How to cut with a jigsaw at 45 degrees

How to cut a 45 degree angle

Sometimes you need to trim a particular part or product at a certain angle. As a rule, you need to trim baguettes, fillets, platbands, baseboards and other similar interior elements at an angle of 45 degrees. Anyone can cope with this task. The main thing is not to rush, not to be nervous and everything will work out.

Buy ready-made corner pieces

For example, with regard to baguette or fillets, special corner elements are sold for them, which perfectly fit into the corner and do not need to be trimmed. You just need to glue them in place and press them well.

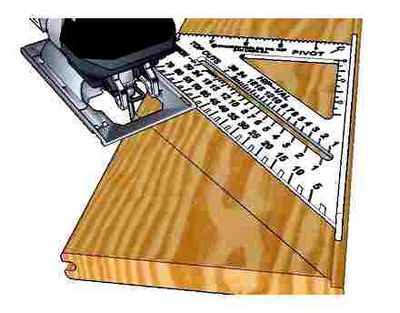

Trimming parts at an angle using a protractor

You can trim the part at an angle using a protractor. This is a measuring tool that is easy to use, and which is designed specifically to measure angles or make the necessary markings on certain parts. The protractor is applied to the part, the angle is marked and the markings are made with a pencil. Using this marking, it will not be difficult to cut the workpiece at the desired angle.

Method of joining platbands without trimming

Platbands today are often not cut at an angle in order to then join together, but make a joint at right angles. This method of joining platbands does not require any special trimming, which is very convenient. In addition, this method looks more modern and attractive.

Angle trimming with a miter box

If, nevertheless, it is necessary to cut this or that part at an angle, then you should stock up on a miter box. the simplest device that looks like a small box. The miter box has slots that are designed for a saw or a long sharp knife. Of course, these slots are made to form an even and precise 45 degree angle.

However, a miter box can have many slots at once, at different angles. This is convenient, because with one tool, you can cut any part at different angles.

There are adjustable miter boxes on sale. The slots in such a miter box can be adjusted, which allows the master to set exactly the angle that is required at the moment. In particular, it is quite easy to transfer the slots of such a miter box to a position of 45 degrees.

Now the workpiece can be cut easily. A baguette, platband or plinth is placed in the miter box, after which a saw is inserted into the slots and the excess is simply cut off. The angle ends up being perfect, exactly 45 degrees.

What if there is no miter box? Very simple. You need to make a template according to which it will not be difficult to transfer the necessary markup to the blanks. As a template, you can choose thick cardboard or something else that will be appropriate in this case.

Ways to cut the platband at 45 degrees without using a miter box

The easiest way is to use an ordinary protractor, which is in every house where a school-age child lives. It is not so difficult to make markup with its help.

Important:

The cut itself is also important. To avoid the formation of cracks, it is recommended to use a hacksaw not for wood, but for metal. Yes, this method takes more time, but for that the cut will be much more accurate and smoother.

When the markings are made using the protractor, you need to position the platband on a horizontal surface so that the front side is at the top. It is recommended to make a cut along the entire plane of the casing.

45 degrees Jig Saw Cuts

If there are no stationery nearby, you can use a regular tile with which you can draw a 90-degree angle. By dividing it into 2 halves, we get a 45-degree angle template that can be used for marking in place of a miter box.

If there is a ruler, the task is simplified several times at once. You just need to take a leaflet A-4 and draw a square, then draw the bisectors of the corners. To make it more convenient, you can take a small board and attach it to one of the corners, which will allow you to fix the structure. Well, then you need to attach the platband and start sawing.

Using templates

If there is no protractor, miter box or ready-made corner pieces available, you will have to look for a suitable template. Of course, the template must have the correct angle. It is applied to the workpiece and the workpiece is marked with a pencil. This is one of the easiest ways to achieve the desired result.

In-place pruning

The walls, floor and ceiling will not always be perfectly flat in practice. Most often they have irregularities. For this reason, there is no need to cut the workpieces at clear and precise angles, because they will not fit perfectly anyway.

Instead, it is sometimes convenient to trim the same skirting board in place. That is, first, one plinth plinth is glued, cut it in the corner, and the second plank is cut under it.

Of course, it is hardly possible to cut off the workpiece perfectly. However, if a small gap appears in the corner, it can always be covered with putty or gypsum plaster. Nothing special.

