How to cut tiles at home

Selection of the necessary tools

Before you cut the tile, it is important to choose a method of laying tiles and make the correct marking. For beginners, experts advise to be sure to make a layout of the modules and see how much work is to be done. If you need to cut several tiles, there is no need to use professional cutting tools for this purpose. In this case, the usual glass cutter, jigsaw or angle grinder will do. If the tile is laid in a complex way (diagonal, for example), there is no way to do without a tile cutter.

Work with each tool has its own characteristics, so it is worth telling in more detail about how tile cutting can be carried out at home.

Apart from the amount of work to be performed it is also important to take into account the type of the cut. The angle grinder and electric jigsaw are the best tools for making curved cuts. They make the operation quick, but they must be handled with extreme care. There is a high risk of injury.

Hand tools, such as glass cutter, take up little space, to work with them do not need to master certain skills, the process of sawing is not dusty, the hands during the work is not exposed to danger.

Pay attention! The choice of tool should be made with the following factors in mind.

How to cut a tile without a tile cutter: a few simple ways

Not every craftsman at home has an arsenal of expensive professional tools. But sometimes when laying small tiled surfaces, there is a problem of how to cut tiles without a tile cutter, which can cause certain difficulties. In such a situation, a variety of available technology is used, following the recommended sequence of actions. The material is preliminarily soaked in cool water for 40-45 minutes.

Varieties of cutting

When working with ceramic tiles, it is required to perform a variety of types of cuts.

- Predominantly cut the material in a straight line with a mowing line. It is taken into account that if there is less than 20 mm to the side edges, then this kind of cut is considered to be shaped.

- It is also sometimes necessary to cut a circular hole of a certain diameter in the tile.

- Making, if necessary, shaped notches.

- To obtain mosaic, small in size elements prefer the method of crushing the ceramic tiles into individual pieces. In this situation, lay the material in a dense bag and with a heavy sledgehammer break it into the necessary fragments.

Cutting tiles with an angle grinder

often than not, the question of what to cut tiles for the floor without tile cutter, solve with such a universal convenient tool in the work, as an angle grinder, which allows you to perform a variety of dimensions and configuration of the mowing line. smooth curved, complex shaped, clearly delineated straight.

5 Ways To Cut Tile. Everything You Need To Know For Your First Tile Project

For the tile cutting operation, it is necessary to prepare:

- angle grinder, which is more commonly referred to as an angle grinder;

- A cutting wheel, oriented for work on hard stone products (the diamond variety can be taken);

- A vice, a portable clamp or another uncomplicated kind of clamp to hold the tile being cut securely in place;

- a compact vacuum cleaner to remove dust;

- Safety glasses;

- gloves;

- special tight clothing with long sleeves;

- It is recommended to use a respirator or a cotton gauze bandage.

After determining the necessary dimensions, conducts an accurate marking of the tiles. The line of the cut should be applied to the face plane, using a sharp tool for scratching. It is possible to use a construction marker. But it is necessary to take into account that in the process of work, when removing a large amount of dust, the ink line quickly rubs off.

If small cuts are made that are close to the edges of the tile, the material is placed on a flat tabletop. Can work on the floor. At the bottom to preserve the integrity of the coating put a scrap of plywood.

Cut through the tiled surface first, penetrating a few millimeters. Usually during this operation, it is sufficient to hold the tile yourself, or you can call for help from an assistant. If shaped cuts are made, then before sawing the tile without a tile cutter, the material is securely attached to the countertop with a clamp. If possible, you should fix it in a vice. For safety, under the jaws are put pieces of cardboard or cloth.

- Repeatedly traverse the marking, each time about 3 mm deeper. Carry out these actions until the necessary tile fragment is completely cut off.

- If you want to cut a small length, about 20 mm, cut all the material at once, to the full thickness.

- When making complex edge cuts or curved lines, it is advisable to mark on both sides. Initially a 2,5-3 mm cut on the front side is made. Then turn the material over and cut from the wrong side to the same depth. Repeat several times. There is practically no damage to the face of the tile during this method.

Using an electric jigsaw

In a situation where you need to quickly decide how to cut tiles without a tile cutter and angle grinder, use an electric jigsaw equipped with a saw on the stone.

Such a tool quite easily performs even cuts in a straight line. Also qualitatively makes curvilinear configurations with a sufficiently large diameter. Rounded fragments with a small radius are more difficult to obtain.

It is easier to work with a jigsaw (by the way, with a small amount of work you can use the manual version of the tool) when sawing a relatively thin wall tile.

Difficulties may arise when cutting denser ceramic floor material.

Using a glass cutter

Another available tool that allows you to independently eliminate the problem of how to cut tiles without tile cutters and angle grinder, is the glass cutter.

