How to cut the doordoorways. The conditions for providing a guarantee

How to cut the door.Doorways

Having set the platform correctly on the door, the entire design of the room changes, ennobles.

Tools and materials

Of course, before starting the installation of door platbands, you must prepare all the necessary tools and materials without fail. So, for work you need to purchase:

Doors installation tools.

- Bocores;

- Drill or screwdriver;

- Screwdriver;

- A hammer;

- Self.Tapping screws;

- Finish nails;

- Liquid Nails;

- Wood drill;

- Pencil;

- Wooden platbands on latches.

It is this set that is enough to perform one of the proposed mounts. Of course, in each case you should take a closer look at those things that are necessary.

Necessary tools

To properly and carefully carry out this procedure, you will need:

See also: Lighthouses for bulk floors: types of lighthouses and floor filling technology using lighthouses of reperture made by yourself

- Flow. Do not know how to cut the platband at an angle of 45 degrees. With its help. It helps cut the product at the right angle. Can be wooden, plastic, metal. Outwardly resembles a box.

- Hacksaw. For metal, plastic, a hacksaw for metal is suitable, for wood. Only on wood. You need to correctly sharpen it so that the cut turns out to be even.

- Nails/liquid nails.

If you can’t use a knock, then you can do with improvised materials: pencil, ruler, cardboard, hacksaw.

Installation procedure

When installing door platbands, you can use different methods of connecting the strips: at right angles and diagonally (at an angle of 45º). In the first case, it is enough evenly cut the edges of the upper bar, measuring the desired length. An ordinary school transporter or construction square will help to make a flat right angle. In this way, you can arrange strips with a flat surface.

If the platel of the platband has a pronounced relief or rounded faces, the connection of parts can only be diagonally produced. This is a classic but more complex way. To obtain a beautiful diagonal joint, it is best to use a knock. A template for the same angles.

If there is no such tool at hand, you will have to use the transport again. Very carefully and carefully, it is necessary to measure the angle of 45º on the end of the plank, draw the cut line with a pencil and sawn off the excess. The sharp (upper) corner of the bar must be placed on the outer edge of the board, and closer to the door should be a stupid angle. On the same principle, arrange another side profile.

When performing a cut on a laminated or veneered bar for interior doors, burrs inevitably appear, significantly reducing the quality of work. To perform the cut of such a product easily and without loss of appearance, you need to stick a strip of painting tape along the alleged cut line. After that, the angles are measured, the label and saw. Removing adhesive tape, the master will receive an even cut with very neat edges.

Fastening for finish nails

After cutting the parts, the platforms on the door can be installed: you need to attach the strips to the door box. When using finish nails, you need to drill a number of holes along the inner edge of the decorative bar. The step of the holes is usually 5-7 cm.

Apply the bar to the door frame from the canopies so that it closes the joint of the wall and boxes. You need to drive out nails carefully, trying not to get a hammer with a hammer: on some surfaces, the tool can leave a noticeable mark. You should not make fasteners on the very hat. The sticking parts of each clove must be cut with side cutters. The wax pencil will help to completely disguise the fasteners. The bar on the other side is mounted in the same way.

Cutting an accordion door in the field

Prepare and install the upper part according to this scheme:

- Mark and cut off the angle at one end;

- Try on the detail, determining its horizontal and coincidence with the side of the sidewall;

- Eliminate defects by making a new cut;

- To measure the desired length of the profile along the upper border;

- Output and cut off the corner on the other side as accurately as possible.

If the master has to engage in the installation of platbands for the first time, then errors can happen even with very accurate work. Too noticeable gaps can be hidden by wax paste.

How to install a platband without nails?

If the door frame has a smooth surface, then installing the platbands of interior doors can be made on glue. There are special fixing compounds, bearing the common name “liquid nails”. They make the installation of any decorative elements simple and quite reliable.

To fasten the planks, you need to apply a strip of glue to the back of the prepared part. Attach it to the door frame and press hard. Having withstand the time indicated in the instructions for liquid nails, leave the bar to dry for complete grasp (usually 24 hours). On the same principle, install another sidewall and the top of the platband.