How to cut a corner of a skirting board or baguette without a miter box

Platband is an overhead frame inherent in the opening of a door or window. This is a decorative piece made in the form of curly strips. There are also carved platbands, their difference is that they are made of wood and are often decorated with abundant carvings. The role of the frame is not only decorative, it allows you to slightly exclude such unwanted blowing in the area of the gap between the wall and the window or door frame, by overlapping.

How to make a miter box at home?

If the above methods are not to your liking, you can make a miter box at home on your own. A miter box is a device that resembles a tray in its shape, which has a U-shape.

It is equipped with saw slots for cutting material at a certain angle. The dimensions of the parts are not very important, but the wider our homemade device is, the wider and more accurate we can cut wide slats.

Important:

Everything needs to be done wisely, you should not overdo it either, because if the width of the miter box exceeds half the width of the hacksaw, it will be inconvenient to saw.

You can do the markup using the methods described above, then use small pieces of plywood and a hacksaw. And in order to hold everything together, you can use self-tapping screws or even super glue. However, all this is more complicated and will take much more time, although it will provide the most accurate result (of course, if you do everything right).

However, if for some reason a situation arises that it is impossible to get the tool in the shortest possible time, you can use improvised tools, such as a ruler, protractor or even tiles, with which it is easy to create a template with the necessary markings or even completely recreate a miter box at home.

You will need a piece of paper. It is necessary to draw a large square on it, where the diagonals will also be drawn. It should look like this:

Imagine that the square is your ceiling, the corners of the square are the joint of the plinth.

Next, take a block and attach it to the wall (that is, to the bottom side of the square. Attach the plinth to the block. Saw off the plinth along a diagonal mowing line. That is, it should look like this:

With the skirting board on the side wall, do the same using the side of the square. If you do everything right, then everything should turn out clearly and smoothly.

To cut the skirting board at an angle of 45 degrees, you need to measure its width and set this value along the length at one of the ends of the skirting board. You get a square. Now draw a diagonal in this square in the desired direction and saw off.

The fastest option is this:

- Find the longest point of the skirting board, mark it out with a pencil or anything at right angles on the flat side of the skirting board.

- Next, with any suitable object, preferably flat (even a piece of paper is suitable) for a more accurate result, measure the width of the plinth and mark it on this object.

- The next step is to transfer this length to the plinth along its length from the marked point towards the working surface.

- Move the point at a right angle to the opposite side and mark it.

- We check the lengths of the sides. they must be equal, i.e. it should turn out to be a square.

- Now you need to draw a diagonal in a square from the farthest point of the plinth to the nearest.

- We visually check if you have marked the line correctly.

- It remains only to cut the skirting board, but it’s not so simple, because they are made with different profile patterns and the cut line may go in the wrong direction and there will be a gap in the joint, or two skirting boards may not be compatible with each other, so you need to find a surface where fix the plinth parallel to the horizon, and the direction of the saw should be strictly perpendicular.

- Now you can cut the skirting board, if all the conditions are met, then the skirting board will be cut strictly at an angle of 45 degrees.

How to cut at corners: a plan of action

Sawing at an angle of 45 degrees consists of several step-by-step activities:

- Preparing the corner template.

- Purchase of a miter box.

- Fastening the miter box.

- Slotting.

- Lumber processing.

- Sawing process.

- Features of the sawing process.

preparing a template for an angle cut

This tool is a profile in the form of an inverted P. On the sides there are slots for sawing at an angle of 45, 60 and 90 degrees. complex corner templates or miter boxes have devices for setting different cutting angles.

sawing at the right angle

The hacksaw must be inserted into the corresponding grooves of the corner template and cut the workpiece. The grooves will restrict the movement of the saw and the cut will be carried out in the desired direction.

How to saw off an angle at 45 degrees: step by step instructions.

the best option to saw off an angle of 45 degrees is to cut along the miter box

The tool can be assembled by attaching pre-prepared parts together. The box of the corner template must be fastened with wood glue or screws. The side walls of the miter box should be strictly parallel to one another. The horizontal beam should create a strict perpendicular with lateral.

we mark the slots at different angles to cut laminate, platbands, etc.

