How to disassemble a starter on a tiller

Design modification

Are there options to improve engine starting? You can replace the mechanical component with an electric starter, then the need to pull the handle with all its strength will simply disappear. But this modification is not available for all models of manual tillers.

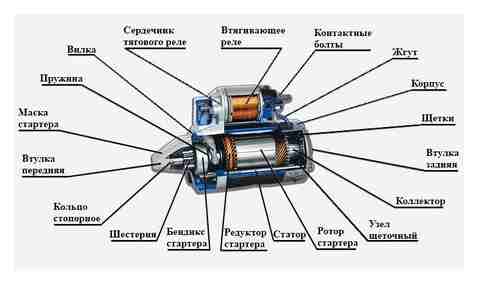

Electric starter device.

In addition, the wiring diagram chosen for installation is not suitable for every engine, so it is worth looking at other varieties of the tiller starter. One solution could be a mechanical spring mechanism.

The factory starter on the tiller initially starts the engine with just one movement. This smooth operation of the mechanism can last for a year, but the more often it is used, the faster it breaks. To avoid this for as long as possible, it is worth checking the amount of lubricant before starting, and also not pulling too much on the handle of the cord. This will only reduce the likelihood of breakage, but will not allow you to completely avoid it.

Do-it-yourself repair and installation of a starter on a tiller: read the points

The tiller starter allows the main motor to start properly and quickly, but problems may arise with it during operation. What needs to be done if it fails, and is it worth trying to repair it with your own hands?

What other types of starters are suitable for a tiller?

- Spring starter. It is considered not only easy to install, but also quick-start, because the device will start immediately after shifting the tiller handle. Thanks to the semi-automatic operation of the spring, the engine accelerates. over, it will take no more than 2 hours to replace a manual starter with a mechanical one;

- Electric starter for tiller. The specified type is powered by a rechargeable battery. Naturally, it is this autonomous source that will determine the power level of the electric starter and the duration of its operation. But it is worth noting that not all models of tillers with manual start can adapt to the specified one, therefore, before starting work on replacement, this moment should be foreseen and carefully studied the capabilities of the existing mechanism.

Every tiller owner should understand that at first, absolutely all starters function perfectly and can delight their owners with a similar state of affairs for about a year. But without periodic lubrication of parts, their inspection and a commensurate jerk force, such joy will not last long. Take care of your starter and it will respond to you with high performance and long service life.

How to repair a manual starter for a tiller with your own hands?

- It is advisable to find a diagram from the manufacturer before starting all the procedures or use the document presented on our website;

- A wrench should be prepared, which in the future will be needed to unscrew and remove the nuts;

- Before disconnecting the starter itself, it will be useful to photograph everything in order to reassemble it correctly at the end;

- Unscrew the washer located in the central part of the drum;

- Inspect all elements inside and find damaged parts.

The main thing is very careful with all small gizmos, so as not to lose them. Most often, repairing a starter motor involves updating unusable parts. For example, replacing the starter cord will be relevant if it is completely worn out or torn.

With a large spring, everything is somewhat more complicated, because there are special hooks at the ends of the attachment points. If they are absent, it is necessary to heat these very ends and bend in a suitable direction. An important point: you should not try to return the element to its former functionality when there is a pronounced fatigue of the metal. Replacement would be the best solution.

Starter operation

To start the engine of powerful tillers, a spring starter is mainly used, but manual options are very common. The manual starter is much easier to install and operate, and therefore more profitable for production. The construction of this node is quite simple and straightforward:

Starter design.

- drum-shaped body;

- coil;

- large spring;

- cord;

- small spring;

- reeds;

- washer;

- fastening elements.

The cord is attached to a spool, which in turn is mounted on the core of the drum. A large annular spring is placed around the axis in a special section of the drum; it returns the coil to the starting position after scrolling. This is how you can briefly describe the design. It all works as follows: the user sharply pulls the starter handle, thereby setting the initial rotation to the mechanism, which is transmitted to the engine. As soon as the torque required to start the engine arises, it immediately starts working. Usually you need to pull the handle on yourself 2-3 times so that the starter accelerates well.

The recoil starter for a tiller is terribly inconvenient, since it takes a lot of effort to start the technique with it. In addition, this unit often breaks due to excessive efforts.

How can you repair or improve it?

