How to cut ushm correctly.

Is it possible to safely cut a tree with a grinder?

The corner grinding machine is in almost every house, without it it is difficult to imagine many types of repair work. This multifunctional tool can be cut different material: brick, concrete, metal, porcelain stoneware, etc. The question of whether it is possible to cut a tree with a grinder is the subject of disputes.

Arranged angles (Ushm) is quite simple. The electric motor through the corner gearbox transfers rotation to the shaft, on which interchangeable nozzles are fixed. The area of use of the grinder is extremely wide. It is used for cutting, stripping, peeling, grinding and sharpening. The type of work performed is determined by the functional purpose of the shift disks. Each nozzle for Ushm has its own purpose.

Such an instrument is used during construction work, in mechanical and repair shops, during rescue work and in other areas of activity. The grinder is indispensable both in everyday life and in production. We also recommend this video:

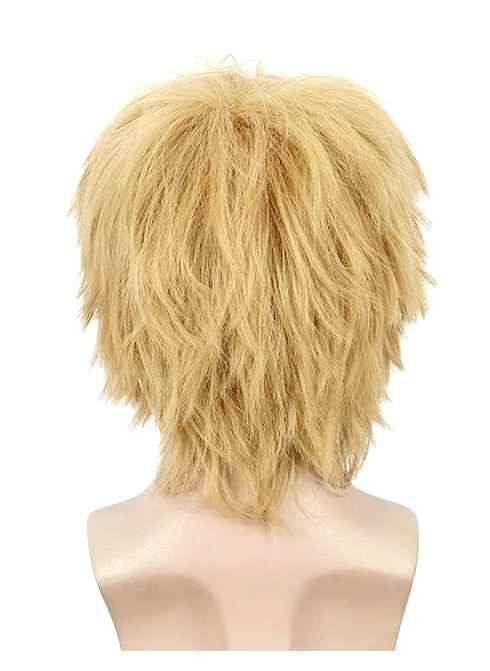

Wood wheels on a grinder

The angle.Grinder is used to work with solid materials and is not a specialized tool for processing wood. But you can use it for this purpose, although you will have to observe some conditions. It is strongly recommended to use standard equipment, t.To. It is not safe.

Industry produces a number of specialized wood discs recommended for Ushm:

- The cuts of a special shape and expanders located on the cutting part have detachment, which allow you to prevent the instrument jamming.

- Chain discs are intended for modeling, milling and cleaning wood. They are a high.Alive steel disk, on the outer edge of which a chain from a chainsaw is installed.

- Special petal petals are designed to align irregularities and cleaning. Such a nozzle consists of several layers of sandpaper laid radially one on the other so that they block each other.

- The disc disk is used for black wooden processing, for example, in the construction of a log house. This nozzle replaces Plotnitsky ax.

- Wood mills allow for coarse milling work.

- End discs are used to align the end surface.

- Grinding disk for wood with interchangeable sandpaper circles of various granularity.

Operations that can be performed using a grinder

Bulgarian is a multifunctional tool. The drive mechanism in it is an electric motor, which through the gearbox transfers the movement of the shaft with a replaceable nozzle fixed on it. The general view of the device is presented in the photo below.

On the market are models that differ in power and design:

Professional Big Bulgarian 230mm STERN AG230B

Powerful devices are powered by a three.Phase voltage of 380 V, and domestic voltage. From a single.Phase network 220 V. There are also low.Power battery models.

HOW TO CUT EFFECTIVELY || LOSE FAT, KEEP MUSCLE

Corner grinding machine (Ushm) can be made with different materials the following The main types of work:

4 Hacks / Tips to GET THE MOST out of the Zoom H1n

Ushm is designed to work with such materials:

Bulgarians are widespread both in everyday life and in industrial conditions. This is caused by their wide functionality, due to the following factors:

- Large choice various nozzles from different materials to perform various operations;

- Possibility fixed fixation using special fasteners;

- Presence in some models additional pens and several speed modes.