Slotting will affect the accuracy of the work performed in the future. Therefore, this process must be approached with particular painstaking attention. It is advisable to make cuts using the same hacksaw that will perform the work.

preparation of material to be sawn off at an angle of 45 degrees

It is necessary to secure the finished corner template to the work table with a clamp. Next, markings of the future cut should be applied to the workpiece. Next, you need to combine the workpiece with a 45-degree slot inside the miter box and press tightly.

Using a ready-made miter box

Self-made miter box

- 1. First, you need to assemble the box of the future tool. To do this, it is necessary to drill holes in its side walls, for future fastening with screws and, having smeared the ends of the parts with glue, connect them in such a way that both walls are strictly perpendicular to the bottom and parallel to each other, after which we fix them with screws.

- 2. Using a protractor, mark an angle of 45 degrees with a pencil, if necessary, add additional mowing lines for the grooves. The most critical part is the cuts, it is best to make them with the same hacksaw blade as you will be cutting products. It is necessary to cut by holding the blade, avoiding strong pressure on the tool, first we cut one side, then the other.

- 3. We start processing the material. With a clamp or screws, we fix the miter box on the working surface. At the place of the future cut on the plinth or board, we make a mark. How to cut at an angle of 45 degrees becomes clear if you press it tightly against the side wall and align the mark with the slot on the template. We insert the hacksaw into the groove and cut the workpiece, while the work of the blade is limited to cuts, which allows you to make the cut as smoothly and accurately as possible.

- 4. Before sawing the skirting board, make sure that the corner of the room is really straight and, if it is not, you need to adjust the cutting angle of the workpiece. To do this, measure the inner corner of the junction of the walls, and divide the result by two. If you do not have a professional rotary miter box that can change the cutting angle by the required amount, then to achieve the result, you need to saw additional grooves at the desired angle in a homemade miter box. This way you can cut the skirting board for the most accurate alignment.

Now you know how you can cut a workpiece at a 45 degree angle. Perhaps the time has come to move from theory to practical action. The team of the mebeldok.com portal is sure that everything will definitely work out for you. stay with us!

How to use the miter box

A miter box will help you cut the plinth at a 45 degree angle. By the way, do you know how to use the miter box? The specialists of our portal have prepared for you a step-by-step.

How to cut at a 45 degree angle

Often, during repairs, you can face a situation when it is necessary to saw off a piece from a part, at an angle of strictly 45 degrees. Usually, this is needed to connect two parts at right angles, 90 degrees, such as: door trim, plinth, pieces of furniture and much more. An experienced craftsman, professionally engaged in repair work, can often do without special devices, and practically by eye is able to cut the necessary part evenly and clearly. But if you are a novice repairman, and you have a desire to do the work as efficiently as possible, without damaging expensive parts, then you just need to purchase a miter box. a special device that allows you to saw off material at a given angle without any special tricks.

To work, you need to have: a miter box, a hacksaw, a protractor with a pencil, a workpiece made of wood, a screwdriver with screws or a clamp.

How to cut the corners of a ceiling plinth

This is an instruction manual on how to cut the corners of a ceiling plinth. Considered options for solutions, such as.

Cutting corners

At what angle the ceiling fillet should be cut directly depends on its location, or rather on whether the slope will be internal or external.

Cutting the inner corner using a miter box is performed in a strictly defined sequence:

- The required length of the plinth is measured on the ceiling.

- The workpiece bar is placed in the fixture as it will be on the ceiling surface. To do the job correctly, the fillet must be placed face up.

- The workpiece is pressed against the far wall of the device and held with the left hand.

- Next, the file is placed at an inclination of 45 degrees so that its handle is as close to the left hand as possible. To saw down the ceiling plinth. the cutting is performed without too much pressure on the hacksaw.

- Then you need to prepare a striker, for which the workpiece is moved to the far wall and held with the right hand.

- The hacksaw is turned at a 45-degree tilt. In this case, the handle is directed to the right and part of the plinth is cut off.

- After cutting the inner corner of the decorative fillet, the correctness of the work performed is controlled by joining the strips.

Acting in accordance with the above algorithm, it is possible, with an accuracy of one millimeter, to cut the corners of the ceiling plinth without much effort.

Experts advise to start cutting the outer corner after solving the problem with the inner corner, since the length of the product is not always enough.