It can be replaced by any other sharpened instrument made of pobedite, diamond, or other hard material. This may be drills, knives or other implements.

You will also need a metal rail for the work. If you use wooden or plastic rulers, you will need extreme care, because the cutting edges can easily damage this material, and the line of the cut will turn out uneven.

When using a glass cutter, keep in mind that such a tool can only be used when cutting a straight cut line of tile tiles. Note that the minimum width of the fragments to be removed is 20 millimeters.

To make the cut turn out even without chips, it is necessary to scratch the upper layer of the tile evenly along the entire length. If the tool is hard and well sharpened, it is usual to make the groove to the required depth in one pass, applying sufficient force. Sometimes it is necessary to make several repetitions, achieving that the scratch is deeper than the basic glossy layer.

Before you carry out any subsequent actions to split the tile, the hard end of the glass cutter should be knocked on its underside, focusing on the line of the cut. Then use several techniques to break the tile:

- Against the edge of the table. Place the cut ceramic finish on the edge of the table, which must coincide exactly with the cut line. Pressing the material with one hand to the tabletop, the other hand sharply press the cut part. When properly acted upon, the tile cracks directly at the mark.

- Against a sharp corner. After completing the scratching of the risk, with your hands take the tile from both sides tightly. Then sharply strike against the sharp corner. Orient the material so that the point of impact is exactly on the mowing line of the split. It is important that the corner element. metal or wood above the horizontal plane rises at least 10 cm. This will avoid hitting the surface with your hand, eliminating the distortion of the cut line of the tile split.

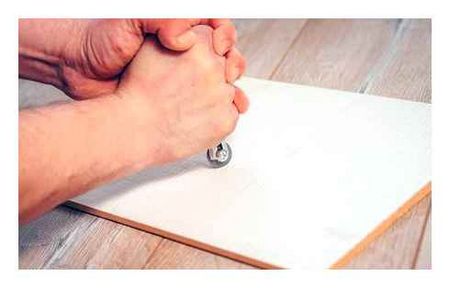

- On a solid rod. The prepared tile is placed on a hard, long enough rod with its underside so that the place of the future split is exactly in the center of this device. Press sharply and evenly on both sides at once with both hands. As a rod take a pencil, a drill with a diameter of 8.5-15.5 mm and a length commensurate with the drawn line.

- Between the clamps. Using this technique, you can break out a part of the tile, or cut it on a scythe line passing through the entire length of the material. It is necessary to prepare two clamps. Use rectangular pieces of thick plywood. Wooden bars are well suited. If necessary, make a homemade machine by connecting two pieces of plywood with self-tapping screws, allowing the tile to fit inside. It is important that the clamps have clear edges. The tile is placed so that the groove is exactly at the edge. Clamp the upper clamp by pressing down firmly with the hand, then press the free edge of the tile sharply.

How to make the circular holes

Selecting options demonstrating how to cut tiles without a tile cutter with your own hands, if you need to get round holes in it, turn to household tools that have rotating tips. These include electric drill bits like screwdrivers, drills, rotary hammers or hand-held rotary hammers.

It is important to set a relatively low speed of rotation, not exceeding 500 rpm, in order to obtain a flat hole. Select nozzles according to the diameter of the hole to be drilled.

Ø 20-30 mm

- Spearhead drill bits oriented for tile work. Good for drilling through regular tiles.

- Special drills, sharpened on one side, with a sharp edge. They can even be used when hard floor ceramic tiles need to be drilled.

- Stone and concrete drills, with carbide inserts. They are not durable, but they can drill a few holes.

Ø 31-50 mm

- Core bits. They can be corundum, diamond, tungsten carbide. Suitably priced.

- Ballerina. Is a lance-shaped drill with a second cutter that is set to work with the movement of a rod fixed to the center leg. Although the durability of such a nozzle is not high, it is valued for the ability to cut a variety of hole diameters.

If you want to get a hole in the tile over 50 mm in diameter, use an angle grinder.

Shaped scraping

Before cutting tiles without a tile cutter in order to obtain a shaped mowing line near the edge, you must first make cuts with small intervals between them. The cuts should be a few millimeters short of the main mowing line.

When everything is ready, special tongs with wheels or ordinary pliers gently break out the segment by segment. The remaining pieces of ceramic are removed in small fragments.

It is more difficult to choose a way to cut a tile without a tile cutter, if the project requires making curvilinear through figures, which are located inside the tiled slab. For this purpose first make a hole, and then in the direction from it start carefully breaking out small fragments with wire cutters. Along the edge, a deep groove is made with a sharp tool to prevent unnecessary chips.

Tongs with a cutter

For a fairly thin tile, aimed for finishing walls, the problem of how to cut tiles without tile cutter, can be solved with the help of pliers, equipped with a cutter.

