How to cut the rafters of a gable roof. The device of the rafter system of the gable roof

DIY rafters for a gable roof

The roof of the building is an important and crucial structure of the design that performs several functions at the same time. The main task is to protect the walls and ceilings from the hit of rain or melt water that destroys the materials of the walls and the entire structure as a whole. Additional functions are the preservation of thermal energy, ensuring the operation of various life support systems, protection from wind, dust and other atmospheric and climatic manifestations. The roof design is complex, the roofing, which takes on all the main tasks of sealing and cutting off low temperatures, needs a reliable and strong bearing system.

The roof is one or more planes covered with roofs and designed to cut off external weather or atmospheric manifestations. Each plane is called a slope, so the gable roof by definition has two protective planes. They can be symmetrical or asymmetric, have the same or different angle of inclination. The configuration is due to the intention of the architect, the characteristics of the climate in the region, the presence of strong winds, and t.D. Symmetric gable structures are most common, as they create an uniform load on the walls and foundation.

The angle of inclination of slopes

Roof planes must have a slope that ensures snow or water. The size of the angle is the calculated indicator, it cannot be chosen arbitrarily. Factors affecting the choice of slope:

- The amount of snow falling in the winter, characteristic of this region.

- The amount of rain, their strength and duration.

- The prevailing winds, their strength and duration, the possibility of squalling impulses or hurricane values.

The meaning of calculating the angle of slope of the slopes is to determine the optimal position of the planes that ensures timely snow gathering, the flow of rainwater and, at the same time, does not create excessive resistance to wind streams. The loads from snow in the winter are calculated in tons, and gusts of wind create a significant effect on the supporting structures of the house and the foundation. You have to look for a “middle ground” that allows you to get a sufficient slope with low resistance to the wind. In some regions that have certain prevailing winds and large amounts of precipitation, the asymmetric shape of the roof is the optimal choice, laid down from the windward side and steep on the grooved slope. To achieve this form, you have to create two planes of different areas with a fracture line located outside the axis of the symmetry of the building. When creating a project of the house, it is necessary to take into account the prevailing direction of the winds so that the load falls on the slopes of the roof and creates a minimum voltage of the supporting structures.

What is a rafter system

Gable roofs usually have vertical continuation of the walls from the end. pediments. Small buildings may not have a rafter system at all, when the roof is laid on the longitudinal strips laid on the slopes of opposite pediments. For larger buildings, it is necessary to have a solid support. This is what the collection of the rafter system of the gable roof with your own hands looks like:

The roofing is capable of ensuring the tightness of the outer protective layer, without passing moisture or wind. At the same time, the roof has no bearing capacity, it needs a well.organized support system. The rafters that perform several tasks act as such:

- create a supporting plane for the roof, form a frame;

- form the configuration of the roof, create the required number of planes. slopes;

- provide the necessary rigidity and strength;

- connect the roof with the supporting structures of the building.

The functions performed are put forward to the system of a lot of requirements, the main of which are strength and ability to maintain a form despite the long service life and transferred loads. Here is an example of the simplest way to calculate the strength of each individual rafter:

Outwardly the rafters of the gable roof look like two rows of inclined strips connecting in the upper part. To ensure the strength and stiffness of the structure, there are various elements that need to be considered in detail.

Engineering an Open Attic with Site Built LVL Trusses

Elements of the rafter system

The design of the rafters is one of the most difficult buildings among all the systems. It includes:

- Mauerlat. A strapping belt from a beam 100 × 150 or 150 × 150 mm, laid along the perimeter of the walls in the upper end part. Serves as the basis for rafters, connects the roof to the walls.

- Sill. Laid along the longitudinal axis of the building, provides support for vertical supporting elements. Used only on buildings with an inner average carrier wall.

- Sprengel. Enhances the corner compounds of the Mauerlat. Is a genus of a strut laid down horizontally and provides a diagonal ligament.

- Puff. Connects the opposite Brusia of Mauerlat, compensating for the bursting load from inclined elements.