To make the correct cut of the outer corner, you must proceed as follows:

- First, as in the situation with the inner corner, markings are made on the ceiling by marking with a pencil.

- Further, the fillet blank is placed close to the near wall of the carpentry device.

- Holding the bar with your left hand, turn the hacksaw handle to the left by 45 degrees and cut off.

- To saw off the mating element, it must be brought closer to the front wall of the miter box, holding it with your right hand. The fillet is cut with an inclination of 45 degrees, turning the handle to the right.

- At the end, the cut parts are joined and, if necessary, the surfaces are trimmed, creating a neat outer corner.

Using a template

There is a way how you can cut the corners of the ceiling plinth without a miter box. using a template. It is made of wood, cardboard or paper.

The markings are applied to the material in the following order:

- first draw two clear parallel straight lines of the mowing line;

- between them determine the central point and outline it;

- using a protractor, the required angles are applied, which can exceed 90 degrees.

Before using the template, consider the angles between touching walls and between the ceiling and the walls. Cutting technology using a template is almost the same as using a carpentry tool.

Self-made miter box

To make this device with your own hands, you can use one of the following methods:

- A U-shaped box is assembled from three slats or planks, on the walls of which grooves are marked and cut out under certain slopes.

- They take two boards and knock them down strictly perpendicularly. A piece of paper depicts a template with oblique lines for cutting at an angle of 45 degrees. The product is applied to the corner and pressed by hand, as when using a miter box, and a paper template is placed on the opposite side. Fillets are cut in accordance with the lines applied to the paper sheet. When cutting ceiling plinths, you can use anything that forms an angle of 90 degrees.

How to properly cut the corner of the ceiling plinth. rules and methods

In order to hide the joints between the walls and the ceiling surface and to give the ceiling a finished look, fillets should be installed. In the process of performing this type of work, difficulties often arise, but they are mainly related to the fact that there is not enough knowledge of how to properly cut off the corner of the ceiling plinth.

Used tools

Before you install the moldings, you need to have certain tools at your disposal. Some of them are always at hand from a home craftsman, while others will have to be purchased or made personally. When installing these decorative products, the problem certainly arises with how to make a cut on the ceiling plinth, observing the required slope.

To solve this problem, they use tools that allow you to do the job correctly and as quickly as possible, including:

- pencil;

- roulette;

- hacksaw;

- an ordinary, but better clerical knife;

- miter box.

The last in the above list is the miter box. this is an easy-to-use and popular carpentry device that allows you to cut the corners of the ceiling plinth at a certain slope. Different materials are used to make this tool. wood, metal or plastic.

There are always vertical slots on the side walls of the miter box, necessary in order to cut fillet corners at an inclination of 90, 60 or 45 degrees.

Professional samples of this carpentry tool have a swivel mechanism that allows you to fix the file relative to the baseboards at almost any angle. As a result, solving the problem of how to cut fillets for the ceiling at the desired slope is greatly simplified.

Other corner trimming methods

When the contacting planes of the walls of the room form a right angle, the best solution would be to use a miter box. In other cases, you can use other methods, such as sawing the ceiling plinth at an angle, for example, by marking this product on the ceiling. This technology allows you to take into account all deviations regarding the size of the angle, as well as the unevenness of the walls.

In this case, the work is performed as follows:

- First of all, two workpieces are cut according to a straight vertical mowing line.

- Next, one of the planks is applied to the surface, resting it with its butt against the perpendicular wall. Do the same with the second part of the skirting board.

- Their contours are outlined on the ceiling plane with a pencil. The intersection point is the mark relative to which the fillet is cut, forming an angle in it.

- Then reapply each of the planks and mark the cut line on them, which will connect its two edges.

- The plinth is cut in accordance with the intended lines, after which both parts of it are connected and applied to the installation site.

If of all the ways how to cut the corners of the ceiling plinth, this one is chosen, it is important to take into account several nuances:

- it is best used for interior corners;

- you should not proceed to fastening the fillets one at a time, without making a preliminary docking of the two parts and without checking their relative position. The gaps remaining between the slats must be putty.

Types of decorative ceiling skirting boards

Before proceeding with the installation of fillets, they need to be purchased, and for this you should have information regarding the range of these products.

Skirting boards are made from various materials, namely:

- polyvinyl chloride;

- polyurethane;

- wood;

- polystyrene (foam).

