How to cut the corners of a ceiling plinth at home

How to make a corner on a skirting board. How to make an even corner on a ceiling plinth without special tools with your own hands.

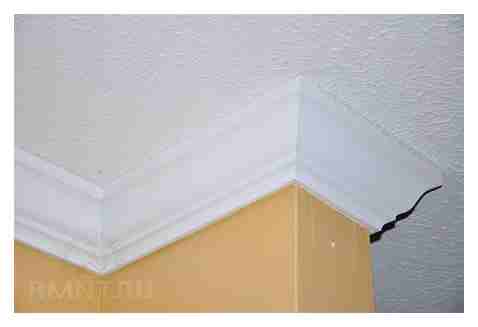

The ceiling plinth allows not only to give the decorative finish an aesthetic appearance, but also perfectly hides the uneven border between the ceiling and the wall.

The process of its installation is quite simple and may well be done by hand. Difficulties most often arise only when cutting corners. Usually the corners on the ceiling plinth are cut using a special miter box fixture.

But what if he is not there?

You should not rush to buy a miter box. An even angle can be made with your own hands and without special devices. How? Consider below.

We will make the markings for cutting the inner corner of the ceiling plinth on the ceiling using a regular pencil.

To do this, apply the plinth to the corner, pushing it against the wall. Using a pencil, draw a line along the plinth directly on the ceiling.

Then we put the plinth on the opposite side and draw a line with a pencil in the same way.

As a result, there are two mowing lines on the ceiling that intersect. It is at the intersection that the plinths of the ceiling plinth should converge.

This is the top point of the future cut.

Now you need to transfer the markings to the ceiling plinth.

To do this, again apply the ceiling plinth to the corner and use a pencil to mark the upper cut point on its outer edge. On the inside. mark directly in the corner.

We also perform the action from the opposite side.

After the markings are applied to the ceiling plinth, we start cutting the corner using a clerical knife.

We put the ceiling plinth on a hard surface, and focusing on the marks, we cut.

The cut skirting board is applied to the corner to control the cut quality. If the unevenness of the joint is noticeable, we correct them with a knife, after which, you can proceed to further installation.

So, without using special devices, you can make an even corner with your own hands.

Marking on the wall

This method is useful when there is no protractor. You only need a pencil for marking.

- bring one panel to the corner, draw a line with a pencil on the upper border of the plinth on the ceiling;

- make the same markings for the second plinth;

- the corner on the wall and the intersection of the lines on the ceiling are guidelines for cutting. To mark the cutting line, you need to attach the plinth to the wall and connect the resulting points.

After that, the curbs can be cut.

How to join a ceiling plinth. Trimming skirting boards without miter box

In some situations, you have to dock the skirting board without a miter box. For example, if it is not at hand, or the walls are crooked. Therefore, it is advisable to know how to join the corners of the ceiling plinth using other tools.

There are several ways to do manual docking:

- using a protractor;

- by making markings on the wall;

- by drawing a miter box.

An important point. in addition to the fact that the planks need to be marked, when cutting, they must be kept in the same position as they will be on the wall. Otherwise, the cut will turn out to be a curve. Usually, a 90 degree template is made for this.

It’s easy to make it:

- screw a regular bar to any surface. it will serve as an emphasis for joined baguettes;

- if there is no bar, draw a flat line on the plane, and use a square as a limiter.

It should be noted that the miter box does not always help. Therefore, you need to know how to manually join the skirting board.

Docking with a protractor

In general, a goniometer should be included in the arsenal of any finisher. in our apartments, angles are rarely 90 degrees. When using this tool, docking a ceiling plinth consists of the following steps:

Installing Gyprock plasterboard. How to cut and install Gyprock cornice

- the angle is measured with a protractor;

- the value obtained is transferred to both plinths of the ceiling plinth. It is important to align the planks in the same way they will be glued to the wall;

- after marking, the plinths are cut with a hacksaw or a knife, while you do not need to rush so as not to overwhelm the knife blade. then there will be cracks when joining.

If everything is done carefully, the corners will turn out beautiful.

It is convenient to measure the angle with a protractor

Different materials and their features

- . The most durable material in comparison with the other two, listed below, the advantages of which are in hardness, impact resistance and the ability to withstand certain mechanical loads. Nevertheless, wooden skirting boards (also called fillets) glued to the ceiling are also relatively easy to process. they can be cut (a hacksaw is used for this), varnished. Wood will add warmth to the interior. Of the minuses, you can name a higher cost than foam. However, wooden fillets also retain their appearance longer than foam fillets.