In this case, you need to constantly remember that only special discs are used to process each material.

How to cut the pipe with a grinder

To cut pipes, it is recommended to use cutting circles with a thickness of not more than 1 mm, otherwise it is harder to cut, and there will also be too many sparks and flying hot particles.

- The pipe is fixed in a vise or fixed in another way. In this case, the cut part should glow. It is not allowed to have a workpiece between the two supports and carry out a cut in the middle, t. To. Jamming the cutting blade will occur (due to sagging the pipe).

- Using a strip of paper and painting tape, marking is applied. The ends of the tape should converge as accurately as possible. Homemade craftsmen recommend lowering the pipe into the liquid at the required angle, and then mark the cutting line along the dry and wet border.

- The section should be performed from the top of the pipe, gradually lowering the grinder below. The cutting disk should pass along the very edge of the glued strip.

A large diameter pipe is cut a little different, since the working part of the circle does not allow you to do this at a time. The wall is cut chosenly, and the pipe is rotated with the right side.

Types and features of Ushm use

The people known among the people are nothing more than an angular grinding machine. This power tool, according to the townsfolk, is necessary for each more or less self-respecting owner.

It is not surprising, because in addition to grinding, the device is able to perform high.Quality cutting of various kinds of materials, ranging from simple wood and ending with metal corners and reinforcement.

Most often in everyday life, this tool is not used for grinding operations, but for cutting materials.

How to Properly Cut (Lose Fat, Gain Muscle) | My Viral Transformation

Reinforcement, metal corners, metal pipes and other metal products most often have to be cut precisely by grinder. Therefore, her presence in the arsenal of the owner of the house or apartment is quite reasonable. Not to invite an outsider to elementary work for the elementary work

Processing of brick products is a popular phenomenon, especially during the repair period. For these purposes, the grinder should be equipped with special disks. A device for cutting metal and reinforcement in this case will not work

For concrete or concrete product such as a wall, floor, individual elements, a cut.Out disc recommended by the manufacturer for performing specifically these tasks is to be used. Over, in view of increased dust, the smell organs should necessarily protect

For wood and its derivatives, you need to use special discs, which the manufacturer offers to use to work with wood. You also need to put on the corresponding type of protective casing, which will protect you from heavy sawdust, chips and wood dust

Safety precautions when working with a grinder

The use of grinding and cutting power tools belongs to dangerous activities. Therefore, when working with a grinder, you need to take into account the possibility of direct or indirect action of hazardous factors:

- Cold or heat;

- Poor illumination of the workplace;

- Strong noise, vibration from the machine;

- Large physical activity;

- Rotating parts of the equipment;

- Falling objects (processed materials);

- Flying sparks and solid particles of parts;

- Work at height, depth or in a closed, inaccessible place;

- The danger of electric trauma.

Minimize the effect of dangerous factors, and as a result, preserve life and your own health, you can observe the safety rules when operating devices with open rotating parts. To do this, you need to use personal protective equipment (abbreviated PPE), well fix the processed parts, choose a safe place, start and finish the work correctly.

Individual protection means

Under the name PPE, or personal protective equipment, means personal use products that are used to protect against pollution, prevent or reduce the action of harmful and dangerous factors. For most employees, this is workwear that corresponds to the profession. It usually includes trousers, jacket, headdress, closed shoes. Since the Bulgarian is an instrument of increased danger, the clothes are complemented by other means of protection:

- Glasses or shields;

- Anti.Noise headphones or bers (traffic jams);

- Vibration.Insulating mittens;

- Respirator, especially during cutting stone, tiles, concrete or slate.

Glasses will protect from sparks, small crumbs or a sipped disk. The use of headphones or traffic jams helps to get rid of noise, which avoids difficulties after work with hearing. Mittens will protect from abrasive and vibration. And a respirator from a large amount of dust formed.