This method is convenient for MDF profiles and plastic, which have even surfaces. But the choice of elements must be made with special care, since it will be difficult to glue the curved details.

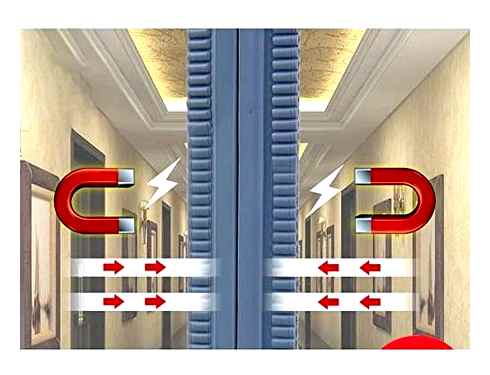

Another option for fastening without nails is the installation of telescopic platbands. These are modern models, which are usually supplied with a door leaf and frame. In this case, the aircraft element of the door box has a special groove into which the protruding part of the platband can be driven.

The convenience of such fastening is that additional materials are not required for fixing. The details are adjusted very accurately, and the home master can only prepare the edges for the docking. After that, the spike on the side of the bar is placed in the groove of the input and pressed the platband to the wall.

Whatever the installation method of the platband is chosen, the most important step is the fitting of the joined edges. If this operation managed to cope well, then the fixation of the decor with nails or glue will not cause difficulties.

How to install door platbands

To install wooden platbands, you will need:

- At first, the platbands are applied in height of the door, and the required length is measured. Then the bar is placed on a flat surface and a right angle is noted using a square. Excess is cut off;

Zoom H1N VS Zoom H1. Audio Recorder Comparison

- The platband with the finished angle is applied to the door box, is aligned at the edges and down. The height is noted corresponding to the inner hum of the door frame;

- Then, starting from the mark made, with the help of an angler, an angle of exactly 45 degrees is measured and marked with a pencil. The excess is cut off and the platband is temporarily deposited to the side;

- After both lateral platbands are cut, their installation begins. Cloves are driven into the doorbox, after which they, with the help of nippers, remove the hat, leaving a sharp corner. The length of the clove on the surface for installing the platband is left approximately 5 mm;

- Nails are clogged with a distance of about 50 cm. Usually they are located at the top, below and two in the middle;

- For better adhesion of the platband with the box, glue is applied to it. At this stage, the main thing is not to overdo it, and when pressed, the glue should not be squeezed out;

- Nitting the bar to the door frame, it is not recommended to beat right on it. For this purpose, a wooden block wrapped in a cloth is prepared;

- By applying the finished platband and leaving it, we plant it on nails with strong blows through the bar;

- When both side platbands are installed, the marking of the upper. Both of his angles at 45 degrees are measured not by an angle, but directly applying it over the side planks and drawing a cut place with a pencil.

Installation of door platbands completed.

Types of platbands and tools for their installation

To frame doors, you can use different types of platbands that differ both in terms of manufacturing and in their form. Material for platbands most often serves wood (whole or fraught) or plastic. Steel or aluminum platbands are produced, as well as from plywood or laminate.

The shape of the platbands can be flat, rounded and curly. Flat. The simplest and most democratic, they will not be striking in any interior. Rounded are different from flat in that they have a rounded frontal part, which gives them unusualness and some sophistication. The most beautiful are curly ones that are mainly made to order.

But all this variety of types of platbands can be divided into two large groups. The first includes platbands that have the shape of a rectangle in the end. Their advantage is that they can simply be jointed, without making angles in 45º.

The second group is platbands that have a semicircular or figure section on the end. Such forms look wonderful, but when installing intoleaned or cut carelessly, their central part will protrude above the lower end, which will immediately be striking. Therefore, their trimming is strictly at an angle of 45º is required.

To install the platbands on the door, you will need a tool:

Types of door platbands

Before installing door elements, you can familiarize yourself with the types of platforms produced.

Telescopic. In appearance it is no different from a standard platband. But, it has a special ledge for communication with the dose, doorbell. When installing such a platband, fasteners are “hidden” and become invisible. This makes the surfaces of the doorway of a single structure without obvious points or buttons. If measurements and calculations are incorrectly made, then there may be a gap between the platband and the box, which you do not shake almost anything. The appearance will be spoiled.