Styrofoam. Perhaps this material is the most fragile. it is unstable to mechanical damage, scratches and even minor impacts. Of the advantages. light weight, the ability to paint in various colors and ease of processing (it can be cut with a clerical knife. however, very carefully).

Expanded polystyrene. This material can be considered a type of foam, however, its strength characteristics are slightly higher (extruded polystyrene foam is denser than foam). With regard to processing. expanded polystyrene is just as easy to cut with an ordinary sharp knife, and also has a low weight, and this is an important factor when considering the load on the walls.

How to cut the corner of a baguette correctly. Using a laser level

In modern conditions, many home craftsmen already have in their instrumental “arsenal”, which are excellent for checking the straightness of the angle, and marking the baguette when forming both internal and external corners.

How this is done is described step by step in the following instruction table.

| First, you need to accurately position the laser level itself. For this, the same distance, for example, 500 mm, is laid from the corner along the lines of the floor and wall joint. The marked points are connected by a diagonal line. After that, they find and outline its middle. The laser level is installed on the floor, turned on, and then placed so that the vertical plane specified by it (its projection in the form of a line) passes through the middle marked on the diagonal and coincides with the corner of the room. The beam should pass vertically along the mowing line of the corner. this will at the same time show how evenly the corner of the room is formed. In fact, a plane is set that cuts the corner of the room exactly in the center. It is in this plane that the joint of the skirting boards should be located. |

|

| In this case, the level should be located so that the projection of this plane is also displayed on the ceiling. You can fix the resulting bisecting line with pencil marks. But even better. do not remove the device, since it will help to more accurately display the desired cutting line and on the plinth attached to the place of future fastening. Probably, it is clear that the next step is to install one baguette at the installation site. The plank must be resting with the end side against the wall. The beam from the laser builder, passing along the surface of the plinth, and even along all its embossed protrusions, will accurately show the cut line. |

|

| After that, along the mowing line of the beam, with the help of a pencil or a thin marker, the cutting line is outlined. | |

| Using a knife, a corner is cut along the intended mowing line. in this case it is impossible to make a mistake. Then, in the same way, the mowing line of the cut is marked and the second plinth is cut. |

|

| Now that both parts for forming the corner are ready, they need to be connected to each other at the place of future fixing. If the joint is neat, then you can mount the baguette with glue. If a small gap has formed between the planks, then the ends of the plinth must be corrected with a knife. |

|

| When installing the ceiling plinth, the strips that form the corner are first glued, and the flat trims are fixed last. | |

| If, when carrying out the approximate alignment of the corner side of the baguette, its other end will find on the already fixed segment of the plinth, you should immediately mark the required length in order to cut off its excess. In this case, the straight edge is trimmed just at right angles. |

|

| To correctly cut the baguette for the outer corner, it is also necessary to start marking from the floor using a laser level. There is a slight difference in the primary build here. At first, mowing lines are simply drawn along the ruler, which are a continuation of the walls. Then an equal distance is laid on them from the corner, these points are connected by a diagonal, on which the center is determined. The beam is directed through this mark to the protruding angle, also with the projection of this plane on the surface of the ceiling. |

|

| Further, segments of the baguette are alternately applied to the wall and the protruding corner so that the beam passes through them. Marking is carried out along the mowing line of the projection, and then the end part of the skirting board is cut. After that, it is necessary to try on both segments at the installation site, aligning the sections. If necessary, the ends of the strips are adjusted. If everything is fine, proceed to fixing the fillets on the surface. |

Internal elements

How to neatly cut the innermost corner that is on the skirting board? After completing the markup, work according to the following algorithm:

- Place the bar in the bottom of the miter box so as to repeat the position on the surface.

- Press the plinth against the far wall of the miter box.

- Holding the product, clamp it with your free hand.

- Place the hacksaw at a 45 ° angle into the recess and cut.

- Trim an adjacent element in a similar manner.

On a note! The inner corner made of PVC or expanded polystyrene can be processed with a stationery knife or a hacksaw for metal.

Outside corner cutting

In the case of external corners, the cutting technology will look like this:

- For greater accuracy, it will be better to start with the inner corners, and only then proceed to the outer corners. If this is not done, then the length of the plinth in the end may simply not be enough.