Fixing the processed parts

All details of small and medium sizes must be reliably fixed in a vice or using a clamp. When mounting, it is necessary to provide a safe place for a possible drop in cut off parts.

Sometimes there is a need to process large details or structures with a grinder that cannot be fixed in a vice. It can be:

In such cases, you need to make sure that the processed surface is securely fixed (stable or lies), after processing it will not lose stability, and the cut part will not fall on the employee or others. At the slightest doubt, it should be supported by stops, jacks, or confused and securely fix the slings to the surrounding metal or reinforced concrete structures.

Safety of the workplace

Regardless of where the workplace is. In the garage, in the country or free site, it must be well lit, meet the elementary safety requirements.

Requirements for the equipment of the workplace:

- A workbench, a table, a rack, a cabinet or a nightstand for storage, as well as the placement of devices, tools for productive safe operation should be installed.

- All real estate equipment is securely placed (attached) on the floor.

- The surface of the workbench and the rack must be no less than the processed parts and the tools used.

- The surface of the workbench is made of sheet steel, aluminum, and other non.Combustible materials.

- The vice must reliably clamp the processed parts. On the surfaces of the vice sponge there should be a cross notch with a depth of 0.5. 1 mm for each 2. 3 mm.

- The vise is attached so that the processed parts are at the level of the elbow level.

- On a closed grip, the gap between the lips should not be more than 0.1 mm. Handle and sponge. Without potholes and burrs.

- The mobile part of the vice should not fall when completely twisted and move smoothly, without jerks.

- The floor is around the workbench, as well as all the place of work should be dry and even.

- Rosettes for power tools have above the level of the work surface of the workbench.

When working at a height (more than 1.5 m), you need to use forests (underlines) with railing 1 m, below lined with a height of 150 mm or higher.

Proper start, stop and breaks

Before turning on the device, you should carefully inspect and carefully check the disk. You can not use nozzles with chips, strata, cracks or any other damage.

Before including the network on the grinder, you need to install a cut.Out (grinding) circle with a pattern upward, then clamp it with a special nut. Size, as well as permissible turnovers are indicated in the technical documentation for the tool.

When examining the tool, you need to check that:

- There are no damage or cracks on the case;

- Serviceability of the cable (cord), protective tubes and forks;

- The handle is well screwed;

- The circle is fenced, and the casing is securely fixed.

After that, the work of the tool is verified. To do this, you need to connect the fork to the outlet, turn on the power button and the latch. Observe a minute at the work of the grinder. Make sure that it works without extraneous sounds, excessive vibration, and the disk does not hurt the protective casing. When disconnecting, the malfunction or performance of the power button and the latch will become clear. If everything is fine, you can start work.

The brigade uh

Hello. I saw this post about the grinder and the disk on the tree and decided to bring his story to the piggy bank.

Who read my posts can understand that I taxed and worked on my truck, and now I am working as a driver on an ambulance.

I don’t remember what year I was definitely. But it seems 2017 or 2018. But not the point.

I don’t have a truck truck. And such an ordinary Japanese three.Tonk with a booth. The last where he worked on it. Transported beer for shops and bars of all sorts.There was a step behind the van so that it could be easily climbed inside. But for some time of all movements back to all ramps. With microuds, a crack was formed on the fastening of the step and as a result, it broke off. Well, I’m a man Shark Sometimes a hand. Having a weld, a grinder, BUT. Having no experience how to cook it all and began to do the like. In general, Svarchny’s helmet was available (although I guessed something, my eyes remember the bunnies since childhood). Cleaned, welded. And decided to remove excess ward to the grinder to look more sympathetic. I go to bed, it means on the back under the car, and I begin to gently grind the scale. Everything seems to have passed smoothly. But something got into the eye. And I tried to rinse with water. It did not help. I arrived home I looked in the mirror and see Maaalenic such a point in the right eye straight on the iris. Well, I think it can be scratched and pass. He did not say anyone. Went to sleep.

