How to Disassemble a Bosch Rotary Hammer Reducer

The puncher is a construction tool with which they perform mortising and drilling operations. Thanks to a special mechanism, the punch is very effective and quickly punches a hole in different materials. It can be used in work with concrete, brick, metal, wood, stone. Bosch brand rotary hammers are very common among builders and ordinary people, so it is very important to know how to repair these devices in case of breakdown.

Important Pay attention to the original models! There is a fake Bosch Hammer Drill 32 hammer drill. Beware of fakes!

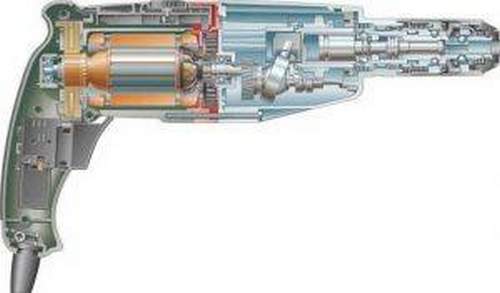

Bosch rotary hammer device

Hammers are of two types:

- with horizontal installation of the engine (the barrel and engine armature are placed in parallel);

- with vertical engine mounting (the same parts are at right angles).

Electrical and mechanical parts are the main components of this tool.

The electrical part consists of:

- engine;

- engine control device (sometimes combined with a switch);

- on / off switch;

- elements that suppress interference;

- power cord.

The composition of the mechanical part is as follows:

- gearbox, which is mounted on the motor shaft;

- shock mechanism;

- clutch.

Various add-ons in the form of a drill, crowns, a vacuum cleaner and other details can be attached to this device in the kit.

Dismantling the punch and removing the cartridge

To repair a hammer drill, you must first disassemble it correctly. And we begin to do this by disassembling the cartridge.

- Remove the rubber tip and circlip;

- We remove the washer and conical spring;

- We get the side balls (preferably with a magnet);

- We put the lever of the operating modes in the position equivalent to the maximum, and remove the switch knob. We fix the position;

- Remove the back pad on the handle and brush of the engine;

- Unscrew the 4 screws near the drill to remove the front cover;

- We take out the barrel and shaft, and with a screwdriver. the bracket and bearing;

- Open the back cover and take out the reverse switch;

- We remove the rotor, for which we unscrew the crepes and disconnect the terminals from the starter, which also needs to be removed by removing the protective cover.

Video: How to Disassemble a Bosch Rotary Hammer Reducer

Important! When disassembling, be extremely attentive to where and when you remove certain parts. Fold them so that in no case lose. It depends on whether you fold the tool back or not.

DIY Bosch rotary hammer repair

If any parts in the tool are damaged, broken, or poorly perform their function, then they just need to be replaced. If the brushes are worn out, then when parsing them, they simply replace them with new ones. The hammer drill during slow rotation of the rim, a worn out boot, defective bearings are also replaced. But there are other malfunctions that you can fix. If a breakdown of the winding occurs, then the stator and the armature must be rewound. Care must be taken to lubricate and lubricate some parts from time to time.

Repair of Bosch 2 punchers 26

Before you fix something in this model, you need to familiarize yourself with the features of the device, the circuit and the principle of operation. The rotor shaft transmits rotation to the shaft shaft through an intermediate shaft, the bearing of which directs the return movement to the shock piston.

When disassembling the barrel shaft in the impact block, special attention must be paid to fixing the spur gear. Before removing it, it is necessary to remove the 3 pins on which it is fixed in this model.

Repair of Bosch 2 24 punchers

In this bosch gbh 2 24 dsr rotary hammer, the countershaft consists of a shift part, bearing assembly and clutch. The latter spoils most often, because the teeth wear out quickly in it. Repairing this breakdown consists in correcting the profile of the teeth in engagement. Often you can see that there is no blow. The hammer can gradually stop hammering due to wear of rubber parts that need to be replaced on time. And if more force is used than necessary, this can lead to jamming of the firing pin in the shock piston.

Repair of Bosch 2-28 punchers

In this model of tool, the splines sometimes wear out. In this case, it is necessary to disassemble the gearbox (it is almost similar to Bosch 2-24, only the bearing is different). It is better to replace the entire barrel, because the strikers wear out along with the splines.

As you can see, hammer repair can be done at home with your own hands. At the same time, do not spend large sums on various types of repairs in service centers, which, as we know, are very expensive. But do not forget that you must adhere to the rules of use and safety.