Observe the following sequence of actions:

- On the outer plane of the material with a ruler and a marker, they draw a precise marking.

- Lead the cutting part of the pliers along this mowing line, pressing the tool so as to make a groove without chipping or deforming the tile. Start drawing in the direction from the farthest side toward yourself. Repeat the process, if necessary, until the desired depth is reached.

- Then the tool is turned over so that the pliers grasp the material along the marking. squeeze and cut off the excess piece.

If required, the edges of the cut are smoothed by using an emery board and then sandpaper.

All of the above methods, demonstrating how to cut tiles without a tile cutter, are available and allow you to do it yourself if a small amount of work is expected. It is advisable to train in advance to get the right skills to work, on pieces of defective tile. This will allow you to more accurately determine the methods of work, the efforts made to get a quality cut of any shape.

Using an electric tile cutter

This is an expensive professional tool that will cut any tile equally quickly, evenly and accurately. With its help, cutting in a straight line and at an angle of 45 degrees, drilling holes and recesses, as well as shaped cutting is available. The cut strips are less than 5 millimeters wide. The cut edges are smooth, slightly rounded.

Some models work with a tile, one side dipped in water, others require only regular wetting of the cut. This method prevents the formation of dust.

The tool consists of a base, a knife and an electric motor, and the cutting process is as follows:

- Water is filled into the tray at the level of the cutting disc, so that it is lowered into it by 2-3 centimeters (for immersion models).

- The tile is clamped and slowly moved under the cutter along the marking. The force must be uniform to avoid chipping and jamming the motor.

- To cut an angle, repeat the procedure two times at the desired angle.

Like any similar tool, the electric tile cutter requires compliance with safety requirements and the use of protective equipment.

For quality work it is necessary to change worn discs and water in time.

Features of curved carving

When carrying out repair work, there is a need for curvilinear tile cutting. The grinding wheel, saw or chisel makes a straight cut only. The drill will allow you to cut a hole that can be connected in straight lines to the edge of the workpiece. But careful curvilinear processing of tiles requires the master to have experience: with a sharp movement, you can spoil the workpiece. For smoothing the edges, an abrasive tool is used, but the workpiece cracks under force or heat.

- power drill with a nozzle for cutting holes;

- jigsaw with a manual or electric drive, which allows you to process tiles made of soft material due to the elasticity of the cutting blade;

- electric tile cutter with additional degrees of mobility, which provides cutting of the workpiece in several directions;

- a manual tool that allows you to chip the material in small pieces (with appropriate edge quality).

Experienced craftsmen perform shaped cutting with an angle grinder. On the surface of the ceramic tile glue a scotch tape and apply a line of marking, and then carefully make the cuts, going from one area to another. The disadvantage of this method is the presence of traces on the glaze from the disk, which will have to be hidden by grout or additional framing made of plastic.

No lateral load on the cutting tool is allowed, which can break and injure a person.

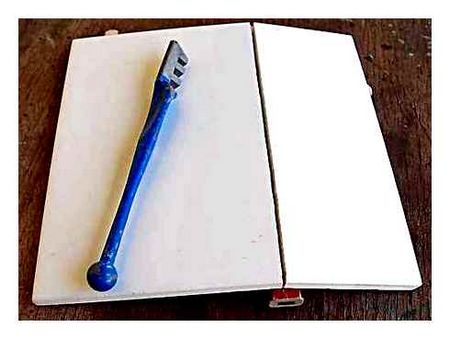

Using the ballerina

The tool consists of a central drill bit and an auxiliary cutter which allows you to make circular cuts. On the glossy side glue paper masking tape and mark the center with a pencil. The tool is then clamped into the chuck of an electric drill and drilled a channel. Several nearby holes make a curved edge. The disadvantage of the ballerina is the roughness of the cut, which requires additional grinding with a file or emery paper.

Use a ballerina to make circular slots.

Ceramic tile cutters

To make a shaped cut, you need an electric cutting tool and special wire cutters. The design of the pliers uses jaws that allow you to break off small pieces from the workpiece. There are cutters with a tungsten carbide roller for trimming the glaze and then cutting the piece. The handles of the tile cutters are equipped with stops to prevent damage to the jaws. The workpiece with the marked break line is placed on a metal edge with the glaze down and pressed to the opposite plane with a V-shaped piece.

There are pliers of different size, the tool is used to remove strips up to 5 mm wide, or for breaking up small pieces of tile (edges require subsequent grinding). Pliers are only suitable for work on edges.

The jaws of the tool should be set at a distance of 2-3 mm from the marking. a reserve is necessary for subsequent grinding with an angle grinder or other tool.

