How to determine the sharpening of the chain of the chainship. Manual and electric machines

How to use a device for sharpening a chain of a chain

The most fundamental when sharpening the chainsaw is to achieve the right angle of the upper blade, which should be within the boundaries of 60-50 degrees. The angle of the end blade is observed within the boundaries of 85-60 degrees. It is also worthwhile to adhere to the angle in plan (sharpening angle), and specifically what is perfectly visible when you look at the chain link from above. It moves away from the side edge along the mowing trimmer line of the front and should be 10-15 degrees.

The productivity of operations of the cut of wood in the transverse direction is growing if an increase in the angle of sharpening of the chain of the chainsaw is to a very probable and opposite. The chains created for longitudinal cutting of the wood trunk should be hidden with an angle of approximately 10 degrees.

Under no circumstances, a limiter of depth can be touched again: incorrect grinding can lead to vibration when working as a tool. His refinement is done according to a special template.

When to work?

With intensive use of the chainsaw, sharpening is carried out quite often, often several times in one day. Particular attention should be paid to the fact that the meeting of the chain with the soil significantly accelerates the process. Therefore, the chainsaws should be used in such a way as to exclude the likelihood of contacting the chain and soil. After several contacts, the chips will be very small, and the chain will deepen into the material slightly.When considering such a question, it can be noted: the more often you have to sharpen the chain of the chainsaw, the smaller layer of the metal is removed. Also if you sharpen often, then the service life of the cutting element of the chainsaw is significantly increased. The main condition can be called the correct performance of the work if you do it with your own hands. It is possible to perform the procedure correctly only on condition, if there is a special machine.A sign that the cutting element of a hand chainsaw has dulled can be called a significant supply effort. Correctly conducted sharpening of the circuits determines a significant reduction in the indicator of the supply force, that is, the chainsaws are easy to enter with a slight press. Another sign of the need to sharpen the circuits can be called a very shallow shavings.Carrying out the sharpening of the chainsaw when the signs of considered are required. Sharpening of circuits is carried out in order to reduce the voltage in the body, reduce the cyclic load, fuel consumption. Also, if you do not sharpen the teeth of the chains in time, there is a possibility of increasing wear of all nodes, as a result of this, there is a reduction in the service life of a hand chainsaw.

In order to properly sharpen with your own hands, even if the machine is used, you should know the geometry of the tooth. Its components include:

In this case, the tooth blades consists of the following elements:

It is necessary to sharpen it correctly with your own hands, taking into account the fact that the end and upper blade should be located correctly relative to each other to ensure the best cutting indicators. The back of the tooth forms a certain angle of the upper blade. A similar angle is formed to cut the blades into the material. With your own hands should also be sharpened with the fact that the blade back has a narrowing. This design feature forms the angle of the end blade. It is created to ensure side cutting of chips.

Sliding surface and the end part of the blade forms the front angle. In this case, the angle has a fixed value, it varies from 60 to 85 degrees.If you sharpen the teeth with your own hands, it is worth considering that it is the upper blade that is the main one, and the angle formed by it is the most important angle.Summing up when considering the issue of geometry features, we note that the angle of sharpening may vary depending on the conditions of application. The basic rule that should be observed, if you sharpen the tooth with your own hands, can be attributed to the following: the higher the angle, the greater the performance of the chainsaw, but the reduction in the indicator provides greater smoothness of the stroke of the blades, a decrease in vibration and an increase in the service life. It is worth sharpening taking into account the fact that the indicator should be in the range from 25 to 35 degrees. An exception can be called the option of execution of the blade, which is intended for the longitudinal saw. 10 degrees are maintained by many manufacturers of the cutting element of the chainsaw.

How to understand that it’s time to sharpen a chain

If you do not sharpen the chain on time, this can lead to the following problems:

When sawing a dumb chain, the following things happen:

- Getting a chain in a tree

- Chips have a small size

- A large pressure on the chain is required so that it can saw

- The speed of sawing is low

If there are such signs, then the chain is dull. But besides the presence of these signs, it can also be visually determined whether the chain is dull or not. Just look at the cutting tooth and its edge.

Grinding angles and sawflies configuration

As previously noted, the product under consideration is characterized by a rather complex configuration. Among the features of modern execution options, the following points can be noted:

- The selection of the chain for longitudinal sawing is carried out for a specific chainsaw model, since the configuration largely depends on the power and some other points.