- The part is applied to the ceiling, and marks are made on it in the right places. Then the plinth is placed in the miter box, held with the left hand near the near wall and cut off at the desired angle using a hacksaw.

- The opposite plank is laid near the near wall of the miter box, but is already held by the right hand. The hacksaw is at a 45-degree angle and the workpiece can be cut off. Finished planks need to be docked with each other to make sure that the cut is correct.

Cutting skirting boards with a miter box is only suitable if the walls and ceiling are at right angles to each other. If there are any irregularities, it would be better to use another method.

Polyurethane

Polyurethane skirting boards are the most expensive products. The high cost is due to a large number of advantages, among which are excellent resistance to moisture, high mechanical strength, reliability and elasticity. For most situations, this option will be optimal.

However, there are exceptions. polyurethane does not withstand temperature extremes. If you place such skirting boards in the kitchen near the stove, then over time, the polyurethane will deform and crack. Cutting of such fillets is performed with a special knife, and no complications arise in the process of work.

Expanded polystyrene

By and large, expanded polystyrene is a type of polystyrene that has an increased margin of safety. The cost of products from extruded polystyrene foam is slightly higher compared to foam, but the reliability of such skirting boards is much higher. It is already problematic to break such a detail.

Cutting styrofoam skirting boards requires any sharp tool, such as a construction knife or a hacksaw. Due to their high strength, it is much easier to work with such products. they practically do not break or deform during operation. There will be less waste in the end.

Finished corner pieces

Unfortunately, this method is not relevant in all situations. The dimensions of the corners produced at the factory are adjusted to certain standards. but the skirting boards themselves do not always meet the standards. Of course, such details can be combined, but the result will look unaesthetic. If corners of a suitable size are not on sale, then you will still have to cut the baseboards yourself.

Inner corner cutting

The inner corner cutting technology is as follows:

- The first step is to attach the baseboard to the ceiling. The required length is set on the plinth.

- The skirting board is inserted into the miter box in the same way as it will subsequently be located on the ceiling. The part is pressed against the far wall of the miter box and held in a stationary position.

- The hacksaw is positioned in the slots that mark the 45-degree angle. The workpiece laid in the miter box can be cut, and the effort required for this is minimal. you should not press too hard on the hacksaw.

- Now you need to cut off the opposite plank. The operation itself will be carried out in the same way, only the plinth must be placed not at the near wall of the miter box, but at the far one, so that the corners can be joined in the future.

- The cut skirting boards must be joined together to make sure the cut is correct. When cutting internal corners, it is recommended to start work from the outside of the product. After work, it is advisable to slightly adjust the cuts with a file in order to improve the quality of the joint.

Styrofoam

Styrofoam fillets are one of the cheapest options. However, the advantage in the form of low cost is offset by a large number of disadvantages. In particular, the foam itself is a rather brittle and soft material that is very easy to break. Even if you just squeeze such a product in your hand, it can deform.

Due to the low strength, it is very difficult to process foam skirting boards. If there is little experience in cutting such parts, then most of them in the process of work will become unusable, so all the benefits from the cheapness of the skirting boards will be leveled. A hacksaw or a well-sharpened knife is usually used to cut foam fillets.

Cutting skirting boards for ceilings without miter box

You also need to figure out how to glue the ceiling plinth without a miter box. this tool is far from always available. One of these methods involves marking the skirting boards on the ceiling. Perhaps the only drawback of this method is the fact that it is not very convenient to keep the bar motionless while applying the markings. Otherwise, the method is quite reliable. the measurement accuracy is higher, since when the plinth is applied to the place, all errors become noticeable.

Another method is associated with corner trimming of the plinth. The edges of the two joining workpieces are cut at right angles. One of the planks is applied directly to the corner, after which a fishing line is applied to the ceiling along the contour of the plinth. The same operation is repeated with the opposite skirting board.

The point at which two separate mowing lines intersect is the point where the skirting board will need to be cut. The workpieces are again applied to their places in turn, the cut mowing line is marked on them. A straight line is drawn from the mark to the opposite edge of the part. The skirting boards are cut in accordance with the markings applied to them and are joined in place. This method is an excellent answer to the question of how to connect the corners of the ceiling plinth without a miter box, especially when it comes to internal corners.