Tiller starter device. design features of the mechanism

Each tiller model has its own design features and is equipped with different mechanisms. So, to equip more modern agricultural units, manufacturers use two starters at once.

A spring-loaded or auxiliary starter helps the main starter to start quickly and smoothly. The main mechanism is the manual starter, which is responsible for starting the tiller motor. Among the main elements of the tiller starter are:

- Coil;

- Drum body;

- Washer, large and small spring;

- Tongues;

- Cord;

- Fixing nuts and bolts.

The reel on which the cord is wound is mounted in the core of the drum case. A large spring is installed in the inner chamber of the drum, which is responsible for returning the drum to its previous position after each pull of the cord.

Some tillers are equipped with an electric type starter. The electric starter for the tiller takes power from the battery. The larger the capacity of the latter, the longer the motor starting mechanism will work.

Both the manual kickstarter and the electric starter to the tiller have shown themselves to be quite reliable mechanisms with long service life and resistance to mechanical damage.

Conclusion

You can independently figure out the reason for the breakdown of the starter on your tiller if it has a manual starting mechanism.

This type of assembly is quite simple to dismantle and disassemble. Over time, it loses its original characteristics and starts the engine only after 3 or 4 strong jerks. This means it’s time to replace it.

For some domestic models of tillers, there are special modification kits that allow you to install a different type of starter on the unit. Unfortunately, they cannot be used on Chinese and American models.

How to put a starter on a tiller. the algorithm in detail

With the dismantling, disassembly and installation of the manual tiller starter, there are no problems even for novice farmers. However, the assembly and installation of an electric starter for inexperienced owners of tilers raises a number of questions. As a result of incorrectly performed procedures, the engine starting mechanism refuses to work, which is why the starter has to be carried to the workshop. To avoid this need, we will study how to install a starter on a tiller at home. The installation looks like this:

- To install and secure the wreath on the tiller’s flywheel, the flywheel will need to be removed. To do this, remove the unit’s air filter in order to gain free access to the inner structure of the chiller;

- After that, remove the protective cover, unscrew the screws holding the recoil starter basket, the flywheel nut and the flywheel itself. Dismantling the tiller starter flywheel can cause certain difficulties, therefore, to remove this part, it is better to purchase a special removable key in advance. After removing the flywheel, do not forget to unscrew the key located immediately behind it;

- Next, you need to install the generator. At the same time, push its wires into the hole in the steel wall of the engine, and install the generator in the seats on the engine wall;

- Then, inside the flywheel, install the generator magnets so that the holes in both elements match. Connect both parts with screws and install the crown. Before this, the crown must be heated using a canister-shaped burner;

- Install the assembled unit back to the engine, simultaneously screwing in the keys and flywheel hook;

- Screw in the recoil starter basket, secure the cover and refit the tiller air filter;

- Next, remove the starter installation plug and install the starter itself on the tiller;

- After that, connect the generator wires to the charging relay;

- Connect the starter terminals to the unit battery and start the tiller.

As you can see, installing a starter to the tiller is not so difficult as it might seem at first glance. The main thing when assembling with your own hands is to strictly follow all the rules and recommendations listed in the algorithm.

All described methods of repair and installation of a starter are suitable for mounting the mechanism on Tileri Neva, Cascade, Agro and agricultural machines of other well-known manufacturers.

DIY repair and installation of a starter on a trailer

Many farmers ask how to install a starter on a tiller. When operating a motor-cultivator, starters are used: main and auxiliary.

Installing the starter on the tiller

There are various designs of starters:

- manual;

- spring;

- electric.

The most common is the manual starter for the tiller, since this device is very easy to put on the tiller, and its repair is easy to do on your own. If such a device is used correctly, then its durability is several years.

Consider what elements a starter for a tiller consists of:

- a drum-shaped body;

- springs: large and small;

- washers;

- coil;

- cord;

- reeds;

- fastener parts.

In the center of the drum there is a reel on which the cord is fixed. A large spring is located in the body around the axis and is designed to return the coil to its original position after scrolling.

The mechanism of this device is quite simple, you can assemble it yourself.

Tiller operation with a manual starter is carried out as follows. The driver starts the mechanism by pulling the handle of the device. In this case, the device starts to work and starts the engine. In order for the device to successfully transfer the initial rotation to the motor, the handle of the device must be pulled twice.