- Standing (grandmother). Vertical part supporting the horse.

- Hobby (run). Horizontal timber (or board) forming the upper rib of the roof connecting inclined planes. slopes.

- Rafters (rafter legs). Inclined strips forming the planes of slopes. The lower ends they rest on the Mauerlat beam, the upper. on the run.

- Straws. Inclined elements that serve as additional supports for rafters at points of the largest load. Installed perpendicularly (or at a slight angle) to rafters.

Important! The listed list is not exhaustive, there are still many different elements of rafter systems, but on gable roofs they, as a rule, are not used.

What are the rafters made of

The material for the manufacture of rafters traditionally serves wood. a beam and a trimming board. Advantages of wooden details of the rafter system:

- Relatively small weight, eliminating high loads on the supporting structures of the house.

- Accessibility, prevalence of material.

- Wood is easily processed, cut, connected.

- High maintainability of the material. Any element can be replaced or put in order during operation.

- Strength, reliability of the structure.

There are shortcomings:

- Wood is subject to rot, the appearance of mold or fungus.

- High susceptibility to water, the ability to absorb and give moisture.

- Swelling, wood changes linear dimensions.

- Wood is fire hazardous.

- Installation of rafters requires the use of material with high requirements for humidity and quality.

Recently, an alternative type of rafters has appeared. metal. They are deprived of most of the shortcomings of wooden details, are not afraid of water, strong and durable. The disadvantages include only the possibility of corrosion (although the metal has a protective coating), a relatively high weight and increased compared to wood. In addition, metal rafters are much more expensive, which limits their use in private housing construction. The main consumers of such details are builders of large objects that need a strong roof of large sizes. The loads experienced by the rafter system in such conditions are very large and require the use of reinforced parts.

The installation process of a metal rafter system is nothing more difficult than the assembly process of a wooden structure. You can verify this yourself:

There are combined rafter systems that use both metal and wooden elements. This option allows you to slightly reduce the weight of the structure, it is more economical and easier to install. The only crucial point is the need to waterproof the compounds of metal and wooden parts, since the condensate formed on the metal can fall on the wood, cause decay and failure.

How to choose?

The gable roof for the house built by the frame method is the main protective structure based on the rafters system, which are connected among themselves along the entire length of the roof with longitudinal bars, placed across the rafters and collapse.

For frame houses, two types of rafter systems are used. hanging, based on the ends only on the walls and layered, having different points of support. walls and intermediate support in the center.

The choice of type is determined during the design of the house and depends on its size and design. In the case when the span of the roof is 10 or more meters, the rafter system will need to be strengthened with additional internal supports, in which case the layered type of rafter system is taken.

At the base of the rafter farm lies a triangle of 2 rafters, which provide the most rigid structure. The upper parts they rest on the support beam. skate run, lower. on the walls. The upper fishing line for the trimmer, which is formed by the connected rafter triangles, is called the skate of the roof.

When designing the roof, climatic characteristics are taken into account, especially the direction and strength of the wind and the amount of precipitation, and also determine the constant and temporal loads created by the roof.

He will tell about the rafter system of the gable roof

Beginning of work

Before starting construction, a roof project is carried out, during which they determine:

The pitch of the roofing of the roof is associated with the roof material. Soft euro.rulering requires a continuous crate, for this, sheets of OSP or wood.fiber slab are installed for this. Under the slate and metal tile, the crate should have a certain lumen, the degree of which is determined by the weight and size of the roofing material.

The composition of the “roofing pie” depends on the level of use of the attic premises, for the warm operated attic, it is filled with the following layers:

- lower crate;

- a steam.barrier to keep water vapor from penetration into the thickness of the heat insulator and release them into the atmosphere;

- The insulation, as a rule, is mineral or basalt wool, which has a high indicator of thermal resistance, is not afraid of either fire or frosts and at the same time has a high operational period for more than 50 years;

- The hydraulic tank protects the insulation from emergency leaks from the roof;

- Contracuble;

- crate for the installation of roofing building materials;

- roofing sheet.