In order to have an idea of each type of decorative ceiling elements and choose the right product, you must own at least their brief characteristics:

- Skirting boards made of polyvinyl chloride have a favorable cost, but this material has the ability to accumulate static electricity.

- Polyurethane stucco molding is distinguished by high quality, strength, moisture resistance and elasticity. Its main disadvantage is insufficient resistance to sudden temperature changes and for this reason, polyurethane products should not be installed in rooms with high humidity.

- Wooden fillets are exposed to high temperatures, moisture and are heavy.

- Polystyrene skirting boards are characterized by moisture resistance, good quality and attractive appearance, but break under mechanical stress.

In addition, fillets differ in other parameters. width, length, relief and shape. Their use in rooms of different sizes depends on these characteristics.

For example, wide products look harmonious in tall rooms. There are nuances in how to cut wide skirting boards. The fact is that these profiles are joined at an angle of 90 degrees. For an accurate cut, use a miter box. But, when the corners of the room deviate from the standards, the work is done manually.

How and how to cut an OSB board?

Oriented strand board is a fairly popular material used in construction. This material is abbreviated as OSB or OSB. Such a large-format sheet needs to be adjusted to the required dimensions, so the craftsmen have to perform similar actions directly in the process. The article provides detailed information on how to easily and efficiently cut an OSB board.

Tool overview

With a not very large amount of work, you can even cut the slab at home with a hand saw or knife. But in this case it is unlikely that it will be possible to do it qualitatively. A hand hacksaw is not the best tool for sawing an OSB board. Even experienced craftsmen can rarely do such a job up to the mark. In the absence of other, more suitable tools, it is better to cut the plate with a saw with fine teeth, leading the tool gently. The knife is also least suitable for working with OSB sheets, it is more often used only for marking.

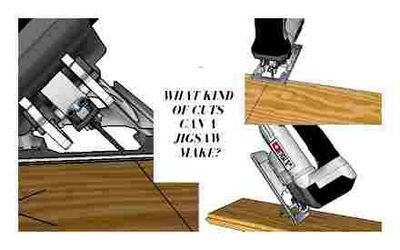

�� Amazing JIGSAW JIG for vertical 45 degrees miter cuts

Here is a list of suitable tools to use when sawing sheet material.

Jigsaw. This tool is more suitable for making curved cuts. Cutting the sheets in a straight line with a jigsaw is quite difficult. In the process of work, defects in the form of chips and pile may appear on one of the sides of the product, therefore, the correct choice of a file in this case is very important.

- Manual electric router. Using this tool will cut the slab clean and straight. But at the same time, it is often necessary to make several passes with a large plate thickness.

- The most successful option for cutting such materials is considered to be a circular. When using a circular saw, the cut is very high quality. The motor has enough power to cut even fairly thick sheets. Working with such a tool will allow you to get an edge perpendicular to the face of the sheet when cutting. Changing the slope will allow you to make the edge at a 45 degree angle. For best results it is worth using discs with a large number of teeth.

OSB boards are usually large, so it is preferable to cut them on the floor. If it is necessary to cut a large number of such sheets, it is advisable to do this on a special scaffold.

Regardless of the choice of tool, it is necessary to slightly raise the slab using small blocks of wood. When working with a jigsaw or hacksaw, they are placed along the cut.

Using a circular saw, lay the blocks across. The successful arrangement of the lining bars will not allow the material to break.

Basic Rules

OSB boards are one of the most popular materials used for interior decoration. With their help, you can create load-bearing elements of buildings, choose as different types of cladding. Similar materials are used in the assembly of cabinet furniture, stairs and other structures.

When choosing this product for work, you should familiarize yourself with the principle of manufacturing this material. OSB is a material having 3 or more layers. Each of them consists of crushed chips mixed with resin. The length and thickness of the chips can be very different, while they are oriented in opposite directions. To make the board more durable, all layers are located in a clear direction, while the location of the chips in each layer occurs perpendicular to the previous and next layers.

The wood-based panels contain resin and glue for bonding veneers, chips and sawdust. Thanks to this, the slabs are elastic and rather dense.

While these materials outperform solid pieces in some respects, they are sometimes more difficult to work with. This mainly concerns their sawing.