But despite the fact that the manual starter on the tiller is considered a reliable device, it also sometimes fails. If the structure breaks down, you can repair it yourself.

Cultivator Repair. Replacing the Transmission (Powermate Part # A200759)

DIY electric starter on the tiller

In order to make an electric starter for a tiller with your own hands, you must:

- select the main structural elements: body, coil, small electric motor and cam mechanism;

- prepare wires, bolts, nuts and other fasteners to connect parts;

- according to the wiring diagrams and drawings of the factory device, connect the motor to the working elements by connecting it to a 12-volt rechargeable battery;

- after checking the circuit for operability, put all the components of the future starter into the case;

- install the resulting electrical device on the tiller and connect using wires.

How to repair the starter of a motor cultivator with your own hands

Consider how to repair a tiller starter with your own hands. Before you start repairing a recoil starter, you need to find its instruction manual, which contains a diagram of the device. Then you need to prepare a wrench to unscrew the mechanism.

Before starting to dismantle the device, it must be photographed in order to then correctly assemble all the parts and components.

After that, unscrew the washer, which is located in the middle of the body. Having opened the lid, you need to carefully inspect all the parts that are located inside the drum and determine which ones are damaged. It is necessary to inspect small parts very carefully and carefully so as not to accidentally spoil them and not lose them.

In most cases, repairing a kickstarter on a tiller consists of updating components that are out of order. For example, replacing the starter cord is performed if it is torn or frayed.

Repairing broken pull starter cord on Troy-Bilt chipper with Briggs & Stratton Motor

If a large spring fails, then you need to remove it from the drum. There are usually hooks where the spring is attached. If they are not in the design, then it is necessary to heat the ends of the spring and bend them in the desired direction. If the spring is completely out of order and there is pronounced metal fatigue, then there is no need to try to restore functionality to such a spring. In this case, it is best to replace it with another one. After that, we install the device in its place.

In addition to the manual starter, there is also a spring and electric starter for the tiller. The spring mechanism has a simple structure and is easy to start. The device starts up after shifting the handle of the cultivator. The motor accelerates by means of a semi-automatic spring operation. You can replace the manual starter with a mechanical one yourself.

The tiller’s electric starter is connected to the battery, from which it receives power. The electric start of the device is carried out using the start button. The battery determines the power of the electric starter and the duration of the operation of the device. Installation of an electric starter is carried out according to the electrical diagram of this design. Tiller with electric starter is durable, reliable, long-term.

Unfortunately, not all designs of manual cultivators can be converted into spring or electric ones. Therefore, before starting work on replacing the manual mechanism, you need to study the instructions and the capabilities of the tiller and find out if such an alteration is possible.

Farmers should be aware that at the beginning of work, all cultivators are working properly. Gradually, on the assembled unit, various components fail. In order to extend the service life of the tiller and all its parts and assemblies, it is necessary to regularly inspect the mechanism and properly maintain it. All assemblies and components must be periodically lubricated with machine oil and checked for performance. To increase the productivity of the cultivator and extend its service life, constant proper care of this technique is necessary.

How to put an electric starter on a tiller

If you cannot figure out how to put an electric starter on an agricultural unit, follow the recommendations below:

- To remove the engine flywheel, it is necessary to remove the tiller air filter to open access to the “native” manual starter for dismantling.

- Remove the protective cover of the unit, unscrew the fastening screws of the starter basket and dismantle the flywheel using a special wrench. Behind it is a key that must be unscrewed.

- Next, you need to install a generator for which there is a seat on the engine. All wires can be easily threaded through the hole in the wall of the motor housing.

- Place the generator magnets inside the flywheel so that the holes coincide, fix them in this position with the fasteners.

Heat the crown with a gas burner, and install the device. - The resulting assembly is installed on the internal combustion engine, the keys and the fixing nut are screwed in.

- Fasten the basket, replace the filter and protective cover.

- Install an electric starter, connect to the battery. In this case, connect the generator wires to the charging relay. Check the health of the system by running the tiller.

How to make a manual starter on a tiller

As in the case of making an electric starter from improvised means, making a manual starter for a tiller (Neva, Oka, Cascade, Patriot and others) will be an easy task for a craftsman with the appropriate knowledge.

