taken into account when choosing a cutting method

All of the options that we will talk about below allow you to cope with the task, but each of them is suitable for certain conditions, so you need to determine in advance to several factors:

| Scope of work | Naturally, if you need to cut one board, then you can use the simplest devices, but if you have to process a certain volume, then you should approach the choice of work method more responsibly, since if you are incorrectly solved, you can spend more time and effort than everything on all Other events |

| Quality | Sometimes this factor is unimportant, but sometimes the reliability of the construction and the attractiveness of the construction depends on how accurately and high.Quality cutting. Therefore, it is important to achieve exactly the result that will be optimal for your object and at the same time spend a minimum of means |

| The nature of the processing | Naturally, sawing logs on the boards will differ from work on loosening boards and will demand the use of completely different equipment. The choice also depends on the thickness of the processed elements |

| Type of wood | It is no secret that different wood of wood has different hardness, and cutting the same pine is much easier than oak or beech, in addition, with an increase in hardness for carrying out the same works, much more power is required. Also, do not forget about the wear of the equipment |

Important! Sometimes the most optimal solution may be the purchase of a finished board, especially if the volume of work is large.

Types of equipment used

We will consider some options for conducting work with our own hands and tell you about the devices used, you have to choose the decision that will be the best for you in a particular situation.

Boil sawing

This type of work as a longitudinal cut of boards in size can be produced in several ways:

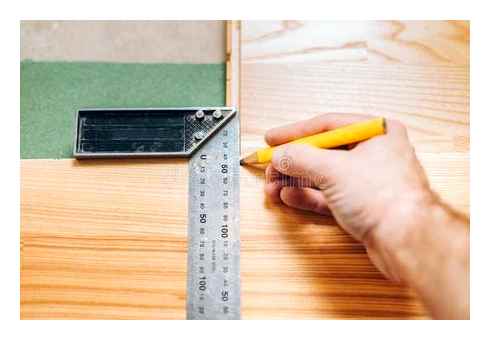

- If the volume of work is small, then you can use a manual hacksaw, though you will need a special option for longitudinal sawing, which differs in the shape of the tooth. The instruction for the work is as follows: it is necessary to carry out a thorough marking using a square and roulette, and then draw a clear line, then the element is carefully fixed so that the board does not move during the work;

Important! With manual processing, pay special attention to the vertical position of the cutting canvas, otherwise the edges will be nervous.

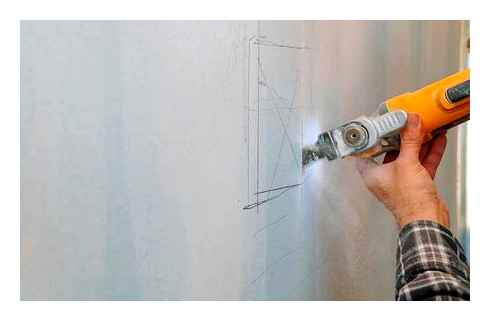

- The second option is the use of an electrician for wood, but it is also suitable for small volumes of work, while the thickness of the board is limited, the marking process is similar to the above. It is easier to work, since it is not necessary to apply physical strength and monitor the vertical of cutting. The sole in the equipment provides compliance with a right angle;

- Now we consider how to sprinkle the board along with the help of a disk saw, two options for carrying out work: if the edges of the element are uneven, then the line is previously drawn along which the cutting is carried out (most often this is done with a non.Cut lumber), if one edge is even, then The emphasis is preliminarily put up at a certain distance, and you simply lead the tool, pressing the stubborn part to the end;

- Of course, the simplest solution to the issue of how to cut the board along is a circular saw, and both full.Fledged installations and compact options can be used. This option is very well suited when cutting a large number of elements to one size, you can put up or attach it and not waste time on marking and fixing, in addition, this type of equipment has the highest performance;

Sloving logs

A more complex option for conducting work for which the equipment needs more powerful. Of course, purchasing a full.Fledged sawmill is not the best, so the logging on boards in the field is made using a chainsaw and a special set Timbergzhig.

