How to cut thick foam rubber at home

How to cut the thickness of the foam rubber evenly

At home criteria can be cut foam with a string, a knife, string and other improvised devices.

- Foam billet to be cut.

- The pad (you should not spread the material on the flooring or table, because they will be damaged when cutting). As an underlay it is recommended to use plywood sheets with cardboard laid on them.

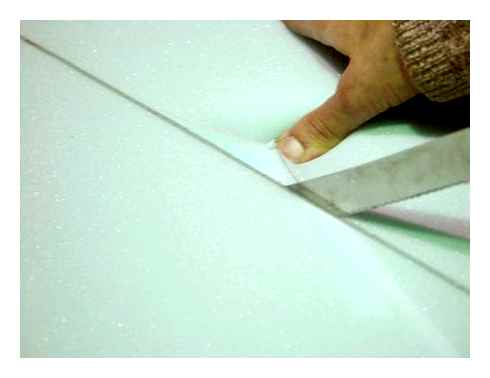

- Construction knife. The best option. for cutting linoleum. These knives have several removable blades in the kit, so you can quickly change them when cutting foam rubber.

- Ruler. You can also use a template if you want to make a precise shape cut of the material.

- A felt-tip pen or marker (to make the cut with scythe line).

What’s the problem with scissors??

The problem is that when you cut it with scissors, it breaks the structure of the foam at the edges of the cut. The edges are pressed in and will not straighten back out. So a pair of scissors won’t cut it straight either.

Cutting instructions

If you follow the instructions, your foam will cut perfectly. So, here we go:

- Since we decided to cut the foam rubber on the pad, but not on the linoleum or parquet, we put it down first. First the plywood, then the cardboard sheet.

- Lay on top of the layer of foam that we want to cut. Make sure that the trimmer line of the future cut is on the lining.

- We take the ruler and according to the given sizes draw a line for the trimmer, which will be the future cut.

- Remove the ruler. If we cut along the ruler while also pressing it down, the cut will be straight, but the edge will be as depressed as in the case of the scissors. If you decide to cut on the ruler, then under no circumstances press on it.

- Take the knife, adjust the blade to the right length and make a small cut over one side. Many people wonder how to cut thick foam rubber so that even at the edge, in the place of the initial cut, it is flat. Actually it makes no difference how thick the foam itself is. The main thing after the first cut is to insert the knife into the original trimmer line of the cut and make the first full cut, slightly gripping both edges of the cut foam on both sides of the knife with your free hand. Then the cut will be perfect.

- In many articles, the advisors recommend that you keep the knife upright. They copy each other’s notes without understanding them. Don’t listen to idiotic advice. Hold the knife on the other hand and bend it toward you. This plane of the knife blade must always be in a vertical position in relation to the ground. It should not be tilted neither to the right, nor to the left, otherwise the edge of the cut will be trapezoidal.

- Surely the first cut will not cut through the foam rubber to the end. Patience. No big deal. Spread the edge of the cut, insert the knife and make another even cut. Eventually the tip of the knife will rattle on the cardboard, and the task will be done.

Here is some helpful tip on how to cut foam rubber to get the perfect cut. If you feel that the knife began to make peculiar hooks while wiring, it means that somewhere the blade became blunt, and it begins to tear the foam rubber without cutting through, forming a strip of foam burrs. In this case, the blade should be changed immediately to a new one. It is best to do this without waiting for it to happen. Made five or six passes, changed blade. They can be used again later for any other purpose, but they will be useless for cutting foam rubber. A simple cutting of foam rubber with a knife is clearly shown in this video.

Bad advice about the thin wire

It is better not to listen to this advice. Even if you are cutting foam rubber outdoors, you risk inhaling hazardous toxins that can kill your health in an instant. The fact is that foam rubber is not the usual plastic. To give it a foam structure, all kinds of toxic impurities are added to polymers, which are completely harmless in the normal cured state and at room temperature, but instantly turn into a strong poison when heated strongly.

Yes, the production of this material is cut by red-hot nichrome filaments. But there people work in protective clothing and respirators, or even in a protected operator’s booth with excellent exhaust. And since the cut foam rubber you are going to home, in the absence of such protective equipment you risk poisoning not only themselves but also their loved ones.

Plus, this method is only suitable for straight cuts. To make a curved one, you still need to take a knife.

about the shape cutting

How to cut foam evenly on curved lines? It is the same as in the case of straight cutting. The only thing is that the angle of the knife tilt to itself should be increased to the maximum, otherwise the cut parts will be a little “askew” at the edges, as if you hold the plane of the blade to the non-vertical plane of the foam rubber. That’s it. Nothing complicated. The main thing. have patience and a brand knife, and the edges of cuts you get as factory.

