How to Disassemble a Bosch Gbh 2 24 Hammer

Forum. Apartment Repair

You are not logged in. Please login or register.

Repair forum → Tools → Dismantling the Bosch GBH 2-26 DRE rotary hammer cartridge.

To send a response, you must login or register

Posts 5

- Vasiliy

1 Thread by Ivanovich 2013-04-04 00:09:43

- Ivanovich

- Participant

- Inactive

- Registered: 2012-11-11

- Posts: 175

Subject: Dismantling the Bosch GBH 2-26 DRE rotary hammer cartridge.

The perf has broken. Recently I had to drill the foundation of a cottage half a meter thick. For all this time, the operation tended only 4 times in earnest, so that the protective sleeve worked and the drill had to be twisted with a gas wrench. Although the perforation hardly warmed up, only the gearbox seemed warmer than usual, the result was not the best. Everything is in order with the drill, and grease poured from the punch. Leakage occurs from under the part of the cartridge which is closer to the handle.

I had to disassemble the cartridge, and in time the camera came under the arm. Perhaps my photo report will help someone who will do the same procedure. And I will try to describe each stage:

1. Move the plastic part of the cartridge (1) and then remove the rubber seal, prying it with a thin screwdriver (2) (1 photo)

2. Pry in the direction along the barrel and remove the first retaining ring with a thin screwdriver. (photos 2 and 3)

3. The next element is the fixing washer, remove it (photo 4)

4. Pulling off the plastic part of the barrel, we see the second locking ring (photo 5)

5. Closer to the cut part of the barrel, we turn the ring break and remove it with a screwdriver (photo 6)

6. Having removed the plastic part of the cartridge, the SDS clip will remain (as seen in photo 7 it consists of a washer, ball and spring)

7. Take out the ball, for this you need to compress the spring (photo 8)

8. Next will be the washer and spring (photo 9 and 10)

9. And the last we take out the metal spring from the plastic part of the cartridge (photo 11)

When finished, we wash all the parts with nefras and wipe them dry with a new grease. The barrel itself must be gently wiped and grease only the guides for the drill. Well, for now, all that is, later if I have time, I will post the rest of the photos and comments on them.

2 Reply from Ivanovich 2013-04-04 00:12:55 (2013-04-04 00:15:44 edited by Ivanovich)

- Ivanovich

- Participant

- Inactive

- Registered: 2012-11-11

- Posts: 175

Re: Dismantling of the cartridge of the Bosch GBH 2-26 DRE puncher.

Dismantling the Bosch GBH 2-26 DRE rotary hammer cartridge.

01.JPG 77.95 kb, 735 number of downloads from 2013-04-04

Dismantling the Bosch GBH 2-26 DRE rotary hammer cartridge.

02.JPG 56.71 kb, 554 number of downloads from 2013-04-04

Dismantling the Bosch GBH 2-26 DRE rotary hammer cartridge.

03.JPG 52.65 kb, 480 downloads since 2013-04-04

Dismantling the Bosch GBH 2-26 DRE rotary hammer cartridge.

04.JPG 65.91 kb, 488 number of downloads from 2013-04-04

Dismantling the Bosch GBH 2-26 DRE rotary hammer cartridge.

05.JPG 45.93 kb, 497 number of downloads from 2013-04-04

Dismantling the Bosch GBH 2-26 DRE rotary hammer cartridge.

06.JPG 50.48 kb, 484 number of downloads from 2013-04-04

Dismantling the Bosch GBH 2-26 DRE rotary hammer cartridge.

07.JPG 65.81 kb, 660 number of downloads from 2013-04-04

Dismantling the Bosch GBH 2-26 DRE rotary hammer cartridge.

08.JPG 47.58 kb, 506 number of downloads from 2013-04-04

Dismantling the Bosch GBH 2-26 DRE rotary hammer cartridge.

09.JPG 56.59 kb, 521 number of downloads from 2013-04-04

Dismantling the Bosch GBH 2-26 DRE rotary hammer cartridge.

10.JPG 57.29 kb, 524 number of downloads from 2013-04-04

Disassembly Instructions Bosch rotary hammer

The principle of action of the Bosch 2-26 puncher does not differ in any way from the punchers of recognizable brands.

A spinning rotor transmits torque to the countershaft of the mechanical assembly of the perforator, immediately transferring translational motion through the rolling bearing to the percussion mechanism of the perforator is not a shock pulse. Torque with a translational shock pulse is transmitted to the working tool. This principle is implemented in all rotary hammers.