Particularly thorough calculation requires the thickness of the insulation, which protects not only from the losses of internal heat, but also from the receipt of street noise. Which is especially important when installing metal roofing material.

The thickness of the heater over 100 mm helps to fully protect the internal sub.seal space from the acoustic effect that occurs during hail and rain.

Before you choose the type of rafter system, experts perform a technical and economic comparison of two options. Price. a significant argument during the construction of the house, and the roof sometimes takes up to 30 % of the total cost.

At a cost of 1 m2 of a gable roof from one roof material, an inclined rafter system comes out cheaper. This is due to the fact that a board and a beam of not a very large section are used to obtain rafters, since these rafters are based on 2 reliable supports, so the requirements for their strength are less than for a hanging structure.

The rafters for the hanging gable roof are made only of thick timber, the same cross.section of the beam is used to make tightening. Therefore, even in case of refusing to install the Mauerlat, the expense of funds for lumber will be much higher than for the inclined system. At the same time, saving on varieties, due to the acquisition of material of the 2nd grade, it will also not be possible.

The working conditions of crossbars and stretching for stretching allow only a beam of the 1st grade for these products. The only where it is allowed to use the 2nd grade lumber of the 2nd grade, lying and grandmas, but their specific gravity in the total volume of wood is not so significant as to reduce the total cost of the roof.

Also, the rise in the cost of the hanging of the rafter system is affected by the fact that such farms should be assembled on the construction site next to the erected frame. After that, the collected they rise to the base of the roof.

The rise is carried out using rented vehicles, which is quite expensive. Yes, and the work of specialists in the assembly of complex nodes of a hanging gable roof is much more cost to the customer.

After the developer is determined by the type of rafters, the calculations are performed according to the geometry of the roof, constructive sizes and choose the composition of the “roofing pie”. Further, the roof diagram is drawn in detail and the volume of basic and auxiliary materials is determined according to the drawing. Depending on the selected materials, tools and devices are prepared for CMR.

The angle of inclination of slopes

The slope of the gable roof in construction is set at the design stage. Structures with an angle of up to 30 ° are considered gentle, 30-45 °-with an average slope, 45-60 °-steep.

The choice of slope of the slopes is the determining value:

- Wind loads. The larger the roof is, the higher the sailing and stronger exposure to the wind. In areas where hurricanes often rage, the optimal angle is 15-20 °.

- Snow loads. The dependence is the opposite. The less slope, the more precipitation accumulates on the roof. To perceive the weight of snow, a more powerful design is required, which is inappropriate. In snowy regions, the most favorable slope of slopes is about 25-40 °.

- Type of roofing material. For each type, recommendations have been developed about the maximum and minimum acceptable installation angle. If they are not observed, the tightness and appearance of the roof can suffer.

- Design features. In projects of houses with a gable roof and attic, the slope of the slopes should provide the necessary height of the room. Sometimes the roof is made broken so as not to raise the horse too much.

The most universal angle of inclination of the gable roof is 20-45 °.

There are also multi.cocked roofs where each slope is located at its own angle. But such systems should be used very carefully, since in terms of architecture they are quite non.standard, and their installation is more complicated than symmetrical structures.

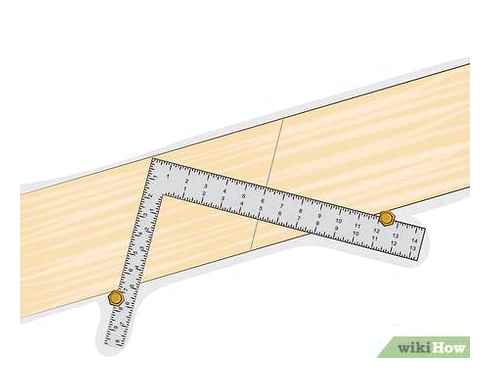

How to calculate the angle

Slope of the slope is used in calculations of the elements of the rafter system. It is determined in degrees or percent, so you need to carry out some mathematical actions.