To assemble a homemade kickstarter, to the materials and procedure described above, you should add the installation of a handle for transferring force manually, which will replace the operation of the electric motor. The kickstand of the recoil starter can be made from a thin metal tube, which will need to be bent into the shape of the foot and installed in the hollow hole of the reel. After assembling the device, be sure to weld it.

What starter is installed on your tiller?

Preparing for repair

Before proceeding with the repair of the starter, you should make sure that it is he who is faulty. First of all, attention should be paid to the battery. Its charge must be sufficient to start the motor. You should also inspect the terminals. If they are oxidized, then they need to be cleaned and sanded.

To repair the starter, you must first dismantle it from the car. To do this, you need to disconnect the power and control wires, and also unscrew 2-4 fasteners.

The removed unit must be checked for the absence of a short circuit. The starter can then be connected directly to the battery. This will allow you to check the traction relay and the electric motor for serviceability.

When the electric motor is not running, inspect the wire that connects the traction relay and the electric motor. Over time, it decays and may fall off. If contact is found, solder or weld on a new conductor.

For further repairs, it is required to disassemble the unit. First you need to disconnect the traction relay and the electric motor.

Troubleshooting and repair of the starter armature

First of all, you should check the breakdown to the case. This requires a multimeter. In the absence of a device, the “continuity” can be performed using a light.

Thermal damage occurs on the manifold. Minor defects are removed by grinding. In case of significant damage, the entire anchor must be replaced.

Mechanical breakdowns requiring repair

The first step is to check the mechanical part. The clutch should move easily under the influence of a screwdriver.

The rotation of the bendix gear should be done in one direction only. Any wedging is unacceptable. Backlash also indicates a malfunction of the assembly. In case of defects in work, the bendix must be replaced.

Significant wear or damage to the teeth is unacceptable on the gears. The gear cannot be restored, therefore, in case of defects, it requires replacement.

Failure of the bushing is accompanied by extraneous sounds during the operation of the unit. It is convenient to remove it with a tap.

Most modern starters are planetary gear. The grease in it thickens during operation. To restore the gearbox to work, you need:

- Parse transmission.

- The next step is cleaning. First, you need to scrape out the thickened grease with a screwdriver and a cotton swab.

- Wash all gears in special equipment.

- Bulkhead ends with the cleaned gearbox should be lubricated with new grease.

Despite the fact that cleaning the planetary starter gearbox is not included in the scheduled maintenance, many car owners recommend doing it periodically at intervals of 40-80 thousand km.

List of tools required for repair

To repair a starter, approximately the same kit is required depending on the model and manufacturer of the unit. The table below provides an indicative list of tools that will be needed for repair.

Table. Tools required to replace the A-pillar

| TORX head | Required mainly when repairing starters from foreign cars |

| Head | “by 8”, “by 10”, “by 12”, “by 13”, “by 14”, “by 15”. Size varies by brand and model of starter. |

| Open-end wrench | For access where you cannot crawl with a head or spanner wrench |

| Vorotok | With ratchet and extension |

| Multimeter | To check the electrical parameters of the starter |

| Drive shaft | Required if access to the starter or wire mounts is difficult |

| Screwdriver | With a flat or cross blade. On foreign cars, a special-shaped sting is sometimes required, for example, a flat with a notch or an “asterisk” |

| Insulating tape | To restore insulation |

| Penetrating lubricant | For loosening bonded threaded connections |

| Rags | For cleaning dirt and grease residues |

In order to repair a faulty starter, it is recommended to purchase a special repair kit. It includes the main elements of the assembly that are most susceptible to wear. Sometimes this repair kit includes some of the tools needed to restore the unit to work.

Brush assembly

To access the brush assembly, disassemble the starter as shown in the image below.

The first step is to check how the brushes move in the brush holders. In the presence of jamming, the defective areas should be sanded.

The brushes should be inspected for melting and thermal damage. Particular attention must be paid to the point of contact with the collector. Minor defects are removed by grinding.

During operation, the brushes wear out. The critical size ranges from 4 mm to 15 mm, depending on the design. If it is reached, replacement of the brushes is required. Their depending on the brand and model of the starter.

Starter repair

During the operation of the car, its starter may fail. The unit consists of a solenoid relay and an electric motor, which are subject to both natural wear and tear and damage due to improper starting of the motor or malfunction of any accompanying element.

The starter is an expensive spare part, so do-it-yourself repairs and self-maintenance of the unit can save the car owner a lot of money.