In the morning my eyes are annoyed, but I’m still sure that I just scratched it, Coca washed my eyes. There is still a wife like that with you, then also mom (apparently how she felt called). As a result, he heard my story drove me at the kicks in the injury.

In injury, as always. Who is with a foot, hand, cut, dislocation and so on. One with my eye. I waited for the turn, I go in. I explain my story to the traumatologist. He looks at me and says: “Young man, you are not for me, but at the end of the corridor right of the office of an ophthalmologist.” I’m sorry. I’m moving away. The desired cabinet did not have a queue.

The girl took me. Having set the complaints, she began to inspect. And found a splinter at this small point! Steel chips! Then sprayed or dripped (I no longer remember) analgesic. I put me in my Torture machine microscope. I rested my chin and HAD SEEN, that she is passing into the eye Needle. I burst into a little. Even thoughts were: what will happen? If so far it appears with a needle and I will sneeze in my eye, coughing. At that moment I even forgot how to breathe. But everything went successfully that piece of chips took out and recommended drops for 5 days and sent home. Now I even make a bell to get glasses for 5 seconds. But you never know the sneezer.

Cutting a profiled sheet and metal tiles

Quite often, in practice, one has to face the need to cut a profile sheet or metal tile. These materials are made of steel, which is covered with zinc and polymer protective layers, stained.

Regarding the possibility of applying a grinder for their cutting, different opinions are expressed. The installation instructions say that the profile cannot be sawn with the help of an angle grinding machine. To do this, use other tools. But they need to be acquired, which is not always justified by the volume of upcoming work, and also requires additional financial investments. When there is no tool except Ushm, before cutting a grinder, you should know the possible Negative consequences.

- If you cut a metal tile or corporate grinding machine, then the protective coating in the sawing area and a little near it will be destroyed, and the cut edge will begin to rust.

- The material is removed from the warranty.

- Spreading sparks can ruin not only the appearance of the rest of the sheet (spread the paint), but also damage the polymer coating.

- The edge of the cut can turn out to be torn.

All considered negative consequences can be minimized if you cut the corrugated board or metal tile, observing the following recommendations:

- Do all the work immediately before installation;

- Treat sections with anti.Corrosion compounds;

- Cover the cut edges with a primer and stain;

- Use the disks for the metal of the minimum thickness (up to 1 mm);

- In order for the edges to remain neat, you need to cut quite quickly;

- Gently polish the torn edges.

Before sawing, as usual, they carry out Marking sheets.

If you need to cut a square, then do this:

- Draw it on the surface of the sheet;

- Cut the material along the marked contour by a grinder;

- At the end, every corner is carefully cut out.

Circles or other figures cut out, working in the same scheme.

The use of a grinder for cutting metal tiles and a profiled sheet facilitates the work. It becomes more convenient to perform it, because you can adjust the sheets in size directly on the roof.

Metal cutting with a grinder is a cheap, almost affordable and fairly effective way to cut it. In this case, the corresponding discs without defects should be used for each material. Not only the quality of the result obtained will depend on this, but also its own health. Be sure, cutting the metal, it is required to comply with the safety rules and use personal protective equipment. It should be constantly remembered that when working with an angular grinding machine, any shortcomings and inattention can turn into an injury. Therefore, you need to work with concentration and carefully.

Safety precautions when cutting tiles with a grinder

To cut the tiles with a grinder, paving stones or porcelain tiles, the following safety regulations should be followed.

- All operations must be performed In overalls, excluding the possibility of falling into spinning parts.

- Mandatory use protective glasses.

- It is recommended to use Berushi.

- Tools, carrying and other devices should be in good condition.

- Persons at least 18 years old and trained by the operating rules of cutting equipment should be allowed to work.

- If used Wet processing, make sure that the grinder does not get into the water. Otherwise, electric shock is possible.

- Do not process the workpieces at maximum speeds, work in rooms with good ventilation.

To maintain life and health, these conditions should be strictly observed. And then it will be possible to finish the repair on time and enjoy its results for many years.