The gable roof in the context is an isosceles triangle (if the slopes are the same). It can conditionally be divided into 2 rectangular triangles. One of the sides N is the height to the level of the skate, the other l is half the flight of the house. They are measured on finished walls and a pediment. It is required to calculate the length of the rafter B, which can be found based on trigonometric formulas.

Tangent of the angle of the slope relative to the horizontal:

According to the brandis table or help with an engineering calculator, we find the corresponding angle value in degrees. For example, the height of the roof is 3 m, the width of the house is 9 m, half the span is 9/2 = 4.5 m.

This tangens corresponds to an angle of 34 °, that is, the roof has an average slope. You can use the cosine function and calculate the length of the rafters as b = l / ss 34 ° = 4.5 / 0.829 = 5.42 m.

Also, information about the angle of inclination is needed to navigate in roofing materials.

To calculate the length of the rafters (and checks), you can use the second way. the Pythagoras Theorem:

B² = h²l² = 920.25 = 29.25, from where b = √29,25 = 5.41 m is the length of the rafters (without overhang).

To eliminate precipitation on the walls, you need to add at least 40 cm for overhang. We get the minimum length of the rafters for our building 5.81 m with a slope of the slope of the slope 34 °. For convenience, you can take B = 6 m, which corresponds to the standard board.

Calculation of the frame elements for a gable roof

If a gable roof is built with your own hands, it is necessary to perform thorough calculations in advance. The rafter system of a simple gable roof consists of a set of triangular farms. this shape gives the design maximum rigidity. Such figures are easiest to calculate. However, if the slopes have a different shape, the wrong rectangles are obtained. In this case, they are divided into simpler forms and calculations are carried out for each element separately. In the end, all the data is summarized.

Please note that the more complicated the shape of the roof, the larger the number of rafter farms and other details will be required to ensure its strength. All of them increase the total mass of the roof, which, with the wrong calculation, can damage the supporting walls.

Rraft load according to the scheme

The slope of the slopes is calculated based on the type of roofing material:

How to frame a Gable roof. Full demonstration on layout, cut, and assembly.

Note that the sharper the slope, the more material will be required for roofing.

Materials for rafters

Rifts are made from boards or bars. For this purpose, coniferous wood is used. The thickness of the board should be from 40-60 millimeters. Wooden elements should not have cracks and knots, and the moisture content of the material cannot exceed 20-22%. Since logs have a lot of weight, builders do not advise using them (how to make a roof at home).

As for the rafters from the boards, they are not heavy, and it is convenient to install them. With this material you can easily work yourself without resorting to outside help. Many experts do not advise making connections using nails. it is better to use screws. If the work is carried out using nails, do not forget about the overlays and liners.

As for how to build a rafter system, to connect racks with a run or lying, it is better to use rubbish.

Rift system connection options

How to make rafters properly depends on the span between the outer walls. Forms 10×10 centimeters are used to create ridge run. The watering and Mauerlat can be made from logs by sewing them to two kanta, or taking a bass 10×10 centimeters.

When designing the ridge node, it is necessary to beat special clamps made of a steel strip with large nails to Mauerlat and run, taking into account the Mauerlat section. You can not use steel clamps, but then twisted wire twisting with a diameter of 6 millimeters are needed.

Regarding how to make rafters for the roof of a brick or stone house, then a Mauerlat must be laid on the masonry. For reliable fixing it, it is recommended to put a segment of a log or a beam under each rafter leg about 50 centimeters. Then they are attached to metal hooks using clamps, which were pre.installed 30 centimeters below Mauerlat.

Many people have a question about how to make rafters on the roof of wooden houses. Rafters in wooden buildings are laid on the upper crown of the wall. A plank rafter farm can be created using a crossbar or with spans (6-8 centimeters). Its structural elements are equipped as follows. Make a single puff with boards, the thickness of which is equal to the thickness of the rafters. For double puff, more thin boards are used (with a thickness of 40 millimeters). For a crossbar and linings take 30 mm parts.