Features of cutting different materials

The following materials are used for the manufacture of ceiling plinths:

- Styrofoam;

- Wood;

- Expanded polystyrene;

- Polyurethane.

Each option has a number of characteristics, so they need to be considered separately.

How to cut a ceiling plinth

Every summer resident or owner of his own home should know how to cut the corners of the ceiling plinth, and do it at home without the involvement of builders. In our time, repairs are expensive. Therefore, many try to do as much as possible on their own. Indeed, in fact, if you make an effort, have patience and the necessary materials, you can do as well as construction foremen. And in order to make a beautiful ceiling, you need to know how to create a beautiful plasterboard vault, both for the kitchen and for the hall.

Cutting skirting boards for the ceiling

Many people think that cutting a ceiling galtel does not involve any difficulties, and in general what is the problem? In fact, there are many features that have negative consequences. Therefore, in order for the ceiling to be perfect, you should know how to cut the skirting boards correctly and accurately by making high-quality wall decor of your own production.

Beautiful ceiling with skirting boards

7 Common LED Strip FAILS and How To Avoid Them

Polyurethane

Nowadays, polyurethane baguettes are the most optimal in terms of value for money. Although its cost is considerable, but in comparison with gypsum, this material wins significantly. Advantages: lightness, no cracks, excellent adhesion, nice texture, the possibility of factory staining, the ability to create an imitation of various natural materials, as in the photo below. In addition, installation does not require much effort. To cut it, you should use a special knife that will not form crumbs.

Polyurethane ceiling skirting boards

Extruded

This type of skirting board is also called stretched. Because the cross-sectional drawing in any part of the segment will be the same. The entire pattern is identical and consists of bumps or grooves that run along. The selection of the picture does not threaten you, but in the case of filling the cracks, it will take a little more effort.

Extruded skirting board

Injection

This type of skirting board requires the most attention and effort for installation. Here the drawing has a periodicity, but the scrupulousness of trimming should be at its best. In this case, the putty will not hide the sides, because the effect of artistic modeling will be created. In terms of aesthetics, this type of material is really chic.

Injection skirting board

Cutting fillet without miter box

If you don’t have a miter box or the corners of the room want to stay the best, then the next option is perfect. Cutting the ceiling plinth should be done step by step.

Features of trimming the ceiling plinth

Next, let’s talk about how to cut the corners of the ceiling plinth at home and at the same time maintain the beauty and accuracy of the appearance. There are two ways to perform this task. with a miter box and without it.

Ceiling markings

By basing the ceiling, you are guaranteed to cut the excess correctly and to the exact size. You just have to work hard, because keeping the fillet on weight and at the same time making a basting is rather inconvenient. But this method is the most accurate and practical.

Attaching the baguette to the ceiling in the right place, you will immediately notice all the features. This will allow you to immediately outline them and take them into account when trimming and editing.

Basting the ceiling

All About Cutting Ceiling Plinth Corners

In a workshop engaged in woodworking or repairing metal parts, this operation is not difficult. The bar is placed on the machine, fixed in the desired position, then the excess is removed with a circular saw. The machine has a device that allows you to rotate the baguette at a given degree and measure the required distance from each side. It is much more difficult to work without precision instruments. After marking, you need to hold the blade in the correct position. Making a diagonal cut is much more difficult than making a straight cut. Such operations should not be performed on the eye. Everything needs to be measured carefully. There are several ways to simplify the task and avoid mistakes. First, you need to choose the right tool and understand what scheme to follow.

How to trim ceiling plinths in corners using a miter box

In the middle of the workpiece, a square is drawn and grooves are made along it in the sidewalls to the very bottom. Placing the saw in the farthest furrows will give us the 45 degrees we need. The sides should not bend or wobble when cutting, otherwise the blade will get stuck in them, and the cut will turn out to be uneven. You can only work with products made of solid materials that keep their shape well. You need to make sure that the product is absolutely reliable, and its sides will not fall off at the most crucial moment. Handling a sharp object can cause injury.