Different companies producing rotary hammers have their own design features.

Bosch rotary hammers are considered the best in their own sector of power tools. But there is nothing endless.

If your hammer drill Bosch 2-20, 2-24, 2-26 did not work, then it is an option to return without the help of others. It is necessary to have the simple abilities of a locksmith, not a little to understand electrical engineering.

Another important detail, the design of Bosch rotary hammers is so ordinary that it does not cause difficulties when performing repairs.

When performing repairs on power tools, including repairs on Bosch rotary hammers, strictly observe safety precautions when working with electrical appliances.

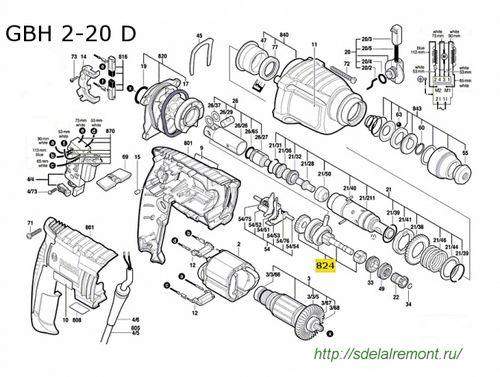

To facilitate the repair of the Bosch punch, its disassembly is not assembly, study the assembly diagram of the tool:

Schematic of the Bosch 2-26 rotary hammer

Any disassembly of the bosch 2-26 puncher begins after inspection, a trial inclusion, without revealing the circumstances of a device malfunction.

Video disassembly punch Bosch 2-26

Bosch 2-26 punch disassembly procedure

Since the procedure for disassembling Bosch 2-20 rotary hammers; 2-24; 2-26 is actually similar, let’s take a look at the disassembly sequence using the example of a Bosch 2-26 punch.

Disassembly of the Bosch GBH 2-26 dre rotary hammer begins with the disassembly of the quick-detachable cartridge.

Quick Disassembly

Two types of chucks are commonly used in Bosch rotary hammers: SDS-plus chucks and not SDS-max chucks. The difference is in their essentially clamping the tail of the working body.

The design of the Bosch hammer drill chuck differs in the design of the tool mounting rods based on the SDS-plus model, in other words, SDS-max. In addition to the listed types of cartridges there are SDS-top, SDS-quick cartridges.

The difference between the cartridge mounts

The disassembly procedure for the cartridge of the Bosch 2-26 hammer drill is normal:

- remove the rubber tip pos. 34;

- remove the snap ring pos. 87;

- remove the iron washer pos. 833;

- remove the conical spring pos. 833;

- carefully, so as not to lose, using a magnet, remove the barrel balls pos. 89.

SDS-plus cartridge

Read the same

Closely inspect our customer remains cartridge details.

Disassembled quick release SDS-plus chuck

SDS-plus chucks have been developed specifically for drilling tools. The diameter of the tool shanks is 10 mm, the length of the working tool in the spectrum is 110. 1000 mm. The diameter of the Boers lies in the range of 4. 26 mm.

How to remove the mode switch

With the rotary hammer on its side, remove the mode switch pos. 832.

First, turn the switch to the “Drilling” position, press the screwdriver fully in the end of the switch button (similar to reddish oil), do not turn the switch counterclockwise by an angle of 70º.

Bosch 2-24 How to change a raster Coupling repair Tool repair Maintenance RB

Group in VK: VK: Life channel:

How. Disassemble and assemble the BOSCH 2-26 hammer drill _ at home_ with your own hands.

How to disassemble and collect bosch 2 rotary hammer-26 at home do it yourself. We disassemble the engine, gearbox

Shaking the switch handle, remove the switch handle from the housing.

Dismantling the shock assembly

Putting a hammer drill Bosch 2-26 vertically on the handle, remove the four screws pos. 90 holding the cover of the mechanical assembly body.

Press the shaft end of the percussion mechanism; do not remove the cover. The lid is plastic dark.

Now you need to remove the barrel pos. 821 not the intermediate shaft pos. 826. They are not fixed by anything.

Next, when using a screwdriver, you need to remove the bracket pos. 48 of the rolling bearing pos. 830. When, in a simple way, it is called a "drunk bearing." They are removed in turn: the sleeve pos. 26 is not a “drunk bearing”.