For high-quality cutting of OSB sheets, you should use special tools, and also adhere to some rules.

The sheets are cut first across the fiber, and then along it. This will protect the material from deformation and splitting.

The correct selection of tools is an important factor. For sawing on the inside, a saw (hand saw or band saw) is more suitable. When working on the reverse side, a contour or disc plate is more often used.

When using a circular saw, it is necessary to keep the rpm at a fairly high level.

The material should be fed smoothly, without jerking, otherwise there is a possibility of damage.

The choice of tools suitable for this material will allow you to work without creases and other defects.

Cutting recommendations

Using the advice of experienced craftsmen for cutting such materials, you can cut OSB sheets quickly and without defects.

Before cutting the sheet, it is necessary to make a test cut by selecting an unnecessary piece of material. This will make sure that the markings are well visible, as well as choose the most suitable speed, evaluate the quality of work, and determine the size of the finished product.

The basic rule when sawing sheets is continuous and smooth guidance of the tool, since when stopped, traces often remain. Many beginners, trying to avoid chips at the end, begin to cut the slab from both sides, which is incorrect.

You need to make sure you have access to the markings, it is convenient to distribute the cable of the working tool.

It is necessary to cut not along the mowing line of the marking, but next to it.

When marking, it is necessary to take into account the thickness of the cut.

Before starting work, make sure that the tool is working at full power. This will protect against “kickback”.

After completing work, you must wait until the disc has completely stopped, and then remove it from the sheet.

The main task of the masters when fixing the plates is to exclude the possibility of jamming of the equipment in the sheet during work. And also it is necessary to exclude excessive vibration. To protect the front surface from raising the pile and from chips, use suitable tools for this, and also select the necessary modes of their operation. Some experts advise sticking masking tape along the cutting line of the cut, making a marking directly on top of it. this will allow you to get a high-quality cut.

Many people recommend using a sharp knife to mark the line. In this case, the knife blade will cut through the fibers in the upper layers, reducing the likelihood of chipping. To obtain a clear cut mowing line, it is advisable to choose a “guide” in the form of an edged board, a bar, trimming material with smooth edges or aluminum rules. The guide is fixed on the plate using self-tapping screws.

By choosing the right tool and preparing it for work, you can provide the desired result without wasting time and effort.

Watch a video on how to cut an OSB board.

Plywood box: how to do it yourself?

- Tools and materials

- How to make?

- Internal and external finishing

- Recommendations

Each person has certain talents, and the more there are, the wider the opportunities for their realization. The ability to make something with your own hands is an advantage for both girls and guys, because it allows you to create something unique and inimitable for yourself, family and friends. The simplest and most successful solution for a gift or presentation is a box that can be used for a wide variety of purposes. Let’s figure out how to make a plywood box with your own hands.

How to make?

After the preliminary preparation is completed, it is worth making sure that there is enough knowledge on how to create a box with your own hands.

You should not rely on your vision or an approximate theory of work, it is better to read the materials and watch the video.

This information will help you more clearly understand the process of creating drawings and assembly diagrams, as well as the sequence of actions, which will avoid difficulties in the work.

A plywood box is created thanks to the correct algorithm of actions, which consists of such items.

- Think over how the future product will look like, and transfer the diagram to a paper sheet. If all the calculations were performed correctly, you can start marking the parts on plywood. To get even sides and corners, it is best to use a square in the work.

- Once all the drawings are made, each detail is cut out using a conventional or jigsaw. When using a power tool, you must wear protective goggles so that sawdust does not get into your eyes, and gloves will also be useful as additional protection.

- Finished pieces must be processed using a cutter set at 45 degrees. This manipulation will allow you to hide the ends from the outside and make the product neat and beautiful.

- Before starting the collection of the box, it is necessary to process all parts with sandpaper. To avoid plywood chips and creases, you need to start work with finer sandpaper, moving on to a larger one, with a grain size of 200 to 800.

- Once all the parts are complete, the next step is to assemble the structure. For this product, it is necessary to use polymer glue, which is applied to the joints to glue the entire structure. To prevent the corners of the box from shifting, you need to glue them only on a flat surface. To make the assembly process more convenient, you can use clamps, under the legs of which it is better to put fabric, otherwise traces of pressure may remain.