But, if the house has ordinary hinged interior doors, then the capital, of course, will be “out of place” and spoil the appearance. To emphasize the beauty of the door, the corresponding platband should be selected.

Necessary tools for work

There is a basic set of tools, it includes:

But with such tools, the installation will be quite long. Instead of a saw and a little, you can use the end saw. This will facilitate the cutting of the platbands, reducing the required time up to 1-2 minutes

You will need a hammer to install the platbands

Instead of a hammer, you can use a pneumatic gun with hairpins. Under air pressure, the hairpin is driving in a second. The tool does not require special skills, everything is extremely simple.

Instead of a screwdriver, a convert and drill are suitable. The listed analogues will save time significantly, but the entire set is rarely found from the average user, you should not purchase all tools for the sake of one platbands. It is quite possible to do with a basic set.

Figure breakdown

Sometimes you need to make curves of a mowing trimmer line. Kosilian trimmer line can be not only straight, but also semicircular. Such breaks are more problematic when they do not start from the edge. In such cases, you will have to first make a hole and then break out of it.

For curly breakdown, it is recommended (if possible) in any way to apply deep risks of the breakdown. This will reduce the number of possible chips.

Figure breakdown of tiles.

There is a special tool for breaking off. Tweezers with a wheel. But for one.Time work to purchase a special tool is inappropriate. Therefore, you can do with ordinary pliers.

Breathing technology is very simple. Plafers (or forceps) are strongly compressed, the material is crumbled, or compressed and sharply rotated (only far from the braid trimmer line, at least 5 mm). Small pieces are broken off. When trying to break off a large piece at once, you can ruin all the work. Part may break off the risks.

Long, straight, narrow pieces through all tiles are broken off by a sharp turn of the pliers to the side. Previously holding them on a mowing trimmer line risks (scratch, of course, should be applied). In this case, the tiles may not break off for the entire length and the procedure will have to be repeated on the rest. Then they also carefully break the remaining sharp ledges.

The easiest way is to apply risks and a blow to an acute angle. In this way you can easily and quickly prepare most of the elements.

Independent installation of platbands on interior doors

How to eliminate the gaps after installing the doors and give them an aesthetic look? For these purposes, experts use platbands. Their main function is to hide the defects that have appeared during installation, cracks. Installing platbands of interior doors is a responsible process that requires experience from a master of experience, dexterity.

The construction market is represented by a wide range of overhead planks. They differ in:

- Performed functions: constructive, decorative;

- Color scheme;

- Form: flat, rounded, curly;

- Texture: simple strips, carved frames made according to templates;

- Sizes;

- Method of installation: overhead, telescopic;

- Material: wooden, metal, aluminum.

The finish should be selected based on personal preferences, as well as taking into account the characteristics of the interior, the exact place of installation. When buying platbands, it is important to correctly determine the material. Any type of raw material has its pros, cons of.

Wooden

Ten years ago, this type was the only option for decorating the door. But, despite the improvement of the construction industry, it is in demand until today. The main advantage is versatility: wooden planks are approaching any type of door structure.

They may differ from others in their appearance. Depending on the taste of the consumer, the decor can be carved, with different figures in forms.

Lack of wooden platbands on the door. The need to update them. But this is not a reason to refuse them. Modern platbands are made in such a way that they can be restored without problems, putty, apply paints and varnishes.

Most people compare this material with fiberboard. On the one hand, in terms of properties they are similar. On the other hand, in the production of MDF, the latest technologies are used to provide higher qualities of the material.

MDF is a wood.Fiber plate with an average density. In terms of environmental friendliness, it is the same as a tree. And the veneered MDF is even difficult to distinguish from it.

How To Cut Down A Hollow Core Door

MDF invoices are preferred due to low cost, durability. But when choosing, it must be borne in mind that he has poor moisture resistance. Therefore, it is not recommended to install it in rooms such as a bath, toilet.

Plastic

Such strips are made of strong plastic, which is not subject to changes under the influence of climatic factors. During operation they do not burn out, they do not melt. In addition, they do not need special care. Wet cleaning once in a week. That’s all that is required of you.