Reached intoxicated bearing

Dismantling the drum assembly

- disassembling the barrel assembly of the Bosch rock drill, unfamiliar cavities begin, removing the cylinder pos. 26 from it with the hammer, pos. 27;

- from the cavity you need to get the firing pin assembly;

- unfamiliar cartridge shaft remove the retaining ring pos. 85, the iron ring pos. 38 is not another retaining ring pos. 85;

- remove the spur gear pos. 22.

Impact assembly, countershaft not intoxicated bearing

Cylinder disassembly

A drummer, pos. 27, is inserted inside the cylinder, from which it is necessary to remove the rubber ring pos. 73. With at least some disassembly, the rubber parts change necessarily.

At the opposite end of the cylinder, the hinge pos. 29 is inserted, not two flat washers pos. 41.

Intermediate shaft disassembly

The intermediate shaft can be disassembled by removing the shaft pos.24 without pulling out the “drunk bearing” from the housing pos.77.

Bearings are removed by pullers or manually, using the device.

Uncommon malfunction of a Bosch rotary hammer

Bosch rotary hammers are very reliable. But there are malfunctions that are not actually encountered in practice. Below is the one there.

Bosch punch drills but does not hammer

Video: How to Disassemble a Bosch Gbh 2 24 Hammer

If the puncher has finished hammering, but allows you to drill, the most possible prerequisite for you will more like the destruction of the “drunken bearing”. This malfunction occurs occasionally; it can be difficult not to find it.

To eliminate it, you should not visit the repair shop. Such a malfunction will be removed by at least some person who understands mechanics.

Read the same

New intoxicated bearing

First need make out Bosch hammer drill to the countershaft. models gbh 2 24 d, gbh 2 26. The disassembly procedure is given above.

Removing the intermediate shaft, you will get to the "drunk bearing". Broken cage, scattered balls, cage pieces show destruction of a rolling bearing.

Take out the bearing, remove the dirt, our client is left with parts of the destroyed mechanism.

You buy a new “drunk bearing” without lubricating what remains to make our client parts the latest lubricant, do not replace the assembly, in sequence, reverse the steps of disassembly.

Dismantling the electric part of the punch Bosch 2-26

Punch disassembly Bosch 2-26, its electronic part, begins with the removal of the back cover on the handle of the drill, unscrewing the three screws.

Next, pull out the reverse switch.

Turn it into a neutral position; do not lift it personally. Reverse switch pulled out.

To remove the stator cover, you need to hold the mechanical assembly in your right hand, in the left stator housing, drag them in different directions, shaking.

The stator cover will separate.

Separation of the impact block with the non-stator rotor

To separate the rotor from the mechanical unit, it is enough to drag these parts in different directions. The rotor is mounted in the mechanical assembly with a small helical gear inserted in contact with the large helical gear of the mechanical assembly.

The rotor freed can not closely examine the condition of the manifold, bearings.

Bosch rotary hammer rotor

To remove the stator, it is enough to remove the protective plastic protective cover, do not knock a wooden blank in other words with a mallet on the end of the housing into which the stator is inserted. Before this, it is still necessary to keep in mind the two screws securing the stator in the housing.

The stator is removed, the rotor is pulled out, it’s natural to break to their inspection not to defect all the parts included in the electronic part of the Bosch rotary hammer.

When examining a disassembled Bosch 2-26 puncher, pay special attention to the condition of the carbon brushes, the raid on the brush holders is not their mounting reliability, the integrity of the contacts of the reverse switch, the condition of the wire at the entrance to the puncher.

The length of the brushes cannot be shorter than 8 mm. On brush holders, it is not necessary to make traces of non-sparking sparks from the brushes; on the contacts of the reverse switch of the Bosch 2-26 rotary hammer, there is no burnout, in other words, damage to the contacts.

Bosch rotary hammer electronic part

Read the same

Related posts

Replacing the Brushes on the Hammer

Hammers are called percussion drilling devices designed for drilling and chiselling holes in particularly strong materials. Two ideas are implemented in the puncher: the working tool rotates and immediately moves longitudinally, creating a shock impulse. Hammers always work in extreme conditions. The duration of the drill depends not only on the correct operating criteria, but also on the reliability of the parts included in the product. Alas [.]