So that the roof can withstand wind loads, in the transverse direction, in each slope, you need to install a couple of diagonal connections that can be made using a board 30-40 millimeters thick. For layered rafters between two adjacent racks and it is recommended to install braces under the skate. They can not be used if it is planned to be done according to the crate with a scythe (diagonal) flooring (read also: “Installing the rafters with your own hands, their types and features”).

Features of the installation of the rafter system of a wooden house

The main point is the walls, which are the basis for rafters, change geometry and give shrinkage in different weather, temperature and humidity inside and outside the building.

To compensate for distortions of the rafter system that occur when shrinking wood of natural humidity, we need a “sliding”, or sliding support. It consists of a bent plate and a corner with a guide.

During the shrinkage of the construction, the rafters slips along the guide, due to which there is a removal of distortions of the general rafter system. When installing the gable roof, the “slide” is attached to the rafter beam so that there is a gap between them. The corner itself with the guide is fixed on the beam.

The sliding support is attached to the rafters strictly perpendicular, with the installation of the base in the backbone in the beam. To ensure a sliding support maximum course during the shrinkage of structures will help install it in the most extreme position.

The level of shrinkage of wooden construction (and, accordingly, the size of the progress acting on the rafters) varies depending on the material used for the walls.

So, a bar of natural humidity will give maximum shrinkage, dry profiled wood. much smaller (about 6 % of the total height of the house). The smallest degree of shrinkage in glued beams.

Calculation of the rafter system when installing a gable roof

No need to be afraid of the calculations that are necessary before the installation of a gable roof. They are quite simple, although they require maximum concentration and thoroughness. The main thing is to double.check all the data at the end.

A leading indicator, without which no serious calculation can be presented, is the total area of the roof. And so that the calculation process goes as smoothly as possible, it is important to understand what this parameter is.

In the process of calculations, you should adhere to such general provisions:

- First of all, the length of one and the second slope is calculated. It is equal to the intermediate distance between the point on the skate (the highest) and the point on the cornice (the lowest).

- When calculating this figure, it is necessary to take into account all the side structures of the roof: parapets, overhangs and other elements that give the structures volume.

- At this stage, you also need to decide on the roofing material.

- To calculate the area, elements such as ventilation or chimney, do not need to be included.

Calculation of the parameters of the rafters

Here you should focus on the size of the step, which is set depending on the individual roof structure, its weight and the selected roofing material. This parameter can vary from 60 to 100 cm.

To determine the number of rafters, you need:

- determine the length of the slope;

- divide it into a selected step;

- Add 1 to the resulting number;

- The second slope will need the same amount of material, so we multiply the result by 2.

The calculation of the length of the rafters is carried out according to the Pythagoras theorem, into which the following indicators are substituted:

- The height of the roof. This indicator is selected individually in accordance with the need to arrange the room under the roof. Suppose the parameter is 2 m;

- half the width of the house, for example 3 m;

- The hypotenuse of the triangle, which is determined from the given data. The result is 3.6 m.

note! To the result of calculations of the length of the rafters, you need to add 50–70 cm. the amendment for the Water.

The next indicator is the width of the rafters for the installation of a gable roof. To make the correct calculation, you should take into account:

Determination of the angle of inclination

Roofing material is taken into account here, because different requirements are put forward to each of them:

- The slate roof should be arranged with an angle of a slope of no more than 22 °. If the angle is reduced, there is a risk of water entering the gaps;

- Installation of a metal tile on a gable roof involves a slope of a slope of more than 14 °, otherwise there is a risk that the sheets of the material will tear the wind;

- For corrugated board it is necessary to observe an angle of at least 12 °;

- For bituminous tiles, this parameter should not exceed 15 °, with a larger indicator there will be a risk of sliding the roofing material in the heat, because the binding mixture in this case is mastic;

- For rolled materials, the angle can vary from 5 ° to 25 °, depending on the number of layers of the selected material. The more of them, the more you can make the angle of inclination of the slope.