- For longitudinal sawing, the step of the cutting plates is 0.325 inch. Due to this, high stability is ensured at the time of operation.

- The cutting edge can have a thickness of 1.3 mm. There are also execution options that have a thickness of about 1.1 mm, but they are difficult to sharpen at home. In addition, small thickness allows you to cut non.Thick branches.

- Attention is paid to the height of the profile, which varies in the range from 0.625 to 0.762 mm. For household options, the option with a low profile is suitable. This indicator determines the likelihood of vibration at the time of sawing.

The angle of sharpening of the chain of the chainships largely depends on the purpose of the tool, since some are suitable for transverse cutting, others for sawing. The longitudinal resistance of wood for sawing is very high, so the edges should be very sharp. The recommended sharpening angle is 6-12 °. The difference in the cutting angles is selected depending on the task, as well as some other points.

When performing work, do not forget that too small the sharpening indicator causes a quick grinding of the edge. This moment is the most important when the product is made when using alloy steels, for example, 40XGS brands.

The design of the chain

Chains of chainsaws consist of teeth. Each element is a separate link in which there are special holes for the axis for connecting into a closed circuit. The tooth has two edges: upper and side. The first is located at an angle to the direction of movement and performs the removal of wood. The second plays the role of the end blade and is designed to take the raised chips to the side. The design of the cutting link also provides for the presence of a cut depth limiter, which determines the maximum height of the removed layer.

Despite the same device, for each saw there is its own configuration, which accurately indicates the values of such parameters as the angle of the cutter, the distance between the edge, the height of the profile of the link, etc. D. These parameters directly depend on the nature of the work and density of the processed material. Two forms of the teeth of the saw chain are distinguished:

One. Chisel: Direct stamping. Differs in a high saw speed due to the smaller contact area with the surface. Used for sawing solid. Disadvantages. Quick wear, the need for constant editing and complex sharpening.

Chipper: sickle.Shaped line. The presence of rounding reduces the efficiency of the saw chain, but simplifies the maintenance. Sharpowing can be done using an ordinary round file.

Increased load, inaccurate operation, abrasive effects of soil particles and other factors can damage even a new chain. The procedure for timely sharpening the chain of the chainships allows you to save the tool: extend its service life and reduce the risk of breakdown. The operation is carried out planned and as necessary.

Sharpening the chain with a grinder

If you have a grinder, then you can sharpen a chain of chainsaws much faster. It is best to use a small grinder with the 125th circle. Sharpowing is carried out at low speeds. There are two ways to sharpen Ushm.

The 1st method

Install the chainsaw on the table, and clamp the tire with a vice so that in the process it does not move. We set low speeds to the Ushm (if there is only smooth adjustment, then press the start button lightly). We direct the disk at an angle of 30 ° relative to the plane of the tooth and tilt slightly (as shown in the photo). Press with light soft movements on the tooth.

With this method, the main thing is not to overheat the tooth and not to hide too much metal. Dilling the teeth, thus tightening, is much easier than a manual file, but the sharpening speed increases significantly.

The 2nd method

In this case, it is the Bulgarian that must be fixed motionless. Can be squeezed in a vice or screwed to the workbench with a bracket. Sharpowing is carried out, as on a normal toe circle. Hold the chain with our hands and turn it so that the tooth is sharpened at an angle of 30 °. With this method, the hands are less tired, since you need to hold the chain, not a grinder. However, the chance to get an injury increases significantly. We recommend using this method infrequently or not to use at all, since safety is still more important than speed or sharpening quality.

Manual method

This is the simplest and slowest method for sharpening the teeth of the chain. Nevertheless, the method is good when sharpening is done in place in the forest. Do not carry a whole machine with you all the time?! But here it is worth being more precise. Not one tool is implied, but a whole set, where are included:

Each of them fulfills its duties. The main purpose of a flat tool is to sharpen a depth limiter.

The round file already performs the main operation, makes the cutting edges more acute. In this case, for each chain, a certain diameter of the tool is required:

For PICCO chains, which are equipped with a rospe “Shtil” 180 with a 3/8 step and a quarter of an inch, a file with a diameter of 4 mm is also suitable. It is important to keep it correctly. Regarding the vertical plane, the file must be placed strictly perpendicular to the chain, and in relation to the horizontal one at a small angle (about 30 °). A specific angle of sharpening is selected depending on the needs, but within 25-35 °.