Rhythm Map Puncher 500 Repair

Punch rhythm map 500 repair sku: 010255 (35) Availability: There are sku: 1 610 591 016 K Availability: There are sku: ZC- (MK24-50) 23 Availability: There are sku: 2400 Щ Availability: There are sku: 68.03.01.09. 00 Availability: There are sku: 001 113 Availability: There are sku: 001 110 Availability: There are sku: 213128-7 Availability: There are sku: 010166 (13X9X8) Availability: There are sku: 010170A Availability: There are sku: 010336 (11) Availability: [.]

Bosch Punch Repair Video

bosch video How to disassemble a Bosch hammer drill First, inspect the hammer drill with the intention of detecting visual defects. The vulnerability of the punch is a plastic boot on the cartridge: it often breaks, which causes loss of stoppers. To prevent this problem from occurring, a long drill bit is recommended. The puncher begins to disassemble from the top node. First remove the rubber tip, then the lock washer, and [.]

The most widespread among professional builders of Russia were Bosch punchers, and among amateurs household models Bosch 2-20, 2-24, 2-26. Hammers not only work well, but are also easily repaired. On them you can easily find any failed part.

The designs of the described punchers have the same principle, to transmit torque from the rotor to the shaft of the barrel of the shock unit while transmitting the translational pulse to the working tool.

Structurally, perforators are made in the same way, but individual components or parts have their own characteristics.

If you know the specific differences between the models of the described Bosch rotary hammers, then disassembling and repairing with your own hands will not be difficult.

Along with the originals, the Russian market has a large number of counterfeit tools, including Bosch rotary hammers.

The design features of the models and how to disassemble and repair them yourself are described below.

The principle of operation of perforators is the same, but the design features differ.

The main parts used in the listed Bosch rock drill models are interchangeable. This applies to the mechanical and electrical components.

But there are nodes and did, differing in the details used.

To repair a Bosch 2-20, 2-24, 2-26 rotary hammer, you need to know these differences. Knowledge of the design features of each perforator facilitates the repair process, finding breakdowns and eliminating them.

The designs of Bosch rotary hammers are so simple that they allow you to carry out simple repairs with your own hands and replace any part without contacting customer service. You must have the skills of an assembler, have basic knowledge of electrical engineering and understand the principle of the punch.

Key Design Differences with Bosch Rotary Hammers

When repairing a Bosch rotary hammer, you will not be able to do without the electrical and disassembling tools for the model you are about to repair.

The electrical circuits of Bosch 2-20, 2-24, 2-26 rotary hammers are almost the same. Although some unprincipled differences exist.

But the mechanical blocks are equipped with parts that differ structurally from each other. The main differences are collected in two nodes: in the intermediate shaft and the shaft of the shaft of the shock block.

The greatest differences are presented in the designs of the intermediate shaft, the assembly of the “drunken bearing”, in the mode switch. Unprincipled features are present in the structures of the barrel of the shock block, striker, striker.

Let’s start with the Bosch 2-20 punch.

Diagram and designs of the Bosch 2-20 hammer drill

Repairing a Bosch 2-20 hammer drill will not be possible without knowledge of the design of the repaired tool.

The principle of operation of the Bosch 2-20 rotary hammer is based on the transmission of torque from the rotor shaft pos. 3 to the shaft of the shock block pos. 22 through the intermediate shaft pos. 824, while transmitting a longitudinal impulse to the working tool.

The rotor pos. 3 transmits torque to the helical gear of the intermediate shaft pos. 824.

The helical gear is fixed on the intermediate shaft and transmits the torque to the shaft. A drunk bearing is mounted on the shaft, which receives a torque through the clutch. Due to its design, the drunk bearing transfers translational motion to the barrel barrel of the percussion mechanism.

The design of the intermediate shaft of the Bosch 2-20 hammer drill

The intermediate shaft of the Bosch 2-20 hammer drill consists of a rolling bearing assembly (drunk bearing), a clutch, a large helical gear, a small spur gear.

Most often, breakdowns are manifested in the wear of the splines of the clutch, which leads to the loss of rotation of the perforator cartridge in the presence of a shock pulse.

Corrected by replacing the clutch or restoring the teeth of the clutch parts.

Design features of the Bosch 2-24 hammer drill

Repairing a Bosch 2-24 hammer drill is best started with an introduction to the design and design features of the tool being adjusted. The principle of operation of the Bosch 2-24 rotary hammer is similar to the principle of operation of the Bosch 2-20 rotary hammer.