Inspection of the stator

The stator should be checked using the diagrams shown in the image below.

The stator of a modern starter often has no windings. They are replaced by magnets. Therefore, “dialing” is not required, but it is only important to inspect everything for mechanical damage.

If you encounter any problems during the repair of the starter, it is recommended to watch the thematic video.

DIY tiller starter repair

Despite the high quality and reliability of modern starters, some owners sometimes face the need to repair them. Most often, the breakdowns of the mechanism are insignificant, which allows you to quickly fix the malfunction with your own hands. The procedure for dismantling and further repairing the mechanism is as follows:

- Repairing the node should begin with studying its diagram. If an electric type starter is provided in the tiller’s design, then before dismantling the mechanism, you need to familiarize yourself with the location of its terminals;

- Using the wrench supplied with the tiller, unscrew all screws and nuts that hold the mechanism in the tiller structure;

- If the assembly is being dismantled for the first time, then we advise you to photograph the starter before finally removing the mechanism from the assembly;

- Next, unscrew the washer located in the central part of the drum housing and carefully inspect the internal parts for damage;

- All further actions depend on malfunctions of the starter parts. If the cord is out of order. it is worn out or torn, then to replace it, you will need to wind up a new product, adhering to the marks on the drum housing of the mechanism;

- Another common breakdown is a malfunction of the spring, or rather, its antennae, the edges of which should be bent in the form of hooks. If the antennae break off, then the edges of the spring will need to be heated and bent so that the spring can be hooked into the holes in the drum. In this case, the residual length of the spring is of great importance. make sure that the part does not stretch too much. If you find that the spring is very short, or it has already begun to rust, then it is better to replace it entirely.

Before mounting the starter back on the tiller, we recommend that you first clean the space inside the unit structure. This will prevent debris from entering the engine, carburetor, and spark plug.

Tiller starter device. design features of the mechanism

Each tiller model has its own design features and is equipped with different mechanisms. So, to equip more modern agricultural units, manufacturers use two starters at once.

A spring-loaded or auxiliary starter helps the main starter to start quickly and smoothly. The main mechanism is the manual starter, which is responsible for starting the tiller motor. Among the main elements of the tiller starter are:

- Coil;

- Drum body;

- Washer, large and small spring;

- Tongues;

- Cord;

- Fixing nuts and bolts.

The reel on which the cord is wound is mounted in the core of the drum case. A large spring is installed in the inner chamber of the drum, which is responsible for returning the drum to its previous position after each pull of the cord.

Some tillers are equipped with an electric type starter. The electric starter for the tiller takes power from the battery. The larger the capacity of the latter, the longer the motor starting mechanism will work.

Both the manual kickstarter and the electric starter to the tiller have shown themselves to be quite reliable mechanisms with long service life and resistance to mechanical damage.

Starter for a tiller: device, installation and repair with your own hands

The tiller starter is a mechanism that drives the engine of an agricultural machine. In the design of the tiller, the starter plays no less important role than the carburetor, clutch and ignition system of the car. Below we will consider the design of the tiller starter, as well as its do-it-yourself installation.

How to put a starter on a tiller. the algorithm in detail

With the dismantling, disassembly and installation of the manual tiller starter, there are no problems even for novice farmers. However, the assembly and installation of an electric starter for inexperienced owners of tilers raises a number of questions. As a result of incorrectly performed procedures, the engine starting mechanism refuses to work, which is why the starter has to be carried to the workshop. To avoid this need, we will study how to install a starter on a tiller at home. The installation looks like this:

- To install and secure the wreath on the tiller’s flywheel, the flywheel will need to be removed. To do this, remove the unit’s air filter in order to gain free access to the inner structure of the chiller;

- After that, remove the protective cover, unscrew the screws holding the recoil starter basket, the flywheel nut and the flywheel itself. Dismantling the tiller starter flywheel can cause certain difficulties, therefore, to remove this part, it is better to purchase a special removable key in advance. After removing the flywheel, do not forget to unscrew the key located immediately behind it;

- Next, you need to install the generator. At the same time, push its wires into the hole in the steel wall of the engine, and install the generator in the seats on the engine wall;

- Then, inside the flywheel, install the generator magnets so that the holes in both elements match. Connect both parts with screws and install the crown. Before this, the crown must be heated using a canister-shaped burner;

- Install the assembled unit back to the engine, simultaneously screwing in the keys and flywheel hook;

- Screw in the recoil starter basket, secure the cover and refit the tiller air filter;

- Next, remove the starter installation plug and install the starter itself on the tiller;

- After that, connect the generator wires to the charging relay;

- Connect the starter terminals to the unit battery and start the tiller.