How to cut foam rubber at home: tips from experts

Foam is a great product. Soft, comfortable and harmless. It is most often used to make mattresses and cushioning for upholstered furniture. It comes in various degrees of rigidity and thickness. But no matter how firm and thick it is, it should only be cut with a knife. You will learn about how to cut foam rubber foam with a knife, and why it should be done only with this tool, you will learn in this article.

The process of cutting

- Clear the place, remove all the things that can interfere.

- Placing the sheet of foam rubber. Mark the line for the trimmer cut with a ruler and a marker.

- We take a knife with a blade of the right length (the width of the foam rubber) and accurately make an incision on one side.

- Tilt the flat of the blade toward yourself to get an even cut.

- If the blade clings to the foam rubber, then it is blunt. Then it is necessary to change it, otherwise there is a possibility of spoiling the material.

- In case you could not cut a thick sheet of foam rubber the first time, do not worry. Spread the line for the cut trimmer with your hands, put the knife and spend again.

To make a curved cut, you should proceed in exactly the same way. Just maximize the angle of the blade toward you, so that the mowing lines bend evenly.

How to quickly and easily cut foam rubber at home. Dexterity and no cheating.

To conduct the cutting of the material such as foam rubber, buy everything you need and have patience.

How to cut foam

Hello all, just recently I faced the problem of how to cut foam evenly, and at home. For all the time of carpentry, I have never once faced with foam rubber, and understandably, I usually work with wood.

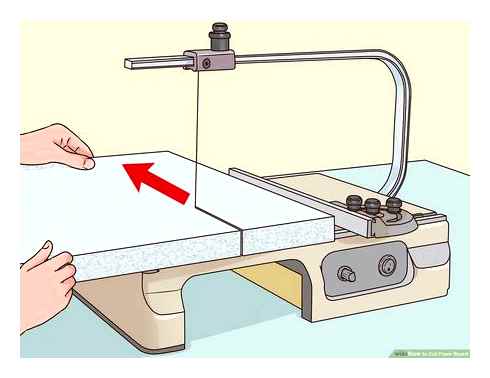

So how to cut the foam rubber? And what it takes. The first thing that came to my mind was some expensive machine, which is just not realistic to buy, because I once cut foam rubber, but a long time ago, and it did not work out well.

At work, in a nearby shop are engaged in upholstered furniture, and then at lunchtime I met a guy who does it in the street. During the conversation I found out that in order to cut the foam rubber, they use an ordinary knife, and they do not have any expensive equipment for this. We got to talking, and he told me how to cut the foam neatly at home.

- A sharp knife, preferably a box cutter or a linoleum cutter

- A highlighter or marker pen with a thin rod

- Cardboard or something else for the base

- A good ruler

So, how to cut the foam rubber, first of all using a marker, make the cut lines on the foam. If they are straight lines, it is better to use a ruler, if you have to cut under the radius, it is better to use some kind of template, template or other device to draw exactly the radius.

Next, to cut the foam rubber, you will need to prepare the base. As a base, many advise using plywood or particle board. I would advise against it because when you cut the foam rubber with the knife, the knife tip will blunt against the plywood. So for the base I suggest you use cardboard. By the way, I forgot to tell why you need the base, the base serves not to spoil the floor or other substrate on which you are going to cut the foam rubber, and as you have understood for the protection of the tip of the knife.

And the last point how to cut foam is the process of cutting. For this purpose take a very sharp knife. Here clearly your kitchen knife is not suitable, as the blade is thicker. So I advise to use a penknife, or a construction knife, like those used for cutting linoleum. It is very important that the blade and the tip were sharp, otherwise you will not be able to cut evenly foam.

Well and then proceed to work, exactly along the line of the knife, preferably without the use of the stop, as the stop will press on the foam rubber, thus creating a load in it, and the knife will not cut well. If in doubt of your abilities, it is better to practice a little on another piece of foam rubber, so as not to spoil the workpiece.

And in general, foam rubber is usually cut in order to cover them upholstered furniture. So you can not do it perfectly straight, and you can not 100% cut it all equally. On top of the foam will still be a cloth, which will smooth out all the irregularities and uncertainties of the cut.

Here I am, this article may be useful to those who have thought about how to cut foam rubber at home with his hands. I’d be happy to comment, tell me what you think about it, and if you have experience, share it.

What to watch out for

Foam is not just a kind of plastic, and plastic with the addition of various kinds of chemical impurities, toxic polymers that give this material porosity.

At room temperature foam rubber is absolutely harmless to humans, but as soon as exposed to heat, the material immediately becomes toxic. Therefore, you can not use to cut foam rubber at home, as some amateurs advise, heated metal thread or wire.

In production, foam sheets are cut in this way, but workers necessarily use protective masks, and in the production hall where this operation takes place, a powerful ventilation is installed.

Ordinary household scissors are also not helpful for cutting foam rubber. The edges of the material cut in this way lose their porous structure.