Torque is transmitted to the tool mounting shaft, simultaneously with the transmission of the shock pulse. The puncher has three operating modes: drilling with impact, drilling without impact, impact.

The helical gear of the rotor pos. 803 transmits torque to the helical gear of the intermediate shaft pos. 826.

Bosch 2-24 punch countershaft design

The intermediate shaft of the Bosch punch 2-24 consists of a rolling bearing assembly pos. 830, a clutch pos. 823, switching parts pos. 44. Most often, the clutch fails. The teeth wear out in it. Coupling repair consists in correcting the gear tooth profile in the coupling and on the intermediate shaft.

Impact shaft design

The shaft of the barrel of the shock block is designed to transmit a rotational impulse while moving the hammer.

The rotation is transmitted from the spur gear of the intermediate shaft to the large spur gear pos.22 of the barrel shaft pos.821.

The reciprocating movement is transmitted through the drunk bearing pos.830, the shock piston pos.26, the striker pos.27, the impact bolt pos.28 to the drill fixed in the cartridge pos.756.

The design is a shaft hollow on one side. Parts are mounted on the shaft on both sides.

On the side of the chuck mounting, the spur gear pos.22 is mounted on the shaft and fixed on the shaft using the roller pos.88, pressed against the shaft shoulder by the spring pos.88. The spring itself is fixed by a lock ring pos. 85.

In the cavity of the shaft of the barrel of the shock block is inserted: the assembled impact bolt pos. 28 and the shock piston. The shock piston pos. 26 is inserted into the shock piston pos. 27 with the new rubber ring pos. 73 put on it. All rubber products are lubricated with recommended grease.

Malfunctions of the shaft of the barrel of the shock mechanism

Due to the weakening of the spring force, the loss of the locking roller, the gear can rotate on the shaft. This is manifested in the disappearance of the torque with the presence of a shock pulse.

Hammer hammer, but not drill.

When the rubber products (o-rings) are worn, the hammer stops working in the “Chiselling” mode. This happens gradually. The force of impact weakens as the rubber rings wear. The thing is that from a drunk bearing the movement is transmitted to the shock piston pos. 26, in which the striker pos. 27 creates air pressure and acts on the impact bolt pos. 28.

The puncher drills, but does not hammer.

If you apply great force during the work of the puncher, this can lead to the destruction of the shock bolt, jamming of the hammer in the shock piston. Such malfunctions can only be eliminated by the complete replacement of a failed part. Learn more about troubleshooting a Bosch rotary hammer.

Design features of the Bosch 2-26 rotary hammer

Repair of the Bosch 2-26 rotary hammer should begin with an introduction to the design features of the tool being adjusted. The principle of operation of the Bosch 2-24 rotary hammer is similar to the principle of operation of the Bosch 2-26 rotary hammer.

The rotation is transmitted from the rotor shaft, through the intermediate shaft, to the shaft of the shock shaft. At the same time, the drunk bearing mounted on the intermediate shaft transmits reciprocating motion to the shock piston.

The puncher has three operating modes: drilling with impact, drilling without impact, impact.

The helical gear of the rotor pos. 803 transfers the torque to the helical gear of the intermediate shaft pos. 823.

The intermediate shaft is similar to the shaft in the design of the Bosch 2-24 punch and is interchangeable with the parts included in the intermediate shaft of the Bosch 2-24, 2-26 punch. Instructions for disassembling the Bosch rotary hammer.

Impact shaft design

The shaft of the barrel of the shock block is similar in design to the shaft of the barrel of a Bosch 2-24 hammer drill. Failures are caused by malfunctions of the same parts as in the Bosch 2-24 hammer drill.

The features of the shaft of the Bosch 2-26 puncher are that the driven spur gear pos.22 is fixed to the shaft with three pins pos.37, in contrast to the locking roller in the Bosch 2-26 puncher.

When disassembling the shaft of the barrel of the shock block of the Bosch 2-26 hammer drill, pay attention to the way the gear is locked. Before removing the gear, three pins must be removed. The correct assembly procedure for the Bosch rotary hammer.

Conclusions:

Knowing the differences between the given models of Bosch rotary hammers will allow you to quickly disassemble the tool, replace defective parts. To do this, you do not need to contact service.

Structurally, Bosch rotary hammers are so simple that they allow you to repair almost any complexity.

All that is required of you is the presence of desire and basic knowledge in mechanics.

It happens that there are fake models of Bosch rotary hammer drill about this in more detail.