Unlike the sharpening of the chain of the chainsaw on the machine, the angle here can be installed using a template, which is considered a useful assistant. To do this, it is equipped with two slots: Soft/S (for soft wood) and Hard/H (for solid breed). The template should be fixed over the chain, which endows it with the privileges of the limiter.

It should only be borne in mind that this method is not intended for constant use, but serves only as the editing of the blades. Too frequent use of the file over time leads to the wear of the chain, and the teeth themselves will be hidden uneven.

Automated sharpening

Sharpening The chains of a chainsaw in automatic mode is performed on special machines, which are a design with an integrated sharpener. They insert the saw into the “box”, fix it and close it. Then it remains only to include the equipment for the highest capacity. The chain rotating, begins to hide on a sharpener without the help of others, in automatic mode.

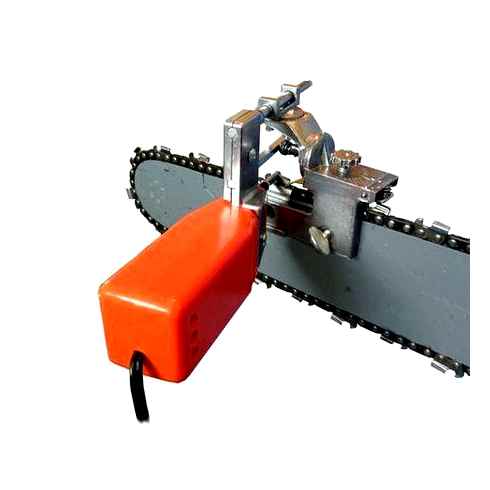

Gaspile sharpening device

Princes Auto /Harbor Freight electric chainsaw sharpener

The introduction of a special machine allows you to carry out work on sharpening the chain of the chainsaw is rapidly and excellent, without physical effort and certain special abilities. This is trivial and just the process of service equipment for equipment takes only a couple of minutes.

Knowing how to sharpen a chain of chainsaws, you can save significant funds to pay for service services and transport expenses.

Types of files and customs advice

As it has already become clear, to select a ratfille for sharpening the teeth of the chain of the chain of the chain of the chain of a round diameter and a thin. Many manufacturers of the motorized tool of this specificity for the convenience of consumers along the way are produced by sharpening sets, where such ratfins are already in the kit. But here it is also fundamentally not to be mistaken: for a certain chain, a right dialect ratfil is needed. Its value is determined based on the step of the teeth of the chain.

Following the rules, before you choose a rapper for sharpening the chain of the chain, the marking of the chain determines its clear step. Further adhere to the tips:

There are saw chains where it is appropriate to use round ratphyli with a cross.Cross.Cross.Cross, equal to 2×1.6 mm.

With the proper selection of the tool for sharpening the chainsaw tooths, the protrusion of it above the surface of the horizontal edge of the tooth during the process will not exceed 1/5 of its own diameter, which can be a guideline when selecting a ratfille, when the chain step is unrealistic define.

How to exclude the risks of buying chain falsifications

Separate unscrupulous manufacturers and sellers are trying to give out their crafts for high.Quality products of well.Known brands.

They fake the chain itself and proprietary packaging. Externally, the tool looks exactly the same, but since falsifiers save on materials, it will not last a long time.

Packaging, as a rule, is made of loose cardboard, the seal often greased and fuzzy. If you take several of these packages, there will be the same serial number for everyone.

Experienced masters advise not to play roulette, independently trying to recognize a fake. It is better to buy chains in branded service centers or in trusted construction stores, valid for their reputation and do not associate with falsifiers.

The frequency of sharpening chains of a chainsaw. How to sharpen a chain of a chainsaw: order of work, features

A good master and the tool should be good, and always be in combat readiness. This applies to any masterful person. All cutting and sawing devices should always be properly sharpened. This requirement is relevant for such complex tools as saws, especially to electric and gasoline. In today’s review, we will figure out how to sharpen a chain of chainsaws, what you need to know for this in order to make work efficiently.

Features of sharpening saw chains

The saw chain is a set of interconnected joints of the cutting teeth of complex configuration. When processing the chain, it is necessary to ensure the uniformity and the same sharpening of all the teeth, withstand the correct angle of the cutting edge, and maintain the desired configuration of the tooth. To solve these problems, there are several ways to sharpen, as well as many different tools and devices.