Preparing the tools for cutting foam rubber

So, how to cut foam rubber at home so that the edges were as flat as possible and close to those that are obtained in the production cut? To do this you will need to prepare the following tools and supplies:

- The actual foam rubber that we are going to cut.

- Padding for the foam material we will be cutting. It is clear that if we spread it on the linoleum or on the parquet in the apartment, these very materials will end, because they will all be in scratches from the knife. As a pad it is better to use a sheet of plywood with cardboard on it, so that the knife tip does not blunt on hard plywood. Cardboard can be used by unzipping any cardboard box of suitable size.

- It is desirable to have a construction type knife. They’re also called linoleum cutters. It has a complete set of removable blades, which in the case of blunting can be replaced. Use better branded European, not Chinese knife, as steel in the “Chinese” low-quality, and a blade blunt after the very first wire.

Cutting instruction

If you follow all the instructions, your foam rubber will cut perfectly. So, let’s go:

Some good advice on how to cut foam rubber so that the edge is perfect. If you feel that the knife began to make peculiar hooks during the wire, it means that somewhere the blade became blunt and it begins to tear the foam rubber without cutting through, forming a strip of foam burrs. In this case, you should immediately replace the blade with a new one. It is best to do it without waiting for this to happen. Made five or six wires, changed the blade. They can then be used again for any other purpose, but for cutting foam rubber, they will not be suitable. A simple cut of foam rubber with a knife can be seen in this video.

How to cut thick foam rubber evenly at home?

But it is not recommended to do this at home, because foam rubber releases harmful substances into the air, which even in small doses are highly toxic and affect the respiratory and nervous system. Let us not risk our health, as the foam rubber can be cut well with a usual knife.

Mark the piece of foam rubber with a marker or felt-tip pen, making small marks in the process. Connect the marks with each other using a ruler (a straight edge can be used).

Put a piece of board, plywood, chipboard or just heavy cardboard under the place of the future cut. This will prevent the floor from being damaged as you cut.

It is recommended to cut the foam rubber without a ruler. Use your knife to move it firmly and precisely along the marking you have made. Hold the knife upright at the same time.

If the foam rubber doesn’t cut through to the end, use your fingers to extend the cut and use another cut to cut the foam all the way through.

If you get burrs when you cut, it means the blade is blunt. Break off the tip of the blade or replace it with a new one.

The curved cuts are made using exactly the same technique. Then cut the foam rubber along the line, making sure the knife is upright and not tipped over. The quality of the cut will not be perfect, but it is good if you want to cut a cushion for upholstered furniture, which will then be covered with fabric.

Pre-wetted foam is much easier to cut with scissors.

Cutting instructions

If you follow the instructions, your foam will cut perfectly. So, here we go:

- Since we decided to cut the foam on the pad and not on the linoleum or parquet, the first thing we do is to lay it. First the plywood, then the cardboard sheet.

- Lay on top of the layer of foam rubber that we want to cut. Make sure that the line for the trimmer of the future cut falls on the lining.

- We take a ruler and according to the given dimensions we draw a line for the trimmer, along which the future cut will be made.

- Remove the ruler. If we cut along the ruler while also pressing it down, the cut will be straight, but the edge will be as depressed as in the case of scissors. If you decide to cut with the ruler, do not put any pressure on it.

Here is some helpful advice on how to cut foam rubber to get the edge perfect. If you feel that the knife began to make a kind of hooks during the wiring, then in some place the blade blunted and not cutting through, begins to tear foam rubber, forming a strip of foam burrs. In this case, immediately replace the blade with a new one. It’s best to do this without waiting for it to happen. Made five to six wires, change the blade. They can be used again later for any other purpose, but they will be useless for cutting foam. A simple cut of foam rubber with a knife is shown in this video.

Cutting instructions

If you follow the instructions, your foam rubber will cut perfectly. So, here we go:

- Since we decided to cut the foam rubber on the mat, but not on the linoleum or parquet, we put it down first. First the plywood, then the cardboard.

- Lay a layer of foam rubber on top of it, which we want to cut. Make sure that the trimmer line of the future cut falls on the lining.

- We take the ruler and according to the given sizes we draw a line for the trimmer, along which the future cut will be made.

- Remove the ruler. If we cut along the ruler while also pressing down on it, the cut will be straight, but the edge will be as depressed as with the scissors. If you decide to cut along the ruler, do not push it in any way.

Here is a tip on how to cut foam rubber to get the perfect edge. If you feel that the knife began to make a kind of hooks during the wire, it means that in some place the blade is blunt, and not cutting through, begins to tear the foam rubber, forming a strip of foam burrs. In this case you should immediately change the blade with a new one. It is best to do this without waiting for this to happen. Made five to six wires, changed the blade. They can then be used again for any other purpose, but for the cutting of foam rubber, they will not be useful. A simple cut of foam rubber with a knife is clearly shown in this video.