- As soon as the base of the box is made, it is necessary to proceed to work on the lid. Each part of it must be sanded and prepared for gluing. Having connected all the parts of the lid, it is worth checking how it fits into the box, and, if necessary, adjust the location of the internal parts while the glue is still viscous.

- When all the parts are dry, it is necessary to putty the box to exclude any cracks and cracks.

- Once the putty is completely dry, the whole product is carefully sanded again.

- After completing the preparation of the future product, it is necessary to install curtains on it, for which it is worth marking places for them and using a cutter to make recesses on the box and lid. Before twisting the structure, you need to check if the holes match and, if necessary, correct them.

- The last step is to install screws, but you should not screw them into a solid layer of plywood, otherwise it may begin to crack. It is best to drill small holes into which the screws will be screwed.

It is this sequence that allows you to create a neat and easy-to-use box, which you can keep for yourself or donate to someone. The final look of the product can be very diverse and depends on the preferences and purpose of the thing.

Tools and materials

Making any thing with your own hands requires knowledge of the product diagram, the main stages of work, as well as the availability of the necessary tools and materials.

To make a box using plywood as the main material, you must have the following things.

- A sheet of well-dried plywood, the optimum thickness should be at least 8 mm. Wet or poorly dried wood is poorly cut and polished, which will cause a disappointing appearance of the finished box.

- High-quality polymer adhesive for fixing parts.

- Jigsaw or jigsaw for sawing parts.

- Protective equipment for face and hands. glasses and gloves.

- Sandpaper of varying grain size.

- Putty.

- Small awnings.

- Short screws and screwdriver.

- Gas-burner.

- Acrylic varnish.

- Decor paint.

- Manual Router or 45 Degree Angle Router.

- End milling cutter.

Internal and external finishing

To preserve the appearance and performance of the plywood box, it should be covered with acrylic varnish. Once the surface is well dry, it is possible to complement the product to your liking, creating an individual design. The most presentable and beautiful will look like carved elements that are cut out with a jigsaw from thin plywood.

The pattern must be thought out in advance so that the finished product has a complete look. It is best to place the decor over the entire surface of the box. To create a more original look, you can use different colors.

Another option for decorating the box is to burn the pattern directly onto the item, which looks spectacular and interesting. If you have some experience in working with an electric burner, almost everyone will be able to create a unique design of the box.

Many people prefer to tint the finished product in dark colors, artificially aging it, for which it is necessary to use a gas burner and burn the plywood with it. The result is fixed with a semi-gloss or matte varnish. the box is ready to use.

The inner side can remain intact if all sorts of little things are placed in the box, or it can be finished with cloth if jewelry or important items are stored in it. Velvet is best suited for upholstery, which has an attractive appearance and good wear resistance. Fastening is carried out using a stapler, which secures the inside of the upholstery, after which the main.

To make the use of the box for any purpose convenient, it is worth taking a few more additional measures.

- Install a latch that will fix the cover to the main structure, which will prevent the product from opening due to falling or turning over. This fact is important if there are children or animals at home.

- Glue felt legs to the bottom of the box to prevent scratches on other furniture. It is not always possible to make a perfectly flat surface and varnish it with high quality, therefore traces may remain from using the box on other surfaces. On the bottom, you can stick a single piece of felt, equal to the bottom of the product, or cut out pieces of any geometric shape and place them in the corners.

In order for the box to last long enough, it is worth choosing high-quality materials for its manufacture and covering them with a durable varnish that will withstand any atmospheric changes. One layer of coating is usually not enough for the desired result, so it is worth re-painting the box. The varnish can be used transparent, translucent and matte, the choice is made based on personal preference. To give the box an interesting look, you can use tint paint.

Decorative elements must be quite strong and well fixed so that during use they do not get damaged and do not break off from the box.

Plywood boxes can be created as a gift to someone you know or for personal use.

Appearance, dimensions, decor. all this is dictated by the purpose of the product. The presence of interior decoration will be desirable for a gift option, especially when it is created for a girl. The large dimensions of the box are suitable for household little things that often have nowhere to put, but it is important to have it always at hand.

Having correctly prioritized, defining the tasks and purpose of the future product, you can build a high-quality and useful box that will serve for many years, performing its task every day.

In the next video, you will learn how you can quickly make a plywood box with your own hands.