- You will need standard chainsaw, it is desirable that its power is quite high;

- It is also necessary to purchase a set consisting of a guide and stop, it is sold with a set of the required fasteners, so no additional elements are required;

- Then the device is assembled for sawing logs onto the boards, for this, an emphasis of two boards is primarily placed, one of which is attached to the middle of the other, a very strong T-shaped element is obtained, which will serve the guide during the work;

- The log is placed on an even base, after which the stops are screwed to its ends, which are made from the boards connected by the corner, it is important to control their level and arrange it smoothly, the quality of the work depends on this;

- Now you need to attach the guide to the stops, it is exhibited along the line of the future cut, while the fact that the tire of the chainsaw will be taken 10 mm above the upper edge of the guide should be taken into account. Fixation is carried out using clamps, which are also included;

- There is a saw on the frame, the frame allows it to occupy the same position in the process of all work. To ensure convenience, we recommend lifting the log after fastening so that the chainsaw is located at an angle, so it will be much more convenient for you to work. The photo shows the design during operation.

Conclusion

Longitudinal wood cutting is a difficult process that requires the use of appropriate equipment and devices, but if everything is done correctly, the result will meet the highest standards. The video in this article will tell you about some of the described processes more expanded and thoroughly.

Cutting boards at home

You can cut off the board at home with such tools and equipment as:

How to work correctly a disc saw

Safety precautions when working with a disc saw. Rules and tricks when working with disk saws. For Up.

A circular saw. How to saw it

- Set minimal depth to cut, adjusting the size of the disk output down.

- Set the parts for size, measuring the length from the edge of the disk to the edge of the sole of the saw. Mark the material.

- Make an initial cut in size 3-5 mm.

- Continue to saw the material without stopping the entire path of the drive of the blade.

- Use sticky tape at the site of cut to avoid chips.

Nirvana. Smells Like Teen Spirit (Official Music Video)

What is a disc saw for

It is intended to carry out the cut of coniferous and deciduous boards with humidity, which is not more than 50% and a thickness of not more than 64 mm. It is allowed to cut plywood, aerated concrete, wood-based, asbestos-cement and cement-brown slabs.

Make two cuts instead of one. The first shallow pass will clean the wood fibers located on the surface, and when the final incision is made, they will not be tightened.

Device and principle of operation of a disc saw

The main details of the manual disk saw include:

- Electric motor. With its help, rotational energy is created, which is needed for the cut of the material.

- Frame. For its manufacture, use plastic resistant to temperatures and impacts. It has ventilation holes.

- Handle with a start button. The latter is equipped with a lock designed to exclude random pressing.

- Platform with a guide (it is also called the sole or supporting plate). Thanks to this element, the tool is moved along the sawing workpiece.

- Shop for fixing shift disks.

- Gearbox. It is designed to reduce the number of revolutions, load on the rotor and bearings of the electric motor.

- Home and additional handles.

The principle of operation of the equipment is to transmit torque from the motor shaft to the cutting disk. The latter is spinning around its axis with high speed, this allows you to easily cut the prepared surface.

Disk saw device

How to cut a plywood sheet evenly?

You can cut it more evenly and plywood not a jigsaw, but a circular saw, but better, on a special sawing machine. They use saws with winning surfaces and saw the material on both sides at the same time- at the same time minimal.

Vizio Smart TV: Factory Reset without Remote Control (Buttons on TV)

Insert the lobby blade into the starting hole. As soon as you level your jigsaw, press it for a few seconds to fix it on the faner. Now you can start cut a circle. All the time try to adhere to the maximum speed of the blade and attach the average pressure when moving.

How to cut a plywood sheet evenly?

You can cut it more evenly and plywood not a jigsaw, but a circular saw, but better, on a special sawing machine. They use saws with winning surfaces and saw the material on both sides at the same time- at the same time minimal.