Due to the low price, good resistance to humidity, the plastic finish has found a wide circle of consumers. However, there are negative points.

The disadvantage of such a decor is a small selection of models, as well as the color scheme. White and several shades of brown are usually sold. Capaches of a different color are made by individual order.

Dismantling

When replacing old or unusable edging, they have to be dismantled. This must be done carefully so as not to cause severe damage to the walls.

You will need an ax and a hammer. Nails cannot be used, strong dents on the partition will remain from it.

The door must be completely open so that it does not interfere with work.

Occupy a position in the input opening. Start disassembly from the upper part. They put an ax with a blade into the gap between the jamb and the overlay, the blowing of the hammer drive it deeper.

Then the blade is gradually torn off the bar.

Similarly pass throughout the framing.

Restoration of the place of cut

After the work carried out, the cut place must be carefully cleaned with sandpaper. This will allow to polish the surface at the platter of the platband and make it smooth.

At the final stage, you need to give the cutting end of the platband the corresponding color shade. To do this, use paint, varnish, sealant or self.Adhesive tinted film. With the correct conduct of all actions, to notice the place of the cut with the naked eye will not work. The most important thing is to carry out work with maximum accuracy and only using the required tools.

Dismantling

Removal of platbands is usually required when replacing cashing out. Do not worry about their safety, but the work is done carefully. Taking an ax with a sharp blade and a hammer, they start dismantling:

-

To remove the platbands carefully, the interior door gives an open position. Settled in the doorway, the tip of the ax is inserted in the upper corner between the bar and the box.

The procedure must be carried out carefully so that the dents are not left on the door frame. Instead of an ax, homemade sharpened strips made of durable metal or other similar devices are suitable.

How to cut the platbands on the door correctly? Doors, partitions

We will show you how to put door platbands, how to work with a gun, explain various nuances of work.

Marking and trimming platbands

First of all, before installing, the platbands must be torn. We take four platbands and end. The center of gravity of the platband can be determined by putting it on the finger. When the Reika balance, we determine its center of gravity. Cut and carry the platbands to the door.

Any door has a radius of rounding. There are straight platbands, but very rarely.

Here we put the platoon flush, even a little shifting it inside the door to hide what is under it.

You need to install the platband from the place where the radius ends:

Put two marks above the door. We do this by eye, but you can measure this roulette.

On the other hand, there is a response, and it is also not to move it closer. Do not forget to numb the platbands.

We remove garbage from under the platbands so as not to cut off more from the rail than required.

Where the radius is over, put the mark. We measure similarly and on the other hand.

From the part of the inputs, everything is much easier. Again, we do not flush, but a little with a displacement. We put the mark not along the good, but a little below.

Accordingly, the same thing on the other hand is 1 mm below:

Similarly, we make marks on the platband. Not flush, but with a slight displacement. We carry out the trimming of platbands under 45 °.

There are situations when the wall is not entirely flat. In some places it performs, and then when installing the platbands, a non.Storage is obtained. Sometimes it happens that the platbands must be a little overwhelmed when they are not flush, but shifted inside. That in such cases it is necessary to do? Imagine that we have a wall on the right, and on the left is the door. It is necessary to nail the platband to it.

If we cut down the plane, then when nailed the corners will disperse. How to deal with it?

Here we have a hole of about 2 mm. If we fill it out like that, we must also cut off, that is, make some kind of lining.

Our wall rises by 2 mm, and we must put some 2 mm high under the corner.

If the gap is obtained from the back, then the front is the platband without cracks in front. This is if the door is drowned inside the opening and it turns out on a ledge. In such cases, it is necessary to take into account the rear gap. The protrusion of the wall. Then we saw off long rails.

Installation of platbands

Now we will work with a pneumatic microshpiller. A gun, the air into which is supplied from the compressor. With it, we will attach the slats to the wall with special nails. Hairpins.

Dried foam should not be ripped off, but cut off with a knife.