Chainsaw Photo: Spila.Ru

The saw must be sharpened on time, otherwise you can get a lot of troubles. A decrease in performance, deterioration of cut quality, accelerated wear of the mechanism, even injury.

Tooth configuration and angle of sharpening of the chain of the chain

The tooth of the chainsaw has a complex configuration, which depends on the direction of the circuit. The tooth has two working edges: side, located perpendicular to the axis of the movement of the links, and the upper one, which is at a certain angle to the direction of the chain movement. Each tooth has a cut depth limiter. It determines the height of the shot chips. The main effort with the abroad falls on the working edge. The angle of sharpening of the tooth determines the quality of the tool.

Functional parts of the tooth of the chainsaw and their type Photo: proinstrumentinfo.Ru

Each saw model has its own step of cutting edges, the value of which for household and semi.Professional models is associated with the power of the unit and the torque. For longitudinal sawing, a step is taken less (for example, 0.325 inches). The performance of the work will decrease, but the required effort will also decrease. With a roll of trees with a large engine diameter, the engine power does not exceed 2500 watts. The thickness of the cutting edge in most chainsaws is set to 1.3 mm.

The height of the chain profile is either 0.625 mm, or 0.762 mm, and a low profile is used for household saws. At the same time, the vibration of the saw increases slightly.

The edge of the tooth for the longitudinal saw should be very acute and have an angle in the range of 6º 12º, for the transverse. Up to 25º 30º.

In the first case, sharpening should be carried out more often, since the small angle of inclination of the tooth contributes to its Rapid painting unacceptable. This is especially noticeable in links that are made of structural alloy steels containing silicon and manganese, for example, 40 HGS or 35HGS.

Templates and appliances for sharpening the chain of the chain

It is much easier to work, having great confidence to get the right result, if the master has provided himself with a set of auxiliary devices, which includes a template. With it, the correct values of all angles of tooth sharpening are withstanded with it. The angle of the front edge is recorded in the instructions, usually its value is 65º. 80º. The assessment of the value of the rear angle of the upper blade can be performed only according to the template. Its value should be in the range from 50º to 60º.

The rear angle of sharpening of the saw decreases with an increase in the hardness of the wood. The optimal with a longitudinal cut is considered the value of the angle of 10º 12º, and 25º 30º. With a transverse cut.

Pilate tooth configuration templatePhoto: proinstrumentinfo.Ru

The frequency of sharpening chains of a chainsaw

The decision to sharpen the saw chains is made not according to the calendar, but according to its work. First of all, the sawdust should be examined. If they look like fine dust, then the chain requires sharpening. Otherwise, you can overheat the engine, which will lead to the formation of bully on the cylinder. The stupid saw has increased vibration and the difficulty hiding of the headset into each new cut, which significantly reduces the performance of sawing work.

How to sharpen a chain of chainsaw at home with a file

Correctly sharpen the chain of chainsaws with a file will help a tool of exceptionally round section. The parameters of the file are determined by the size of the saw itself. It is important to know the step of the location. One round sharpener is not enough. For sharpening and editing chains, two types of tools are used. The first, this is a gun file with a diameter corresponding to the diameter of the rounding of the working edge of the saw tooth. To process the limiter of the saw depth of the guide tooth, you need a flat file.

Sharpowing can be performed manually using a round file with a working diameter of 4 5.5 mm. It is extremely important to correctly install the tool relative to the hidden tooth. The upper edge of the working part of the file is located approximately the fifth of the upper edge of the processed part. The tool is held perpendicular to the axis of the chain at an angle of 25º 30º to the upper edge of the tooth.

For sharpening saw chains of a household tool, round files with a diameter of 4 and 4.8 mm are used, since they have a small tooth. For professional models, more powerful chains with a large tooth are used. Therefore, you need files with a diameter of 5.2 and 5.5 mm.

To sharpen the limiter, a flat file will be required, and to clean the place of work. A hook that removes the formed sawdust. There are also special holders on sale, on which the files of the movement of the file of the file relative to the axis of the chain are sophisticated. The holding can be installed on the tooth on top, resting on its upper edge. Since its height is adapted to a certain step in the chain, this device should be selected in relation to the chainsaws of specific models and brands. The minimum necessary set in order to get the right angle of sharpening the circuit manually, shown in the photo.