Обзор ZOOM H1!!!/ Качество звука на ZOOM H1/ Он того стоит???

Insert the lobby blade into the starting hole. As soon as you level your jigsaw, press it for a few seconds to fix it on the faner. Now you can start cut a circle. All the time try to adhere to the maximum speed of the blade and attach the average pressure when moving.

How to dissolve a non.Coded board

The first thing to do is make sure that there is no sand, nails and other extraneous objects in the processed material. For example, a metal brush copes well with sand. There are even special miniature metal detectors to search for hidden nails. But there is a budget option. A magnet on a rope (preferably rare earth from a hard drive). We sway the magnet on the rope above the surface of the wood and in places where the nails fall into the magnetic field, the magnet changes the frequency and the oscillation trajectory. So we discover hidden nails even with a torn hat.

The next stage will require a creative approach. The amount of waste and losses on the material depends on it. For optimal dissolution with a minimum of losses, it is necessary to decide on the strategy of each individual board. The strategy depends on your needs and the board itself. The location and depth of cracks, a review, curvature of the board itself. Determining the strategy, the first drink. To do this, you can use a lace, roulette, ruler, long rail.

Next, we do the first cut. You can dissolve the board with almost any tool capable of sawing wood, if only there was enough thickness of the thickness. You can dissolve a hand.Saw or a hand.Lobsy, on a saw machine, on a ribbon saw and even a chain saw. Not forgetting about security. Here the rule is simple: the more accurately drank, the less waste during further processing. I used the saw machine. A line on which a saw disk should pass on the board.You have to direct the board manually. You need to lead a saw disk along the line as accurately as possible.

The board can be twisted with a screw and during wiring it can “walk” relative to the plane of the table. Because of this, a saw disk can be a wedge, there is a fuse. This is especially true during the dissolution of large blanks made of heavy wood. Therefore, it is desirable that the disk drive is belt, and not a straight line, and when wiring the board, you should not rush. When directing the board to the saw disk, we do not forget about safety precautions. Use pushers when working near the disk, do not work in gloves, push, and not pull the blanks and other rules of safe operation.

After the first saw, we put the longitudinal emphasis and dissolve the board on the lamellas in the usual mode.

Cut the board along the thickness

The tree has found application in a variety of industries. This raw material has always been popular, thanks to its multifunctionality, ease of production and processing. Furniture, interior items and even whole houses make furniture from wood.

Any master faces this material, but, as practice shows, not everyone manages to make a neat cut. After the tools on the cut, chips or zabines often remain, which does not add beauty to your product. So how is it better, cut it with your own hands or order?

Many companies offer to cut your boards when buying, moreover, the price of this service is not too high. In the production of the cuts, the boards make a qualified master on accurate equipment, which allows you to get high.Quality blanks of the desired size and shape.

Of course, you yourself can acquire expensive equipment, but is there any sense if you need to cut several boards. Choose only you, but if you still decide to saw the boards at home, then I will tell you how and what is more convenient to do.

Circular saw. High performance and ease of work

Circular saw is the best option for performing work. It has excellent performance and allows you to cut a considerable number of blanks in a relatively short time, and with high quality. In addition, such a saw allows you to perform a longitudinal cut of the material, but you need to know how to cut the board along exactly.

One of the most important criteria when choosing a circular is the maximum cut depth. There are devices on the market that saw materials with a thickness of 30 to 130 mm. That is, you can choose a machine for cutting only thin boards, and for sawing bars.

It is also worth paying attention to the cutting tool itself. Disks with a large number of teeth will provide a neat high.Quality cut, the speed of cutting will be low.

Stages of work

To cut the workpiece quickly, it is necessary to act in stages:

- Take a board of the right size, determine the tool. If the workpiece has a large size, you should take a hacksaw with large teeth. With a smaller size of wood, take a saw with a smaller size of teeth.