As you can see, installing a starter to the tiller is not so difficult as it might seem at first glance. The main thing when assembling with your own hands is to strictly follow all the rules and recommendations listed in the algorithm.

All described methods of repair and installation of a starter are suitable for mounting the mechanism on Tileri Neva, Cascade, Agro and agricultural machines of other well-known manufacturers.

Assembling the starter lawn mowers

When servicing and repairing the starter, it is important to assemble it correctly. as if the assembly was carried out by the manufacturer. Any part that is incorrectly installed will prevent you from fully using your trimmer or lawn mower.

- After winding the spring, turn the coil over and place it so that the second spring hook falls back into place. To control the correct installation of the spring, there are technological windows on the coil itself.

- Install the starter pulley and make sure that one of the spring hooks fits into the groove located on the starter cover.

- Insert the spring and washers on the sides to prevent the spring from rubbing off the plastic compartment in which it is located. If the spring is broken, but the other is not the same, an additional washer is placed in its place.

- Insert the cup with antennae into the slots of the coil.

- Install the coil in its place, tighten the bolt until it stops, but without fanaticism.

If you do not shield the mainspring with washers from the compartment where it moves when winding and unwinding the starter cord, the reel will often jam when you try to start the trimmer or lawn mower. Loosening the coil bolt will result in its loss.

How to assemble a lawn mower trimmer starter, watch the video.

Lawn mower starters: device and installation features

- How does the starter for lawn mowers or trimmers work??

- Worst breakdown

- How to replace or replace the starter spring?

- How tight the spring is cocking?

- Assembling the starter lawn mowers

- How to assemble a new lawn mower starter?

- How to change the starter cord?

The recoil starter for a lawn mower or petrol trimmer is a mechanical unit that includes a pulley fitted to a ratchet. A rope is wound on the pulley in the initial position. At the start, it is pulled outward. The pulley is spring loaded. as soon as you let go of the end of the rope, it will reel back. A flat tape rolled into a ring is used as a spring. It resembles a spring in a large mechanical watch that is wound once a day. The starter itself is located more often at the rear than closer to the front end of the mower or trimmer. To correctly perform all manipulations with the starter for lawn mowers, you need to know the features of the device and installation.

How to assemble a new lawn mower starter?

To assemble the starter, do the following manipulations.

- Pass one end of the cord through the opening at the beginning of the spool and tie it in a knot. The knot must not pass through the hole. Otherwise, you will disassemble the starter again.

- Wind the cord onto the spool itself.

- Install the spring into the starter housing, hook one end of it in the groove and wind it. For convenient winding, twist the body counterclockwise.

- Place the ratchet on the spring.

- Hook the return spring to the ratchet itself, attach it to the spool.

- Install the main spring and housing with the assembled ratchet, connect the parts of the starter together and tighten everything with the main bolt.

After assembling the starter, pass the free end of the cord through the hole in the housing for the reel. Re-pass the same end through the hole in the handle that the cord is pulling on. Tie a strong knot on the handle. Check the operation of the starter handbrake.

How to replace or replace the starter spring?

If everything is in order with the rope on the starter, suspicion falls on the reel itself. It is driven by a ribbon spring, coiled into a roll. To change the spring, certain steps must be taken.

- Remove the starter from the lawn mower.

- Remove the starter coil.

- Unscrew the main bolt holding the pulley to the housing.

- Pull out the gripping tendrils and spring, the ribbon spring is almost fully extended or coiled into larger diameter rings.

- Hold it in advance.

- Check if the spring is intact (rusty streaks, fractures, etc. may be present). If the hooks at its ends are torn off, it will not be possible to bend new ones. high-carbon steel breaks when you try to bend it. Loose hooks are suitable for slight bending.

- Make sure the auxiliary (regular) spring and washers are in place. These parts protect the coil body from being punctured by the ends of the main spring. If the washers and spring are broken, and new ones are not available, do not tighten the coil bolt tightly, but watch it. it can unscrew and get lost.