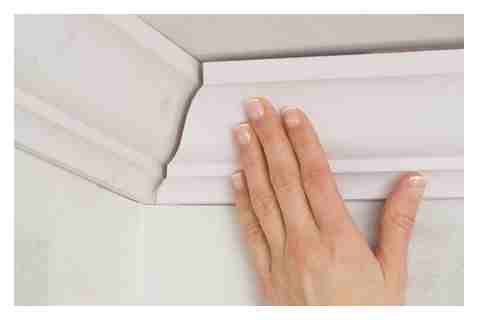

Inner joint

Before gluing the ceiling plinth and cutting the corner, it is applied to the installation site. This is necessary not only in order to check how even the base is. This makes it easier to understand in what position the part will be located, and to properly lay it in the miter box. Let’s imagine that its bottom is a ceiling. Let’s place a rail in it. We turn the tool towards us with the open side, from which the main part of the baguette, intended for installation, looks out. Now press the baguette with its perpendicular back faces to the bottom and left wall. Insert the saw into the holes so that its handle is on the left and closer to us. When working, do not press on the handle, otherwise dents will remain on the edges. The blade should be moved smoothly, trying to avoid burrs and chips.

If the holes in the sidewalls are too wide, you have to pay attention to the distortion of the saw. When making a miter box, it is advisable to take into account the thickness of the blade. The product should be easy and free to cut. A gap with walls is necessary, but it is better to keep it to a minimum. this will simplify the task and help avoid mistakes.

One of the most crucial moments is the final stage, when the cut has almost reached the end. The hanging part of the workpiece must be fixed in the hand. Plastic and Styrofoam often buckle under their own weight, creating dents. Wood can crack along the grain. As a rule, the bottom of the front part suffers. Dents cannot be fixed. The array will be easy to glue, returning the piece that has come off to its place. It will need to be cut and secured to where it came off. You can use PVA glue, “Moment”, any other composition. The chip is firmly pressed against the smeared surface. Excess glue is gently removed with a rag or napkin.

The second bar is a mirror image of the first one, so we apply it to the right side of the miter box. The rest of the technology does not differ from the manufacture of the first bar. It is cut at the same angle, but from a different sidewall.

External joint

In this case, the parts are also fixed. To cut the lath pressed against the left sidewall, insert the saw from the right.

In the case when the rail is an integral part of the external and internal joint, the internal joint is first drawn up. Then the rail is applied to the installation site to make markings for the external one. Doing it right away is very risky. You can cut off the excess, and then the length of the prefabricated element will not be enough. There will be a noticeable gap. It is easier and faster to perform actions in the correct sequence. Step-by-step instructions on how to cut the corner of the ceiling plinth with your own hands, see the video.

How to calculate the line connecting parts on their sides

On the back upper side of the plinth, a distance equal to its width is laid. It is measured from the edge and a line is drawn parallel to the end. On the upper face, it forms a square with it, on the side, if its dimensions differ, an elongated figure.

When finishing a column or a free opening, the markings are applied as follows: from the corner of the bar facing the room, a hypotenuse is drawn from above, dividing the square in half. Its projection is transferred to the face facing the wall. For this, the space measured on the edge is also divided in half diagonally, drawing a line from the hypotenuse. The extra piece is cut along the two resulting diagonals.

If the joint is facing inward, the diagonals are drawn in the opposite direction.

Methods for joining factory products

- Use of ready-made corner pieces that are glued to the inner and outer sides. They produce wide and narrow baguettes. They differ in material, shape and color, but it is not always possible to choose them for the interior.

- Internal connectors for the ceiling. ordinary strips are glued to them. These connectors fill the interior space formed by the straight ends of the rails at 90 degrees to each other.

- Docking couplings. the baguette is inserted inside the docking decorative boxes.

The size and shape of the parts must match the basic set of profiles.

Choosing a tool for cutting different materials

- Fillets made of expanded polystyrene. despite their softness and low strength, it is difficult to work with them. They crumple, crumble, bend. To fix them, you need to make a certain effort, but dents remain on the foam, even after light pressure. You can get a straight line only with a very sharp blade. It does not put pressure on the edging and easily passes through the soft porous structure. As a rule, use a carpenter’s or kitchen knife, or a hacksaw with fine teeth.

- Polyurethane and plastic products. they are much stronger and denser than foam. The surface is more difficult to crush. A special tool is used for cutting. the saw will crumble the butt, and it will take too long to work with an ordinary blade. If there is no such device, a long sharp kitchen knife or a saw with fine teeth will do.

- Wooden baguette. the butt can be cut with a wood saw. Hardwoods such as oak are easier to cut with a metal hacksaw.