- The necessary marking is applied with a pencil and the ruler. Draw the lines barely visible to the naked gaze. You need to follow in accordance with the well.Known proverb: “Measure seven times, cut one”.

- First make a back. So that the canvas does not wag, experts advise to hold it with the help of a thumb or a special device called the stall. The procedure is greatly facilitated.

- Cut the wood straight, do not wrap the tool with the tool from side to side. If the hacksaw is stuck in the material, carefully free it and try to cut it again.

When performing recommendations, the procedure will pass without problems. There is no need for special skills for implementing. Anyone can cut the material.

Circular saw. High performance and ease of work

Circular saw is the best option for performing work. It has excellent performance and allows you to cut a considerable number of blanks in a relatively short time, and with high quality. In addition, such a saw allows you to perform a longitudinal cut of the material, but you need to know how to cut the board along exactly.

One of the most important criteria when choosing a circular is the maximum cut depth. There are devices on the market that saw materials with a thickness of 30 to 130 mm. That is, you can choose a machine for cutting only thin boards, and for sawing bars.

It is also worth paying attention to the cutting tool itself. Disks with a large number of teeth will provide a neat high.Quality cut, the speed of cutting will be low. But the wheels with a small number of teeth will provide high performance of work, but the quality of the cut will be worse.

Now about how to cut evenly a circular saw. One of the conditions of high.Quality work is a reliable fixation of the workpiece. If the material is weak, then with the cut, the board can “go”, and the cut will be uneven.

If the circular saw is manual, then all the work should be done on a workbench equipped with stops and guides for blanks. Such a device can be made independently, taking as a basis any table.

Before the cutting, it is important to correctly establish the depth of the saw. Some hand saws have an adjustable side guide, with which you can perform a longitudinal sawing of the material. If there is no such device, then use the same workbench.

Convenient in terms of work is a table circular, which is already equipped with everything necessary. Guides, fixators. Often such equipment allows you to make a cut of workpieces at an angle.

In the process of sawing, it is important not to exceed the effort on the tool, otherwise the cut quality will be low, the increased load on the saw will lead to a Rapid blunt of the cutting disk.

Do not forget about safety measures when using such equipment. Work should only be performed after checking the health of the saw and the correctness of fixing the workpiece. Also, do not neglect protective means. Masks, glasses.

Wood balance during sawing

| The diameter of logs | Volumetric yield of sawdust,% | General Volumetric output,% | Volumetric output boards,% | Volumetric output Shpal,% |

| 61.3 | 12.Nine | 6.3 | 74.Eight | thirteen.7 |

| 55.3 | thirteen.One | 5.2 | 75.7 | 20.4 |

Cock the boards

Circular saw, is one of the basic tools for processing wood. The main operations that are done on the circular of three: dissolve the boards on the blanks along the width, saw off in length (ending) and sawing at an angle. The last method is used if the circular saw is adjustable not only in height, but also in the installation corner. There is another necessary, although intermediate operation, sawing the board in thickness. For example, you have a plowing plate 70 mm thick. And it must be dissolved into three boards with a thickness of 18-20 mm. Or what I have to do most often, 45-50 mm thick boards I dissolve it on planks with a thickness of 18-20 mm which I use in the manufacture of furniture.

What is required for this:

Firstly, it is very desirable that the circular is with a variable saw height. It can be difficult to immediately saw such a material as beech, oak, birch. Therefore, sometimes you have to do this in two to three passes, gradually increasing the height of the drink.

Secondly, you can work in this way only with a strict board. If the workpiece is even even, then it is enough to pass the plate and edges of the board on Fuganka once at a fuganka.

The third, which is also necessary to pay attention to, the board should not be too short. If the saw closes and the board plays, you can stay without fingers. This is not a joke, I know such cases.

We dissolve the boards to thin strips.

Here a strict block is 50 mm thick Blows into three rails with a thickness of 12 mm When calculating, do not forget to take into account the width, that is, the thickness of the saw along the extreme points of the divorce. Also, pay attention to, after sawing the finished strings will have to be put on Fuganka, or even better on the flight machine. Therefore, we need a supply in thickness at least a couple of millimeters.