- If the main (flat) spring is damaged, insert the same new one. Place the hook on the end of the spring in its place and bend it, inserting coil after coil into the space where it should be.

The rewinding of the spring takes a minute. Dexterity in this action is acquired quickly.

How to replace or replace the starter spring, see the following video.

How tight the spring is cocking?

It is possible to give the spring the necessary potential force necessary for a clear and quick winding of the cord, by determining the length of the cord in turns. To prevent the cord handle from drooping, add 1-2 more turns to the number of turns. So, if the cord has a length of 5 turns of the coil, then when charging the spring, turn the coil 6-7 full turns.

How does the starter for lawn mowers or trimmers work??

The starter is a generally single and universal mechanism for lawn mowers, trimmers, gasoline and diesel generator sets. It is not a problem to equip them even a car, motorcycle or scooter, if your vehicle has free space for its installation. It was not for nothing that many Soviet cars and trucks were equipped with a starter tool that remotely resembles a crowbar bent twice.

The modern “handbrake” starts exactly from the cord. it is tied to the mechanism, and it is impossible to lose it.

The starter assembly has the following parts:

- hook ignition spring;

- cord wound on a reel;

- return spring;

- ratchet drive and main spring;

- mechanism housing protecting the ratchet;

- locking bolt.

Worst breakdown

There are times when the starter is still operational, but a worn out cord can break, for example. The ratchet has not yet had time to work when the engine is started, and the remnants of the cord are immediately wound on the reel, the return spring loses its hooks, the grooves in the starter housing break. The result is the replacement of both the springs and the housing.

If a lawn mower or trimmer model has long been discontinued, it will be difficult to find exactly the same parts, and the starter is changed entirely.

How to change the starter cord?

It happens that it is not the spring that is to blame for the inability to start the starter, but the cord itself. It can seize or even break. Disassembling the starter of the lawn mower or trimmer is versatile in its steps.

- Remove starter block from trimmer or lawn mowers.

- Remove the main bolt holding the handbrake.

- Pull out the spool and rewind the remnants of the worn out cord from it.

- Untie the knot on the cord handle and pull the end out of it.

- Untie the knot at the other end (at the beginning of the spool) and remove the old cord. Knots that have become tight are untied with pliers or pliers.

- Tie a knot at one end of the new cord, pass it through the hole at the beginning of the spool (closer to its axis).

- Wind a few turns of the new cord onto the spool. If it is long, then cut off the excess.

- Load and charge the spring-loaded cord tensioner (if removed) and spring-loaded elements in the correct sequence.

- Replace the spool and thread the free end of the cord through the starter outlet and handle.

- Reinstall the starter block.

Twist the starter by the cord, start the engine on lawn mowers or trimmers. The larger and more powerful the engine, the more jerks of the cord will be required at startup, the norm is no more than 7 times. The result is a quick and smooth start of the motor, the readiness of the unit for operation.

Tiller manual starter device Cascade

Auto mechanic specializing in agricultural machinery

Tillers, although not a complex technique, have their own characteristics. For example, when using the unit, two starters work simultaneously: the auxiliary and the main mechanism. As the first, an electric, spring and manual starter is used.

The latter option is most often used in Cascade models of tillers, since it can be easily installed by yourself. Such structures are durable and unpretentious.

In this article we will talk about how to independently replace the starter on the cascade tiller.

How to put a starter on a tiller

The device of the manual starter of the tiller Cascade is quite simple and does not cause difficulties even for novice gardeners, however, the assembly and installation of the electric starter device is a more complicated procedure. It can cause a lot of questions from the owner of the unit about how to properly install the electric starter and how to put the starter spring on the tiller Cascade. To avoid problems with this operation, we will consider step by step how the installation is carried out:

Tiller starter device

This design consists of several components:

- drum body;

- reeds;

- coil;

- two springs of different sizes;

- washer;

- cord.

In the middle of the drum, a spool is fixed, on which a strong cord is wound. A large ring-shaped spring is located around the drum axis, which allows the drum to return to its original position regularly after rotation.

The essence of the unit is quite simple. When the operator pulls on the cord, the reel spins and transfers RPM to the unit motor.

In this video, you will learn how to repair a starter:

DIY repair

With proper operation, the mechanism can last for several years, but there are times when the cascade tiller’s starter fails, and then the summer resident faces the problem of repairing or replacing worn parts. In order to do everything correctly, you must use the instruction manual, which contains the design diagram.