We apply foam to all other platbands:

The foam will create a certain layer, and the platband will not hang out. Since the wall is not entirely flat, all irregularities need to be compensated by foam. You can wait up to three minutes so that the foam forms. A small film will allow the rake to stick quickly.

A guideline is rounding on the platband. The corners of the upper rail, of course, are better not to beat, but to put long rails, and already determine the position of the upper one. Where to lower, where to raise. We had a small tubercle under the platband, but it is practically not visible, and the discrepancy between the platbands is small.

Net up one nail below. Then we have frozen foam, which does not allow Reyke to hang out, but where it hangs, we fasten. We advise you to score nails after 20 cm. It is better not to score them at the eye level, otherwise such a nail will be too noticeable. In our case, this is a microshpilka, it can be lubricated with wax, then it will not be visible at all. It is advisable, of course, to fasten the platbands from the ends.

However, there is one important point. Since the pistol uses lubricants such as oil, then when firing on light wallpaper, air is released, and an oily spot will fall on the wallpaper. Therefore, when you nullify, put a piece of paper. The microshpilka is good because it breaks easily. If the microshpiletor is not pressed when firing, the gun leaves and, accordingly, a hat remains, which does not clog, because it is very thin and bends.

In such cases, we clamp it with pliers and tear off with rotational movements.

It makes no sense to pull it out, because there is a hole, and you will never score a hairpin in this hole.

Nuances when installing platbands

Here we have either the platbands are slightly different, or the master did not set the corner of the corner. Such irregularities can be rounded with a hammer. It is only good that the client does not see this.

This is how the angle is rounded so that the tip is not visible. Therefore, it is better to cut the angle first, measure 90 °. If it turned out a little less, finalize with a saw.

Let’s say a few words about the oily spot on light wallpaper. It is not visible on the dark wallpaper, and the whites can be seen very well. Suppose this is our wall, we shoot. And here is our oily spot:

In fact, all these holes are visible at the time of acceptance, and after operation of the doors after 1-2 months, you simply will not see these holes. Try to remove acrylic right away, otherwise it will be difficult to wash it off then. Another moment from practice. Wooden platbands are, of course, cool, but not practical. It is better that the platbands are from MDF.

The tree has one feature. From a change of humidity it turns it.

If the wooden platband is beaten on a premium without foam, then over time, after six months, especially in the off.Season, it begins to twist and the run of the angles begins. Capaches from MDF do not respond to such climate differences. They will not lead them.

Another moment in relation to nails. For white doors, never add Hi-Gear to the gun, no other grease. Shoot the gun somewhere so that the whole grease comes out, otherwise there will be a black spot on white and bright doors, which will be very noticeable in contrast.

Complex cases

Not all doors are installed so that the platbands are installed without problems. Difficulties can be different.

The most common option is one of the walls is too close. If there is at least some gap, you need to saw off from one plan “extra”. Only the assembly will then be in a different order: install the uncircumcised side bar, to it the upper one, and put the very latter to it.

Sometimes the wall thickness is larger than the width of the door frame. Then either they put an additional bar-preference, or use the Mr. Depends on the distance that does not overlap the box. If small-1-2 cm, you can block the platband, you need to close more solid good.

When gluing platbands, you can fix them with clamps

The procedure for marking and installing the platband.