In this case, approximately the same calculation is obtained: we set the saw for 14 mm. From the guide line, only three strips will be obtained 141414 = 42 mm Plus, two widths drank two widths, here is a sawdust of a saw 3.5 mm That is, all sizes are at the limit, so you need to work carefully.

Board width 120 mm But these sizes belong to this workpiece precisely. We will cut on both sides on the edges. To cut the board in two passes, the height of the saw should be slightly more than half of the width of the board. In this case, the height of the saw from the table of the circular 65 mm

Another point that guides the ruler should be sufficient height, for example 70-80 mm so that the board does not fall during the sawing.

We gently pass the first drank, while your hands should always be higher than the saw. Never push the part under the saw from the end of the hands, use wooden pushes.

Then we turn the board in a vertical plane and pass the oncoming cut. The first bar is 14 mm thick. Ready.

Then we put the rest of the boards with the side to the guide line and pass the next cut. We turn the workpiece again and sing along the depth from the back.

Don’t relax for a second when working, listen to the sound of a saw. If it starts to wedge, reduce the feed speed. When cutting at the output, the board may close. If the saw is not acute enough, or the divorce is small, then the material will burn. Когда горит это не очень хорошо, пила перегревается и её может вести, да и запах крайне неприятный. Subject on the topic how to saw plywood.

Therefore, I wrote at the beginning of the article, if the material is difficult, then it makes sense to pass the part twice in height from each side. And never forget, circular saw a dangerous tool. Therefore, use all protective and clamping devices that are available.

Drinking discs

For disk saws with manual control, sawing discs of several types are produced, each of which is designed to work with certain materials or for use for certain purposes. First of all, discs differ in quantity, shape and size of the teeth.

Disks with a small number of most often carbide teeth are used to cut thick blanks made of hard and soft varieties of wood. The main drawback of such discs; They leave rude edges.

Pure sections

The more teeth the disk, the cleaner it cuts. For sawing materials requiring delicate circulation-for example, thin plywood, fibers or veneer sheets-use wheels with 60-112 teeth. The shape of the teeth is also of great importance, behind which the names have already been fixed. “large tooth”, “Swedish tooth”, “wolf” or “acute.Angled tooth”. A special shape of the teeth allows you to either saw at high speed while removing sawdust from the cut, or get a very thin cut. In the latter case, the speed of rotation of the disk should not be too high. Such a valuable improvement also deserves attention, as a veteflon coating that protects the disk from jamming in wood.

Standard equipment

It is enough for the home master to have two sawing disks: one with large carbide teeth, the other with small teeth and Teflon coating. A small.Toothed precision disk can be useful to those who work with a variety of materials. Such discs cut not only wood, but also plastics reinforced with fiberglass and even non.Ferrous metals. True, the cost of the disks is quite high.

Any modern disk saw is equipped with a device that allows you to regulate the depth of cutting. When preparing the tool for work, it is very important to ensure that the position of the disk corresponds to the thickness of the part. Follow the rule: the cutting depth should exceed the thickness of the material by half the height of the tooth.

The guide ledge

Almost all disk saws with manual control on the front edge of the plate of the platform have a plate with the protruding end (in some machines the plate replaces the incision), which helps to lead the saw in a given direction.

If the end of the protrusion (or incision) coincides with the marking line, then the part will be cut correctly.

The owner of the old disk saw is not easy to conduct an instrument. In old models, there is no dusting device, and therefore they drive the clubs of wood dust right in front of the guide protrusion. You have to constantly blow it. When working with the latest disc saws, visibility always remains good, even if the machine is not equipped with a dust quirrel or vacuum cleaner.

Help in orientation

Nevertheless, the guide ledge only helps to control the movement of the disc saw, that is, the very presence of the protrusion does not serve as a guarantee of obtaining a neat cut: despite all the efforts of the master, the saw may go aside. Therefore, you can rely solely on a ledge only in cases where the accuracy of the movement of the saw does not matter.