How to choose the right angle?

The cut of the solid wood is characterized by low performance and a large load on all the components of the chainsaws (we recommend that you read in more detail about The device of the chainsaw). The most “running” solid rocks are ash, beech, birch, elm, maple, oak and hazel.

The photo shows a specialty device for sharpening, which allows you to reliably fix the file.

In order to effectively produce the cuts of these rocks, it is necessary to observe the angle of sharpening under 25 °. This value will provide optimal work of the chainsaw with average performance characteristics.

Soft breeds include all coniferous, with the exception of larch. This is spruce, pine, fir, cedar, as well as deciduous. Alder, linden, aspen, willow and poplar.

For longitudinal sawing

As already mentioned, the recommended angle of sharpening is 10 ° with a possible deviation up to 2 °. This is due to the need to quickly cut deep into the tree with a longitudinal cut.

For working with soft wood, the optimal angle value is 25 °. The fibers of the soft wood of wood are distributed unevenly, that is, the solids are interspersed with soft. The value of 25 ° allows the cutting of alternating fibers without a periodic increase in the number of engine speeds.

For transverse sawing

For transverse cut of soft and hard varieties of wood, a value of 35 ° is recommended. This value allows you to achieve optimal characteristics of power and load on the circuit when cutting.

Table of angles

Sharpening angles of saw circuits are presented in the table below. By the table you can even understand what file will be required to sharpen a particular circuit.

Sharpowing angle table for all types of saw circuits, as well as cutting depths. To increase, click in the photo.

Types of sharpening saw chains

There are a number of tire sharpening technologies. In the field or in houses, you can use a grinder or file. This method is suitable for budget models of chainsaws when high accuracy of adjusting the teeth is not required. The main disadvantage of this method is the need to control mechanical pressing on a manual tool, with increasing pressure, you can bring the excess metal layer, deform the teeth.

Professionals recommend using special machines for primary sharpening, and then a vice with guides for grinding, adjusting each link. This method helps to save time, and when using the holders adapted by a specific chain step, the probability of error is minimal.

How to sharpen using special equipment?

The most convenient way to sharpen the saw is the use of special tools and machines. This allows you to quickly work any severity. When purchasing a chainsaw, it is recommended to immediately buy a template to determine the values of the end and upper blade, the front angle of the edge. In addition, you need a file to eliminate small shortcomings.

How to Sharpen a Chain Saw with the Harbor Freight Sharpener

On a manual machine

In practice, this method is usually used to trim the teeth after each prolonged operation of the chainsaw, work with solid wood rocks. “Handing machine” looks like a regular radiation saw with a small vice for fastening on a headset. Instead of the canvas, there is a round file on it.

Before starting work, you should fix the tool on the headset, set the parameters in accordance with the features of the saw. This is done only manually on certain marks on the machine. Stopping at each blade, make 3-4 movements for sharpening. This method is not suitable for restoring highly blunt saws.

On an electric machine

Figure 3.Electrust for sharpening a saw set

This is the most convenient way to sharpen the tire of the chainsaw of any brand. The presence of special skills and skills is not required, the process itself takes no more than 10 minutes. The machine is equipped with an electric drive, operates from a dredue current with a voltage of 220-240 V. When choosing a device, pay attention to the following features:

- The presence of the function of sharpening of teeth with a different interval of links, the volume of the upper edge;

- The ability to correct the angle of sharpening;

- Replaceable grinding circles in the configuration;

- Stable value of cut width.

The saw chain is fixed into the guide in the composition of the base platform, it has a special mechanism for holding teeth. He can move in a horizontal direction. At the adjustable angle, a grinding circle is lowered to the cutting edge, the degree of pressing can be controlled by the regulator. Directly immersion of the sharpening element is carried out by the operator. For the convenience and accuracy of working on all models, there is a measuring scale with which you can evaluate the degree of sharpening of all components of the teeth of the chain.

Bulgarian

This method is used only in the absence of other necessary devices to correct the chain. It is optimal for rough editing of teeth, but has a serious drawback. It is difficult to control the angle, and there is a risk of damage to binders.

To subside a chain, the Ushm must be securely fixed in a vice. Turn on the tool, and then alternately bring each cutting edge and keep until the shine appears. You can check with the required angle with the help of a caliper.