Do-it-yourself starter repair for the tiller Cascade should be carried out in the following sequence:

- There is a washer in the middle of the drum body. It must be unscrewed first.

- Next, remove the housing cover and carefully inspect all components of the structure for damage and wear.

Important! The starter is equipped with many small parts that cannot be lost during the repair process.

If you figure it out, replacing worn parts is a simple procedure. The main thing in such a case is to follow the recommendations set out and not try to return damaged parts to their previous shape. Otherwise, such actions may lead to more serious damage.

Installation completed

The starter on the trailer is an important part of the whole design, so every farmer needs to know how to repair it and install it correctly.

Design modification

Are there options to improve engine starting? You can replace the mechanical component with an electric starter, then the need to pull the handle with all its strength will simply disappear. But this modification is not available for all models of manual tillers.

Electric starter device.

In addition, the wiring diagram chosen for installation is not suitable for every engine, so it is worth looking at other varieties of the tiller starter. One solution could be a mechanical spring mechanism.

The factory starter on the tiller initially starts the engine with just one movement. This smooth operation of the mechanism can last for a year, but the more often it is used, the faster it breaks. To avoid this for as long as possible, it is worth checking the amount of lubricant before starting, and also not pulling too much on the handle of the cord. This will only reduce the likelihood of breakage, but will not allow you to completely avoid it.

What is a starter on a tiller?

- 1 Starter operation

- 2 Repair tricks

- 3 Design modification

- 4 Conclusion

The tiller starter allows the main motor to start properly and quickly, but problems may arise with it during operation. What needs to be done if it fails, and is it worth trying to repair it with your own hands?

Repair tricks

Repairing a recoil starter most often consists in correcting the unbent spring attachment points or replacing some parts. Sometimes it happens that the starter cord needs to be replaced. To check what eventually broke, you need to disassemble the part of the tiller where the starter is located.

- First of all, we arm ourselves with a diagram of our unit, which describes the fastening of all parts, as well as a wrench for removing nuts.

- Disconnect the starter unit, do not forget to remember what and how it was installed before.

- In front of you will be a drum with a washer in the center, which you need to unscrew. After the upper washer has been removed, we disassemble everything inside and check the elements for damage.

The most common breakdowns are as follows:

Tiller starter ratchet design.

- the cord broke;

- one of the ends of the annular spring has unbent;

- the hook in the center of the reel is torn off;

- reeds do not work.

If the cord is torn, it is simply replaced with a new one. There are two hooks at the ends of the annular large spring. If there is no such at one of the ends, you need to heat the metal and bend it with a crochet. The ring spring can also be replaced if necessary.

You can both assemble and disassemble everything with your own hands, the main thing is to look at the instructions and the diagram of the unit. Disassembly of the tiller starter is mostly the same for all models of this agricultural equipment. The only difference will be the number of tabs under the washer. from 1 to 2.

Starter operation

To start the engine of powerful tillers, a spring starter is mainly used, but manual options are very common. The manual starter is much easier to install and operate, and therefore more profitable for production. The construction of this node is quite simple and straightforward:

Starter design.

- drum-shaped body;

- coil;

- large spring;

- cord;

- small spring;

- reeds;

- washer;

- fastening elements.

The cord is attached to a spool, which in turn is mounted on the core of the drum. A large annular spring is placed around the axis in a special section of the drum; it returns the coil to the starting position after scrolling. This is how you can briefly describe the design. It all works as follows: the user sharply pulls the starter handle, thereby setting the initial rotation to the mechanism, which is transmitted to the engine. As soon as the torque required to start the engine arises, it immediately starts working. Usually you need to pull the handle on yourself 2-3 times so that the starter accelerates well.

The recoil starter for a tiller is terribly inconvenient, since it takes a lot of effort to start the technique with it. In addition, this unit often breaks due to excessive efforts.

How can you repair or improve it?

Conclusion

You can independently figure out the reason for the breakdown of the starter on your tiller if it has a manual starting mechanism.

This type of assembly is quite simple to dismantle and disassemble. Over time, it loses its original characteristics and starts the engine only after 3 or 4 strong jerks. This means it’s time to replace it.

For some domestic models of tillers, there are special modification kits that allow you to install a different type of starter on the unit. Unfortunately, they cannot be used on Chinese and American models.