The protrusion (or incision) on the front edge of the platform of the disc saw helps to lead it in a given direction.

Protection from chips

Many people believe that the facing coating of wood and combustion plates can be protected from chips when sawing, if you first apply adhesive tape on the marking line. This really helps, but only partly, which is confirmed by the photo below.

Chips on the facing coating are formed even with a careful supply of a saw, although not to the same extent as without a protective tape.

A neat cut line turns out if the part is put with the front side down, since chips are formed only when the teeth release of the saw from the material.

How Modern Shoes Harm Your Health and Performance

Adhesive tape on a stove with lining from layered plastic does not fully protect the coating from chips when sawing.

A flaw out of the cut will turn out if the part is laid down the side.

How to do something yourself, with your own hands-a site of a home master

And a little magic

When all verification operations are completed, time to start the project itself. Having rummaged in my lumber supplies, I found a piece of wood with a fascinating pattern of fibers, which, I thought, would look amazing in the form of panels 6 mm wide on the cabinet doors for storing jewelry. I set the guide at a distance of 8 mm from the saw canvas (6 mm plus 1.5 mm for the next grinding) and started dissolution. I chose the speed of submission, taking into account the density of the workpiece (it was an ambroine tree) and its width (approximately 18 cm). Checking the first sawed piece showed that the installations of the saw were correct-and I sawed off the 2nd piece. The ultimately resulting a couple of facial panels (photo from the bottom) is a good example of how beautiful boards can be beautiful.

After gluing the veneer to the substrate, the front side must be sanded. Multi.Layer plywood or MDF sheet is completely suitable for a substrate, since they are actually not subject to expansion and compression when humidity changes.

These freshly-saw parts still had to adapt to the level of humidity in the workshop, because I put them in a stack, laying them with rails, for a day or two, so that they would not be crumpled (photo above the left). After which I glued them and rebuilt to the final thickness of 6 mm.

If I needed to get a veneer from the workpiece, my deeds would differ in the most insignificant way. I would regulate 3 mm wide guiding sheets for sawing, and before each new cut, I would take a pipe or polish the workpiece. Such a technique allows you to get one smooth and even side on each veneer sheet, applicable for gluing. You see, but you thought that the strip saw is suitable only to cut out the crooked lines!

Tool for home and garden, needlework, etc. The are very low

Take a canvas with a more brutal cut. A blade with 3 teeth per inch and large hollows between them removes sawdust better, which can cause bending and twisting the cutting canvas. Keep the workpiece tightly pressed to the guide and to the table. A special pusher conveys the desired tightness to the guide and allows the hands to be at the non.Hazardous distance from the canvas when it was dissolved.

After the strip saw is perfectly configured, you need to pay increased attention of the saw tape. The sawing of wide boards asks for a canvas, which moderately passes throughout the thickness of the workpiece, removing a huge number of sawdust during all this. The more extensive the blade, the more it drank, so try to use the widest canvases that are suitable for your saw.

Install the square at a distance of 6 mm from the saw canvas (to put it, it may come in handy lift the protective casing) and press your finger to the middle of the blade. From the average pressure of pressure, the blade should touch the square. In this photo, the saw canvas is very much shifted back on the upper drive wheel: therefore, the cut deviates to the guide. If the canvas is very very shifted to the front edge of the wheel, this leads to the opposite result.

Most of the strip saws work little with 12 mm canvases, and many with even more wide. Usually, an extensive canvas with 3 teeth per inch length (3 TPI) offers an impeccable combination of brutal, but smooth sawing with active removes of sawdust, which is required when the tree was allowed. In the end, we will talk about the guides. The cutting for the saw should exceed the height of the guide less than half. So, for example, a 100-mm guide is suitable for racing boards with a width of 200 mm. If you need a lot of height, use home.Made additional guides.