Tile types and cutting features

The most common is glazed tile. Their cutting is very similar to cutting glass. It is necessary to mark grooves on the face side. If there are only tongs or a weak tile cutter at hand, you can facilitate the cutting of thick floor ceramics with an angle grinder. To do this, the cut line is duplicated from the front to the back. with an angle grinder carefully make a groove about half the thickness of the tile. After that it is already much easier to break it.

It is better to make the breakage, having set the tile along the whole notch on a flat surface, a corner of a tabletop or a metal corner. Look at the tile cutter for an example and how the support on the mowing line of the cut is implemented on it. There is a small even along the entire length of the ledge and slightly beveled edges of the surface on the sides of it.

If you need to cut porcelain tile or any textured tile, there are very few options left. For this purpose, you can only use tools with a diamond disc, which cuts through the entire thickness of the tile.

Cutting with an angle grinder or machine is always done on a flat surface without tearing the tile off. Otherwise it is easy to chip the material in a situation where the cutting blade gets stuck in the cut.

Cutting with improvised means

It is not always necessary to carry out a large amount of work. Why waste money if you need to cut several tiles. In this case you can use the following tools:

Important! It is recommended to use a drill bit with a Pobedite bit. Thanks to it it is possible to apply a deep scratch on the surface of the ceramic.

How to cut ceramic tiles with a glass cutter? The algorithm is as follows:

- Measures out the extra fragment.

- A marking is made along it.

- A metal ruler is placed along the mowing line. It is important to do it perfectly straight.

- The only thing left to do is to use the glass cutter or other sharp material handy along the ruler. In the process, the ruler should be held well. The result is a noticeable scratch.

- The tile is placed on the edge of the table or workbench. The scratch on it should coincide with the edge line of the table.

- With a strong, firm and hard hand movement, press the edge of the tile.

The right piece will chip off. It is clear that to make the cut perfectly will not work. But you can save money. And afterwards it is enough to mend the cut with sandpaper. Besides, if you put the tile in clean water for just an hour, then the cutting process will become qualitative.

Please note! Some people ask whether it is possible to cut ceramic tiles with a jigsaw. Yes, but the cut will not turn out as qualitative as one would like it to be. Using an electric jigsaw is rational when correcting tiles laid in an inconspicuous place. But, there are special diamond-tipped saws for hand or electric jigsaws. This option is allowed.

Although cutting tiles is not an activity, dangerous to human life, to take some safety measures and use protective equipment is still necessary, because the risk of injury exists. Wearing special plastic goggles is recommended to shield your eyes from dust and possible debris. Construction gloves will protect your hands from cuts and scratches.

You should be especially careful with tiles for the floor, t. к. The most common repair jobs that can be done with ceramic tiles are: they are very hard and have sharp edges. When carrying out a large amount of work with the release of dusty particles, it is recommended to use a respirator to protect the respiratory organs.

What are the tools for cutting tiles, what is the difference between them

All tools for cutting tiles can be divided into: hand tools (glass cutter, tile cutter, cutters) and power tools (electric tile cutter, angle grinder, jigsaw).

The choice of each tool depends on several factors:

- the amount of work to be done. For sawing one or two tiles is enough glass cutter or angle grinder, for finishing of the whole apartment or house the tile cutter is needed.

- The type and quality of cut you want to make. Rectilinear and curvilinear cuts are made with different tools, for round holes diamond core bits and a drill may be needed. To cut a thin wall tile and a thicker, more durable porcelain floor tile, you need to use different equipment.

- Speed of execution. The larger the area of the object, on which the tiles are laid, the more perfect must be the tool for its processing.

- The amount of money a craftsman is willing to pay for a tool. Professional manual and electric tile cutters are expensive, but you can get by with more affordable tools.

Professional tilers, as a rule, have a full set of cutting tools to solve any problems. For independent laying of tiles by the owner of the house it is not necessary to buy expensive professional equipment, you can do the work with inexpensive equipment or rent power tools in a construction store.

Porcelain tiles are relatively new on the market of construction materials, but have already gained popularity due to its high performance qualities, combining the properties of natural stone and ceramics. This tile material is obtained by dry pressing of a homogeneous mixture of quartz sand, illite clay, kaolin, feldspar and mineral dyes. Porcelain tiles take their final look after firing in special furnaces at high temperature (12001300°C).

The material has the following characteristics:

- high hardness of 7-8. on the Mohs scale (corresponds to corundum);

- strength;

- Abrasion-resistant and long-lasting;

- Hygienic and easy to care for;

- antistatic properties;

- low water absorption;

- resistance to corrosive environments;

- environmental friendliness;

- frost resistance;

- fire resistance.

Due to the almost total absence of pores, the extremely high strength and other characteristics of the material are difficult to work with. It is recommended to use a special tool for cutting porcelain tiles, that allows to get even and qualitative cut.