Search for equipment

Choosing equipment for the production of foam rubber will be more successful if you first consult with the owners of existing production. If you can do your own investigation on the matter, then you will definitely not make mistakes made by others.

There are several ways you can find out this information.

- Call your future competitors and introduce yourself as the manager of a company that sells Chinese spare parts for equipment. You can find out which manufacturer’s equipment is used in the shop and how often it fails.

- You can call the sales department and tell them you go to buy products. And ask which equipment is used to produce the polyurethane foam. You can come and see advertising samples yourself to ensure the quality of products.

- Communicate in forums where business owners of foam manufacturing discuss their problems with this or that equipment. In addition, in this way, you will be able to understand which area of production is the strongest obstacle to the production of the product. Most often it is a package of finished products.

How to replace foam in upholstered furniture

Replace outdated filler can be their own hands. it’s cheap and easy, it does not require any special efforts and special skills. The main question you need to decide before you start the repair is whether you will replace the padding completely or only partially. Most often, the filler in the seat needs to be replaced.

If you bought the material in a thick block, it will have to be sliced. How to cut foam rubber at home? Put a pad (thick cardboard over plywood) underneath so as not to damage the floor. Take a ruler and a marker, make a marking of the cutout with an allowance of 7-8 cm for the inner surface. You can remove the former filler and make a new cut from it.

Then take a linoleum cutting knife, make an incision on the surface of one side. Along the original mowing line, cut further and deeper, pushing the edges apart. Holding the knife at an incline toward you, lead the stapler along the mowing line of the cut. After that, use scissors to cut similar patterns out of thick fabric.

In addition to the ruler, foam rubber and a knife, you will need:

- Phillips and flathead screwdriver;

- furniture stapler of the manual type;

- pliers or wire cutters;

- Spray gun or paintbrush;

- wrench 10×13;

- work gloves;

- Hammer and nails.

Before disassembling the sofa, take pictures of the parts and their location. Remove the sofa and, if necessary, the backrest, then the transformation mechanism.

Carefully remove the upholstery of the upholstery by prying open the retaining clips with a flat-blade screwdriver. Remove the top layers, if any, and remove the filling. Then clean and secure the sofa frame, assess the damage to the foam. When replacing the “stuffing” you need to go to the previous height of the seat and backrest, measuring the new padding on the old. If necessary, climb lower to fix broken or sagging springs.

You can begin to replace the padding! Put the unfolded padding on the wooden base of each piece, press down firmly and secure with staples. You can add volume to the armrests and backrest, but remember: more volume requires more upholstery fabric.

Put 2 layers of padding on the seat for comfort and durability. Fasten it to the frame with staples and wrap it in a thick material, like a sailcloth, so the FPU retains its shape longer and is extra protected. In the meantime the upholstery can be washed in a washing machine or dry-cleaned.

When the sofa is finished replacing the polyurethane foam, the upholstery should be put back on. When attaching the fabric to the base, press firmly into the soft material so that it sits snugly. Close the couch and try to sit on it. Got it? You can be rightly proud of yourself!

Replacing the furniture padding with your own hands will only require time and diligence. This is a simple activity, which over time can even grow into an original hobby and earn money.

Cutting instructions

If you follow all the instructions, your foam rubber will cut perfectly. Here we go:

Good advice for trimming foam rubber to a perfect cut. If you feel that the knife began to make peculiar hooks during the wiring, it means that in some place the blade has blunted and, without cutting through, begins to tear foam rubber, forming a strip of foam burrs. If this is the case, you need to replace the blade with a new one straight away. It is best to do this without waiting for this to happen. Made five to six wires, change the blade. They can then be used again for any other purpose, but they will no longer be suitable for cutting foam rubber. A simple cut of polyurethane foam with a knife is clearly shown in this video.

Can foam rubber be glued to wood with Pva?

When gluing foam rubber to a hard surface, you can get mediocre results, and in some places it does not stick at all. But for gluing foam to foam rubber, this glue is good. The next thing you can use is PVA glue (for 250g.).

Remnants of polyurethane foam can be used to make a bench. For this you need to use foam rubber, plywood, fabric, thread, and of course the pattern, and imagination. furniture. A great option would be to make a mattress for a crib from polyurethane foam, you can use foam to cover the ironing board.

What is the density of foam?

The first two digits indicate the density (Kg/m³) and the second two digits indicate the degree of firmness (kPa). Density. a physical quantity, which reflects the ratio of mass to volume (kg/m3). Characterizes the carrying capacity of polyurethane foam and significantly affects the cost of foam.

The fastest and strongest setting is provided by Rapid-100 glue, but it must be used very carefully, because after a few seconds of pressing you will not be able to detach the individual foam elements without damage.