- It is important to consider that a large angle of slope involves an increase in the cover space. Together with the angle, the required amount of roofing material, and, accordingly, will also grow, and the amount that will be needed for its purchase.

note! The value of the angle of the slope should not be less than 5 °.

It is easy to calculate this indicator, based on the initial values: the width of the structure and the height of the ridge. If you submit a triangle in the context and substitute the available data, the calculations can be carried out according to the brandis table or using an engineering calculator.

The tangent of the acute angle in the triangle is calculated by the formula: tg β = NK / (Losn / 2). In the above example: 2/3 = 0.667.

Calculation of loads on the rafter system

Before starting calculations from this section, you should get acquainted with different types of loads. Depending on this parameter, the design of the gable roof is selected, the rafter system, the installation of which you have to. The load can be several types:

- Constant. This type of load continuously turns out to be the design of the roof, material, crate, heater, insulation and other small structural elements. On average, this indicator is 40–45 kg/m 2.

- Variable. Depends on climatic conditions in the location of the house, since this parameter is affected by the amount of precipitation in each particular region.

- Special. Gains relevance if the structure is located in the zone of increased seismic activity. To strengthen this design, there are usually enough additional elements.

note! When calculating strength, it is necessary to make a reserve by adding another 10 % to the result. It is also worth remembering that the maximum recommended load should not exceed 50 kg/m 2. Special attention should be paid to wind pressure, the indicators of which can be taken from the documentation of SNiP in the chapter “Load and influence”.

To calculate the load carried out by snow, it is necessary:

- Find out the weight parameter of the snow cover. Usually it varies from 80 to 320 kg/m 2;

- multiply it by the coefficient necessary when taking into account wind load and aerodynamic characteristics. This parameter is indicated in the SNiP table and is taken into account individually (SNiP 2.01.07-85).

With the layers

In gable roofs, a wooden frame with layered rafters is based on the outer walls, and the other on the inner walls or columns. Spit.spacing and impersonent schemes of rafter systems with knitting nodes are applied.

Space systems

The rafters are hardly fixed by the vapor on the Mauerlat. As a result, rafter legs rest against the walls, as if pushing them out. External fences erected from masonry materials (brick, slag block, etc.), “Calmly” withstand these loads.

In wooden houses, the spacer can destroy the walls. For fences from logs and a beam, diagonal loads from above from rafters are critical. Therefore, for buildings of this type, uninhabited diagrams of the layered rafter system are used.

Bezenny and knots rubbish

The essence of the unbridled scheme is in the method of supporting the rafters on the Mauerlat. To do this, use a sliding knot. sling.

The bending tension in the layered rafter leg passes into a vertical load on the Mauerlat through the sliding node. The removal of inclined beams outside the walls balances the entire system, and the freedom of displacement of the rafters along its axis makes it sprayed.

Special Krubok nodes in the skating node are used in spraying systems. The upper end of the rafters is laid on the ridge scrap with a chopper separately from the opposite rafter leg. It looks like if two single.sided roofs converged in one place without connecting to each other.

With fights

A fight is a horizontal beam, the task of which is to tighten the opposite rafter legs. This achieve uniform redistribution of the load along the entire length of the rafter legs.

In a triangular classical farm, the role of the fight is often played by the beam beam. Depending on the place of position and type of load (compression or stretching), the fight is called a crossbar or screed.

In hanging systems for organizing spacious space, in order to arrange the attic, the contractions are transferred upward. They become the beams of the attic and the basis for lining the ceiling. The ends of the screeds are attached to the rafters with nails.

In some cases, the middle of the fight is connected to the suspension. a vertical rod made of a beam or metal profile, articulatedly connected to the ridge crossbar.

In large.melted houses in systems with layered rafter legs, contractions are connected to racks based on the inner walls. The lower ends of the rafters with the Mauerlat form a hinged-moving nodes (sliders or sluts).

With struts

A feature of the layered rafter systems is the installation of undergone legs. sockets. These are beams from a wooden profile of the same section as the rafters. They are attached at the top to the rafter legs at an angle of 45 degrees. Below, the struts are rested on the lying (Mauerlat of the inner carrier wall).