Example No. 1. ✓ Play using an electric end of three strips (two long and one short) at an angle of 45 °. At the same time, the length of two long platbands is fixed, t.E. To the required size, and the length of the upper transverse (short) is cut off with a margin. I cut a 800 mm length on the door with a width of the platband with a width of the platband, for a door 700 mm cut 900 mm, for 800 → 1000 mm, for 900 → 1100 mm. We need this stock to fit the angles at the connection of the transverse with the right and with the left bar of the platband. Note. That the supply must be done in order to prevent marriage in work. Better when so. ✓ We will have decorative cloves on the left and right cut racks, retreating 7-10 mm from the inner edge of the box, if this is the side-where there are loops (awnings). On the side where there are no loops, you can not do the indentation. ✓ We take a short transverse bar and try to dock the left corner. If the angle does not converge, then cut or grind until there is an accurate conjugation. ✓ Proceeds of the left side of the left side we mark the right side. ✓ This must be put to put the transverse bar under the right and just draw the cut line line with a pencil or ordinary felt.Tip pen. Advice. For marking, do not use a moisture.Resistant marker, because you do not wipe the drawn lines. But that is not all. ✓ I also cut off the right side behind a drawn line with a small margin (15-20 mm) for fitting. ✓ Overted, put it, looked at the accuracy of the connection, if I had to cut. And, only then I cut finally next to the line, t.E. The drawn line remains. I just wash her. ✓ Preight, everything is cut out and fitted, you can fix the platbands finally. You can fix the platband to the box with “liquid nails” glue, or you can also small decorative cloves. I’m more inclined to the second. More reliable. This method can be considered classic and most common. But there are times when this method is not quite suitable. I will explain why. Example No. 2. Suppose the door block is installed in a narrow corridor, as a rule. This is the entrance to the kitchen or pantry. The width of the corridor is slightly larger than the width of the box (louds). In this case, there is no necessary space to fit the upper barnage bar. What to do and how to fit the angles of the conjugation in this case? ✓ In this case, first I cut out in size and stuff the bar the platband up the box above the door. ✓ I will cut at an angle of 45 ° the left bar of the platband and the right, but so far I do not cut off the length, which is called back, but again I make a reserve for a couple of centimeters for fitting. ✓ Preight how the corners are fitted, cut into size and attach finally. Example No. 3. In those cases when one of the doorways of the door frame, tightly adjacent to the wall and it must be ennobled by the platband. It turns out that a whole platband of 70 mm wide is not placed. He just rests against the wall. In order for him to get into, he just needs to be reduced in width. Typically, this size of the cut platform is 25-65 mm. ✓ can be able to use this machine from an electric jigsaw. ✓ if the platband is not very well cooked in the corners, then it can be slightly adjusted with the help of a tape grinding machine. Example No. 4. There are still situations when, after facing the walls of the tiles in the toilet and the bathroom, the depth of openings increases. And I want, without changing the old door block, so that the platband is from two sides. ✓ This is added to the door frame (preference), and only then we stuff the platband. I specifically painted additional bars and the platband in a different color so that it is better visible.

But in order not to be visible to this “multilayer pie” from the added rails, you can close in stripes of fiberboard. Then putty and paint over. DVP does not give up the fraught box and will be the form of a whole product. You can, of course, make slopes with tiles. This is already as I like. Example No. 5. Perhaps, The most difficult method. The situation is quite common when, due to the incorrect installation of the door block in the opening or improper plaster of the walls, the box does not stand flush with the wall, and a little (5-15 mm) is drowned inside. In this case, you can cut and attach the platband, but it ultimately turns it, and the angles of the mating diverge. Here you can go in three ways.

But this is destruction and prolonged trouble.

But this is not possible when the difference from the door opening.

Just under the cut.Off platband you need to put the bar with a thickness equal to the size of the wall difference with a door block. Then the corners will converge as it should. I guarantee this to you. Example No. 6. There are times when the room where the door is not rectangular, but a trapezoid is installed. This is usually in old Khrushchevs: toilet or bathroom. There one of the sides of the wall is mowed. Inside such a room 2 corners are deployed, so there is no point in cutting corners under 45 °. They will not converge. In this case, the platband must be cut as shown in the photo. There are no other options. As a result, we get. That seems to be everything in this small article. As you noticed, I cut the corners on the end saw, which I recommend that you do it professionally. If not, then you can cut with a conventional hacksaw on wood and struck or manual, a trimming non.Electric saw. By the way, I have plans to write a video in my plans for the future, how I cut any angle (from 0º to 360º) on the simplest end of the electric engine. Therefore, subscribe to the site news.

Dismantling

Removal of platbands is usually required when replacing cashing out. Do not worry about their safety, but the work is done carefully. Taking an ax with a sharp blade and a hammer, they start dismantling:

-

To remove the platbands carefully, the interior door gives an open position. Settled in the doorway, the tip of the ax is inserted in the upper corner between the bar and the box.

The procedure must be carried out carefully so that the dents are not left on the door frame. Instead of an ax, homemade sharpened strips made of durable metal or other similar devices are suitable.