Angle of sharpening on the machine

There is always marking on a quality tool with which you can evaluate the quality of sharpening. When working, you need to FOCUS on its indicators in order to maintain the performance of the headset. The table shows the main characteristics of the teeth depending on the step step and the features of the links.

Figure 4. Warring recommendations depending on the parameters of the chain

Sharbian for sharpening the chain of the chain

By purchasing a chainsaw, it is advisable to get a special template (see. Rice. 3), with which you can easily set the optimal values of the tooth angles. With its help, the values of the rear angles of the upper and end blades are controlled, as well as the front angle of the edge (it is indicated in the manufacturer’s instructions, and may change within 65 80 °).

It is especially important to use the template to assess the value of the rear angle of the upper blade. This angle of sharpening of the chain of the chainsaw is differently difficult to determine, but meanwhile it must be withstanded within a rather limited limits. From 50 to 60 °.

The measurement of the angle of sharpening is performed by determining the angle between the upper cutting edge and the line perpendicular to the guide chain.

The angle of sharpening of the chain of the chainsaw can be changed, depending on what work will be done. With an increase in the hardness of wood, its value should be less. In general, it is considered the optimal value of the angle of 10 12 °. With a longitudinal cut, and 25 30 °. With a transverse cut.

Figure 3. The appearance of the template for pulling the teeth of the chainsaw

Sharpowing can be performed manually using a round file with a worker with a diameter of 4 5.5 mm, or on the machine. In the first case, it is extremely important to properly arrange the tool relative to the hidden tooth. The upper edge of the working part of the file is located approximately the fifth of the upper edge of the tooth. The tool is located perpendicular to the axis of the chain, and at an angle of 25 30 ° to the upper edge of the tooth

One round file is not enough. To sharpen the limiter, a flat file will be required, and to clean the place of work. A hook that removes the formed sawdust. There are also special holders on sale, on which the files of the movement of the file of the file relative to the axis of the chain are sophisticated. As can be seen from rice. 4, the holding can be installed on the tooth on top, and rely on its upper edge. Since the height of the holding is adapted to a certain step in the chain, it should be chosen in relation to the chainsaws of specific models and brands.

The minimum necessary set in order to get the right angle of sharpening the circuit manually, shows in rice. 5.

Figure 5. A set of sharpening tools and devices

First, the teeth of one direction are pulled, and then the other. Begin with light press presses in the direction of themselves, gradually increasing the load. During the sharpening, a round file is periodically twisted along its axis.

The shape of the teeth

The sharpening process begins with determining the principle of operation of cutting teeth. The cutting part of the teeth directly cuts a layer of wood as a rubble, and the cut depth is controlled by the limiter located above.

Hand tools (files and templates) are usually used for sharpening, but you can process the chain on the machine.

Sharpening blades on disposable machines

The element should be tightened only at a certain angle, this directly affects the performance of the chainsaw.

For an effective cut of blades, bent at a certain angle. The back of the back of the teeth creates the rear angle and provides light cut into the wood.

A blade located behind, is needed for side cutting of wood fibers. Therefore, it is hidden at an angle.

The edge of the upper blade should create the front angle from 60 to 85 degrees relative to the lower part of the tooth.

The upper blade can have a tilt of 50-60 degrees, depending on the type of saw.

The angle of sharpening can depend on the type of chainsaw work. For an effective cut of very dense frozen wood, a sharp angle is required (but not less than 25 degrees!), for soft wood, this parameter must be increased. In addition to the quick sawing, this solution allows you to reduce vibration during operation and contributes to a smoother chain.

The distance between the emphasis and the upper edge should be in the range from 0.5 to 0.8 mm. An increase in this distance as a result of excessive overwhelming leads to a decrease in the cut rate, excessive vibration and increasing the risk of recoil when sawing. Therefore, it is important to know how to properly sharpen a chainsaw, so that sawing is as easy and productive as possible, and the chain serves properly and for a long time.

Video about sharpening chains for chainsaws

Ivan, Poltava:

“During the use of a chainsaw, I realized that no machine could sharpen better than hands! I have been with saws for 20 years, but I sharpened the machine only when I need to quickly and without norms in acuity. He began to work with the Urals and the taiga, even worked on a roll of forest, and after now I am engaged in log cabins and in general wooden buildings. All of these machines of bullshit, especially when the turnover is large and the circle is spinning in one direction. “.