It is important to perform an accurate saw so that the cut end of the hunch tightly fit the beams. Shift legs allow you to significantly unload the rafters, which makes it possible to overlap with a rafter frame the span between the supporting walls of up to 14 meters or more.

The upper figure contains an example with the central wall. But it happens that the inner wall is shifted relative to the middle of the span. In this case, the struts are mounted only when the walls are subjected to different sediment. Land.rack legs redistribute the loads and balance the rafter system.

Why are the rafters

The need to spit rafters usually appears for the following reasons.

- The length of the roof is greater than the typical length of the roofing boards. The standard of the length of such lumber is laid in six meters. In the event that a specific slope extends over a greater distance, roofing rafters will have to be increased.

- Often, in the process of construction, there are many excellent quality boards with a length of three to four meters. In order to reduce the cost of the construction project and reduce the number of waste, when installing the rafters, it makes sense to use these segments, carefully adjusting them to each other.

Reducing the strength of the rafters when spitting

Every roofer should be aware that the stiffness of the fought rafters will be significantly lower than the whole.

Accordingly, when using the fraining technology, one must strive to ensure that the layout section is as close to vertical stops as possible.

Methods of fusing rafters

Currently, a number of ways to fet are used at once, while distinguishing among them the most effective is not possible.

At each specific object, the installers usually decide on the choice of a suitable and convenient way based on architectural specifics and their own professional skills.

Slopic slap

This method is used when working with boards, the thickness of which exceeds 35 mm. This method is considered technically difficult, so it is desirable to resort to it only in the presence of solid experience in Plotnitsky craft.

- With all this, a oblique slab provides the least durable connection.

- It is impossible not to note the profitable side of this method, which consists in significant savings in lumber.

- In everyday practice, a scythe is used quite rarely.

Spinning roofing boards

In this case, the length of the rafters increases using a lining, which can be made of both wood and metal.

- If the length of the rafter board is too small for the implementation of a specific rafter assembly, then the fraging of the two boards of VSTS allows you to solve this problem.

- The butt method is favorably impeccable by bending strength. He has found widespread use in the construction of both residential and household buildings.

Flapping the rafters overlapping

With this constructive solution, two boards are fixed by simple attachment of the side surfaces. This is an extremely simple way, while in terms of reliability it is inferior to the layout of.

The weak side of this method is the fact that the total length of the two boards will be slightly larger than the estimated length of the rafter leg.

Norms and rules for the wrap of rafters

Technically erroneous spitting of the rafters in length is fraught with both a significant decrease in the stability of the roofing to the effect of weight load, and a complete swift collapse of the roof.

To prevent such a development of events, it is necessary to strictly adhere to existing construction and engineering standards.

They stipulate such important issues as

Need for strength

Technical standards for the scoop of rafters in length are developed on the basis of prolonged construction practice. One of these useful rules is not to fet using nails, but with the use of iron studs.

DIY rafter system with your own hands from A to Z. Pro advice for assembly and installation of rafters with calculations

The crown of the construction of the box of any house is the roof, this is one of the most time.consuming and complex processes during the construction of the house. Especially if you build this house with your own hands.

During the construction of a private small house, it is usually made by a gable. The popularity lies in the fact that it is not difficult to perform compared to other species and does not require special knowledge. It is enough to have two assistants familiar with Plotnitsky in order to mount such a roof from beginning to end on your own.

Such a system copes well with the wind and snow, which is one of the positive characteristics. It is worth noting all the reliability of this design.

The balance between labor intensity and costs is combined here, and the practicality lies in the fact that the attic can be turned into housing. Any roofing is suitable, it costs relatively inexpensive and finally it looks pretty.

It is necessary to calculate the roof for permissible loads in order to choose the right material according to the characteristics and its number, so that after the construction there is less garbage and it is not so sorry to have spent money.

However, for the most part, they neglect the choice of material with a margin based on their own ideas about security and reliability.